CRS is a leading manufacturer of thermit welding materials in China, we have more than 30 years experience of designing thermit welding to the rails. Focusing on rail welding used for railroad, metro, tram, crane rails, turnel construction and maintenance.

We have production area of 2500 square meter, with fully automated batching system, sand mould automatic production & drying machines, equipped with full range of raw materials and welding joint testing equipments. Rail aluminum thermit welding material has been promoted and well applied in the railway lines such as the Beijing-Shanghai high-speed railway line, Jinqin passenger line, Daqin line, Tong-Rang line and Tong-huo line. Materials have been exporting to Australia, Indonesia and other countries many years, the products have won praise.

CRS possesses a qualified team of technicians and engineers who have been improving the quality and performance of products, Certified to the ISO9001:2000 standard, CRS’ welding products have been supplied to a wide range of customers worldwide. Thermit products have been passed Chinese rail welding standard TB/T1632-2005 test, Railway Ministry of China, as well as Australia standard AS1085.15-1995 test, Indonesia welding joint inspection test, Taiwan SGS quality inspection test. We are ready to provide technical & operation training, qualification and certificate for customers to ensure a standardized quality and performance of the welding products.

Hebei Abter Steel Pipe Co.,Ltd is a professional steel exporter in China. We specialize in the production of steel product, including stainless steel, galvanized steel, pre-painted steel and carbon steel pipes, ceramic lined composite steel pipe and fittings,elbow, bending and the related products, covering pipe & tube , fitting, bar etc. Based on the standing better and faster service,we have been the best partner both of the steel factories and suppliers.

We offer perfect service to the mills and bring in the highest quality levels at the most competitive price for our customers. Our entire operations are focused on the precise demands of our customers needs.

Our production bases cover most of China, with a production capacity of 300,000 MT annually, Size range from O.D: 8–141mm, W.T.0.8–12mm. (cold drawn tube). O.D 141mm–610mm, W.T :5–25mm(hot rolled pipe). With a strict quality assurance system to the manufacturing process, including steel making and finished products inspection.

Factory and industrial products

In addition to our steel products for construction, we also offer a variety of steel fabrication products for use in industry. We provide local factories with steel cutting, fabricating, and distributing pipe fittings anc composite pipes.

Our versatility ensures we will be able to provide you with the steel products you require to to complete a project, from start to finish.

Our team

Our team are highly trained and experienced in servicing and producing all types of steel supplies. Whether you’ve got a large construction project, or need parts for industrial machinery, our team of steel fabrication consultants will ensure that your project is provided with the parts you need, when you need them.

Fujian Dongya Machinery Co., Ltd. was founded in 1988 in China West Strait Economic Zone, Putian, Fujian, China. It covers an area of 127,050㎡, with capital assets of 430 million RMB and registered capital of 116 million RMB. It has 1,120 employees, including 130 experienced engineers and management staff with senior professional titles.

For over 30 years, DY piston rings produced by Fujian Dongya Machinery Co.Ltd., provide companies such as Dachangjiang Group, Zongshen Power, Longcin General Motors, Lifan Technology, Qianjiang Motorcycle, Honda Power, Sundiro Honda, CFmoto Power, QS Suzuki, Briggs & Stratton, STIHL,etc. for motorcycles, general-purpose engine, drones, and outboard engine manufacturers general support.

Piston ring products are widely exported to all over the world such as Europe, USA, Middle East, South America, Africa, and Southeast Asia, with good global reputation for its high quality and market share.

Gate valve is our company’s earlier product. During the long period of time, our company has made the gate valve famous in and out with perfect designing and manufacturing techniques and quality system assurance. The manufacturing experience and technique innovation have made the products reach BS, DIN and other international standards.

Metal Seated Gate Valve Features:

-High reliability of strength and rigidity.

-The sealing is copper alloy which is wear-resisting and has long life.

-When opening, no other parts in the way.

-The installation direction is various iwith the same performance.

Product Range:

Standards: BS&DIN

Suitable medium: water, sea water.

Suitable temperature:≤100℃

Material: Ductile iron, GJS500-7. GJS400-15, GGG40,GGG50

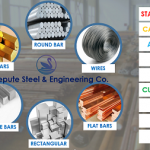

Established in 1996, Vintex Steel & Engg. Co. has gained immense expertise in supplying & trading of Stainless steel, carbon steel, ferrous metal etc. The supplier company is located in Mumbai, Maharashtra and is one of the leading sellers of listed products. Buy Stainless steel, carbon steel, ferrous metal in bulk from us for the best quality products and service.

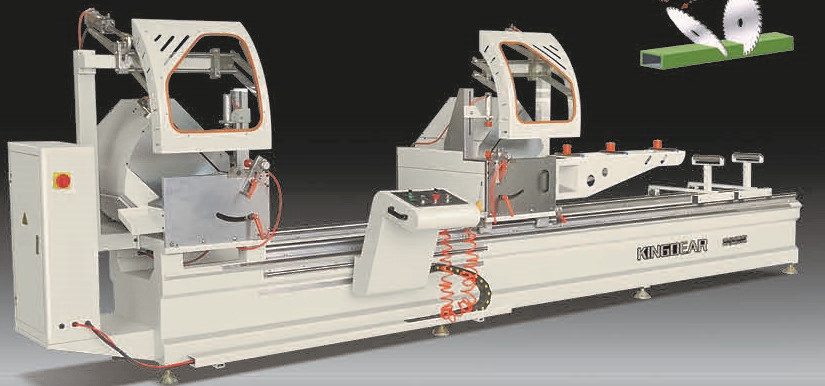

Model No.: LJZ2 -450×3700

PRODUCT DESCRIPTION

Double Head Cutting Saw Equipment Feature

■ Used for aluminum profile cutting.

■ Carbide saw blade give accurate processing and high endurance.

■ The two heads can work independently and simultaneously.

■ Cutting off the required length and two end angles is available by one time processing

Double Head Cutting Saw Technical Parameter

1) Power supply: three phase, four line 380V, 50Hz

2) Saw motor: 1.5Kw x 2, 2,800r/min

3) Pulling motor: 0.55Kw, 1,400r/min

4) Working pressure: 0.4 – 0.6MPa

5) Air consumption: 200L/min

6) Cutting length: max 3,700mm; min. 400mm

7) Cutting width: max 120mm

8) Cutting height: max. 200mm

9) Cutting angle: 0° – 45°

10) Cutter feeding speed: 0 – 3m/min

11) Saw diameter specification: 450mm x 4mm x 30mm-120

12) Overall dimensions: 4,500mm x 1,100mm x 1,400mm

Processing Accuracy

■ Repeat locating length: ≤0.2mm

■ Cutting angle allowance: ±5′

■ Cutting profile surface planeness: ≤0.10mm

■ Cutting profile surface roughness: Ra12.5μm

If you want to know more, you can click here.

Model No.: LJJS-CNC-500×600

PRODUCT DESCRIPTION

CNC Corner Connector Automatic Cutting Saw Equipment Features

■ This machine is mainly for alum windows corner stake cutting, also used for cutting Alum & PVC profiles.

■ PLC auto program controlling, man-machine interface is colored touch screen, input the cutting size and quantity, then it can cut automatically.

■ Automatic feeding system take the linear guiderail and high precision ball screw, driven by stepping motor. High feeding precision and efficiency.

■ Saw blade spindle take special high accuracy spindle, end face and radial runout are less 0.01mm, cutting surface is highly polished.

■ Saw blade feeding system adopts linear guiderail, with high accuracy and high speed (can be stepless speed regulation)

■ Carbide saw blade give accurate processing and high efficiency.

■ Special workpiece clamping system, besides processing common corner stake, it can also process middle frame corner stake.

■ All closed machine body and cover, with good appearance, safe working and low noisy.

CNC Corner Connector Automatic Cutting Saw Technical Parameter

■ Power: 380V 50Hz

■ Motor Rate: 2.2Kw

■ Saw Blade Diameter: Φ500mm

■ R.P.M: 2800r /min

■ Cutting Width: 135mm

■ Automatic Profile Feeding Length: 4-600mm

■ Working air pressure: 0.5-0.8Mpa

■ Weight: 600kg

If you want to know more, you can click here.

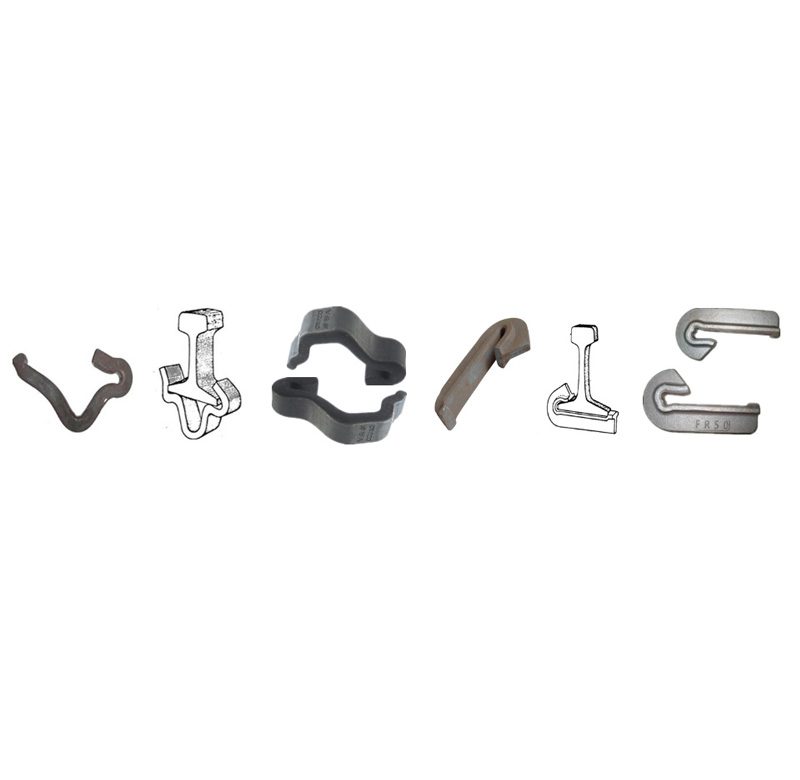

Standard Reference: AS1085.10-20002, DIN, ISO-9001

China Rail Anchor Surface Treatment: Plain / Oxide Black / Zinc Plated / Normal Painting / Sandblasting, etc

Raw Material: 60Si2MnA / 45# / QT500-7

Production Engineering: Forging ,Casting

Our company supply track fasteners, which include rail clamp, rail anchor, rail clip. Our products have high quality and competitive prices, please feel free to contact us.

Wir, Fittings und Flansche ist einer der führenden Hersteller Lieferanten und Exporteure von Edelstahl, Kohlenstoffstahl, legiertem Stahl, Duplex-Stahl, Hoch-Nickel-Legierung Stumpfschweißverschraubungen, Flansche, geschmiedete Armaturen, Bleche, Platten, Spulen, Rundstangen, Stangen , Rohre, Rohre, Auslaufarmaturen in Deutschland.

Bath Handle Pull YD-BHP12

Item no.: YD-BHP12

Description: Door Handle Pull

Sanitary Hardware Material: Aluminium/zinc alloy

Size: available, customized

Usage: bath hardware, furniture hardware

Process: die casting, machining, surface treatment

Surface: PVD finished, satin nickel, black, mirror finished, bronze, customized

Werner Flanges Inc. an ISO 9001:2008 certified Company manufacturing & exporting the finest quality Carbon Steel, Alloy Steel, Stainless Steel Butt Welded Pipe Fittings, High Pressure Forged Fittings & Flanges. Immediate Response, Excellent Quality, Quick Delivery and Customer Satisfaction truly define Werner Flanges Inc.

Ductile iron Drainage pipe is available in a range of diameters from 80mm to 1600mm and are suitable for both potable water transmission and distribution (in accordance with BS EN 545) and sewerage (in accordance with BS EN 598).

China tongmao ductile pipe is available in a range of diameters from 80mm to 1600mm and are suitable for both potable water transmission and distribution (in accordance with BS EN 545) and sewerage (in accordance with BS EN 598).

Ductile iron Drainage pipe is simple to joint, can be laid in all weather conditions and often without the need for selected backfill. Its high safety factor and ability to accommodate ground movement make it the ideal pipeline material for a wide range of applications.

ductile iron pipeline wholesale have a number of advantages over other pipe materials:

Easy to install

Full range of accessories are widely available

Suited to a host of applications both above and below ground

Strength of the material allows it to withstand significant internal pressure and also makes it less susceptible to impact damage

It has the nature of iron, the performance of steel, excellent corrosion resistance, good ductility and easy installation.

The main components are carbon, silicon, manganese, sulfur, phosphorus and magnesium.

The ductile iron pipe price list is very reasonable.

Cast iron pipe drain pipe、the cast iron sewage pipe and the cast iron gas pipe are widely used.

The wall thickness of the 150mm cast iron pipe is 6mm.

Hebei Fuhua Wanshixing Hardware and Wire Mesh Products Co., Ltd. was established in 2006, has 15 years of history. Our Company covers an area of 33000㎡. There are more than 10 sets razor barbed wire making machines.

Hebei Zhuocui Trading Co., Ltd For Hebei Fuhua Wanshixing Hardware and Wire Mesh Products Co., Ltd. Shijiazhuang office,Our company owns a group of technician and workers specialized trained.The main products: Razor barbed wire, Wall spikes, Chain link fence, Steel grating, Mobile security barriers, temporary fence, etc. Our quality management system has been successfully approved by the ISOQAR to the standard ISO9001:2000.

All the products are exported to Europe, America, Middle East, Southeast Asian and so on. These products enjoy a good reputation from our customers at home and abroad.

Hebei Fuhua Wanshixing always adhere to the principle of “Sincerity First, Customer First”, and strictly complete each order according to customer requirements, ensuring the quality and quantity.

The KLS titanium-clad steel plate is a typical metallic laminar composites. It is also referred to as titanium cladding or titanium-steel bimetallics. Normally, they are created by contortion bonding: either hot/cold-roll bonding or explosive bonding. The titanium dressed steel plate gets the inexpensive and high toughness of steel with the superior corrosion resistance of titanium.

The wholesale titanium clad steel plates are widely used in numerous applications as well as services. These include petrochemical & chemical industry especially chloral alkali process, food industry, plant food sector, damp metallurgy, electroplating, vacuum salt production, aquatic engineering, smokeshaft industry, pressure vessels, heat exchangers, desalination industry, and power plant, etc.

Roopam Steel is top manufacturer & supplier of seamless steel pipe welded tubes in ferrous and non ferrous material, Stockist of high quality tubular piping products and accessories in India. Call us for more Info at +91-22-6639 4333.

Shijiazhuang Ruite Pump Co., Ltd. is one of the high-enterprises integrating research, design, production and sales systems, produces slurry pumps, dredge pumps, gravel pumps, desulphurization pumps and pump parts. Our standard TAH(R) slurry pump, THH slurry pump, TSP(R) Vertical slurry pump, TG(H) gravel pump and all spare parts are interchangeable with Warman (weir) slurry pumps and spares. Meanwhile, Custom slurry pumps and spare parts are welcome. We will open mold and manufacure as your design drawing or samples. With more than 20years of accumulation and development, our factory was founded in 2003, the covering area is more than 3000 square meters, the registered capital is 50 millions. Our slurry pumps are mainly used in coal, mining, FGD in power station, metallurgy, dredging, petro-leum, chemical industry, building material, paper and other industries.

First-rate goods ! Reliable quality! Our Ruite pump have won well-deserved reputation at home and abroad. Our slurry pumps have been exported to Russia, South Africa, Zambia, Australia, Indonesia, Canada, Peru, Chile, Italy, France, Thailand, Singapore, Vietnam, Philippines, Mexico, Saudi Arabia, UAE…more than 37 countries. The professional pre-service, in-service and after-service provide customer perfect slurry solution.

An ISO 9001:2008 Certified Company, The Metal Factory is India’s most trusted manufacturer, exporter and supplier of stainless steel tubes (ASTM A 312 304/304L, 316/316L), carbon steel pipes (ASTM A A106, A53, API 5L), alloy steel seamless pipes (ASTM A335 P11, P22), mild steel pipes, industrial steel tubes, galvanized steel pipes and black steel pipes.

We can manufacture and supply steel pipes which can be fabricated to customers design and specification in a variety of length and thickness requirements. We can also offer cold drawn seamless steel tubes to meet the custom design and specifications of our customers. We specialise in the manufacture and supply of cold drawn seamless steel tubes, and large diameter stainless steel welded pipes (100% X-Ray Tested). ISO 9001:2008 Certification ensures consistency in our operations and testing procedures.

Steel Pipes and Steel Tubes supplied by The Metal Factory are used across wide range of industries including food processing, power generation, oil and gas, petrochemicals, petroleum pipelines, medical equipment, biopharma, pharmaceuticals, electrical engineering, fertilizer industry, dairy processing, boiler manufacturing and nuclear energy among others.

METLINE has been proudly servicing the steel pipe industry for over 40 years, as a major supplier and manufacturer of custom size steel pipes and steel tubes. We are the exclusive suppliers of stainless steel welded pipes, stainless steel seamless tubes, stainless steel tubing, alloy steel seamless pipes, boiler steel tubes, heat exchanger tubes, capillary tubes, coiled tubing, and galvanized steel pipes. We are serving all major cities and countries in their needs for steel pipes and steel tubes.

Our products are supplied to all major Industrial areas and cities in India such as Mumbai, Delhi, Bangalore, Hyderabad, Ahmedabad, Chennai, Kolkata, Surat, Pune, Nagpur, Indore, Thane, Bhopal, Visakhapatnam, Vadodra, Nashik, Faridabad, Rajkot, Aurangabad, Ranchi, Coimbatore, Raipur, Mysore, Bhubaneswar, Salem, Bhilai, Bhiwandi, Bikaner, Mangalore, Kochi (Cochin), Bhavnagar, Tirupur, Ankleshwar, Assam, Siliguri, Jamshedpur, Warangal, Nellore, Agartala and Thoothukudi.

Our high quality steel pipes, good customer service, and in house pipes and tubes processing capabilities have made us one of the emerging suppliers for steel pipes and tubes in Middle East countries including Bahrain, Cyprus, Egypt, Iran, Iraq, Israel, Jordan, Kuwait, Lebanon, Oman, Palestine, Qatar, Saudi Arabia, Syria, Turkey, United Arab Emirates and Yemen.

India’s #1 Supplier of Stainless Steel Pipes/Tubes, Chrome Moly Pipes, Black Pipes, Galvanised Pipes, Carbon Steel Pipes

Stainless Steel Pipes, Carbon Steel Tubes, Alloy Steel Tubes, MS Pipes Production and Stock Range

Outside Diameter: 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock, OD Size Steel Tubes available Ex-stock

Thickness Range: 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Type: Seamless / ERW / Welded / Fabricated / CDW

Key Steel Pipes & Tubes Products & Grades

1. Stainless Steel Seamless Pipes & Tubes – 304, 304/L, 316/L, 904L, 310S, 321H, 347H, 446

2. Stainless Steel Welded Pipes & Tubes – 304, 304/L, 316/L, 904L, 310S, 321H, 347H, 446

3. Square Stainless Steel Pipes, Round Stainless Steel Tubes, Rectangular Stainless Steel Pipes & Tubes

4. Carbon Steel Seamless Pipes as per ASTM A 106 Grade B/API 5L Grade B/ASTM A 53 Grade B

5. Carbon Steel Seamless Tubes as per BS 3059, ASTM A 179, ASTM A 192, ASTM A 210 GR.A1

6. Alloy Steel Seamless Pipes as per ASTM A335 Grade P1/ P5/ P9 / P11/ P12 / P22 / P91

7. LTCS Pipe – Low Temperature Carbon Steel Pipes as per ASTM A 333 Grade 6

8. Alloy Steel Seamless Tubes as per ASTM A213 Grade T5/T9/T11/T12/T22/T91

9. ERW Black Pipes as per IS:1239/I, IS: 3589 Grade 330 or Grade 410

10. Galvanised Pipes as per IS:1239/I

11. Square and Rectangular Steel Pipes as per IS: 4923

12. ERW Boiler Tubes: BS 3059, ASTM A 214

13. Air Pre Heater Tubes to BS: 6323 PART V

14. Hydraulic Tubes to DIN 2391 ST. 35, ST. 45 & ST. 52

15. Seamless Heat Exchanger Tubes ASTM A 179

16. CDW TUBES IS: 3074 or BS 980

17. CRCA ERW Tubes to IS 3601 OR IS 3074

18. Stainless Steel Electro polished Pipes Manufacturer/Supplier

19. Alloy Steel Fittings Manufacturer – ASTM A234 WP5, P11, P22, P91

ASTM A453 Specification describes detailed requirements of grade 660 in class A,B,C & D.

ASTM A453 Grade 660

ASTM A453 Grade 660 Class A Specification

ASTM A453 Grade 660 Class B Specification

ASTM A453 Grade 660 Class C Specification

ASTM A453 Grade 660 Class D Specification

ASTM A453 Grade 660 Pdf

ASTM A453 Grade 660 Bars Stock

ASTM A453 Grade 660 Bolts

ASTM A453 Grade 660 Chemical Composition

ASTM A453 Grade 660 Class A Bars Stock

ASTM A453 Grade 660 Class A Bolts

ASTM A453 Grade 660 Class A Countersunk Screws Csk

ASTM A453 Grade 660 Class A Fasteners

ASTM A453 Grade 660 Class A Forgings

ASTM A453 Grade 660 Class A Heavy Hex Bolts

ASTM A453 Grade 660 Class A Heavy Hex Nuts

ASTM A453 Grade 660 Class A Hex Bolts

ASTM A453 Grade 660 Class A Hex Cap Screws

ASTM A453 Grade 660 Class A Keys

ASTM A453 Grade 660 Class A Pins

ASTM A453 Grade 660 Class A Push Bolts Rods

ASTM A453 Grade 660 Class A Rings

ASTM A453 Grade 660 Class A Rods Stock

ASTM A453 Grade 660 Class A Set Screws Grubs

ASTM A453 Grade 660 Class A Socket Head Cap Screws

ASTM A453 Grade 660 Class A Stud Bolt

ASTM A453 Grade 660 Class A U Bolts

ASTM A453 Grade 660 Class A Washers

ASTM A453 Grade 660 Class A Wire Rod Stock

ASTM A453 Grade 660 Class B 12 Point Screws

ASTM A453 Grade 660 Class B Bars Stock

ASTM A453 Grade 660 Class B Bolts

ASTM A453 Grade 660 Class B Countersunk Screws Csk

ASTM A453 Grade 660 Class B Fasteners

ASTM A453 Grade 660 Class B Forgings

ASTM A453 Grade 660 Class B Heavy Hex Bolts

ASTM A453 Grade 660 Class B Heavy Hex Nuts

ASTM A453 Grade 660 Class B Hex Bolts

ASTM A453 Grade 660 Class B Hex Cap Screws

ASTM A453 Grade 660 Class B Keys

ASTM A453 Grade 660 Class B Pins

ASTM A453 Grade 660 Class B Push Bolts Rods

ASTM A453 Grade 660 Class B Rings

ASTM A453 Grade 660 Class B Rods Stock

ASTM A453 Grade 660 Class B Set Screws Grubs

ASTM A453 Grade 660 Class B Socket Head Cap Screws

ASTM A453 Grade 660 Class B Stud Bolt

ASTM A453 Grade 660 Class B U Bolts

ASTM A453 Grade 660 Class B Washers

ASTM A453 Grade 660 Class B Wire Rod Stock

ASTM A453 Grade 660 Class C Bars Stock

ASTM A453 Grade 660 Class C Bolts

ASTM A453 Grade 660 Class C Countersunk Screws Csk

ASTM A453 Grade 660 Class C Fasteners

ASTM A453 Grade 660 Class C Forgings

ASTM A453 Grade 660 Class C Heavy Hex Bolts

ASTM A453 Grade 660 Class C Heavy Hex Nuts

ASTM A453 Grade 660 Class C Hex Bolts

ASTM A453 Grade 660 Class C Hex Cap Screws

ASTM A453 Grade 660 Class C Keys

ASTM A453 Grade 660 Class C Pins

ASTM A453 Grade 660 Class C Push Bolts Rods

ASTM A453 Grade 660 Class C Rings

ASTM A453 Grade 660 Class C Rods Stock

ASTM A453 Grade 660 Class C Set Screws Grubs

ASTM A453 Grade 660 Class C Socket Head Cap Screws

ASTM A453 Grade 660 Class C Stud Bolt

ASTM A453 Grade 660 Class C U Bolts

ASTM A453 Grade 660 Class C Washers

ASTM A453 Grade 660 Class C Wire Rod Stock

API 6A Bolting Torque for Flanges (SI Units)

API 6A Bolting Torque for Flanges (USC Units)

ASTM A453 Grade 660 Class D API 6A Full Thread Stud Bolt

ASTM A453 Grade 660 Class D API 6A Tap End Stud Bolt

ASTM A453 Grade 660 Class D Bars Stock

ASTM A453 Grade 660 Class D Bolts

ASTM A453 Grade 660 Class D Countersunk Screws Csk

ASTM A453 Grade 660 Class D Fasteners

ASTM A453 Grade 660 Class D Forgings

ASTM A453 Grade 660 Class D Heavy Hex Bolts

ASTM A453 Grade 660 Class D Heavy Hex Nuts

ASTM A453 Grade 660 Class D Hex Bolts

ASTM A453 Grade 660 Class D Hex Cap Screws

ASTM A453 Grade 660 Class D Keys

ASTM A453 Grade 660 Class D Pins

ASTM A453 Grade 660 Class D Push Bolts Rods

ASTM A453 Grade 660 Class D Rings

ASTM A453 Grade 660 Class D Rods Stock

ASTM A453 Grade 660 Class D Set Screws Grubs

ASTM A453 Grade 660 Class D Socket Head Cap Screws

ASTM A453 Grade 660 Class D Stud Bolt

ASTM A453 Grade 660 Class D U Bolts

ASTM A453 Grade 660 Class D Washers

ASTM A453 Grade 660 Class D Wire Rod Stock

ASTM A453 Grade 660 Countersunk Csk Screws

ASTM A453 Grade 660 Fasteners

ASTM A453 Grade 660 Forgings

ASTM A453 Grade 660 Heavy Hex Bolts

ASTM A453 Grade 660 Heavy Hex Nuts

ASTM A453 Grade 660 Hex Bolts

ASTM A453 Grade 660 Hex Cap Screws

ASTM A453 Grade 660 Keys

ASTM A453 Grade 660 Mechanical Properties

ASTM A453 Grade 660 Pins

ASTM A453 Grade 660 Push Bolts

ASTM A453 Grade 660 Rings

ASTM A453 Grade 660 Rods

ASTM A453 Grade 660 Set Screws

ASTM A453 Grade 660 Socket Head Cap Screws

ASTM A453 Grade 660 Stud Bolts

ASTM A453 Grade 660 U Bolt

ASTM A453 Grade 660 Washers

ASTM A453 Grade 660 Wire

Copper Mould Tube & Plate

We specially in supplying Copper Mould Tube, Crystallizing equipment of continuous casters, Mould cooling jacket, Repair of Metallurgical Copper Mould Tube, etc.

Equipments & Spare parts for Continuous Casting Machine.

- Copper mould tube( square, rectangle and round )

- Crystallizing equipment of continuous casters

- Mould cooling jacket.

- repair of copper tube moulds

The copper alloys chosen for the moulds must maintain their physical properties at the operating temperatures of the continuous casting process.

The temperature gradation from the inner wall of the mould to the outside face of the mould can cause serious distortion problems, and Metallurgical Copper Mould Tube is imperative that the correct alloy is chosen for the various operating conditions.

Square Copper mould tube STANDARD MATERIALS

Phosphorus de-oxidised copper

This alloy has been proven to be excellent for the manufacture of moulds in the continuous casting of billets. The main composition of this alloy are Cu +Ag 99.90min, P0.0015 / 0.040.

Copper -Silver alloy

The addition of a small amount of silver, whilst not increasing the melting point of copper, does increase the recrystallisation temperature by almost 100℃, and also helps to give better thermal conductivity at the operating temperatures.

This alloy is normally used in moulds for the continuous casting of blooms and slabs .In this case, the moulds are much thicker than in the billet moulds, and the moulds temperature can be higher. The main composition of this alloy are Cu+Ag99.90 min. Ag 0.08 / 0.12 O 0.004 / 0.012.

The continuous casting of molten steel into billets, blooms and slab products, has been highly refined over the years into an extremely sophisticated system. The continuous casting process is expected to produce metallurgically sound products at the lower possible cost, and this is being achieved in many steelworks throughout the world.

Copper moulds have played an important role in the development of the continuous casting process. Their funcition is to receive the molten steel and to allow rapid heat transfer from the steel to the cooling water to enable quick solidification.

The mould must exhibit excellent thermal conductivity, be resistant for thermal erosion ,and be resistant to distortion from thermal stress. So far only copper and a few copper alloys meet the above conditions, both economically and technically.

Mould cooling jacket supplier SOLIDIFICATION

The rate of solidification in the continuous casting process dictates the speed of production. The molten steel, which is in contact with the inner faces of the copper mould, starts to sllidify as rapidly as the heat is extracted, forming a shell. The shell increases in thickness as more heat is extracted, and eventually total solidfication is achieved. the process is similar to the solidification of ingots in ingot moulds. In continuous casting, the whole process is speeded up, with the aim to produce and homogeneous shell growth. Consequently, the mould is an important part of the continuous casting process, and the manufactured quality of the mould plays and important role in their length of life.

INNER SURFACE COATINGS

Over the years, Metallurgists and Engineers have been working together to develop better continuous casting moulds. The steel companies require a more economical mould which will give a longer service life. Surface coating of the inner walls of the mould has given the best results to date. Coatings available are Chromium and Nickel plating. Also, a combination of the two give good results on slab casting.

SPECIFICATIONS OF COPPER MOULD

Square 60 x 60 – 350 x 350 (mm)

Rectangle 120 x 160 – 180 x 300 (mm)

Diameter 100-400 (mm)

Size(mm): 90×90, 100×100, 110×110, 115×115, 120×120

130×130, 135×135, 140×140, 143×143, 150×150

155×155, 160×160, 165×165, 175×175, 180×180

200×200, 220×220, 100×170, 100×173, 130×240

150×200, 150×210, 150×220, 160×200, 160×220

150×225, 160×235, 165×225, 175×225, 180×220

200×240, 240×240, 235×235

Radius(mm): 4000, 5000, 5250, 6000, 7000, 7500, 8000, 9000, 10250, 10300, 11000, 12000

Length(mm): 700, 750, 780, 790, 800, 810, 812, 850, 900, 1000

We have cooperated with them for many years,although the amount of the monthly is not particularly large, but very stable.We mainly provide the Forklift Brackets,Forklift Shaft Accessories and other small parts.The quality of our products has been recognized by them..Our products are used in the former more,such as Excavator Parts,Excavator Brackets,Roller accessories,Bulldozer accessories,Construction Machinery Hook, Automobile Casting Parts

HOT-DIPPED GALVANIZED STEEL COIL

- INTRODUCTION:

Hot-dipped galvanized steel coil is made from steel plate, which is dipped into the dissolved zinc bath, with a zinc layer on the surface. It mainly adopts the continuous galvanizing production process. That means the cold rolled coils are put into the dissolved zinc bath for continuous galvanizing process.

- EVER-SHINE Steel Coil APPLICATION:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It’s especally useful for countless outdoor and industrial applications.

They are mainly used in building roof, door, window, roller shutter doorand automobile’s vehicle shell, chassis, door, trunk lid, Oil tank, and fender, and also electric equipments, such as refrigerator base and shell and so on.

- SPECIFICATION

| THICKNESS | 0.11mm-5.0mm |

| WIDTH | 600-1250mm Max |

| COATING MASS | 20g-400g/m2 |

| Surface Structure | Zero Spangle,Regular Spangle,Minimized Spangle |

| SURFACE TREATMENT | Chromated/non-Chromated,Oiled/non-Oiled,skinpassed/non-skinpassed |

| COIL INNNER DIAMETER | 508mm or 610mm |