Jade Special Metals is India’s 10th largest supplier, trader & Exporter of Stainless Steel, Carbon steel pipes and round bar. We are specialised in Stocking & Distributing various Stainless Steel, carbon steel pipes, round bar & sheet plates to worldwide for specific & urgent requirements.

Metallica Metals is known worldwide as the most competitive group in the world of Stainless Steel having its headquarters in Mumbai – India. It was incorporated in the year 1975 by 3 dynamic leaders named as Mr. Babulal Mehta, Mr. Jugal Mehta & Mr. Vallabhchand Mehta & they are the reason behind the exponential growth of Metallica Metals.

Galvanized Steel Fiber, an alternate concrete reinforcing material are high tensile galvanized steel wires with hooked ends, glued together by the water-soluble adhesive for compactness and uniform dispersion in concrete, to increase the concrete properties by 3-4 times.

Compared with the normal cold drawn steel fiber,in addition to all the advantage of normal steel fiber(such as excellent tensile strength, bending and shearing strength, high tenacity, resistance against the cracking, impact and fatigue ), this fiber still has a better corrosion resistance when the steel fiber exposure to the air, as there is a zinc thickness on the surface of this fiber.

The concrete with GuangYa steel fiber can be widely used in industrial floor,transportation constructions(roads, bridges, tunnels, airport runways), the concrete prefabricated unit, etc…

Advantage to use the China steel fiber in concrete:

High impact resistance.

Remarkably increased flexural strength.

Improved structural ductility.

Exceptional control over cracking.

Increased durability by providing crack control.

Ceramic lined pipe is made through the self-propagating high-temperature synthesis (SHS) technique.

Self-propagating High-temperature Synthetic process

Self-propagating high-temperature synthesis (SHS) is used to describe a process in which the initial reagents (usual powders), when ignited, spontaneously transforms into products due to the exothermic heat of reaction.

The combination of high rigidity of ceramic and high elasticity of steel gives the pipe unmatchable features like abrasion resistant, heat resistant, and corrosion-resistant material for use in the fields of power generation, metallurgy, mining, and chemical industry, etc. It has many advantages over steel pipes, cast stone pipes, and steel-plastic compound pipes.

Usage of Ceramic Lined pipe

The ceramic-lined pipe transportation has been widely used in the industries of electric power, metallurgy, coal, petroleum, chemical engineering, building materials, mechanism, and so on.

The ceramic lined elbow throughout the power, metallurgy, coal, petroleum, chemical, building materials, machinery, and other industries, and high-speed development. When lining the wear-resistant ceramic elbow to deliver high grinding material (such as ash, coal, ore powder, etc.), there is a lining of wear-resistant ceramic elbow wear fast, especially the elbow Wear faster. When lining a ceramic-lined elbow to deliver a highly corrosive gas, liquid or solid, there is a problem that the lined wear-resistant ceramic elbow is corroded and is quickly damaged.

There is a problem that it is expensive to use a heat-resistant steel pipe when the material having a higher temperature is conveyed in the lining of the wear-resistant ceramic elbow. After lining the wear-resistant ceramic elbow, these problems are solved.

The ceramic lined elbow is widely used in wear and tear of mine filling material, ore powder and tailings transportation, coal-fired power plant powder, smelting, ash and other things lined with wear-resistant ceramic elbow are also very appropriate.

The ceramic lined pipe, Elbows, Reducer, Tees, and others manufactured in our factory have been used in over 200 thermal power plants, more than 50 mines, and the industries of coal, building materials, mechanism, petroleum, and so on.

Abrasion

Ceramic layer Ceramic Lined Reducer Pipe with flange reducer Al2O3 content greater than 89%, micro-hardness HV1000-1500, which has high abrasion resistance, wear resistance more than ten times higher than carbon steel after quenching, superior tungsten carbide drill.

Application range

- coal pulverizing system of power plant pipeline, including, powder transmission pipeline, thick powder separator pipeline, coal drop pipe, combustion system of a windpipe, a secondary air pipe, three pipeline and burner pipelines, in addition to ash slagging system the discharge pipe, powder pipe, dry ash conveying pipe;

- Iron and steel plant raw material conveying pipeline, collecting pipe, dust pipe, ash pipe, ash pipe, mixing pipe, grinding export pipeline, coal pipeline, coal pipeline, separator pipe, burner radius pipe, etc.;

- Cement plant selection machine outlet pipe, choose machine inlet pipe, pipe dust pipe, vertical mill outlet pipe, circulating air duct, high-temperature air blower, lower material pipe, etc.;

- Petroleum, chemical, mining, coal, coal washing plant, smelting, paper, aluminum, building materials, powder engineering, food machinery, and other processing and conveying material pipes.

Corrosion

Ceramic materials are neutral, chemically stable, have excellent corrosion resistance and acid resistance, resistant to various inorganic acids, organic acids, organic solvents, and their degree of corrosion of stainless steel is more than ten times.

Temperature

Temperature above 2000celsius degree, long-term work in the range of -50 -900 celsius degree.

Easy welding.

The ceramic adjustable tube can be welded, flanged, flexible connectors, and other fast way links, very easy to install.

Clean and easy maintenance

Smooth walls, can prevent scaling, fouling, and self-cleaning functions. Tightness.

Remarks:

- Under the direction of the arrow diagram for the export direction.

- Bend radius is usually 1.5-5 times the diameter of steel pipe (1.5-5D).

- Othe specifications of the composite pipe can be manufactured according to the user requirements.

- The weight is calculated by theoretics, maybe have some tolerance, and real weight will be weigh-in after they finish.

Hoop strength is the resistance against radial pressure. The strength of the ceramic-lined steel composite pipe is 300 to 500MPa.

Features and Advantages of ceramic lined pipe

Ceramic Liner pipe is a high technology production technology-self-fuel high-temperature clutch synthesis method.

1). High Abrasion Resistant:

Vickers hardness of the corundum lining is HV1100 to1500, as high as that of tungsten-cobalt hard alloys, and the abrasion resistance is 20 times as carbon steel pipes. The composite ceramic-lined steel elbow was used in a mining plant for about fifty thousand hours. The general service life of a common steel elbow is about 700 hours.

2). Corrosion Resistant:

Corundum is a neutral material and is acid-proof and fouling-free.

3). Heat Resistant:

Ceramic lined composite steel pipes can work under circumstances of -50 to 800 Celsius degree.

4). Lower Weight and Convenient Installation:

The ceramic-lined steel pipes are lighter than alloy pipes, cast iron pipes, and cast stone pipes and can be welded or connected through flanges, which reduces the expense of transportation and makes the pipes easier to install.

For the pipes with the same sizes, types, and lengths, the weight of the ceramic pipe is about 1/2 of the wearable cast alloy steel pipe’s, while the cost has reduced 10%~20% per meter.

The weight of ceramic-lined steel pipe is about 1/3 of the cast stone bent pipes, 1/2 of the cast stone straight pipes.

Ceramic (Corundum: a-Al2O3) lined abrasion resistant straight pipe and fittings are lined with highly abrasion-resistant ceramic by SHS ——-Self-propagating High-temperature Synthetic process.

- The ceramic-lined steel composite pipe can be joined by welding the steel pipe layer.

- Ceramic-lined pipes can take place of expensive stainless steel, titanium, nickel, cast stone, or alloy pipes.

- Extended service life can also reduce maintenance costs.

Self-Propagating Ceramic Pipe

Self-propagating ceramic steel pipes create a new generation of abrasion and corrosion-resistant engineering pipelines.

The self-propagating ceramic steel pipe has very good wear resistance, Excellent corrosion resistance, and Excellent thermal resistance performance.

SHS-self-propagating ceramic steel pipe and elbow create a new generation of abrasion and corrosion-resistant engineering pipeline. The composite pipe is composed of three layers: ceramic, intermediate, and steel layers.

The ceramic layer is formed by molten alumina at a temperature above 2500 degrees. The molten alumina produced from the reaction Fe2O3+2Al=2Fe+Al2O3 spreads on the inside wall of the steel pipe under the influence of a centrifugal force, then solidifies, so the ceramic layer has high density and smooth surface and bonds to the steel pipe.

Applicable Industries:

- The pipe needs excellent wear resistance property: Power plant, Mining, Sea Port, Coal Plant, And pipe for transporting the powder, slurry, sand, etc.

- Coal washing plant, pipe for transporting coal and other material.

- Pipe for transporting the melted aluminum.

- Any pipe which needs to wear protection, corrosion protection, etc.

Benefits:

- Excellent wear resistance, Alumina content of the ceramic liner is higher than 95%, Hardness HV1000-1500. The wear protection performance is more than 10 times better than carbon steel after quenching,

- Excellent corrosion resistance, stable chemical properties.

- Excellent thermal resistance performance up to 2000℃ Can be used in the area from-50℃ to 900℃ for a long time.

- Can be connected with another pipe by welding, flange and soft fast connecting, and easy installation.

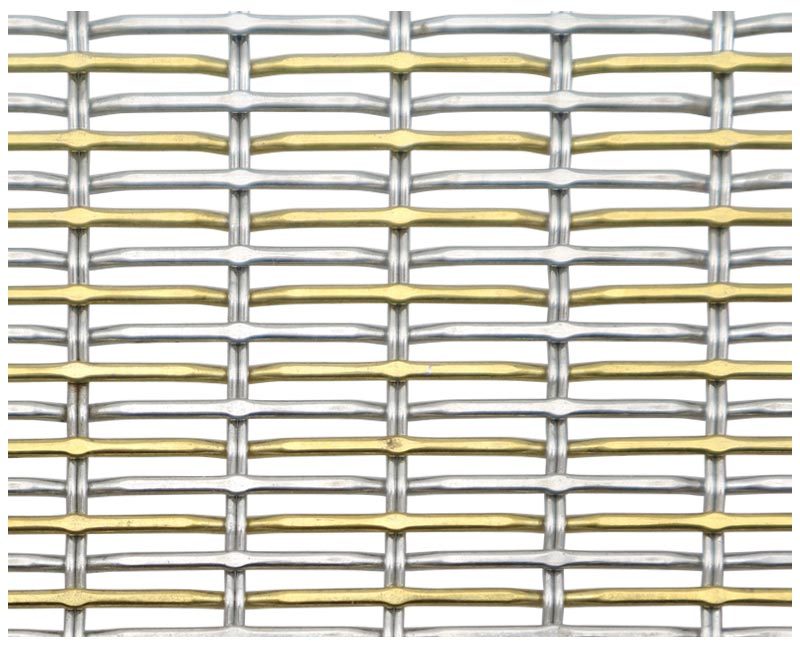

Flexible stainless steel cable mesh

Flexible stainless steel cable mesh, also called stainless steel cable mesh or stainless steel rope mesh, it is made of high quality stainless steel wire cable. According to the production process can be divided into ring type and interweave type. It is mainly used in the construction of wildlife parks, large animal pens or birdhouses, garden greening walls and handrail fillers or safety nets.

The Bzwiremesh plant has been producing this product since 1990. The independently developed equipment and skilled technology of the plant ensure the delivery of high quality products and perfect service on a global scale.

Flexible stainless steel rope net by S.S. SUS304, SUS316, SUS316L and other various material types of wire rope, two main strand structure: 7 * 7 and 7 * 19. Our mesh products are divided into two main lines according to the type of weave: interweave and ferring. Ring type series according to the ring material is divided into aluminum alloy mesh and stainless steel mesh.

Advantages of BZ stainless steel rope mesh:

High tensile strength, light weight;

Good weather resistance and corrosion resistance;

With good transparency, you can watch the animals and appreciate;

Large mesh span allows for large surface mounting.

Wholesale airport security fence, is mostly made use of in the flight terminal for defense. The main panel and also V panel is welded with 4.0 mm/5.0 mm low carbon steel cable. The surface area therapy of QYM airport fencing is galvanized + electrostatic polyester powder coated or galvanized + PVC layered.

airport fence supplier Material:

Material: Low-Carbon Iron Wire

Application:

Airport, Garden Fence, Residential, etc

Airport Fence Y Type Fence China Specification

| Panel | Mesh | Wire Thickness | Surface Treatment | Panel Width | Folds NOS. | Panel Height | Fence Height |

| Big Panel | 50x100mm 55x100mm |

4.00mm 4.50mm 5.00mm |

Galvanized and Electrostatic polyester coated or PVC coated | 2.50m 3.00m |

4 | 2000mm | 2700mm |

| 5 | 2300mm | 3200mm | |||||

| 6 | 2600mm | 3700mm | |||||

| 2 | 530mm | 2700mm | |||||

| V panel | 630mm | 3200mm | |||||

| 730mm | 3700mm |

As a Concertina Razor Wire Suppliers, share it with you.

Feature

Razor barbed wire, also known as scraper barbed wire, is a new type of protective net product developed with strong protection and isolation capabilities. The sharp knife-shaped thorn is formed into a bellows shape by a double-line buckle, which is both beautiful and chilling. Played a good deterrent effect. At the same time, the product has the advantages of beautiful appearance, good anti-blocking effect and convenient construction.

Concertina Razor Wire

Razor-barbed wire is generally used for protection in prisons. Because the blade is sharp and not easy to touch, it has a certain deterrent effect. The razor-barbed wire has a wide range of uses. It can be used for wall protection of residents and can also be used for enclosure. The anti-theft effect of the barbed wire is better than that of ordinary barbed wire, and the price is not high, so the razor barbed wire is more and more widely used.

Razor wire, also known as razor wire, is a new type of protective product developed with strong protection and isolation capabilities.

Stainless steel barbed wire is different according to the different application areas containing nickel. The effect of using 304 stainless steel in a dry indoor environment is quite good. However, if you want to maintain its appearance outdoors in the countryside and cities, you need to wash it frequently. In heavily polluted industrial areas and coastal areas, the surface will be very dirty and even rusty. However, to obtain the aesthetic effect in the outdoor environment, nickel-containing stainless steel is required. Therefore, 304 stainless steel is widely used in curtain walls, side walls, roofs and other construction purposes. However, 316 stainless steel is best used in severely corrosive industries or marine atmospheres.

Razor nets have been widely used in military powerhouses, prisons, government agencies, banks, and living quarters, private houses, villas, doors and windows, highways, railway guardrails, and borders to protect security in various countries around the world.

Our company also has Concertina Razor Wire for Sale, welcome to contact us.

Beijing Shenghe Zhongtai Stainless Steel Co.,Ltd was established in 2009 and located in Beijing, China. In the past 9 years, we have focused the Stainless steel material and surface finish. We have passed the ISO9001 test in 2011, and applied the brand of “SUNSONG”in same year. Following the company developed by 2016, we have built our manufacturing base of Hebei Shengnuo Metal Products Co.,Ltd In Hebei province which is the biggest manufacturing base for Stainless steel surface treatment in North of China.

We have imported the advanced cutting equipment to do the coil cutting and flatting. And we have all process machines such as Hairline finish, 8K finish, Bead blasted, Vibration, Anti-finger print, PVD machine and Bending machine, Laser cutting machine.etc. Especially only we could do the surface treatment for the with more than 1500mm.

And our factory covers an area of more than 16000 square meters, introduces advanced equipments such as CNC shearing machine, keyway planer, Bending and laser machine, provides full-service of stainless steel processing. Our annual outputs has exceeded 3000 mts. We are capable to provide one stop services for architecture stainless steel decoration from stainless steel surface treatment, processing, fabrication, assembly and installation.

SUNSONG Decorative Stainless Steel Sheets is neat and beautiful which widely used into kinds of outside decoration of buildings and elevator decoration. We could do many treatment on the Hairline surface such as etching, PVD and so on. The surface would be different and welcomed by customers.

For more, please click here to customize your stainless steel furniture decoration.

- INTRODUCTION

Welded steel tube/pipes are made of cold rolled steel coil or galvanized steel coil, by cold-roll forming through high -frequency welded machine.

Product Features: Simpler production technical process, Higher production efficiency, Lower production cost.

There are mainly two kinds of pipes: one is Black steel tube/ pipe, the other is Pre-galvanized steel tube/pipe.

- APPLICATION

With excellent characteristics of sound surface finish, highly precise, easy to galvanize, easy to bend or reform. Steel pipes are mainly used in Pipeline, Mechanical equipment, Solar energy equipment, Steel structure engineering, Bridge fence, Auto accessories and etc.

- EVER-SHINESPECIFICATION:

Types: round tube, square tube, rectangle tube.

1) Product Name: Black steel tube / pipe

Thickness: 0.40mm~3mm

Outer Diameter: Round 0.30mm~650mm

Square: 8x8mm~500x500mm

Length: 3m~12m or any length as per customer’s requirement.

Standard: BS1387, ASTM A53, ASTM A500, ASTM A513M-06B, GB/16728-2017

Grade: Q195-Q235, 10#~45#

Technique: Cold Rolled, Hot Rolled

2) Product Name: Pre-galvanized steel tube/pipe

Thickness: 0.35mm~2.5mm

Outer Diameter: Round 0.30mm~650mm

Square: 10x10mm~100x100mm

Zinc coating: 20-275g

Length: 4m~12m or any length as per customer’s requirement.

Standard: BS1387, ASTM A53, ASTM A500, ASTM A513M-06B, GB/16728-201

More information please click here.

We use a variety of advanced equipment including shears, CNC punching machines, laser cutting machines, composite machines, bending machines, hydraulic presses, and various auxiliary equipment such as uncoilers, leveling machines, deburring machines, spot welding machines, etc., Using cutting, stamping, drawing, bending, welding, riveting and other processes, we can manufacture various Wonderful custom sheet metal products of different shapes for you, and can also do surface treatment for the products, including painting, electroplating, wire drawing, etc.

If you need sheet metal fabrication service we are one of the most capable and affordable sources and we can get the job done right.

SHINESTAR STEEL GROUP CO., LTD mainly produce various carbon and alloy steel pipes including oil & gas pipe, pressure pipe, mechanical tubing, and stainless steel tube, etc.

As the most valuable subsidiary under SHINESTAR STEEL GROUP, PRIME STEEL PIPE is the solution provider for the oil, gas, construction, energy and prtrochemical industries.SHINESTAR STEEL GROUP is specialized in manufacturing superior quality steel products, and providing outstanding service for valued clients all over the world.

Hunan Great Steel Pipe Co.,Ltd is specialized in steel pipe & tube production including carbon steel pipe, seamless steel pipe, erw steel pipe, ssaw steel pipe, lsaw steel pipe, etc.

Hunan Great Steel Pipe Co.,Ltd is a world-class production and service provider of seamless pipes and welded pipes as the first subsidiary of Shinestar Group.

Rafit Metal & Alloys produces and Exports impeccable and super compound darting which incorporates: Hex screw, Hex Nuts, Stud fasteners, Threaded Bars, Washers, Hex attachments and so forth according to guidelines ASTM, ASME, DIN and UNI. The application enterprises are oil and Gas, Chemical, Petrochemical, Power and Energy and Marine industries(On Shore/Offshore).

- 起源地;原产地:

-

中国天津

- 品牌:

-

国际商业中心

- 应用:

-

制作管道、切割片材、制作小工具、制作波纹板、制作容器、制作栅栏

- 类型:

-

钢卷

- 厚度:

-

0.21-0.50mm

- 标准:

-

爱思

- 宽度:

-

1501-2000MM

- 长度:

-

按要求

- 证书:

-

API、 SNI、 BIS、 SASO 、SABS 、sirm、 tisi

- 年级:

-

镀铝锌硅,SGCC,DX51D

- 涂层:

-

AZ121-Z150

- 宽容:

-

±10%

- 加工服务:

-

焊接、冲孔、切割、弯曲、开卷

- 铝含量:

-

55%

- 亮片类型:

-

零亮片

- 涂油或不涂油:

-

轻微上油

- 硬度:

-

全硬

- 交货时间:

-

15-21 天

- 产品名称:

-

镀铝硅

- 最小起订量:

-

1吨

- 表面:

-

低碳钢素面,热浸镀锌,彩色涂层

Navrekha Steel today are the major manufacturer, supplier and exporters of the wide range of ferrous and non-ferrous metal products. We have successfully created an important place in the market under the mentorship of Mr. Parasmal C. Shah.

Unifit Metalloys is one of the leading Pipes Manufacturer, Dealer, Supplier and Exporter of Buttwelded Pipe Fittings, Socket Weld Fittings, Threaded Fittings, Forged Fittings, In India. Quality Forge and Fittings is the name of a brand trusted worldwide and used in all leading industries. Trust is the synonym for Quality Forge and Fittings.

| Tycoon Piping is well known for his trusted exporters of best precision tubes in the world. We supply both seamless and welded pipes, in a wide range of stainless steel, titanium, nickel and zirconium alloys. Tycoon Piping is the market leader in supplying of Hot Finished structural hollow sections in the UK and almost 25 years of experience in logistics, stockholding, in-house processing, and sector-specific requirements. We provide the best product guarantee to our clients with full satisfaction. |

Metallica Metals is known worldwide as the most competitive group in the world of Stainless Steel having its headquarters in Mumbai – India. It was incorporated in the year 1975 by 3 dynamic leaders named as Mr. Babulal Mehta, Mr. Jugal Mehta & Mr. Vallabhchand Mehta & they are the reason behind the exponential growth of Metallica Metals.

Belleville Disc Springs also was called “Disc Springs” “Conical Disc Springs”, include disc spring stacks, Corrosion Resistant Disc Springs, High Temperature / Cryogenic Disc Springs, Disc Springs for Ball Bearing, Disc Springs for Valves. Disc Springs are widely used in petrochemical, electric power, metallurgy, engineering, machine tools, national defense, and other industries.

Bearing Preload Disc Springs manufacturer Description

The Disc Spring concept was first invented by a Frenchman Louis Belleville in 1865. So, disc spring is commonly known as Belleville Springs. And sometimes it also was called “Conical disc springs” “Belleville Disc Springs” or “Belleville Washers”.

Hegong Disc Springs are conically washers and have a rectangular cross-section, which is loaded in the axial direction. It has a small volume and large energy storage compared to traditional helical springs and can be used as a single disc spring or in the stack (stack in parallel, in series or parallel & series combination).

The standards for disc springs mainly include DIN2092 (Calculation) / DIN2093 ( Quality Specifications-Dimensions ) of Germany, JIS B 2706- Japan, GB/T 1972-2005 of China and ISO 19690 : 2017 ( HEGONG SPRING ® is the drafting team member for international standard ISO 19690 : 2017 and Chinese national standard GB/T 1972-2005 ). Among them, DIN2093 is most widely used in the world.

belleville washer design are designed & manufactured according to DIN2092 & DIN2093, working for dynamic or static applications. The engineers of HEGONG SPRING® are pleased to design the springs for the specific applications together with the customer’s R&D department. Be free to contact with our engineers. Tech@DiscSpringsMFG.com.

Generally, disc springs include disc spring stacks, Corrosion Resistant Disc Springs, High Temperature / Cryogenic Disc Springs, Disc Springs for Ball Bearing, Disc Springs for Valves.

Surface Condition And Corrosion Protection:

Polish

Phosphating and oil

Mechanical Zinc Plating

Chemical Nickel Plating

Docromet / Geomet Coating

Electrophoresis

Tolerance:

The Tolerance is according to DIN2093 standards

Belleville Spring Washers exporter Specification:

The following specification table covers the “standard” sizes and some non-standard sizes. HEGONG SPRING ® customizes Belleville Disc Springs as well. The max OD is up to 1000mm. If you require the custom Belleville Disc Springs, please contact our sales engineers.