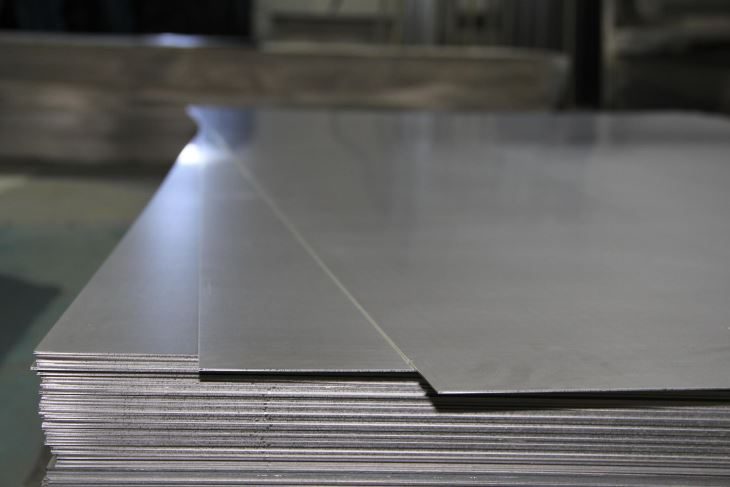

Inner Mongolia Pusheng Iron & Steel Co,.Ltd is a comprehensive company for steel production and trading. Its business includes production, processing, distribution, logistics and import& export of steel. We have been processing and selling high quality , value add steel products to customers throughout all over the world .

Our company lies in Hohhot , inner Mongolia , it is near by BAO STEEL , The superior location provides us with quality products and reasonable prices , By creating long term relationships and building trust with clients and suppliers, Pusheng is able to offer our clients comprehensive and competitive sales packages with quality goods along with excellent customer service, establishing a firm reputation in inner mongolia ’s steel industry.

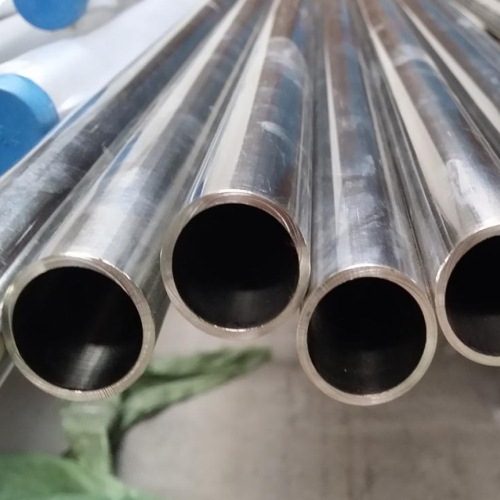

Our main products : hot rolled steel coils/sheet , cold rolled steel coils/sheet , galvanized steel coils/sheet /pipe , prepainted steel coil, corrugated sheets and tinplate coils,Ms pipe /plate, stainless steel sheet /pipe etc.

Hebei Deko Commercial Co., Ltd. (hereinafter referred to as the “DEKO”), the company is located in China’s “Land of Casting” Hebei province, DEKO mainly supplies products involved in municipal engineering and road construction and related products, such as Ductile iron Pipe, Pipe Fitting, Valve, Manhole covers, Gratings, Public Illumination, Urban Furnishing, Flange and Pipe Repair Clamp etc…. we can also produce according to the drawings and samples provided by customers, our products have been exported to Europe, Africa, Asia, Middle East and Southeast Asia etc… providing import and export business for domestic and foreign customers.

DEKO has its own fully automatic vertical production line and now we have reached a strategic cooperation with several manufacturers and become the only designated agent service by manufacturers and can be better provide customers with the best prices, excellent product quality, DEKO’s aim is: to supply the required products and high quality service for every customers and maintain long-term and stable cooperation.

Double-twist stranding machines, high-performance twisting machines

Double Twist Stranding Machineare effective, compact production units primarily for use in the manufacture of highly flexible braids, bundled braids, for stranding pairs of wires, triples, quadruple designs …

The machine concept differs from the single-twist system in that one rotor turn generates two cable twists / turn. The braid is given the first twist at the stranding point of the system feed. At this point, the stranding material still has twice the length of lay of the desired final geometry. The final braid length of lay with the second stranding twist is only completed at the second turning point, before being introduced back into the static coil former.

BOW DOUBLE TWIST STRANDING MACHINE

Application for:

Multistrand 7 or 19 copper wire, aluminum wire, tinned copper conduct etc. Also multistrand insulated conduct for power cable, data cable, control cable etc. Laying up of 2/3/4 cores of small size building wires.

Bow Double Twist Stranding Machine Description:

Payoff

Double twist stranding machine

PLC control system with color touch screen

Advanced function (Optional):

1:Motorized payoff or back-twist payoff, tension keep stable from start to end.

2:Bow material : carbon fibre

3:Brake: serve motor

4:Motorized driven capstan. Lay length set on touch screen, no need to change gear mechanically.

5:Auto lubrication system: regularly lubricate important parts to prolong machine service life.

COMPUTER SIMULATION OF AN INDUSTRIAL WIRE DRAWING PROCESS

Wire Stranding Machine is an important industrial process. Wires are reduced in diameter through a series of die/capstan combinations which provide the desired reduction steps. Typical wire drawing machines within BICC Cables Ltd use up to twenty-one dies in one line and it is necessary to optimise the die drafting for each machine and final wire diameter to obtain good machine efficiency and high quality product. An important aspect in the manufacturing process is to avoid wire breakages with the resultant loss of production due to short final lengths and the associated time required to restring the drawing machine. In order to optimise the conditions for each machine and wire size, computer simulations of the process are used to predict performance by estimating factors such as the ratio of drawing stress to ultimate tensile stress, drawing force, back tension and heat generated.

A computer simulation of the multi-line wire drawing process for copper wire has been modelled by the Wrexham Technology Centre of BICC Cables Ltd using a bulk model. The redundant work during the drawing process was included by formulation and equations for the redundant deformation were derived that were in good agreement with published experimental work.

A new computer simulation has been developed to predict the performance of wire drawing process. The model uses a one dimensional explicit finite difference method to determine the plastic deformation in the dies. The redundant work formulation was used as in the previous simulation. This paper describes the numerical methods used and compared the results from the new computer simulation with the previous bulk model. Significant differences are predicted in the stress ratios, drawing force and heat generated for process predictions. The new simulation of the plastic deformation in the dies also indicated optimum semi-die angles away from the traditional eight degrees.

7 Wire Tubular Type Stranding Machine

Owing to the vast industry experience and in depth knowledge of this domain, we are offering a huge collection of high quality 7 Wire Tubular Type Stranding Machine. These products are manufactured using optimum quality raw material. These products are easy to install and requires low maintenance. Customers can avail these products from us at market-leading prices

Basket Type Stranding Machine

Basket Type Stranding Machine is mainly used to strand not only copper/aluminum conductor for the electric wire and cable but also the cable core, steel core, and steel rope. Machine’s make-up: pay-off, driving part, cylindrical part, hydraulic brake device, wire –bobbin frame, die-holder, haul-off device, spindle-type take-up/traversing (Φ50 bar traversing) and an electrical control part, etc.

Rigid Stranding Machine

The Rigid Stranding Machine is used for stranding CU, Al wires, and conductors. Stranding unilay and reverse concentric, round, compressed, compacted or sector-shaped ( straight or spiraled) as per customer requirements.

Main features:

Self-supporting rigid rotor design with 1 6 12 18 24 30 36 Bobbin Cage

High efficiency and speed

Bobbins mounted on pintles

A line drive by A.C. or D.C. motors with electronic or mechanical synchronization between line components.

Different braking device for bobbins

Centralized lubricating system for bearing

Disk type Pneumatic brake for Cage.

Machines with or without back twist

MMI /PLC Equipped, optional

Easy Lay Setting

High Speed Tubular Stranding Machine

High Speed Tubular Stranding Machine with back twist, for 1+6 Bobbin copper / aluminum round & compact conductors and steel wire stranding. This strander is for manufacturing high carbon & low carbon steel wire rope, copper & aluminum conductor

Bow Type Stranding Machine

The Bow Type Stranding Machine is suitable for a wide range of productions, obtained with high speed and productivity; the back twist process gives high quality products. The Bow stranders use components made with most modern materials, like carbon fiber for the bows, tungstene carbide for bushes, hardened steel for rollers.The control of tension of the cores is assured with electro-mechanical or pneumatic self compensated brake, with set up by control panel.The safe use is assured with control of bearing temperatures and supports vibration.The machine is protected with a soundproof cover, with pneumatic open, inside fans and lights.Is possible the bobbins side loading with a motorized trolley, that avoids the use of bridge cranes and reduces dramatically the total loading time of the line.

For Cables Industry:

Stranding of conductors made with copper, aluminium, aluminium alloy, aluminium steel reinforced or supported;

Laying up of 2 – 7 round insulated cores for low and medium voltage;

Laying up of 2 – 7 straight sector shaped insulated cores, with the rotating cradles version;

Possible application of fillers and tapes of every type.

Tubular stranding Machine

The Tubular Stranding machine consists of bearing stands made of welded steel for the tube bearings. Up to reel size of 630mm .The stranding rotor is built up from welded tubes with wire guidings outside the tube. The reels are held in cradles, which are positioned inside the tube. A light beam along the complete length of the machine monitors, if the pneumatically (optional)operated reel-pintles are securely closed and the cradles are in safe condition. The machine is equipped with wire break detectors for each segment, pneumatic disk-breaks and individual drives for the Stranding Rotor, the Capstan and the Take-Up. The operator’s desk gives full control over parameters like Rotor-speed, lay-length and production length.

Main Features:

• Machine placed on a Rigide steel frame with rotor support, fixed on the floor for an easy installation

• Tube rotating on encircling bearings or rollers

• Machine able to work in torsion or total back twist with the possibility of partial back twist

• Wire back tension kept constant from full to empty spool payoff

• Wire/strand break detector for each payoff unit(optional)

• Spool loading/unloading by crane

• Pneumatic pintles equipped with safety locking system

• Independent driving motors for tube, capstans and takeup units

• A.C. motors with flux vector control inverter

Eastern Steel is a leading manufacturer and distributor

Custom-made

We use the advanced tools and technology to meet the varied requirements of pipes and tubes for the food processing industry, chemical industry, brewing industry, the pharmaceutical industry, cement industry, oil & gas industry, refineries, and water desalination.

Quality advantages

This was achieved by introduction of the unique equipment as well as the latest methods of quality control and testing of the manufactured pipe products. Modern pipe-rolling facilities, powerful technology base and highly qualified personnel make Eastern Steels competitive on equal terms with the worlds recognized leading brands.

IBC GROUP is dedicated to transforming various metal materials all over the world, through the process of coils, steel sheet, steel pipe, wire, profile,Alloy steel, all variety of metal products to the construction and wide manufacture industry. Meanwhile, because maintain long term friendly business relationship with clients. Enjoy solid trust from our regular clients, already working one-stopstation service in other construction related products Such as metal process equipment .All Enjoy highly comments from our customers.Look forward the chance to develop together.

Ashtavinayaka Overseas are manufacturers, suppliers and exporters of high quality stainless steel sheets, stainless steel hot rolled sheet, stainless steel 316 coil, stainless steel polished sheet, stainless steel plate, stainless steel shim sheet, stainless steel coil, stainless steel round bar, stainless steel pipe, stainless steel 304 coil, stainless steel seamless pipe, stainless steel 304 sheet, stainless steel welded pipe, stainless steel 316 sheet, stainless steel erw pipes and tubes, stainless steel 304 plate, in Mumbai, stainless steel 316 plate India.

Our Stainless Steel Products

Stainless Steel Plate

Stainless Steel Sheet

Stainless Steel Coil

Stainless Steel Pipe

Stainless Steel Seamless Pipe

Stainless Steel Welded Pipe

Stainless Steel ERW Pipe

Stainless Steel Round Bar

Stainless Steel Rod

Our High Nickel Alloy Products

High Nickel Alloy Plate

High Nickel Alloy Sheet

High Nickel Alloy Coil

High Nickel Alloy Pipe

High Nickel Alloy Tube

High Nickel Alloy Round Bar

High Nickel Alloy Rod

Know More http://www.ashtavinayakaoverseas.in

Beijing Shenghe Zhongtai Stainless Steel Co.,Ltd was established in 2009 and located in Beijing, China. In the past 9 years, we have focused the Stainless steel material and surface finish. We have passed the ISO9001 test in 2011, and applied the brand of “SUNSONG”in same year. Following the company developed by 2016, we have built our manufacturing base of Hebei Shengnuo Metal Products Co.,Ltd In Hebei province which is the biggest manufacturing base for Stainless steel surface treatment in North of China.

We have imported the advanced cutting equipment to do the coil cutting and flatting. And we have all process machines such as Hairline finish, 8K finish, Bead blasted, Vibration, Anti-finger print, PVD machine and Bending machine, Laser cutting machine.etc. Especially only we could do the surface treatment for the with more than 1500mm.

And our factory covers an area of more than 16000 square meters, introduces advanced equipments such as CNC shearing machine, keyway planer, Bending and laser machine, provides full-service of stainless steel processing. Our annual outputs has exceeded 3000 mts. We are capable to provide one stop services for architecture stainless steel decoration from stainless steel surface treatment, processing, fabrication, assembly and installation.

SUNSONG Decorative Stainless Steel Sheets is neat and beautiful which widely used into kinds of outside decoration of buildings and elevator decoration. We could do many treatment on the Hairline surface such as etching, PVD and so on. The surface would be different and welcomed by customers.

For more, please click here to customize your stainless steel furniture decoration.

Who We Are

Ares Engineering is the expert in the manufacturing metal decorative wire mesh for architectural application. With the most advanced facility, we have the most modern and productive mill in China. Our products―whether they’re expanded metal mesh, laser cut sheet, perforated sheet or stainless steel decorative wire mesh―seamlessly blend form and function, challenging the status-quo. Through consistent growth and innovation we strive for the highest quality products at an unbeatable value.

As a major manufacturer and supplier of metal mesh products, we are committed to quality. Our investment in personnel and equipment provides you–customers with innovative and value-based products that meet or exceed your design expectations. From concept to completion, our team of experts and 35 years of experience in metal products can help you choose the mesh that suits your needs.

Our People

At Ares engineering, we are extremely proud of our employees and our commitment to them. Everyone is full of enthusiasm, diligence, dedication, and always strive to pursue the highest quality craftsmanship. They are the heart of our company and the reason why we are able to provide you with high-quality metal mesh products.

We have professional sales staff, engineers, designer, mesh worker, painting technical worker, quality inspector, customer service representatives, and all of the creative, inventive individuals here at Ares that continue to push the boundaries of what metal mesh can be.

With a professional team of product advisors, we are able to guide you in product selection. If your product requires design and technical support, we can provide suitable suggestions, alternatively we can provide price information, availability and lead times.

Company Profile

Ares engineering has been the leading manufacturer of metal mesh products. We are well respected in the industry for being trustworthy in quality and service.

Ares was built as DBL Expanded Metal Mesh Factory in 1986, which only produce the expanded metal mesh at first. With time goes by, our founder introduced many advanced equipment and enlarge our production range, including not only stretched mesh machines, but also punching machines, laser cutting machines, cutting machines, and decorative wire mesh machines. Then we renamed the company name as Anping County Huijin Wire Mesh Co., Ltd on 2008. Next year, we started the Production of Aluminum Expanded Curtain Wall Panel and Ceiling System and applied for a patented technology.

With the continuous increase of decorative mesh projects, we invested the international-standard PVDF and Powder Coating Painting line, which can control quality well.

On 2019, we set up Branch Company- Hebei Ares Building Decoration Engineering Co., Ltd. The main purpose of the branch establishment is separating projects from traditional businesses, assembling a dedicated project team which can provide solutions and professional service for metal decorative mesh projects.

Now in its 36th year of operation, Ares Engineering looks towards the future. With mechanical and technological advancements, we now offer a wider range of patterns than ever before. New partnerships have allowed us to not only offer new types of products, but to provide technical and design suggestion of projects. Though Ares Engineering continues to build and grow, Quality & To meet and exceed customers\\’ expectations will always remain the fundamental core of our business.

Now in its 36th year of operation, Ares Engineering looks towards the future. With mechanical and technological advancements, we now offer a wider range of patterns than ever before. New partnerships have allowed us to not only offer new types of products, but to provide technical and design suggestion of projects. Though Ares Engineering continues to build and grow, Quality & To meet and exceed customers\\’ expectations will always remain the fundamental core of our business.

History

1986: Built DBL Expanded Metal Mesh Factory

2008: Renamed as Anping County Huijin Wire Mesh Co., Ltd

2009: Started the Production of Aluminum Expanded Curtain Wall Panel and Ceiling System and applied for a patented technology

2012: Invested the international-standard PVDF and Powder Coating Painting line

2019 by now: Set up Branch Company- Hebei Ares Building Decoration Engineering Co., Ltd. Focus on providing solutions and supplying products for metal decorative mesh projects.

Our website:http://www.aresmaterial.com

1958-1990 Hebei XINYU Welding Co., Ltd.

1991-2004 DONGGANG Welding Materials Co.,Ltd, which was founded by Hebei University of Technology and Hongkong Community Service Center,mainly produces High antirust CO2 gas-shield welding wire, Submerged arc welding wire, Stainless steel welding wire & Flux-cored welding wire.

- Now Hebei XINYU Welding Co., Ltd, which mainly produces high strength steel welding wire, Non-copper-coated solid wire, submerged arc & stainless steel welding wire . Our products are widely applied to the welding of low-alloy high tensile large & key steel structures in coal machinery, construction machinery, petrochemical machinery, pressure vessels or tanks, oil & gas pipelines, military industry, shipbuilding, bridge and high-rise buildings etc. At the same time,we are the only interprise in the domestic which produces welding wire as well as welding wire equipment.

All our products have passed ISO 9001-2015 quality system certification and CE certification because of our advanced production lines, top professional testing equipment, intelligent R&D team and scientific management system. Meanwhile, we get 7 invention patents including a national one. We are a member of China Mechanical Engineering Association and China Welding Association. Other honors are ” Consumer Trusting Products in Hebei province” ” Famous Brand products in Hebei province” ” Good Credit Enterprise in Hebei Province” and “China Key &Leading Enterprise in high tensile steel welding wire”.

Our Welding wires and welding wire equipment are exported to USA, Italy, Brazil, Russia and India etc.

Welcome you to our factory any time.

An ISO 9001:2008 Certified Company, Steel Pipes & Tubes Industries is India’s most trusted manufacturer, exporter and supplier of stainless steel tubes (ASTM A 312 304/304L, 316/316L), carbon steel pipes (ASTM A A106, A53, API 5L), alloy steel seamless pipes (ASTM A335 P11, P22), mild steel pipes, industrial steel tubes, galvanized steel pipes and black steel pipes.

We can manufacture and supply steel pipes which can be fabricated to customers design and specification in a variety of length and thickness requirements. We can also offer cold drawn seamless steel tubes to meet the custom design and specifications of our customers. We specialise in the manufacture and supply of cold drawn seamless steel tubes, and large diameter stainless steel welded pipes (100% X-Ray Tested). ISO 9001:2008 Certification ensures consistency in our operations and testing procedures.

Steel Pipes and Steel Tubes supplied by Metline Pipes & Tubes are used across wide range of industries including food processing, power generation, oil and gas, petrochemicals, petroleum pipelines, medical equipment, biopharma, pharmaceuticals, electrical engineering, fertilizer industry, dairy processing, boiler manufacturing and nuclear energy among others.

METLINE has been proudly servicing the steel pipe industry for over 40 years, as a major supplier and manufacturer of custom size steel pipes and steel tubes. We are the exclusive suppliers of stainless steel welded pipes, stainless steel seamless tubes, stainless steel tubing, alloy steel seamless pipes, boiler steel tubes, heat exchanger tubes, capillary tubes, coiled tubing, and galvanized steel pipes. We are serving all major cities and countries in their needs for steel pipes and steel tubes.

Our products are supplied to all major Industrial areas and cities in India such as Mumbai, Delhi, Bangalore, Hyderabad, Ahmedabad, Chennai, Kolkata, Surat, Pune, Nagpur, Indore, Thane, Bhopal, Visakhapatnam, Vadodra, Nashik, Faridabad, Rajkot, Aurangabad, Ranchi, Coimbatore, Raipur, Mysore, Bhubaneswar, Salem, Bhilai, Bhiwandi, Bikaner, Mangalore, Kochi (Cochin), Bhavnagar, Tirupur, Ankleshwar, Assam, Siliguri, Jamshedpur, Warangal, Nellore, Agartala and Thoothukudi.

Our high quality steel pipes, good customer service, and in house pipes and tubes processing capabilities have made us one of the emerging suppliers for steel pipes and tubes in Middle East countries including Bahrain, Cyprus, Egypt, Iran, Iraq, Israel, Jordan, Kuwait, Lebanon, Oman, Palestine, Qatar, Saudi Arabia, Syria, Turkey, United Arab Emirates and Yemen.

India’s #1 Supplier of Stainless Steel Pipes/Tubes, Chrome Moly Pipes, Black Pipes, Galvanised Pipes, Carbon Steel Pipes

Stainless Steel Pipes, Carbon Steel Tubes, Alloy Steel Tubes, MS Pipes Production and Stock Range

Outside Diameter: 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock, OD Size Steel Tubes available Ex-stock

Thickness Range: 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Type: Seamless / ERW / Welded / Fabricated / CDW

Key Steel Pipes & Tubes Products & Grades

1. Stainless Steel Seamless Pipes & Tubes – 304, 304/L, 316/L, 904L, 310S, 321H, 347H, 446

2. Stainless Steel Welded Pipes & Tubes – 304, 304/L, 316/L, 904L, 310S, 321H, 347H, 446

3. Square Stainless Steel Pipes, Round Stainless Steel Tubes, Rectangular Stainless Steel Pipes & Tubes

4. Carbon Steel Seamless Pipes as per ASTM A 106 Grade B/API 5L Grade B/ASTM A 53 Grade B

5. Carbon Steel Seamless Tubes as per BS 3059, ASTM A 179, ASTM A 192, ASTM A 210 GR.A1

6. Alloy Steel Seamless Pipes as per ASTM A335 Grade P1/ P5/ P9 / P11/ P12 / P22 / P91

7. LTCS Pipe – Low Temperature Carbon Steel Pipes as per ASTM A 333 Grade 6

8. Alloy Steel Seamless Tubes as per ASTM A213 Grade T5/T9/T11/T12/T22/T91

9. ERW Black Pipes as per IS:1239/I, IS: 3589 Grade 330 or Grade 410

10. Galvanised Pipes as per IS:1239/I

11. Square and Rectangular Steel Pipes as per IS: 4923

12. ERW Boiler Tubes: BS 3059, ASTM A 214

13. Air Pre Heater Tubes to BS: 6323 PART V

14. Hydraulic Tubes to DIN 2391 ST. 35, ST. 45 & ST. 52

15. Seamless Heat Exchanger Tubes ASTM A 179

16. CDW TUBES IS: 3074 or BS 980

17. CRCA ERW Tubes to IS 3601 OR IS 3074

18. Stainless Steel Electro polished Pipes Manufacturer/Supplier

19. Alloy Steel Fittings Manufacturer – ASTM A234 WP5, P11, P22, P91

Kalpataru Piping Solutions Is An ISO 9001:2015 Certified Company And Has A Track Record Of Offering A Wide Range Of Piping Solution At Very Competitive Prices. In A Very Short Period Of Time, We Have Gained An Excellent National And International Reputation.

Established in 1996, Vintex Steel & Engg. Co. has gained immense expertise in supplying & trading of Stainless steel, carbon steel, ferrous metal etc. The supplier company is located in Mumbai, Maharashtra and is one of the leading sellers of listed products. Buy Stainless steel, carbon steel, ferrous metal in bulk from us for the best quality products and service.

Shijiazhuang Jintai Purification Equipment Co., Ltd was founded in 1994 (reformed from a state-owned enterprise to a private limited liability company in 2004), located at No.69, Tiangui Street, High-Tech Zone, Shijiazhuang , Hebei Province.

The company has been committed to the development of metal porous materials and related technologies and applications. As early as more than 20 years ago, Jintai began to focus on the development and production of metal porous powder sintered filter elements. It has 15 invention patents and utility model patents. It has been a high-tech enterprise and has passed ISO9001 quality management system certification. After more than 20 years of technical accumulation, Jintai can now provide customers with a variety of product materials and specifications to meet customer needs.

The company’s business covers all provinces in China, and some products are exported to Germany, Italy, Spain, India, Taiwan and other places. Some large domestic companies have designated the company’s products. The company’s products mainly include titanium filter, stainless steel filter, sparger, filter, filter device and system, sheet and disc, saucer-shaped filter disc, aeration ring and so on. Products are widely used in medicine, metallurgy, petroleum and petrochemical, fine chemicals, food and beverage, air purification, electronics industry, textile industry, water treatment and other fields.

Cefa Metal was established in 2011. Our company has a factory that has been operating in the domestic market for years mainly engaged in steel grating, iron wire, wirefence and other products. In 2018, we decided to build our export department in Shijiazhuang City, Hebei, China. We are committed to offering stable supply for customers with competitive price, reliable quality and complete solution for your business.

Anping County Anlida Metal Wire Mesh Co., Ltd. was founded in 2001 in July and was formally established company in 2006. Which is located in Anping County, Hengshui City, Hebei Province, next to the da guang express way. It is “the quality standard of qualified enterprises” Hebei ProvinceChina construction metal doors and Windows, curtain wall industry “innovative enterprise”, the national federation of industry and commerce hardware mechanical and electronic chamber of commerce building metal doors and Windows, curtain wall) committee “vice President of units, commodity wholesale market in the development of China market society committee” merchants nationwide credit management model “, “member of” China hardware products association.

Our products:Expanded Metal Mesh,Aluminum Metal Mesh,Perforated Metal Sheet,Grating,Wire Mesh, etc.

The development direction of the company has a perfect IS09001 international quality management system, and has a group of senior team full of enthusiasm, including experienced, technical comprehensive, excellently engineer, technician team. They constitute the company’s a strong backing.

The company has also quality control in production process and a full range of testing test equipment, which makes that the quality of products can be guaranteed for a long time .We sincerely thank the customers who have given us support and love over the years. We hope to get your continued support, as always, we will provide you with the best quality products and services.

CRS is a leading manufacturer of thermit welding materials in China, we have more than 30 years experience of designing thermit welding to the rails. Focusing on rail welding used for railroad, metro, tram, crane rails, turnel construction and maintenance.

We have production area of 2500 square meter, with fully automated batching system, sand mould automatic production & drying machines, equipped with full range of raw materials and welding joint testing equipments. Rail aluminum thermit welding material has been promoted and well applied in the railway lines such as the Beijing-Shanghai high-speed railway line, Jinqin passenger line, Daqin line, Tong-Rang line and Tong-huo line. Materials have been exporting to Australia, Indonesia and other countries many years, the products have won praise.

CRS possesses a qualified team of technicians and engineers who have been improving the quality and performance of products, Certified to the ISO9001:2000 standard, CRS’ welding products have been supplied to a wide range of customers worldwide. Thermit products have been passed Chinese rail welding standard TB/T1632-2005 test, Railway Ministry of China, as well as Australia standard AS1085.15-1995 test, Indonesia welding joint inspection test, Taiwan SGS quality inspection test. We are ready to provide technical & operation training, qualification and certificate for customers to ensure a standardized quality and performance of the welding products.

Our factory is an enterprise manufacturing pipe fittings for more than 30 years. It is supplying Malleable iron fittings, Ductile iron fittings , Gray iron fittings and other steel products, with long history and unchanging faith of producing high quality products.

Main products:Malleable iron pipe fittings, Tube clamps, Air hose couplings, Camlock couplings, Carbon steel pipe nipples, Electric power fittings, Steam couplings, Gas meter connectors etc.

- Founded in 1986, Covering 12,000 square meters, having more than 200 workers. We have a registered capital of 8.88 million, and the annual export volume of 10 million USD.

- As a high-tech enterprise, we have our own R&D team, which can open molds through samples or drawings provided by customers, and even assist customers in developing new products through functional descriptions.

- From purchasing material, casting, annealing, trimming, galvanizing, machining, packing, to exporting, have formed stop production system.

- Various casting techniques: Currently 90% of the products have been changed to coated sand production. And equipped with coated sand production line, which can control the quality requirements of coated sand, and coated sand buried box casting line, further improve the quality of products. Most suitable casting way can be defined according to any products.

- casting surface: our own researched prescription of sand and mold design is used, there’s no joint line, no shift, no sand inclusion, no crack on products, we will satisfy every client.

- Material assurance: on –the –spot sample analysis+ chemical composition analysis after casting, double tests to guarantee stability of material. Electric heating automatic temperature control equipment can precisely control the furnace heats uniformly to ensure product are with the same tenacity.

- Surface treatment: self-color + rust preventing oil, electroplating, hot dip galvanizing, first electroplating and then hot dip galvanizing, first electroplating and then backed galvanizing, first electroplating and then plastic spraying. Different products need different surface treatment, best surface treatment can be defined according to different products.

- Machining technique: we have professional threading machines and CNC lathes to make threads, threads are 100% within specified scope of gauge and plug gauge, included angle of threads is within 90°+-0.5°. High efficiency and high quality producing way make our products have more market value.

- Our certificates: Our factory passed TSE for Turkey, INMETRO for Brazil, and CE, ISO9001:2008, IQNET etc.

- Our clients: Our factory is cooperating with many well-known enterprises, main market for malleable iron pipe fittings is Europe, main market for pipe clamp fittings is U.K., and main market for air hose couplings is USA. There’re also many different kinds of products for specialized application, and are very advantageous in their fields.

Our website:http://www.donghuancast.com

Sambhav Metal are Manufacturers, Suppliers, Exporters, Traders, Stockists and Dealers of Stainless Steel Pipes and Tubes, Carbon Steel, Alloy Steel, Duplex Steel, High Nickel Alloy, Inconel, Monel, Hastelloy, Alloy 20, Copper Nickel, Stainless Steel 304 Seamless Pipe, SMO 254 Pipes, Tubes, Stainless Steel Pipe Fittings, High Nickel Alloy Flanges, Stainless Steel 316 Seamless Pipe, Pipe Flanges, Round Bars, Stainless Steel 304 Butt weld Fittings, Rods, Sheets, Coils, Plates, Stainless Steel 316 Buttweld Fittings in India.

Our Products

Pipes & Tubes – Stainless Steel, Carbon Steel, Duplex Steel, Alloy Steel and High Nickel Alloy.

Pipe Fittings – Stainless Steel, Carbon Steel, Duplex Steel, Alloy Steel and High Nickel Alloy.

Flanges – Stainless Steel, Carbon Steel, Duplex Steel, Alloy Steel and High Nickel Alloy.

Fasteners – Stainless Steel, Carbon Steel, Duplex Steel, Alloy Steel and High Nickel Alloy.

Round Bars & Rods – Stainless Steel, Carbon Steel, Duplex Steel, Alloy Steel and High Nickel Alloy.

Sheet, Plate & Coils – Stainless Steel, Carbon Steel, Duplex Steel, Alloy Steel and High Nickel Alloy.

More info visit us http://www.sambhavmetal.com

Established in 2007, Zhejiang Flexible Technology Co., Ltd. has developed into a leading manufacturer in the flexible conduit market. From day one, we have always been deeply committed to manufacturing, designing and marketing multiple types of metallic and non-metallic conduits, conduit fittings, fiber optic cables, and fiber optic patch cords. With nearly eight years of experience behind us, we have become one of the most prominent suppliers on the market. We are one of China’s most respected conduit solution providers, offering the broadest range of products in our field for even the most demanding market.

We specialize in producing flexible conduits, which can be divided into multiple categories, according to structure, material, performance and application. Our conduits can be made from galvanized steel, be square locked and interlocked flexible metal conduits, cable conduits and shower hoses, just to name a few. With a wide assortment of fittings and accessories, they are widely used in building cable systems, machinery, petrochemical and metallurgical facilities, and other industries that require wire and cable protection. Our flexible tubing can also serve as a liquid or gas transmission medium.

Our company has also placed a strong significance to the introduction and application of world class technology and production equipment, as well as the reinforcement of the production process control, in order to provide high quality conduits, conduit fittings and armored fiber optic cables to meet a demanding market. We have also proudly provided a number of new production and test equipment for fiber optic cables and patch cords. We have also obtained certificates such as the ISO9001:2008, UL,CE, TUV and more. Our company strives to offer the highest quality products, superior services and new technologies for our flexible conduit products.

More information please click:http://www.conduit-flexible.com

Steel grating is generally made of carbon steel, and the surface is hot-dip galvanized, which can prevent oxidation. It can also be made of stainless steel, and the steel grating has the properties of ventilation, lighting, heat dissipation, anti-skid, explosion-proof and so on.

Steel grating is a kind of steel product with square lattice in the middle, which is cross-arranged with flat steel according to a certain spacing and horizontal bars, and welded by pressure welding machine or manually. Steel grating is mainly used as gutter cover. , steel structure platform plate, steel ladder step plate, etc., the cross bar is generally made of twisted square steel.

Advantages of steel grating fence

Material saving: the most material saving method under the same load conditions, correspondingly, the material of the supporting structure can be reduced;

Reduce investment: save material, save labor, save construction period, free of cleaning and maintenance;

Simple construction: on the pre-installed support, it is fixed with bolts or welding, and it can be completed by one person;

Save construction period: the product does not need to be reprocessed on site, and the installation is very fast;

Durable: It has been hot-dip galvanized anti-corrosion treatment before leaving the factory, and has strong impact and heavy pressure resistance;

Modern style: beautiful appearance, standardized design, ventilation and light transmission, giving people an overall smooth modern feeling;

Lightweight structure: less material, light structure, and easy to hoist;

Reduce wind resistance: due to good ventilation, the wind resistance is small in case of strong wind, reducing wind damage;

Anti-contamination: no rain, snow and dust;

Other advantages: ventilation, lighting, heat dissipation, explosion-proof, good anti-skid performance;

Simple design: no need for small support beams, simple structure and simplified design

Acid and alkali corrosion ability: in the range of PH 6 to PH 12.5, a stable protective film is formed on the surface of the zinc layer, and the corrosion resistance is good.

Steel grating use

Steel grating is suitable for alloys, building materials, power stations, boilers, shipbuilding, petrochemical, chemical and general industrial plants, municipal construction and other industries. It has the advantages of ventilation and light transmission, anti-skid, strong bearing capacity, beautiful and durable, easy to clean and easy to install.

Steel grating has been widely used in all walks of life at home and abroad, mainly used as industrial platforms, ladder treads, handrails, passage floors, railway bridge sideways, high-altitude tower platforms, drain covers, well covers, road grilles, three-dimensional It can also be used as a fence for parking lots, institutions, schools, factories, enterprises, sports fields, and garden villas.

Hebei Xingbei Metal Wire Mesh Products Co., Ltd. is located in Anping, Hebei, China, which is Manufacturing & Trading Combo company. Our company was established in 2007 and have advanced technology and equipment, scientific management, and strict quality control system, and we have attained the certificate of ISO 9001:2015. Xingbei has full experience in the production and sales of steel gratings, sound barriers, gabion nets, slope protection nets, filters and fence nets. It can better meet the needs of customers in terms of quality, safety, beauty and convenient installation.