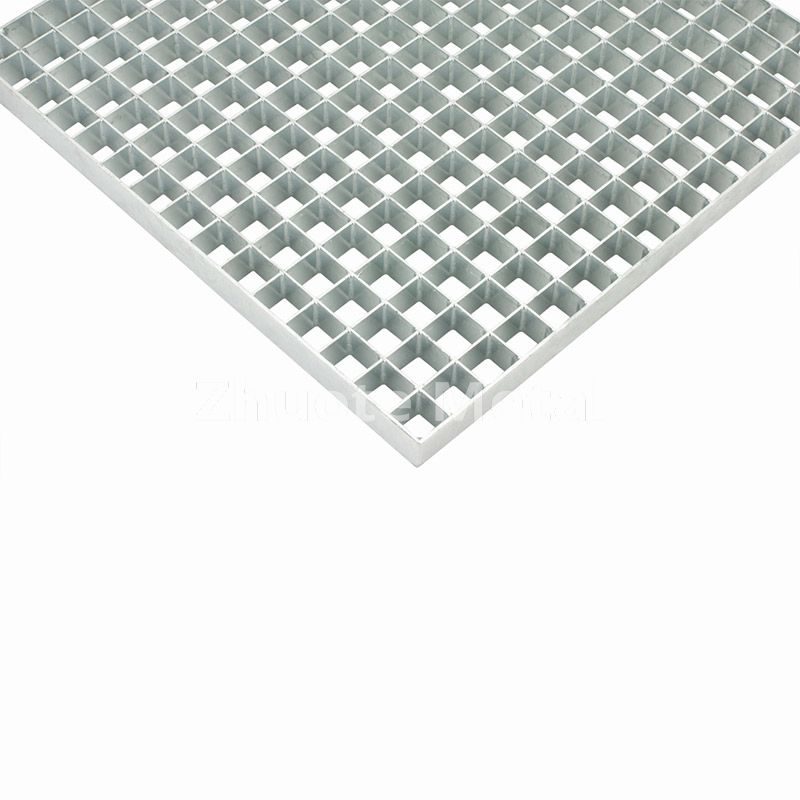

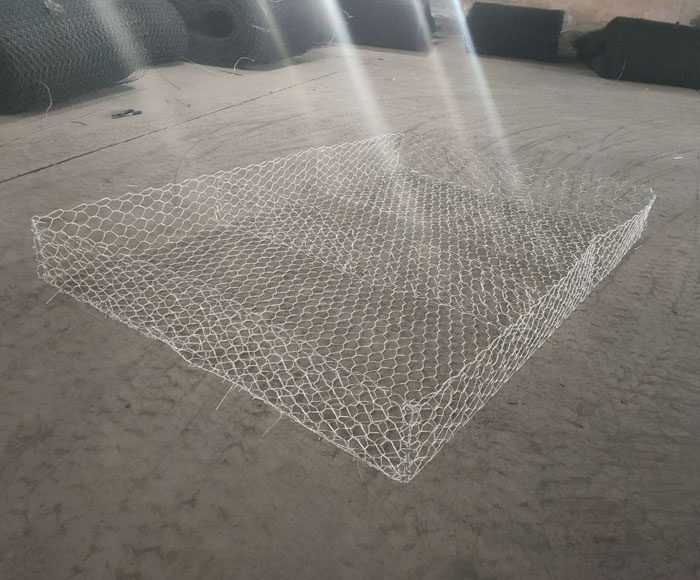

Expanded metal, also known as metal mesh, refers to any type of metal raw material that can expand in response to different climate changes. This expansion capability makes it ideal for many functions, and it also helps reduce wear on components made with this metal structure. Expanded metal can be used to make many different types of objects, including metal grinders, wall art, furniture and other objects, where the ability to cope with climate change helps protect the integrity of the finished product.

One of the most common examples of such metal products is expanded metal sheets. These sheets can be scored and peeled to create perforation designs, which can then be used to create many different metal products. This method can be used to create mesh designs and is often found in outdoor furniture made entirely or partially of metal parts. The same technique can also be used to create large panels for use as wall art, room dividers, and metal products with similar functionality and decoration. Although expanded metal can expand and contract when exposed to different weather conditions, it is very durable and very suitable for use in many different products.

Expanded metals can also be used to increase the strength of many construction projects. By including metal sheets or even metal strips in the masonry work, it can help maintain the integrity of the masonry over a long period of time. The same method can be used to provide additional strength to plaster and other types of concrete structures. When used to create perforated or diamond-shaped grids, expanded metal can be effectively used to create cages or other enclosures, ideal for everything from animal kennel spaces to storage areas for holding various supplies. One of the advantages of constructing these types of enclosures with expanded metal is that it allows air to circulate freely and improves visibility.

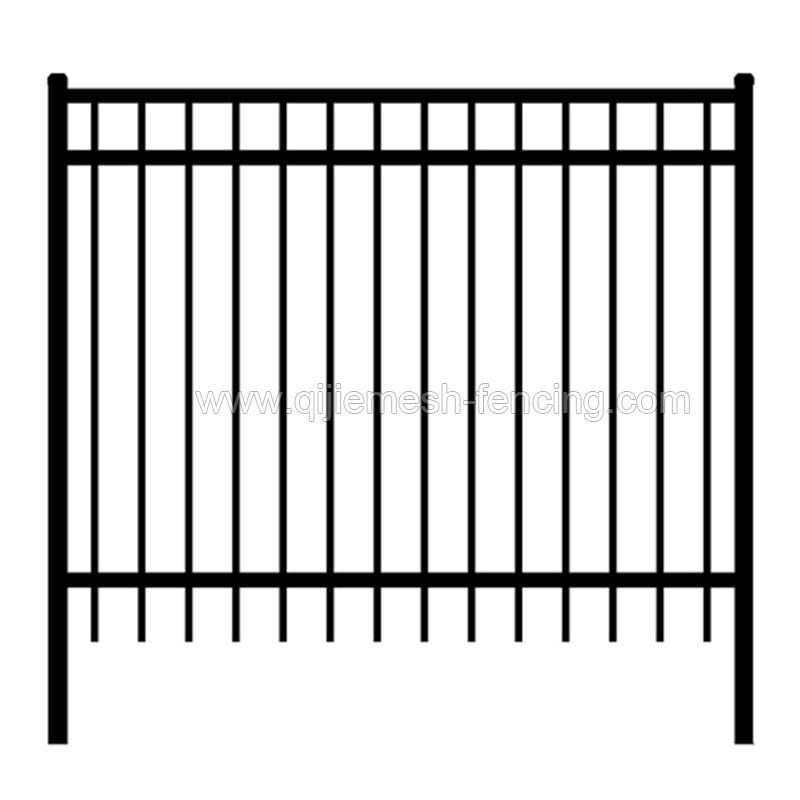

Today, many other applications for metal expansion are also adopted. This includes creating expanded metal fencing that are both decorative and durable. The metal can be used to make grills suitable for outdoor use and various forms of indoor cooking equipment. Many companies use expanded metal to create a variety of products that can be used by individual consumers and business operations, making this metal one of the most widely used material categories today.

Hebei Huahui Valve Co.,Ltd (Botou Yaxing Fluid Equipment Co.,ltd) was established in 2003, specialize in designing and manufacturing various kinds of high quality valves and accessories, such as: Gate valve, Butterfly valve, Check valve, Strainer, Hudraulic control valve(float valve, pressure reducing valve, pressure relief valve,flow control valve),HVAC balancing valve,Air release valve,Rubber flexible joint and Stainless steel flexible joint,Pipe fittings(unicersal coupling, flange adaptor, repair clamp, saddle…) etc, which used in water supply and sewage system\ fire fighting system, and heating ventilation air conditioning system.

Hebei Huahui Valve Co.,Ltd is located in Botou Industrial Zone,Cangzhou City Hebei Province China.Our workshop occupying 150000 square meters, our manufacturing process include machining, shot blasting ,epoxy powder coating,assembling, testing, packing, which is the whole process of valve production from foundry to finished Products. Welcome old and new customers visit our factory and develop business with us.

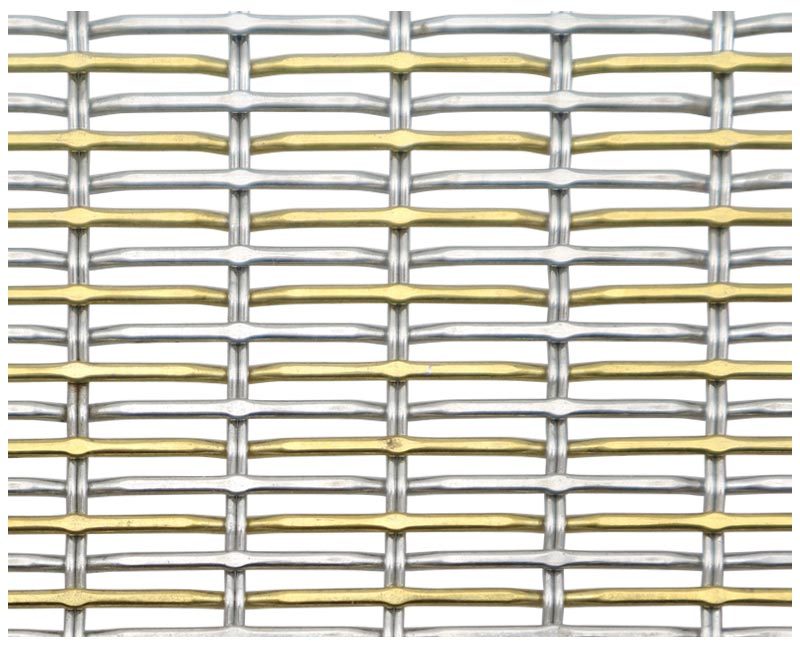

Material: 304, 304L, 316, 316L, etc.

Weaving Pattern: Plain weave and twill wave.

Performance: Excellent resistance against acid,alkali heat,pull and wear.

Stainless Steel Wire Mesh General Use: Mud net for the oil industrial,filter screen for electroplating industrial,they all have excellent performance.

Our factory can design and manufacture various products to meet the need of user and accept customers materials for processing.

Established in 1996, Vintex Steel & Engg. Co. has gained immense expertise in supplying & trading of Stainless steel, carbon steel, ferrous metal etc. The supplier company is located in Mumbai, Maharashtra and is one of the leading sellers of listed products. Buy Stainless steel, carbon steel, ferrous metal in bulk from us for the best quality products and service.

HENAN FORWARD STEEL EXPORT CO.,LTD

Tel: +86-371-61310228 You also can visit us by sa514steel.com througth google

Address: Tower-A Room 3106 Kai xuan Plaza zhengzhou city of henan province China

http://sa514steel.com

Email: admin@qfsteels.com

SA240 TP310S Stainless, SA240 309S stainless, SA240 316TI stainless, SA240 304H stainless

1. What we do?

HENAN FORWARD STEEL EXPORT CO.,LTD Stainless warehouse provide ASME SA240 Stainless steel plate Bevel,Groove and cutting disc stainless steel machined parts .we have 1000tons tp316L,tp310s,tp304l,tp321, tp304h, tp316h,tp310h, tp321h,2205, S31803, 410, 430, 409, 443, 439, 310SI2, 316TI Stainless steel plate stock.

Besides that, our factory also provide the CNC Cutting platform and water cutting platform. Disc cutting, special parts cutting, stainless steel bevel and stainless steel groove service. Our machined precision to min 0.2 for the surface of machined.

Our cutting service had approved by Mexico and USA, and Canada Project.

2. Our mainly stainless steel grade for ASME SA240

SA240 TP202,SA240 TP201,

SA240 TP304,SA240 TP304L,SA240 TP304H, SA240 TP304N, SA240 TP304LN

SA240 TP316L,SA240 TP316, SA240 TP316H,SA240 TP316N, SA240 TP316LN,SA240 TP316TI

SA240 TP309S, SA240 TP309H,SA240 TP309,SA240 TP309Cb

SA240 TP310S, SA240 TP310, SA240 TP310H

SA240 TP347,SA240 TP347H,

SA240 TP348,SA240 TP348H,

SA240 TP321, SA240 TP321H

SA240 TP317L,SA240 TP317

SA240 TP444,SA240 TP410, SA240 TP430,SA240 TP443, SA240 TP439

3. Products Service of our unitedsteel warehouse.

Stainless steel plate

Stainless disc steel plate.

Stainless steel cutting

Stainless seamless pipe

Stainless seamless Tube

Stainless welded steel pipe

Stainless machined bevel

Stainless machined groove

4. Our Stainless steel thickness

Stainless plates

0.25mm-150mm thickness

Width: 20mm to 2500mm

Length 20mm to 10000mm

Max weight of each plate 6 tons.

Stainless seamless pipe

outer diameter 3.2-200mm,

Wall thickness 0.5-12.7mm

5. Stainless Production time:

5-8days in usual size.

If you need the bevel and groove stainless parts, we need min extra 7days.

6. Stainless Payment Item for HENAN FORWARD STEEL EXPORT CO.,LTD

TT payment Or 30% TT advance and balance should be paid after BL documents.

7. Why you choose us?

a. The faster production time, and most of production, we can control them in one week if the total weight are not large.

b. Better service, we promise that your inquiry will be sent official quotation in 24hours.

c. Faster delivery, we had owned transport truck department and transport stainless to our port in 24hours.

d. Quality promise processing: PMI Test at each stainless steel plates before delivery. We accept the third party inspection, GL. SGS.BV, DNV, LR,ABS and others.

8. Trade Item:

FOB, EXW, CFR AND CIF

Packages by wooden pallet, delivery by containers.

9. How to contact HENAN FORWARD STEEL EXPORT CO.,LTD?

Your can searh our company name from google or visit sa514steel and qfsteels through searching them at google.

Mr David

0086-371-61310228

admin@qfsteels.com

http://sa514steel.com

Roopam Steel is top manufacturer & supplier of seamless steel pipe welded tubes in ferrous and non ferrous material, Stockist of high quality tubular piping products and accessories in India. Call us for more Info at +91-22-6639 4333.

As a Concertina Razor Wire Suppliers, share it with you.

Feature

Razor barbed wire, also known as scraper barbed wire, is a new type of protective net product developed with strong protection and isolation capabilities. The sharp knife-shaped thorn is formed into a bellows shape by a double-line buckle, which is both beautiful and chilling. Played a good deterrent effect. At the same time, the product has the advantages of beautiful appearance, good anti-blocking effect and convenient construction.

Concertina Razor Wire

Razor-barbed wire is generally used for protection in prisons. Because the blade is sharp and not easy to touch, it has a certain deterrent effect. The razor-barbed wire has a wide range of uses. It can be used for wall protection of residents and can also be used for enclosure. The anti-theft effect of the barbed wire is better than that of ordinary barbed wire, and the price is not high, so the razor barbed wire is more and more widely used.

Razor wire, also known as razor wire, is a new type of protective product developed with strong protection and isolation capabilities.

Stainless steel barbed wire is different according to the different application areas containing nickel. The effect of using 304 stainless steel in a dry indoor environment is quite good. However, if you want to maintain its appearance outdoors in the countryside and cities, you need to wash it frequently. In heavily polluted industrial areas and coastal areas, the surface will be very dirty and even rusty. However, to obtain the aesthetic effect in the outdoor environment, nickel-containing stainless steel is required. Therefore, 304 stainless steel is widely used in curtain walls, side walls, roofs and other construction purposes. However, 316 stainless steel is best used in severely corrosive industries or marine atmospheres.

Razor nets have been widely used in military powerhouses, prisons, government agencies, banks, and living quarters, private houses, villas, doors and windows, highways, railway guardrails, and borders to protect security in various countries around the world.

Our company also has Concertina Razor Wire for Sale, welcome to contact us.

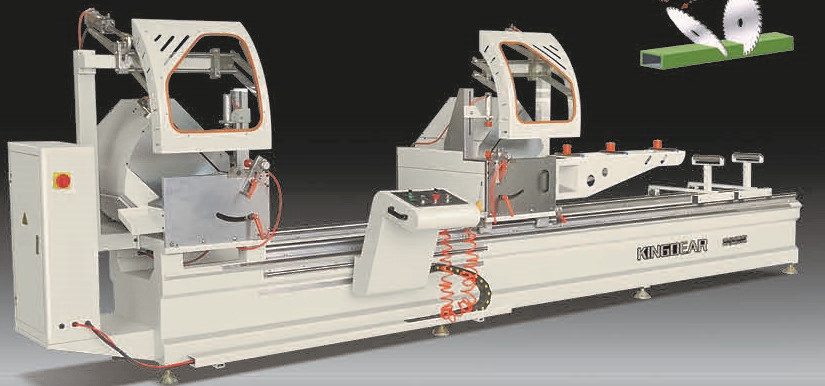

Model No.: LJZ2 -450×3700

PRODUCT DESCRIPTION

Double Head Cutting Saw Equipment Feature

■ Used for aluminum profile cutting.

■ Carbide saw blade give accurate processing and high endurance.

■ The two heads can work independently and simultaneously.

■ Cutting off the required length and two end angles is available by one time processing

Double Head Cutting Saw Technical Parameter

1) Power supply: three phase, four line 380V, 50Hz

2) Saw motor: 1.5Kw x 2, 2,800r/min

3) Pulling motor: 0.55Kw, 1,400r/min

4) Working pressure: 0.4 – 0.6MPa

5) Air consumption: 200L/min

6) Cutting length: max 3,700mm; min. 400mm

7) Cutting width: max 120mm

8) Cutting height: max. 200mm

9) Cutting angle: 0° – 45°

10) Cutter feeding speed: 0 – 3m/min

11) Saw diameter specification: 450mm x 4mm x 30mm-120

12) Overall dimensions: 4,500mm x 1,100mm x 1,400mm

Processing Accuracy

■ Repeat locating length: ≤0.2mm

■ Cutting angle allowance: ±5′

■ Cutting profile surface planeness: ≤0.10mm

■ Cutting profile surface roughness: Ra12.5μm

If you want to know more, you can click here.

Model No.: LJJS-CNC-500×600

PRODUCT DESCRIPTION

CNC Corner Connector Automatic Cutting Saw Equipment Features

■ This machine is mainly for alum windows corner stake cutting, also used for cutting Alum & PVC profiles.

■ PLC auto program controlling, man-machine interface is colored touch screen, input the cutting size and quantity, then it can cut automatically.

■ Automatic feeding system take the linear guiderail and high precision ball screw, driven by stepping motor. High feeding precision and efficiency.

■ Saw blade spindle take special high accuracy spindle, end face and radial runout are less 0.01mm, cutting surface is highly polished.

■ Saw blade feeding system adopts linear guiderail, with high accuracy and high speed (can be stepless speed regulation)

■ Carbide saw blade give accurate processing and high efficiency.

■ Special workpiece clamping system, besides processing common corner stake, it can also process middle frame corner stake.

■ All closed machine body and cover, with good appearance, safe working and low noisy.

CNC Corner Connector Automatic Cutting Saw Technical Parameter

■ Power: 380V 50Hz

■ Motor Rate: 2.2Kw

■ Saw Blade Diameter: Φ500mm

■ R.P.M: 2800r /min

■ Cutting Width: 135mm

■ Automatic Profile Feeding Length: 4-600mm

■ Working air pressure: 0.5-0.8Mpa

■ Weight: 600kg

If you want to know more, you can click here.

Ductile iron Drainage pipe is available in a range of diameters from 80mm to 1600mm and are suitable for both potable water transmission and distribution (in accordance with BS EN 545) and sewerage (in accordance with BS EN 598).

China tongmao ductile pipe is available in a range of diameters from 80mm to 1600mm and are suitable for both potable water transmission and distribution (in accordance with BS EN 545) and sewerage (in accordance with BS EN 598).

Ductile iron Drainage pipe is simple to joint, can be laid in all weather conditions and often without the need for selected backfill. Its high safety factor and ability to accommodate ground movement make it the ideal pipeline material for a wide range of applications.

ductile iron pipeline wholesale have a number of advantages over other pipe materials:

Easy to install

Full range of accessories are widely available

Suited to a host of applications both above and below ground

Strength of the material allows it to withstand significant internal pressure and also makes it less susceptible to impact damage

It has the nature of iron, the performance of steel, excellent corrosion resistance, good ductility and easy installation.

The main components are carbon, silicon, manganese, sulfur, phosphorus and magnesium.

The ductile iron pipe price list is very reasonable.

Cast iron pipe drain pipe、the cast iron sewage pipe and the cast iron gas pipe are widely used.

The wall thickness of the 150mm cast iron pipe is 6mm.

Gate valve is our company’s earlier product. During the long period of time, our company has made the gate valve famous in and out with perfect designing and manufacturing techniques and quality system assurance. The manufacturing experience and technique innovation have made the products reach BS, DIN and other international standards.

Metal Seated Gate Valve Features:

-High reliability of strength and rigidity.

-The sealing is copper alloy which is wear-resisting and has long life.

-When opening, no other parts in the way.

-The installation direction is various iwith the same performance.

Product Range:

Standards: BS&DIN

Suitable medium: water, sea water.

Suitable temperature:≤100℃

Material: Ductile iron, GJS500-7. GJS400-15, GGG40,GGG50

Bath Handle Pull YD-BHP12

Item no.: YD-BHP12

Description: Door Handle Pull

Sanitary Hardware Material: Aluminium/zinc alloy

Size: available, customized

Usage: bath hardware, furniture hardware

Process: die casting, machining, surface treatment

Surface: PVD finished, satin nickel, black, mirror finished, bronze, customized

Copper Mould Tube & Plate

We specially in supplying Copper Mould Tube, Crystallizing equipment of continuous casters, Mould cooling jacket, Repair of Metallurgical Copper Mould Tube, etc.

Equipments & Spare parts for Continuous Casting Machine.

- Copper mould tube( square, rectangle and round )

- Crystallizing equipment of continuous casters

- Mould cooling jacket.

- repair of copper tube moulds

The copper alloys chosen for the moulds must maintain their physical properties at the operating temperatures of the continuous casting process.

The temperature gradation from the inner wall of the mould to the outside face of the mould can cause serious distortion problems, and Metallurgical Copper Mould Tube is imperative that the correct alloy is chosen for the various operating conditions.

Square Copper mould tube STANDARD MATERIALS

Phosphorus de-oxidised copper

This alloy has been proven to be excellent for the manufacture of moulds in the continuous casting of billets. The main composition of this alloy are Cu +Ag 99.90min, P0.0015 / 0.040.

Copper -Silver alloy

The addition of a small amount of silver, whilst not increasing the melting point of copper, does increase the recrystallisation temperature by almost 100℃, and also helps to give better thermal conductivity at the operating temperatures.

This alloy is normally used in moulds for the continuous casting of blooms and slabs .In this case, the moulds are much thicker than in the billet moulds, and the moulds temperature can be higher. The main composition of this alloy are Cu+Ag99.90 min. Ag 0.08 / 0.12 O 0.004 / 0.012.

The continuous casting of molten steel into billets, blooms and slab products, has been highly refined over the years into an extremely sophisticated system. The continuous casting process is expected to produce metallurgically sound products at the lower possible cost, and this is being achieved in many steelworks throughout the world.

Copper moulds have played an important role in the development of the continuous casting process. Their funcition is to receive the molten steel and to allow rapid heat transfer from the steel to the cooling water to enable quick solidification.

The mould must exhibit excellent thermal conductivity, be resistant for thermal erosion ,and be resistant to distortion from thermal stress. So far only copper and a few copper alloys meet the above conditions, both economically and technically.

Mould cooling jacket supplier SOLIDIFICATION

The rate of solidification in the continuous casting process dictates the speed of production. The molten steel, which is in contact with the inner faces of the copper mould, starts to sllidify as rapidly as the heat is extracted, forming a shell. The shell increases in thickness as more heat is extracted, and eventually total solidfication is achieved. the process is similar to the solidification of ingots in ingot moulds. In continuous casting, the whole process is speeded up, with the aim to produce and homogeneous shell growth. Consequently, the mould is an important part of the continuous casting process, and the manufactured quality of the mould plays and important role in their length of life.

INNER SURFACE COATINGS

Over the years, Metallurgists and Engineers have been working together to develop better continuous casting moulds. The steel companies require a more economical mould which will give a longer service life. Surface coating of the inner walls of the mould has given the best results to date. Coatings available are Chromium and Nickel plating. Also, a combination of the two give good results on slab casting.

SPECIFICATIONS OF COPPER MOULD

Square 60 x 60 – 350 x 350 (mm)

Rectangle 120 x 160 – 180 x 300 (mm)

Diameter 100-400 (mm)

Size(mm): 90×90, 100×100, 110×110, 115×115, 120×120

130×130, 135×135, 140×140, 143×143, 150×150

155×155, 160×160, 165×165, 175×175, 180×180

200×200, 220×220, 100×170, 100×173, 130×240

150×200, 150×210, 150×220, 160×200, 160×220

150×225, 160×235, 165×225, 175×225, 180×220

200×240, 240×240, 235×235

Radius(mm): 4000, 5000, 5250, 6000, 7000, 7500, 8000, 9000, 10250, 10300, 11000, 12000

Length(mm): 700, 750, 780, 790, 800, 810, 812, 850, 900, 1000

Ceramic lined pipe is made through the self-propagating high-temperature synthesis (SHS) technique.

Self-propagating High-temperature Synthetic process

Self-propagating high-temperature synthesis (SHS) is used to describe a process in which the initial reagents (usual powders), when ignited, spontaneously transforms into products due to the exothermic heat of reaction.

The combination of high rigidity of ceramic and high elasticity of steel gives the pipe unmatchable features like abrasion resistant, heat resistant, and corrosion-resistant material for use in the fields of power generation, metallurgy, mining, and chemical industry, etc. It has many advantages over steel pipes, cast stone pipes, and steel-plastic compound pipes.

Usage of Ceramic Lined pipe

The ceramic-lined pipe transportation has been widely used in the industries of electric power, metallurgy, coal, petroleum, chemical engineering, building materials, mechanism, and so on.

The ceramic lined elbow throughout the power, metallurgy, coal, petroleum, chemical, building materials, machinery, and other industries, and high-speed development. When lining the wear-resistant ceramic elbow to deliver high grinding material (such as ash, coal, ore powder, etc.), there is a lining of wear-resistant ceramic elbow wear fast, especially the elbow Wear faster. When lining a ceramic-lined elbow to deliver a highly corrosive gas, liquid or solid, there is a problem that the lined wear-resistant ceramic elbow is corroded and is quickly damaged.

There is a problem that it is expensive to use a heat-resistant steel pipe when the material having a higher temperature is conveyed in the lining of the wear-resistant ceramic elbow. After lining the wear-resistant ceramic elbow, these problems are solved.

The ceramic lined elbow is widely used in wear and tear of mine filling material, ore powder and tailings transportation, coal-fired power plant powder, smelting, ash and other things lined with wear-resistant ceramic elbow are also very appropriate.

The ceramic lined pipe, Elbows, Reducer, Tees, and others manufactured in our factory have been used in over 200 thermal power plants, more than 50 mines, and the industries of coal, building materials, mechanism, petroleum, and so on.

Abrasion

Ceramic layer Ceramic Lined Reducer Pipe with flange reducer Al2O3 content greater than 89%, micro-hardness HV1000-1500, which has high abrasion resistance, wear resistance more than ten times higher than carbon steel after quenching, superior tungsten carbide drill.

Application range

- coal pulverizing system of power plant pipeline, including, powder transmission pipeline, thick powder separator pipeline, coal drop pipe, combustion system of a windpipe, a secondary air pipe, three pipeline and burner pipelines, in addition to ash slagging system the discharge pipe, powder pipe, dry ash conveying pipe;

- Iron and steel plant raw material conveying pipeline, collecting pipe, dust pipe, ash pipe, ash pipe, mixing pipe, grinding export pipeline, coal pipeline, coal pipeline, separator pipe, burner radius pipe, etc.;

- Cement plant selection machine outlet pipe, choose machine inlet pipe, pipe dust pipe, vertical mill outlet pipe, circulating air duct, high-temperature air blower, lower material pipe, etc.;

- Petroleum, chemical, mining, coal, coal washing plant, smelting, paper, aluminum, building materials, powder engineering, food machinery, and other processing and conveying material pipes.

Corrosion

Ceramic materials are neutral, chemically stable, have excellent corrosion resistance and acid resistance, resistant to various inorganic acids, organic acids, organic solvents, and their degree of corrosion of stainless steel is more than ten times.

Temperature

Temperature above 2000celsius degree, long-term work in the range of -50 -900 celsius degree.

Easy welding.

The ceramic adjustable tube can be welded, flanged, flexible connectors, and other fast way links, very easy to install.

Clean and easy maintenance

Smooth walls, can prevent scaling, fouling, and self-cleaning functions. Tightness.

Remarks:

- Under the direction of the arrow diagram for the export direction.

- Bend radius is usually 1.5-5 times the diameter of steel pipe (1.5-5D).

- Othe specifications of the composite pipe can be manufactured according to the user requirements.

- The weight is calculated by theoretics, maybe have some tolerance, and real weight will be weigh-in after they finish.

Hoop strength is the resistance against radial pressure. The strength of the ceramic-lined steel composite pipe is 300 to 500MPa.

Features and Advantages of ceramic lined pipe

Ceramic Liner pipe is a high technology production technology-self-fuel high-temperature clutch synthesis method.

1). High Abrasion Resistant:

Vickers hardness of the corundum lining is HV1100 to1500, as high as that of tungsten-cobalt hard alloys, and the abrasion resistance is 20 times as carbon steel pipes. The composite ceramic-lined steel elbow was used in a mining plant for about fifty thousand hours. The general service life of a common steel elbow is about 700 hours.

2). Corrosion Resistant:

Corundum is a neutral material and is acid-proof and fouling-free.

3). Heat Resistant:

Ceramic lined composite steel pipes can work under circumstances of -50 to 800 Celsius degree.

4). Lower Weight and Convenient Installation:

The ceramic-lined steel pipes are lighter than alloy pipes, cast iron pipes, and cast stone pipes and can be welded or connected through flanges, which reduces the expense of transportation and makes the pipes easier to install.

For the pipes with the same sizes, types, and lengths, the weight of the ceramic pipe is about 1/2 of the wearable cast alloy steel pipe’s, while the cost has reduced 10%~20% per meter.

The weight of ceramic-lined steel pipe is about 1/3 of the cast stone bent pipes, 1/2 of the cast stone straight pipes.

Ceramic (Corundum: a-Al2O3) lined abrasion resistant straight pipe and fittings are lined with highly abrasion-resistant ceramic by SHS ——-Self-propagating High-temperature Synthetic process.

- The ceramic-lined steel composite pipe can be joined by welding the steel pipe layer.

- Ceramic-lined pipes can take place of expensive stainless steel, titanium, nickel, cast stone, or alloy pipes.

- Extended service life can also reduce maintenance costs.

Self-Propagating Ceramic Pipe

Self-propagating ceramic steel pipes create a new generation of abrasion and corrosion-resistant engineering pipelines.

The self-propagating ceramic steel pipe has very good wear resistance, Excellent corrosion resistance, and Excellent thermal resistance performance.

SHS-self-propagating ceramic steel pipe and elbow create a new generation of abrasion and corrosion-resistant engineering pipeline. The composite pipe is composed of three layers: ceramic, intermediate, and steel layers.

The ceramic layer is formed by molten alumina at a temperature above 2500 degrees. The molten alumina produced from the reaction Fe2O3+2Al=2Fe+Al2O3 spreads on the inside wall of the steel pipe under the influence of a centrifugal force, then solidifies, so the ceramic layer has high density and smooth surface and bonds to the steel pipe.

Applicable Industries:

- The pipe needs excellent wear resistance property: Power plant, Mining, Sea Port, Coal Plant, And pipe for transporting the powder, slurry, sand, etc.

- Coal washing plant, pipe for transporting coal and other material.

- Pipe for transporting the melted aluminum.

- Any pipe which needs to wear protection, corrosion protection, etc.

Benefits:

- Excellent wear resistance, Alumina content of the ceramic liner is higher than 95%, Hardness HV1000-1500. The wear protection performance is more than 10 times better than carbon steel after quenching,

- Excellent corrosion resistance, stable chemical properties.

- Excellent thermal resistance performance up to 2000℃ Can be used in the area from-50℃ to 900℃ for a long time.

- Can be connected with another pipe by welding, flange and soft fast connecting, and easy installation.

What is Gate valves

Gate valves are widely used for all types of applications and are suitable for both above-ground and underground installation. Not least for underground installations it is paramount to choose the right type of valve to avoid high replacement costs.

Gate valves are used to shut off the flow of liquids rather than for flow regulation. When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low flow resistance. The size of the open flow path generally varies in a nonlinear manner as the gate is moved. This means that the flow rate does not change evenly with stem travel. Depending on the construction, a partially open gate can vibrate from the fluid flow

Gate valves are mostly used with larger pipe diameters (from 2″ to the largest pipelines) since they are less complex to construct than other types of valves in large sizes.

Main gate valve parts of a gate valve are: body, seat, gate, stem, bonnet and actuator. The main operation mechanism is very simple. When the handwheel is turned, it rotates the stem, which is translated into the vertical movement of a gate via threads.

There are three ways to classify the gate valve.

Types of Disk

Solid taper wedge

Flexible wedge

Split wedge or Parallel disks Valve

Types of Body Bonnet Joint

Screwed Bonnet

Bolted-Bonnet

Welded-Bonnet

Pressure-Seal Bonnet

Types of Stem movement

Rising Stem or OS & Y Type (Outside Stem and Screw Type)

Non-rising Stem type

Gate valvesare used in almost all fluid services such as air, fuel gas, feedwater, steam, lube oil, hydrocarbon, and all most any services.

Some special gate valve is used in slurry and powder product also such as knife gate valve

HOT-DIPPED GALVANIZED STEEL COIL

- INTRODUCTION:

Hot-dipped galvanized steel coil is made from steel plate, which is dipped into the dissolved zinc bath, with a zinc layer on the surface. It mainly adopts the continuous galvanizing production process. That means the cold rolled coils are put into the dissolved zinc bath for continuous galvanizing process.

- EVER-SHINE Steel Coil APPLICATION:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It’s especally useful for countless outdoor and industrial applications.

They are mainly used in building roof, door, window, roller shutter doorand automobile’s vehicle shell, chassis, door, trunk lid, Oil tank, and fender, and also electric equipments, such as refrigerator base and shell and so on.

- SPECIFICATION

| THICKNESS | 0.11mm-5.0mm |

| WIDTH | 600-1250mm Max |

| COATING MASS | 20g-400g/m2 |

| Surface Structure | Zero Spangle,Regular Spangle,Minimized Spangle |

| SURFACE TREATMENT | Chromated/non-Chromated,Oiled/non-Oiled,skinpassed/non-skinpassed |

| COIL INNNER DIAMETER | 508mm or 610mm |

Hook Strip Flat Screen is one of the most commonly used screen,can be widely used in drilling operations under different conditions.

Hook Strip Flat Screen is constructed with two or three layers of stainless steel wire cloths bonded to a steel support plank.This kind of sieving screen has many characteristics as follows:

- Every wire cloth in the sieving screen has different meshes,and accurate collocation can make the screen have better effect. In the sieving screen with different meshes,the hole size of support plank is different,so as to get the most effective area on the condition of bearing enough force.

- The Stainless steel wire clothcombines steel support plank into a single closely,so as to enhance the strength of the whole screen and prolong its life.

- The wire cloth is divided into independent small surface by the gird of steel support plank,which can prevent excessive expansion of local damage.At the same time,equipped with a special rubber plug to repair damage,it can save tine and reduce the cost.

Hengying has rich production experience and mature technology, we can produce a variety of specifications hook strip flat screen according to the different needs of customers.

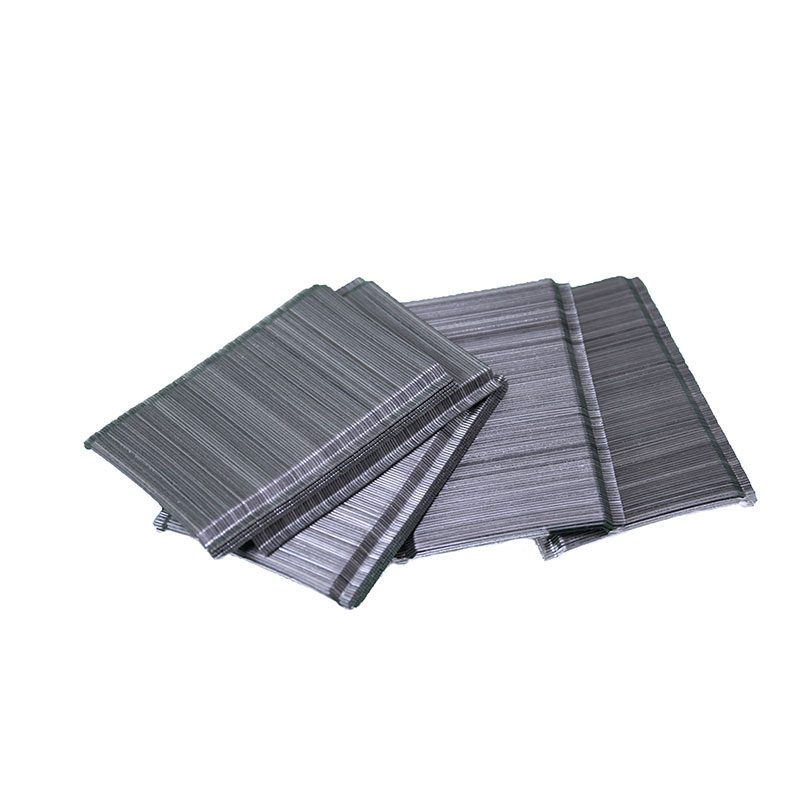

Glued Steel Fiber, an alternate concrete reinforcing material are high tensile steel wires with hooked ends, glued together by the water-soluble adhesive for compactness and uniform dispersion in concrete, to increase the concrete properties by 3-4 times.

steel fiber reinforced concrete supplier improve the mechanical properties concrete and materials such as ductility,

energy absorption, fatigue, and toughness. This fiber helps to controls plastic shrinkage cracking in concrete; helps reduce or eliminate need for conventional reinforcement.

Application of Glued steel fiber reinforced concrete

- For concrete flooring

Industrial floors

Joint-less floors

Floors-on-piles

Lightly loaded floors

Liquid tight floors & composite metal decking

- stainless steel fiber supplierFor Hard Standing & Heavy Duty

Parking lots

Playgrounds

Airport runways

Taxiways

Maintenance hangers

Access roads & workshops

Ports& Containers for port pavements

Container terminals

Bulk storage areas access roads

For army tank movement

- steel fibers for concrete reinforcementOther Applications

Foundations

Traditional cellar and basement walls

Compression layers

Tunnel engineering

Compared with the GuangYa loose steel fiber the operation and advantages of the glued steel fiber:

- Add the steel fiber directly into the belt, the whole row of steel fiber as a whole, evenly dispersed in the concrete corner

- The water-soluble glue begins to dissolve in a row of steel fibers in the premise of the dispersion, it is again dispersed in every corner of the mono filament fiber, showing the perspective in the concrete of the fiber mesh, which plays an integral strengthening.

- Compared with mono-filament fibers, China bonded steel fiberswill not be bundled to ensure that the fibers in concrete do not coalesce and distribute evenly.

Glued steel fibers are loose hook-end fibers that are bonded together in a row. The great difference between loose fiber and glued fiber is that the former is easy to clog and the latter is easy to disperse evenly.

Wholesale airport security fence, is mostly made use of in the flight terminal for defense. The main panel and also V panel is welded with 4.0 mm/5.0 mm low carbon steel cable. The surface area therapy of QYM airport fencing is galvanized + electrostatic polyester powder coated or galvanized + PVC layered.

airport fence supplier Material:

Material: Low-Carbon Iron Wire

Application:

Airport, Garden Fence, Residential, etc

Airport Fence Y Type Fence China Specification

| Panel | Mesh | Wire Thickness | Surface Treatment | Panel Width | Folds NOS. | Panel Height | Fence Height |

| Big Panel | 50x100mm 55x100mm |

4.00mm 4.50mm 5.00mm |

Galvanized and Electrostatic polyester coated or PVC coated | 2.50m 3.00m |

4 | 2000mm | 2700mm |

| 5 | 2300mm | 3200mm | |||||

| 6 | 2600mm | 3700mm | |||||

| 2 | 530mm | 2700mm | |||||

| V panel | 630mm | 3200mm | |||||

| 730mm | 3700mm |

Wir, Fittings und Flansche ist einer der führenden Hersteller Lieferanten und Exporteure von Edelstahl, Kohlenstoffstahl, legiertem Stahl, Duplex-Stahl, Hoch-Nickel-Legierung Stumpfschweißverschraubungen, Flansche, geschmiedete Armaturen, Bleche, Platten, Spulen, Rundstangen, Stangen , Rohre, Rohre, Auslaufarmaturen in Deutschland.

Yoobond Service Team Provides the one-stop Solution for Primary Services needs of its sale and after-sales subdivisions.Updated suggestions and information will be provided to customers in time.

Yoobond Management team strictly follows the ISO9001:2008 Standard system,We have a series of executive sequences a more effective service supply chain to our customers consistently.

Yoobond R&D team is staffed with trained professionals that could help customers find solutions for new composite panels and General feedback . New developing products such as Special surface for Aluminum composite Products,Aluminum PVC foamed Composite panels. Aluminum MDF Composite Panels,metal composite panel and FRP PP Honeycomb composite panels which from sourcing qualified raw materials and improving the Composting production processing.