Rolling Mill Manufacturer offer best quality rolling mill machinery such as, tmt bar rolling mill, section rolling mill, automatic cooling bed and more in attractive price in Ahmedabad, India.

SAL Steel is a versatile steel, Ferro Alloys and Power Company having operations near Kandla Port in the state of Gujarat in Western India. Our product range consists of Direct Reduced Iron (DRI/Sponge Iron), Ferro Alloys, Iron Ore pellets and various finished steel products. We are also selling power to various customers from our 40 MW power plant. The company has double advantage of having proximity one of the busiest commercial port and also to the customer of company’s finished products. We have been successful in securing long term tie-up for our various raw materials by renowned suppliers. This has led up to achieve consistent high standard of quality in our finished products.

We are pleased to introduce Shah Alloys Limited, one of Asia’s largest integrated stainless steel and Special Steel manufacturers and government recognized star export house. Shah Alloys Limited, was incorporated in early 90’s with installed capacity of 15000 MT, has achieved its rightful place as a preferred supplier to Defence, Engineering, Oil & Gas, Railways, Chemical, Pharmaceuticals, Constructions, Heavy machinery and mining industry. Today, the company produces approx. 300,000 MT steel per annum and employs more than 1500 persons. The company’s management system is an ISO 9001: 2008 accredited.

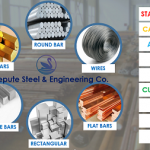

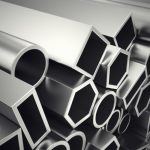

Shah Alloys Limited manufactures Abrasion resistant steel, Alloy Steel, Armour Steel, Chrome molybdenum Steel, Stainless Steel and Tool steel in form of Billets, Slabs, Coils, Plates and Bars.

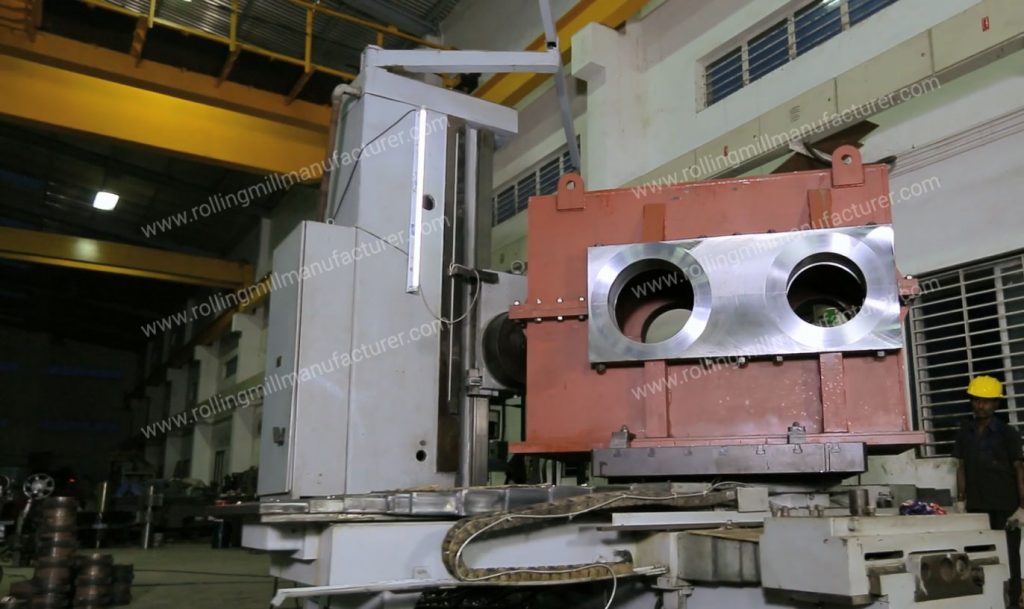

Shah Alloys Limited manufacturing complex near Ahmedabad have ultramodern facilities for melting, rolling mills (for coils, plates, bars and angles), post rolling facilities like annealing, pickling, shot blasting , cold working mills (for coils and bar) along with chemical and physical testing facilities.

Shah Alloys Limited exports its products to Europe, South East Asia, Africa, Middle East USA and South America regions.

The company’s production process is designed to ensure perfect quality and optimum productivity. Stringent quality control procedures, well defined process parameters, ultramodern manufacturing technologies and quality conscious employees supports management’s customer centric attitude to achieve smooth performance of our products at end user’s premises.

Shah Alloys Limited has obtained product related specifications from various agencies for example

• Armour Steel plates are approved by DRDO Ministry of Defense India, Defense Ministry of Georgia. It is tested successfully at HP White Laboratory USA, Beschussamt Mellrichstadt Germany, My Wall Ltd Israel and various customers at their own premises

• Abrasion Resistant plates are approved by third party inspection agencies SGS, TUV

• RDSO Ministry of Railway India has approved stainless steel for usages in railways

• Chrome molybdenum steel plates are approved by Indian Boiler regulations

Product range:

Hot rolled plate of Sizes 8 mm to 50 mm with Width up to 1500 mm in :

Abrasion Resistant Steel Q+T 400, Q+T 450 and Q+T 500

Alloy Steel Grade SAE 4140, SAE 4340, SAE 8620 etc

Armour Protection Steel Q+T 500

Chrome molybdenum Steel i.e. Grade 5, 9, 11, 12, 22, 90

Stainless steel grades i.e. AISI 304, AISI 304/L., AISI 316, AISI 316/L, AISI 321, AISI 410, AISI 420, AISI 430, AISI 409, AISI 409M, 200 series etc.

Tool Steel i.e. Grade O1, S7, A2

Plates are supplied in As Rolled / Heat Treated / Shot Blasted / No. 1 finish.

Hot rolled Coil No. 1 finish of sizes 2.8 mm to 6 mm with width up to 1500 mm in Stainless steel i.e. AISI 304, AISI 304/L., AISI 316, AISI 316/L, AISI 321, AISI 410, AISI 420, AISI 430, AISI 409, AISI 409M, 200 series etc.

Cold rolled coil (2D or 2B finish) of sizes 0.8 mm to 2.8 mm with width up to 1250 mm in Stainless steel i.e. AISI 304, AISI 304/L., AISI 316, AISI 316/L, AISI 321, AISI 410, AISI 420, AISI 430, AISI 409, AISI 409M, 200 series etc.

Bright round bar in 18 mm to 90 mm with tolerances (h9, h10, h 11, DIN 1013, K12, K11) in peeled, ground and polished condition. Main grade for Bars are Stainless Steel (AISI 304, AISI 304L, AISI 316, AISI 316L, AISI 303, 17-4 PH, AISI 410, AISI 420, AISI 431, AISI 403, AISI 430, AISI 310S) Tool Steel (O1, S7, A2) and Alloy Steel (SAE 4140, SAE 4130, SAE 4340)

Tuffal Steel Plate i.e. Tuffal 400, Tuffal 500

We would like to start long term business association with you. Kindly forward us your requirements for our products.

We look forward to receiving your favorable reply at the earliest.

Thanks and Regards.

DPS Bindra

| Sr. V.P. – Imports & Exports | Shah Alloys Limited |

Shah Alloys Corporate House, Sola-Kalol Road, Sante

With 40 years of special steel making experience, Panchmahal is a leading producer of Stainless Steel long products in India. With a dedicated focus on Stainless Steel & fully integrated facilities from steel melting to cold finishing, we offer a comprehensive range of Stainless Steel grades, in hot rolled wire rod & bars and cold finished bars & wires.

Panchmahal’s state-of-the art 150,000 metric ton steel melting facility includes an ultra high powered 50 metric ton electric arc melting furnace, AOD convertor, ladle furnace for superior steel refining and continuous casting. Recent enhancement of capacities for cold finished bars & wires include coil-to-bar drawing & bar-to-bar peeling lines, heat treatment facilities, shot blasting & pickling lines and state-of-the-art spooling, cutting & stamping lines for Stainless Steel welding products.

We offer Stainless Steel in Austenitic, Martensitic, Ferritic, Duplex and low nickel – high manganese (200 series) grades. Panchmahal’s core strength lies in its ability to meet customers unique requirements. Our integrated facilities enable us to produce Stainless Steels with various modified chemistries for customer specific applications.

With ever changing market dynamics, Panchmahal is equipped to provide customised products and services for global markets, for volume as well as for specialty niche market requirements.

Established in 2006, Maxim Tubes, within a short span of 8 years, has been able to transform itself from a regional steel pipes and tubes manufacturing company into a booming global business with a solid reputation as well as a foothold in international markets. With a turnover that has increased fifty-fold since its formation, Maxim Tubes quickly turned itself from a local player to an international customer-centric business that aims at providing innovative tubular solutions to the industry. Having a wide range of ground-breaking products and solutions that deliver additional value to its customers, the organization has successfully substantiated its position as a maximum solutions provider.

With expertise in the fabrication of metal products, Maxim Tubes stands as the vanguard of the tubular solutions industry in terms of quality, standards, products, material range as well as customer satisfaction. The company recognizes and conforms to the Quality Management System certified by Bureau Veritas Quality International.

Maxim as an organization functions on modern methods of manufacturing and employs state-of-the-art technology to deliver top quality products that match global standards. Synonymous with excellence, Maxim Tubes is recognized not just for its high-quality products that are compliant with global standards, but also for developing innovative solutions that deliver additional value to the customers. Maxim’s products are developed to meet specific requirements of emerging sectors like Heat Exchangers, Petrochemicals, Power Plants, Automotive, and Onshore and Offshore Oil and Gas Production, etc.

An ideal partner for managing and powering the performance of businesses across the globe, Maxim is committed to meet customer requirements and aims to manufacture products that can empower the industry, serve the clientele, as well as result in mutual growth.

We are the leading stainless steel bright bars manufacturer in India. Our stainless steel bright bars are have the corrosion resistance and heat resistance ability for different industrial applications.

“Apurvi” is in business of manufacturing of Stainless Steel Pipe for submersible pump & motor.

Apurvi Industries was established in the year 2000 by Mr.Viren Gathani basically a technical person that is production Engineer with a prior experience of 8 years in utensil manufacturing.

“Apurvi” stands for getting right material form right source at right time. Each of our departments Production, Inventory, Marketing, and Sales & Service is fully developed for a better serve management, so as to offer the best product quality & prompt service to our clients. Along with Equipment, Men power is also given special attention.

Apurvi industry has a production capacity of 1200 pipes/day [average length 600mm]. Pipes can be supplied in polished or dull finish or pickled condition. Company can manage grooving operation as per customer requirement.