- Rectangular tube (30)

- Seamless tube (62)

- Square tube (31)

- Welded tube (29)

IBC GROUP is dedicated to transforming various metal materials all over the world, through the process of coils, steel sheet, steel pipe, wire, profile,Alloy steel, all variety of metal products to the construction and wide manufacture industry. Meanwhile, because maintain long term friendly business relationship with clients. Enjoy solid trust from our regular clients, already working one-stopstation service in other construction related products Such as metal process equipment .All Enjoy highly comments from our customers.Look forward the chance to develop together.

Shijiazhuang Jintai Purification Equipment Co., Ltd was founded in 1994 (reformed from a state-owned enterprise to a private limited liability company in 2004), located at No.69, Tiangui Street, High-Tech Zone, Shijiazhuang , Hebei Province.

The company has been committed to the development of metal porous materials and related technologies and applications. As early as more than 20 years ago, Jintai began to focus on the development and production of metal porous powder sintered filter elements. It has 15 invention patents and utility model patents. It has been a high-tech enterprise and has passed ISO9001 quality management system certification. After more than 20 years of technical accumulation, Jintai can now provide customers with a variety of product materials and specifications to meet customer needs.

The company’s business covers all provinces in China, and some products are exported to Germany, Italy, Spain, India, Taiwan and other places. Some large domestic companies have designated the company’s products. The company’s products mainly include titanium filter, stainless steel filter, sparger, filter, filter device and system, sheet and disc, saucer-shaped filter disc, aeration ring and so on. Products are widely used in medicine, metallurgy, petroleum and petrochemical, fine chemicals, food and beverage, air purification, electronics industry, textile industry, water treatment and other fields.

CRS is a leading manufacturer of thermit welding materials in China, we have more than 30 years experience of designing thermit welding to the rails. Focusing on rail welding used for railroad, metro, tram, crane rails, turnel construction and maintenance.

We have production area of 2500 square meter, with fully automated batching system, sand mould automatic production & drying machines, equipped with full range of raw materials and welding joint testing equipments. Rail aluminum thermit welding material has been promoted and well applied in the railway lines such as the Beijing-Shanghai high-speed railway line, Jinqin passenger line, Daqin line, Tong-Rang line and Tong-huo line. Materials have been exporting to Australia, Indonesia and other countries many years, the products have won praise.

CRS possesses a qualified team of technicians and engineers who have been improving the quality and performance of products, Certified to the ISO9001:2000 standard, CRS’ welding products have been supplied to a wide range of customers worldwide. Thermit products have been passed Chinese rail welding standard TB/T1632-2005 test, Railway Ministry of China, as well as Australia standard AS1085.15-1995 test, Indonesia welding joint inspection test, Taiwan SGS quality inspection test. We are ready to provide technical & operation training, qualification and certificate for customers to ensure a standardized quality and performance of the welding products.

Our factory is an enterprise manufacturing pipe fittings for more than 30 years. It is supplying Malleable iron fittings, Ductile iron fittings , Gray iron fittings and other steel products, with long history and unchanging faith of producing high quality products.

Main products:Malleable iron pipe fittings, Tube clamps, Air hose couplings, Camlock couplings, Carbon steel pipe nipples, Electric power fittings, Steam couplings, Gas meter connectors etc.

- Founded in 1986, Covering 12,000 square meters, having more than 200 workers. We have a registered capital of 8.88 million, and the annual export volume of 10 million USD.

- As a high-tech enterprise, we have our own R&D team, which can open molds through samples or drawings provided by customers, and even assist customers in developing new products through functional descriptions.

- From purchasing material, casting, annealing, trimming, galvanizing, machining, packing, to exporting, have formed stop production system.

- Various casting techniques: Currently 90% of the products have been changed to coated sand production. And equipped with coated sand production line, which can control the quality requirements of coated sand, and coated sand buried box casting line, further improve the quality of products. Most suitable casting way can be defined according to any products.

- casting surface: our own researched prescription of sand and mold design is used, there’s no joint line, no shift, no sand inclusion, no crack on products, we will satisfy every client.

- Material assurance: on –the –spot sample analysis+ chemical composition analysis after casting, double tests to guarantee stability of material. Electric heating automatic temperature control equipment can precisely control the furnace heats uniformly to ensure product are with the same tenacity.

- Surface treatment: self-color + rust preventing oil, electroplating, hot dip galvanizing, first electroplating and then hot dip galvanizing, first electroplating and then backed galvanizing, first electroplating and then plastic spraying. Different products need different surface treatment, best surface treatment can be defined according to different products.

- Machining technique: we have professional threading machines and CNC lathes to make threads, threads are 100% within specified scope of gauge and plug gauge, included angle of threads is within 90°+-0.5°. High efficiency and high quality producing way make our products have more market value.

- Our certificates: Our factory passed TSE for Turkey, INMETRO for Brazil, and CE, ISO9001:2008, IQNET etc.

- Our clients: Our factory is cooperating with many well-known enterprises, main market for malleable iron pipe fittings is Europe, main market for pipe clamp fittings is U.K., and main market for air hose couplings is USA. There’re also many different kinds of products for specialized application, and are very advantageous in their fields.

Our website:http://www.donghuancast.com

湖南格瑞特钢管有限公司,拥有24年的钢管制造经验,是盛世达集团第一家子公司,是世界一流的埋弧直缝焊管生产和服务商。

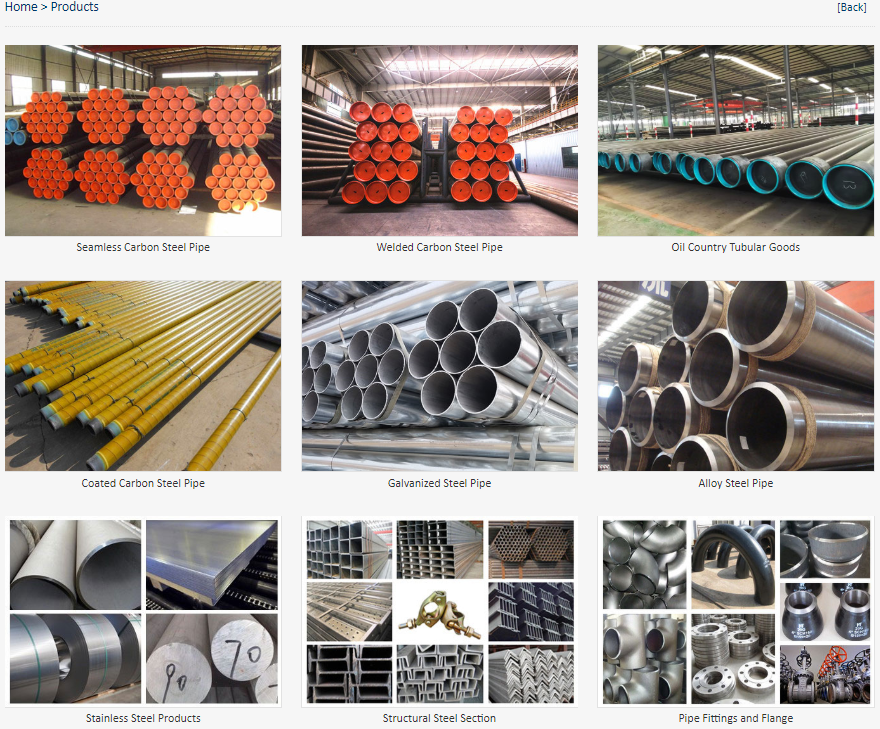

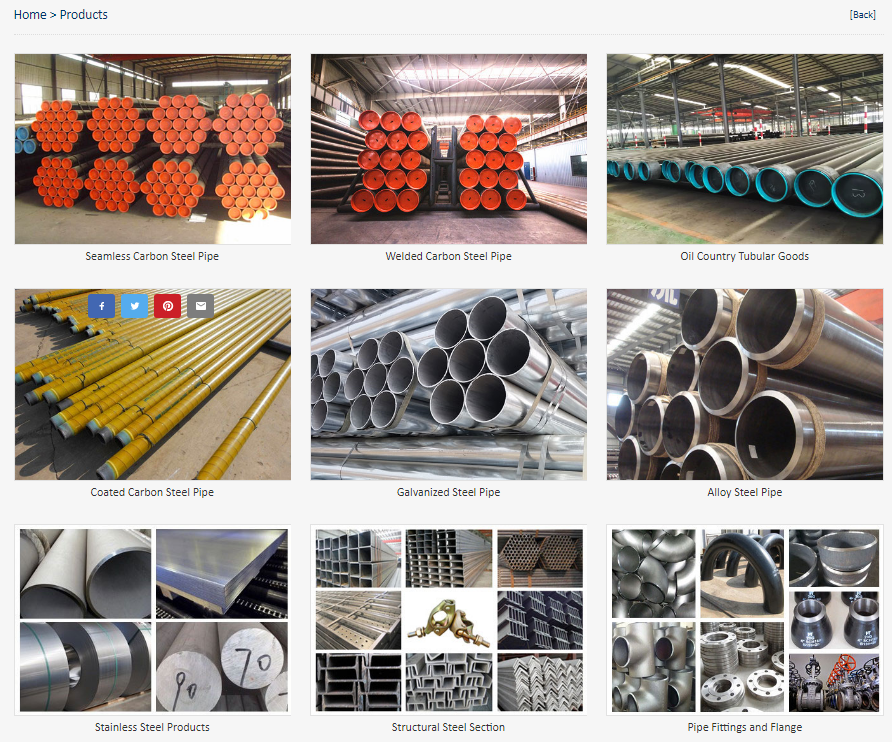

Sambhav Metal are Manufacturers, Suppliers, Exporters, Traders, Stockists and Dealers of Stainless Steel Pipes and Tubes, Carbon Steel, Alloy Steel, Duplex Steel, High Nickel Alloy, Inconel, Monel, Hastelloy, Alloy 20, Copper Nickel, Stainless Steel 304 Seamless Pipe, SMO 254 Pipes, Tubes, Stainless Steel Pipe Fittings, High Nickel Alloy Flanges, Stainless Steel 316 Seamless Pipe, Pipe Flanges, Round Bars, Stainless Steel 304 Butt weld Fittings, Rods, Sheets, Coils, Plates, Stainless Steel 316 Buttweld Fittings in India.

Our Products

Pipes & Tubes – Stainless Steel, Carbon Steel, Duplex Steel, Alloy Steel and High Nickel Alloy.

Pipe Fittings – Stainless Steel, Carbon Steel, Duplex Steel, Alloy Steel and High Nickel Alloy.

Flanges – Stainless Steel, Carbon Steel, Duplex Steel, Alloy Steel and High Nickel Alloy.

Fasteners – Stainless Steel, Carbon Steel, Duplex Steel, Alloy Steel and High Nickel Alloy.

Round Bars & Rods – Stainless Steel, Carbon Steel, Duplex Steel, Alloy Steel and High Nickel Alloy.

Sheet, Plate & Coils – Stainless Steel, Carbon Steel, Duplex Steel, Alloy Steel and High Nickel Alloy.

More info visit us http://www.sambhavmetal.com

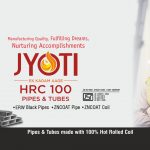

We, Centerway Steel Co.,Ltd, one stop supplier for steel pipes, steel plate, fittings and flanges, valves, round steel, structural steel in China since 1996.

Welcome to contact us for competitive price.

Hunan Great Steel Pipe Co.,Ltd is a world-class production and service provider of seamless pipes and welded pipes as the first subsidiary of Shinestar Group.

Hunan Great Steel Pipe Co.,Ltd is specialized in steel pipe & tube production including carbon steel pipe, seamless steel pipe, erw steel pipe, ssaw steel pipe, lsaw steel pipe, etc.

As the most valuable subsidiary under SHINESTAR STEEL GROUP, PRIME STEEL PIPE is the solution provider for the oil, gas, construction, energy and prtrochemical industries.SHINESTAR STEEL GROUP is specialized in manufacturing superior quality steel products, and providing outstanding service for valued clients all over the world.

Eastern Steel Manufacturing Co.,Ltd is a leading manufacturer and distributor of seamless steel pipe, welded steel pipe, OCTG products and fittings. We supply first-step processing, semi-finished parts and finished parts to help our clients meet fabrication requirements beyond their capacity or to improve operations by moving forward the pre-production processing.

LANDYOUNG GRP pipe is manufactured in accordance with international standard using Helical FILAMENT winding process and Continuous FILAMENT winding process on computer controlled machines.

DESCRIPTIONS

LANDYOUNG GRP pipe is manufactured in accordance with international standard using Helical FILAMENT winding process and Continuous FILAMENT winding process on computer controlled machines.

Helical FILAMENT winding process(Bell and spiogot joints)

GRP Pipe is manufactured using the helical (reciprocal) filament winding process by which impregnated glass fiber reinforcement with resin are applied onto a precision steel mandrel in a prescribed pattern. Repeated application of wetted fibers results in a multi-layered structural wall construction of the required thickness.

Continuous FILAMENT winding process(Coupling joints)

GRP Pipe is manufactured on a continuous filament winding machine. This machine consists of a mandrel composed of a helical wound continuous steel band, supported by beams forming a cylindrical shape. As the formed mandrel turns creating a multi-layered structural wall of the required thickness.

Applications

- Infrastructure &Municipal

- Industrial

- Water Diversion

- Desalination

- PowerPlant

- Petrochemicals

- Oil & Gas and Marine

- Agriculture Irrigation

- Storm Water

- Cooling Water

- Hydropower penstock

Advantages

Minimum 50 years service life

LANDYOUNG GRP pıpes are manufactured with corrosion resistant non-metallic raw materials. Since corrosion is not a problem, cathodic protection and extra insulation against corrosion are not needed; thus operational expenses and difficulties do not exist.

Light weight

Weight of GRP pipe:1/4 of steel pipes; 1/10 of concrete pipes

Can be transported as nested, providing great savings

Quick and easy installation, no need for heavy and expensive equipment

Excellent hydraulic properties

Hazen Williams flow coefficient is 150(c=150). Due to the low friction losses, less pumping energy is required.compared to steel and concrete pipes, same flow rates can be ensured using smaller diameters.

No lime or deposit formation inside

Unlimited service area-application in every environment

Can be installed underground, aboveground, and also underwater.

Bell and spigot joints and coupling joints ensure total leak-tightness.

Flexible:successful experience in earthquake regions

Can be installed inside old lines for relining.

LANDYOUNG GRP pipes are environmentally friend

If you are interested in our products, please visit our website

Product Range and properties

| LANDYOUNG offers a wide product range of GRP pipes and fittings to meet Specific requirements of any project. | ||||||||||

|

||||||||||

I

Madhav KRG Group is one of the best TMT bars manufacturers. Madhav KRG Group is the largest reinforcement bars manufacturing group in India.

Inner Mongolia Pusheng Iron & Steel Co,.Ltd is a comprehensive company for steel production and trading. Its business includes production, processing, distribution, logistics and import& export of steel. We have been processing and selling high quality , value add steel products to customers throughout all over the world .

Our company lies in Hohhot , inner Mongolia , it is near by BAO STEEL , The superior location provides us with quality products and reasonable prices , By creating long term relationships and building trust with clients and suppliers, Pusheng is able to offer our clients comprehensive and competitive sales packages with quality goods along with excellent customer service, establishing a firm reputation in inner mongolia ’s steel industry.

Our main products : hot rolled steel coils/sheet , cold rolled steel coils/sheet , galvanized steel coils/sheet /pipe , prepainted steel coil, corrugated sheets and tinplate coils,Ms pipe /plate, stainless steel sheet /pipe etc.

Black painted Carbon Steel Seamless Pipe

Introduction:

ASTM A106 Grade B, ASTM A53 Grade A, Grade B, API 5L Grade B, GB/T 8162, GB/T 8163 Grade 20#

Detailed Information:

| Product Name | Black painted Carbon Steel Seamless Pipe |

| Thickness | SCH20, SCH 30, STD, SCH40, SCH80 TO SCH160 (3MM to 46MM) |

| Outer Diameter | 1/2″ to 24″ |

| Surface Treatment | Anti-rust oiled or black painting or hot dipped galvanized and so on |

| Production process | Hot rolled |

| Material | 20#, 16Mn, A53(A,B), Q345 |

| Length | General 5.8m, 6m, 11.8m, 12m and also can do as per the customer’s requirements |

| Ends | Plain and beveled end |

| Standard and Steel Grade | ASTM A106 Grade B, ASTM A53 Grade A, Grade B, API 5L Grade B, GB/T 8162, GB/T 8163 Grade 20# |

| Certificate | ISO 9001: 2008 |

| Package: | By bundle, bulk, by waterproof |

| Payment term | T/T or L/C |

https://www.hebeibona.com/seamless-steel-pipes/

Seamless pipe are made of sheet or rod-shaped solid steel, formed into solid circles called billets, which are then heated and cast in forms such as puncture rods to form hollow tubes or shells.

Threeway Steel co.,ltd is a world-class steel pipe provider, one of the largest subsidiary in Shinestar Holdings Group Co.,ltd. As the companys largest export base, we are committed to provide professional one-stop procurement service for customers with excellent quality, competitive price, convenient transportation and timely delivery. At present, customers have been all over world. Including Singapore, Vietnam, Egypt, Nigeria, Arabia, United Arab Emirates, Kuwait, Oman, Mexico, Columbia, Australia etc.In the future,Threeway steel co.,ltd devotes to bring unexpected special experience for worldwide customers by the excellent strength and abundant experience.

As the most valuable subsidiary under SHINESTAR STEEL GROUP, PRIME STEEL PIPE is the solution provider for steel pipes and fittings. We are dedicated in providing high performance-price ratio steel pipes and fittings for the oil, gas, construction, energy and petrochemical industries. In prime steel pipe, we believe honest communication, expertise in steel industry, and prompt execution lead to strong long term relationships. Our professional team provides “one-stop procurement” service to coordinate with clients projects regulation, site and terrain. We ensure the best quality of products by assigning skillful experts at every stage of activities. To keep the honesty in mind, to win reputation by trust is our principle.

Copper Mould Tube & Plate

We specially in supplying Copper Mould Tube, Crystallizing equipment of continuous casters, Mould cooling jacket, Repair of Metallurgical Copper Mould Tube, etc.

Equipments & Spare parts for Continuous Casting Machine.

- Copper mould tube( square, rectangle and round )

- Crystallizing equipment of continuous casters

- Mould cooling jacket.

- repair of copper tube moulds

The copper alloys chosen for the moulds must maintain their physical properties at the operating temperatures of the continuous casting process.

The temperature gradation from the inner wall of the mould to the outside face of the mould can cause serious distortion problems, and Metallurgical Copper Mould Tube is imperative that the correct alloy is chosen for the various operating conditions.

Square Copper mould tube STANDARD MATERIALS

Phosphorus de-oxidised copper

This alloy has been proven to be excellent for the manufacture of moulds in the continuous casting of billets. The main composition of this alloy are Cu +Ag 99.90min, P0.0015 / 0.040.

Copper -Silver alloy

The addition of a small amount of silver, whilst not increasing the melting point of copper, does increase the recrystallisation temperature by almost 100℃, and also helps to give better thermal conductivity at the operating temperatures.

This alloy is normally used in moulds for the continuous casting of blooms and slabs .In this case, the moulds are much thicker than in the billet moulds, and the moulds temperature can be higher. The main composition of this alloy are Cu+Ag99.90 min. Ag 0.08 / 0.12 O 0.004 / 0.012.

The continuous casting of molten steel into billets, blooms and slab products, has been highly refined over the years into an extremely sophisticated system. The continuous casting process is expected to produce metallurgically sound products at the lower possible cost, and this is being achieved in many steelworks throughout the world.

Copper moulds have played an important role in the development of the continuous casting process. Their funcition is to receive the molten steel and to allow rapid heat transfer from the steel to the cooling water to enable quick solidification.

The mould must exhibit excellent thermal conductivity, be resistant for thermal erosion ,and be resistant to distortion from thermal stress. So far only copper and a few copper alloys meet the above conditions, both economically and technically.

Mould cooling jacket supplier SOLIDIFICATION

The rate of solidification in the continuous casting process dictates the speed of production. The molten steel, which is in contact with the inner faces of the copper mould, starts to sllidify as rapidly as the heat is extracted, forming a shell. The shell increases in thickness as more heat is extracted, and eventually total solidfication is achieved. the process is similar to the solidification of ingots in ingot moulds. In continuous casting, the whole process is speeded up, with the aim to produce and homogeneous shell growth. Consequently, the mould is an important part of the continuous casting process, and the manufactured quality of the mould plays and important role in their length of life.

INNER SURFACE COATINGS

Over the years, Metallurgists and Engineers have been working together to develop better continuous casting moulds. The steel companies require a more economical mould which will give a longer service life. Surface coating of the inner walls of the mould has given the best results to date. Coatings available are Chromium and Nickel plating. Also, a combination of the two give good results on slab casting.

SPECIFICATIONS OF COPPER MOULD

Square 60 x 60 – 350 x 350 (mm)

Rectangle 120 x 160 – 180 x 300 (mm)

Diameter 100-400 (mm)

Size(mm): 90×90, 100×100, 110×110, 115×115, 120×120

130×130, 135×135, 140×140, 143×143, 150×150

155×155, 160×160, 165×165, 175×175, 180×180

200×200, 220×220, 100×170, 100×173, 130×240

150×200, 150×210, 150×220, 160×200, 160×220

150×225, 160×235, 165×225, 175×225, 180×220

200×240, 240×240, 235×235

Radius(mm): 4000, 5000, 5250, 6000, 7000, 7500, 8000, 9000, 10250, 10300, 11000, 12000

Length(mm): 700, 750, 780, 790, 800, 810, 812, 850, 900, 1000

We are one of the leading Suppliers and Exporters of Tube Fittings, Pipe Fittings Threaded, and Ferrule Fittings, Needle Valves, Ball valves, Manifold Valves, hex nipple in Mumbai India.