In 2004, Panhua Group Co., Ltd was incorporated by Mr. Xinghua Li in Zhangjiagang City, Jiangsu Province, China, with registered captial of 127 million USD. Initially Panhua consisted of 3 steel mills, namely Zhangjiagang Huada Coating Co., Ltd, Zhangjiagang Wanda Steel Strip Co., Ltd, and Jiangsu Huasheng New Building Materials Co., Ltd. All these 3 mills were fully invested by Mr. Li in 1999, 2002, and 2004 for producing PPGI, GI, and CRC respectively. Before the mergence of Panhua Group, flat steel sales under brand of Panhua had already gone throughout China along with numerous honors and top1 domestic market share among all privately owned Chinese steel mills. After 2006, Panhua further set up several subsidiaries in other business divisions such as real estate, shipping terminals, metal mines, and commercial banks. In 2008, Panhua started to expand its flat steel industry by building a new mill in Chongqing City, Western China. Chongqing Panhua Steel Strip Co., Ltd now forms the same capacity as our mills in Zhangjiagang City, 1.5 million Mt of steel coils per year, but will start to output more in 2011 and widen the existing scope of supply.

Head office of Panhua is located in Zhangjiagang Free Trade Zone as well as Jiangsu Yangtze International Chemical Indutrial Zone. It’s 200KM away from Shanghai International Airport. Today’s Panhua possesses about 10 square kilometers of land and 3400 employees in total. By turnover, Panhua Group is ranked among Top500 Chinese Companies.

Panhua’s manufacturing and management systems have past ISO 9001:2000 and ISO 14001:2004. We have established labs close to all processing lines and cold rolling mills to ensure quality control and environmental protection of mass production. We’ve also established strategic alliances with Top10 state-owned steel mills to achieve mutual benefitial cooperation on stable and qualified HR supply. Panhua is quickening its steps to conduct integrative operation. We are making continuous efforts to provide you cold rolled steel coils, galvanized steel coils, prepainted steel coils, and all dimensions of steel sheets to meet end users’ demands by cut-into-length and slitting lines. Our tandem and single stand cold rolling mills are fully imported from USA, Germany, Japan, and India. Equipped with ABB and Siemens automation, all our equipment can offer you accurate dimensions, minimized tolerance, superior heat & corrosion resistance, and aesthetic appearance.

Since 2006, Panhua has been exporting steel coils to more than 50 countries directly. Our long term supply extends to USA, UK, Germany, Italy, Spain, Belgium, France, Poland, Greece, Ukraine, Belarus, Russia, Turkey, Egypt, Saudi Arabia, Iran, Ethiopia, Niger, Brazil, Colombia, Chile, Peru, Australia, New Zealand, etc… We maintain a relentless pursuit of improvement in every critical performance measure so as to serve comprehensive customers throughout the world. Panhua has always put itself in its customers’ position and our brand has been suggested and promoted by worldwide wellknown traders like Stemcor, MAC Steel,Salzgitter Mannesmann, Thyssenkrupp, Interfer, Primex, Coutinho & Ferrostaal, Midland, Balli, LN Metal, SK, Hyundai, Samsung, Daewoo, and Marubeni Itochu.

Panhua has devoted itself to social charity causes with regular donations to the “Hope Project” to build up Hope Primary Schools in Sichuan Province and help students complete their education in schools and colleges. Growing together with society and giving back to society is one of Panhua’s values.

Panhua is full of vigor and potential. We believe and pursue quality, strength, and opportunities. We are always looking towards the future with confidence and welcome your sincere cooperation

In 2004, Panhua Group Co., Ltd was incorporated by Mr. Xinghua Li in Zhangjiagang City, Jiangsu Province, China, with registered captial of 127 million USD. Initially Panhua consisted of 3 steel mills, namely Zhangjiagang Huada Coating Co., Ltd, Zhangjiagang Wanda Steel Strip Co., Ltd, and Jiangsu Huasheng New Building Materials Co., Ltd. All these 3 mills were fully invested by Mr. Li in 1999, 2002, and 2004 for producing PPGI, GI, and CRC respectively. Before the mergence of Panhua Group, flat steel sales under brand of Panhua had already gone throughout China along with numerous honors and top1 domestic market share among all privately owned Chinese steel mills. After 2006, Panhua further set up several subsidiaries in other business divisions such as real estate, shipping terminals, metal mines, and commercial banks. In 2008, Panhua started to expand its flat steel industry by building a new mill in Chongqing City, Western China. Chongqing Panhua Steel Strip Co., Ltd now forms the same capacity as our mills in Zhangjiagang City, 1.5 million Mt of steel coils per year, but will start to output more in 2011 and widen the existing scope of supply.

Head office of Panhua is located in Zhangjiagang Free Trade Zone as well as Jiangsu Yangtze International Chemical Indutrial Zone. It’s 200KM away from Shanghai International Airport. Today’s Panhua possesses about 10 square kilometers of land and 3400 employees in total. By turnover, Panhua Group is ranked among Top500 Chinese Companies.

Panhua’s manufacturing and management systems have past ISO 9001:2000 and ISO 14001:2004. We have established labs close to all processing lines and cold rolling mills to ensure quality control and environmental protection of mass production. We’ve also established strategic alliances with Top10 state-owned steel mills to achieve mutual benefitial cooperation on stable and qualified HR supply. Panhua is quickening its steps to conduct integrative operation. We are making continuous efforts to provide you cold rolled steel coils, galvanized steel coils, prepainted steel coils, and all dimensions of steel sheets to meet end users’ demands by cut-into-length and slitting lines. Our tandem and single stand cold rolling mills are fully imported from USA, Germany, Japan, and India. Equipped with ABB and Siemens automation, all our equipment can offer you accurate dimensions, minimized tolerance, superior heat & corrosion resistance, and aesthetic appearance.

Since 2006, Panhua has been exporting steel coils to more than 50 countries directly. Our long term supply extends to USA, UK, Germany, Italy, Spain, Belgium, France, Poland, Greece, Ukraine, Belarus, Russia, Turkey, Egypt, Saudi Arabia, Iran, Ethiopia, Niger, Brazil, Colombia, Chile, Peru, Australia, New Zealand, etc… We maintain a relentless pursuit of improvement in every critical performance measure so as to serve comprehensive customers throughout the world. Panhua has always put itself in its customers’ position and our brand has been suggested and promoted by worldwide wellknown traders like Stemcor, MAC Steel,Salzgitter Mannesmann, Thyssenkrupp, Interfer, Primex, Coutinho & Ferrostaal, Midland, Balli, LN Metal, SK, Hyundai, Samsung, Daewoo, and Marubeni Itochu.

Panhua has devoted itself to social charity causes with regular donations to the “Hope Project” to build up Hope Primary Schools in Sichuan Province and help students complete their education in schools and colleges. Growing together with society and giving back to society is one of Panhua’s values.

Panhua is full of vigor and potential. We believe and pursue quality, strength, and opportunities. We are always looking towards the future with confidence and welcome your sincere cooperation

Tube Star-ShengDingYuan

Zhangjiagang City ShengDingYuan Pipe-Making Co., Ltd(hereinafter referred to as Sheng Ding yuan) is located in Yangtze River, it is a equipment enterprise that mainly research and developing high Precision Cold Drawn Seamless Steel Tube, High Pressure Fuel Tube. Company covers a land area of over 15000 square meter,and possesses a total asset of over RMB80 million.

Since established in 2007, Sheng Ding Yuan makes every effort to get much more development, now owns series products, such as Cold Drawn High Precision Seamless Steel Tube, Hydraulic System Brightness Fuel Tube, Diesel Engine Common-Rail High Pressure Fuel Tube, Black Phosphated Hydraulic Tube, High Pressure Seamless Square Tube, which widely used in industry equipment, hydraulic system, cars, ships, diesel engine high pressure common-rail system, engineering machinery, fabric equipments, heat exchanger, chemical machinery, and some other businesses, and now annual output up to over 8000 tons.

Excellent Quality

Sheng Ding Yuan insistson enterprise spirit of “quality means life, customers are gods”, that always seeking excellent quality and service. The mainly products high precision seamless steel tube adopt EN10305, DIN2391, ASTM A519, BS6323 as producing standards, and use such well-known steel material as Bao Steel Group, Xingcheng Steel, at the same time meshed with unique technology. Sheng Ding Yuan devotesto supply high precision products with excellent quality to customers at home and abroad.

The Cold Drawn Brightness Seamless Steel Tube can be used for the fields of high required of precision, smoothness, cleanness, mechanical property, such as hydraulic system, cars, ships…; Adopting DIN2391 Standard to produce Compression-ignition Common-rail Diesel Engine High Pressure Fuel Tube, and the normal working pressure can be over 2000kg, as well as the tubes will not deformation if test pressure over 6500kg, every working technical index can reach the standard of international brand steel, so that it can totally instead of imported fuel tubes, finally to decrease the cost of customers; The DIN High Precision Black Phosphated Hydraulic Steel Tube has excellent appearance and good anti-rust property; High Precision Galvanized Steel Tube use DIN high precision cold drawn seamless brightness steel tube as its basic steel, and do cold galvanizing process on its surface, at the same time cover caps at two ends of the tube to prevent dust, this tube use for cars and the customers has high required of steel precision, smoothness, anti-corrosion property.

Going to the world—Sheng Ding Yuan

Sheng Ding Yuan has passed ISO/TS16949:2002, and implement comprehensive products quality control, testing tubes strictly according to standard to ensure products quality. Controlling every technical strictly to make Sheng Ding Yuan well-known among steel enterprises and gain good reliability, now products are long time and sentinel supply BMW, Benz Heavy Truck, SVW, Dongfeng Automobile, Xichai, Fukuda, Xuzhou Heavy Industry and dozens of well-known enterprises in domestic and some other international enterprises, also sales popular in America, Russia, Australian, Singapore, New Zealand, Middle East…

In order to get much more progress, Sheng Ding Yuan fully implement “6S” management system, and research and development the producing equipments and new products, also acquires five patent certificates, as well as gets CCS and DNV at the same time, now Sheng Ding Yuan has applied for High-tech Enterprise.

Keeping innovation and pursue excellent

Sheng Ding Yuan established a group composited of famous specialists at home and abroad to research and develop a variety of products and engineering. Facing the diversified international market compete, Sheng Ding Yuan will keep moving as before, and get a new record in the future!

Zhangjiagang Huayou Tubular Co., Ltd, a Sino-Japan joint ventured company been invested by Sudian International Trading Co., Ltd and Sumitomo Corporation in 2005. We are one of special company majored in steel alloy pipe stock, sale and distributing for power plant and chemical industry. Huayou Tubular has authority of importing & exporting directly after obtaining authorization from China Minister of Commerce in Sep 2005. Company located in Zhangjiagang Economic Development Zone, closer to the Zhangjiagang gate of expressway at south, near urban and Zhangjiagang port at north. It’s a perfect position for stock, distributing and sale. We have one new warehouse with modern equipments and office building of 35,000m2. Several thousand metric tons’ steel alloy tubes such as ASME A213 T91, as well as other steel pipes required from power plant and chemical industry were available at our warehouse for year.

Sumitomo Group, well known as one of top 500 largest company in the world. His subsidiary, Sumitomo Metals is a leading manufacturer on the high performance power plant and chemical industry using steel alloy’s processing, as well as development and research. The quantity Sumitomo Metals supplied to China major boiler manufacturers, coal power plants, nuclear power plants and chemical enterprises was about 50,000 tons per year, further more stronger ability of adjustment and flexibility on supply was another highlight. We, Zhangjiagang Huayou Tubular Co., Ltd, as the partner of Sumitomo Corporation in China will combine two company’s advantage looking for Win-Win for both sides. We will cooperate with clients honest, make customer satisfy with our reliable products and excellent service and pursue become the leader on steel alloy pipe industry.

We’d like invite our partners both domestic and board growing together upon facing power industry boom. If you have any interesting in our products or company, don’t hesitate contact us.

Zhicheng Steel is a professional company in dealing in producing and sales of galvanized, color coated coils roll , Galvanized steel coils coils and other high-quality steel products , has grown into a production, processing, distribution, logistics, retail in one large iron and steel products suppliers. We import and export right in 2002 and actively to strengthen and expand the business in Southeast Asia , the EU, Russia, Ukraine , Latin America and other countries and regions, more than 50 exchanges . Annual sales of more than 80 million tons of steel products , sales of 3.5 billion.

We, “Zhicheng people” always adhere to the corporate principle, which is “Customer First, Reputation First”. We will also adhere to the people-oriented, excellence-pursuing spirit to further improve and expand the construction of procurement and distribution network, to improve the construction of information platform (ERP) to meet customers’ needs at all levels with more abundant resources, more favorable prices, more flexible operations and higher quality services which achieves the purpose of “value-added services to provide customers with the best”. we’d like to cooperate with you to share interests and to grow and share the success!

Let our co-operation start from today, “Zhicheng” looks forward to your visit!

Jiangyin Comat Metal Products Co., Ltd produces tinplate material professionally,at the same time provides perfect service to tinplate buyers in market.

Comat is located in the center of the Yangtze River Delta, with Yangtze Golden Waterway to the north, Freeway along the Yangtze River and Shanghai-Nanjing Freeway to the south, Xinyi-Changxin Railway to the west, close to the famous Huaxi Village. It enjoys much preponderant geographical position and much convenient transportation.

With Continuously investment and hardwark, Comat has become one important tinplate material

Supplier in China market. Comat tinplate wins good feedback in local market and overseas market.

Strictly operating in terms of ISO9001:2008 International Quality System, Comat has always held the management concept of ¡°quality first, credit first, user first¡± to develop constantly and has always persisted in scientific innovation. To learn more,contact us today.

Huaxi steel Group with three plants, 13 production workshop. 6-high mill group 2, 4 rack of a four-high rolling mill group, 18 four-high mill group, The roller mill 88 Desk, Slitting a unit 4 * 1600, electric furnace 18 retreat, Steam Car furnace annealing furnace 10 sets equipped with chemical composition and mechanical analysis Test equipment, pickling line 28. From the tropics, pickling, cold-rolled, the sub-shear, annealing, packaging one-stop production, and formed a band in production and processing The steel production capacity of 300,000 tons. The main production thickness 0.10 mm-4.00mm width of 12 mm-350mm. Steel: Q195, Q235, 07AL, SPHC, SPCC series such as cold rolled steel strip, hot rolled steel strip and Pipe. e.g. And in soft state, semi-soft, Chilled state delivery. Products as Southeast Asia, Europe and more than 10 countries and regions in the country more than 20 domestic provinces, cities and autonomous regions. Complete plant products, product variety, a wide range of uses. Mainly used bicycles, motorcycles, fitness equipment, furniture and construction industries, telecommunications, stamping parts materials, silicon steel plates, water supply and gas transmission projects. Plant products, “Sincerity-centered, winning through quality,” and does not seek the best, but it must be better. Adhere to the “small profits but quick turnover, and mutual benefit” principle, with new and old customers to develop long-term friendly and cooperative relations, work together.

Steel common knowledge quiz:

1. The higher the carbon content of cold rolled steel strip hardness higher plastic worse?

Answer: carbon content of steel can be divided into three types:-eutectoid steel (0.0218% <Wc <0.77%), eutectoid steel (Wc = 0.77%), a eutectoid steel (0.77% <Wc <2.11%).

Eutectoid steel in Asia from the L phase cooled to room temperature organizational transformation process are: first precipitation ferrite, when the carbon content to eutectic composition when it left the Austrian

Body into pearlite. So at room temperature organization is F + P.

Eutectoid the austenite steel cooling to 727 degrees, eutectoid transformation occurred Generation P. So P is at room temperature organizations.

The eutectoid of steel from L to 727 degrees, will first crystallization into Albright, then precipitated cementite. 727 degrees occurred after eutectoid transformation. Therefore, the P + at room temperature organizations

Cementite.

Ferrite hardness <pearlite pearlite> cementite

Therefore, the higher the carbon content of steel hardness higher plastic worse.

2. Why four categories of steel there?

Four categories of steel is based on the distinction between what criteria? Who is the distinction? In a “verification”, but no one right answer, no one Authoritative departments to a set-lun. So, what is meant by “four” rebar? Some people made such a statement:

A screw steel: the exemption in line with the national standard products, cold rolled steel strip,e.g.mainly by large state-owned iron and steel enterprises produced for the production of major or focus Capital works.

The second category steel: in line with the state standards, but not the exemption products, mainly by the production of some medium-sized steel mills, for general construction of Head.

Three types of steel: It is not in accordance with national standards of production, but “security test” tests fail to return, and tolerance serious Super Size Subscript. Such steel is generally more production of small and medium private enterprises, rural housing construction on the wider application.

Four categories of steel: mainly some rural Office, the County Office by small steel production, some enterprises have not even production permits, generally use five tons of small Electric furnace smelting, IF furnace production than the “manner of Steel” slightly better, the product is often counterfeit, the three kinds of products is l

Jiangsu Darun Machinery Manufacturing Co.,Ltd. is an enterprise specializing in production and sales of seamless steel tube.

It has a complete and effective system of quality control and assurance. We have passed the Lloyd’s ISO9001: 2008 quality management system certification,the national special equipment manufacturing license certification, the EU PED 97/23/EC certification, the American Petroleum Institute certification; the Company can produce seamless steel tube with all sizes,external diameter between……

The company owns a production line of advanced level with Italian Danieli 100 tons ultra-high power electric steelmaking, Arc continuous casting billet and round billet; a production line of Germany SMS Meer Group Φ258 PQF three-roller tandem rolling tube hot rolling; a converted Φ100ASSEL three-roll hot rolling production line; Two lines for steel tube heat treatment; Three processing lines for oil well steel pipe thread.

PanFeng Technology Co., Ltd, locating in hinterland of ChangJiang delta, is a high tech enterprise of JiangSu province, which is a medium-sized corporation that specialized in producing general machinery in China. It will only take approximately 1 hour by car to ShangHai, Suzhou or NanJing.

We engage in science and technology as a priority, holding a plenty of human resource with high-tech, 80% of our staff are specialized people in this industry. With world-advanced level, we researched and produced whole-continuous-complex-pipe production line, high frequency solder for carbon-steel and stainless steel arc-argon solder in serious configuration, through which the pipe can be molded in one time. We mostly produce complex-pipe (Stainless steel clad pipe) with different specialization and in different thickness.

Our stainless steel complex-pipe will be provided with good appearance, high intention, high anti-pressure, high anti-grinding, excellent anti corrosion, and lower price comparing with those kinds of pipes with same specialization. It can be used in very extensive scopes, which means: “From the big realm to the detailed field”, for example, in civil public construction: Guardrail, Isolated area, Signboard, Street lamp pole, for sewage disposal factory construction and road-kiosk, our products is preferred. Also in decoration and advertising, for presentation board, call-board, advertising-board, information-bulletin, our products are good choice. In recent year, in furniture prospect, anti-stolen windows and door, handrail for inner decoration already be adopted of mental pipes.

Deploitation with courage, and attempt with intrepidity are of our principles we persisted. Lately, those new market, for example, components renewal for textile machinery, handlebar of motorcycle and bicycle, ironware for sanitary ware, leisure ware, vent-pipe for auto, muffler, hotel ware and medical treatment, have holden out the invitational arm for us. As a view for the future, the people from PanFeng with aggressive intention should be successful in the market. Also our products have covered almost exceeding half of China Market.

We have advanced producing process, rich technique power. No matter what producing or installation, we have strong technique strength. Also we can produce with materials supplied by clients or produce different thickness steel pipe according to customers’ demand.

Our business are involved in whole-continuous-complex-pipe production line, solder pipe Unit, high frequency solder pipe equipment, stainless steel solder pipe equipment, assistant equipment for solder producing line and rectangle pipe producing equipment, also including siphon machine with digital control, automatic mental fretsaw machine, siphon machine, pipe-cut machine, stainless steel complex pipe producing and selling, further processing is also involved.

Zhangjiagang City Yiyang Pipe Producing Co.,Ltd locates in Zhangjiagang City,Jiangsu Province that is known as the center of Yangtze River delta economic district. It adjoins Shanghai and its one-hour traffic circle contains many large and medium-sized cities such as Suzhou,Wuxi and Nantong etc. Meanwhile the international port-Zhangjiagang port is near at hand.Transportation hear is very convenient by land,water and air.

Our corporation specializes in producing cold-drawing & cold-rolling seamless steel tube as well as bearing rings,with Zhangjiagang Yiyang Pipe Producing Co.,Ltd, Zhangjiagang Yichen Steel Tube Co.,Ltd, Zhangjiagang City Yiyang Precision Bearing Co.,Ltd, Hongze Yiyang Steel Tube Co.,Ltd, Zhang Jiagang City Yiyang Pipe Producing sales Co.,Ltd and Zhangjiagang City Yiyang Import and Export Trading Co.,Ltd as the affiliate enterprises.

Our Corporation has established our own Technology Research and Development Center and possesses professional technology management team. We have obtained ISO9001,TS16949 Quality Management System Certificate,ISO14001 Environment Management System Certificate and CE-PED Certificate. Our corporation’s product is top-grade with stable quality and its general competitive ability tops the list in steel industry.

Currently our corporation covers an area of 230 thousand square meters and possesses 130 thousand square meter’s standard workshop. Our annual production capacity is 100 metric tons’ seamless steel tubes and owns 8 sets of Piercing device,62 sets of Φ30-Φ100 cold rolling machines, 38 sets of 5-80 ton cold drawn machines, 9 sets of continuous heat treatment furnaces, 2 sets of continuous bright annealing & normalizing furnaces as well as appropriate supporting devices. Our corporation’s automation keeps ahead in steel industry in China. With advanced and complete testing equipments, we can put up various tests and analysises. So far we are well-equipped with many testing machine as well as automatic online ultrasonic & eddy-current testing line. We can guarantee our product’s quality and advanced technology with these perfect testing facilities.

We can manufacture various seamless steel tube,high-performance bearing steel tube,various seamless steel tube for autos,tubes for high and low-pressure boilers,as well as seamless steel tube for structure as per various standards and clients requests of specification. Steel industry’s development promotes civilization’s advancement and improves every a spect of the society. With the target of “Enhancing steel industry value,creating top-grade brand”,Yiyang Pipe Producing Co.,Ltd will grow up and develop with clients together,apply ourselves to create a brighter and flourishing futurel!

3V International Co., Ltd. (3VIC) as a leading exporter of cold and hot rolled steel coils/strips and galvanized coils/strips from China Wuxi. 3VIC covers an area of 99,000 square meters and invested USD10,000,000 in the first stage by far.

In order to meet the global market demands, 3VIC has poured multi-million dollars on the production equipment and production line. By now, we have four continuous acid pickling lines, three 750 quadric-hydraulic pressure down tri-rolling mills, two 650 reversing cold-rolled mills, one 400mm-long galvanized and couples of precise production lines. All these ensure annual productivity exceeds 230,000MT.

3VIC always treats customers with great sincerity and gives top priority to clients. The modern management system, advanced cold-rolled techniques, control and heating treatment technology ensure all indexes of each items can reach the leading levels both at home and abroad.

Sunrisingsteel , a leading global distributor and stockist in steel pipes and fittings, and related accessories in piping industry.

Our products consist of alloy pipes, stainless steel pipes, duplex steel, nickel alloys, carbon steel pipes, fin tubes, fittings, flanges, bolts & nuts and production related equipments etc.

Our daily stocking for servicing global EPC clients includes:

Alloy steel: P91, P9, P5, P22, P11.

Carbon steel: A333 Gr.6, API 5L/A106 B, X42, X52.

Stainless steel: TP316, TP304, TP347.

Other grades require special production including: Duplex steel S31803/S32205, N04400, N08800, Line pipes on X42-X60 with size range 1/2”-36”, W.T 0.5mm-80mm.

Our clients widely spread in Europe, Latin America, Middle east, Australia, India, South Korea, Mexico, Singapore in sector of refinery, Oil & Gas, boiler and equipment manufacturer, drilling, ship building and etc.

Based on our long term professionalism, responsibility towards clients, Sunrisingsteel becomes one of the most efficient and trustworthy team in metal and piping industry.

Group members in Sunrisingsteel includes:

Wuxi Sunrising Steel Co., Ltd

Head office:10F,Unit 2,Zhongwei Intl. Building,No.589 Wuyun RD,Huishan District,Wuxi,P.R.C

Branch office:Room 607,Unit 2,No.1588 Youyi RD,Baoshan District,Shanghai,P.R.C

Wuxi Stock Unit:No.2 Daqiao RD,Shitangwan,Wuxi,P.R.C

Tianjin Stock Unit:Tanggu District,Tianjin City.

Activities: Technical analysis, Procurement, Stocking & Processing based on project demand.

Wuxi Sunrising Steel Manufacturing Co., Ltd

No.1 Yunhe East RD,Shitangwan,Wuxi,P.R.C

Activities: Pipe making / Processing in Wuxi City.

Kaviish Focus Steel Pipes Pvt

Survey No.389,Orma,Tal.Olpad,District,Surat-394 540,Gujarat,India.

(Joint Venture in Surat India for Large diameter pipes)

The company is East China’s largest steel pipe production base. It is also one of the integrated manufacturers professed in producing steel pipes for transferring oil, gas and water and large scale structures. Yulong has nine sets of machine unit for Φ219-Φ2850 of SAWH steel pipe with an annual production capacity of around 260,000 tons, two sets of SAWL production lines: one with Φ1422 maximum and one Φ813 maximum with an annual production of 200,000 tons, two sets of machine unit for Φ168 maximum…

Wuxi Huaye lron and Steel Co., Ltd. was founded in Oct., 2000, with total investment of 25 million U.S Dollars, which is a large-scale iron and Steel enterprise specialized in producing hot-rolled and cold-rolled steel strip.

Wuxi Huaye lron and Steel Co., Ltd. is situated in the region of Shitangwan Industrial Park, the Northwest Suburb, and WuXi with advantageous geographical position and convenient communication. Hu- Ning Express Way is on the north and Hu-Ning Railway, Jing-Hang Canal, No. 312 National way are on the south and Xi—Cheng Canal is on the east. The land area of the company is more than 300, 000 M2, in which, the building area is 100, 000 M2. There are 450 workers and staff members, including 75 various engineers, technicians and administrators with senior professional titles.

The main production equipment includes one advanced hot-rolled steel strip production line; 450cold- rolled steel strip reversible rolling mills; 12 acid-washing production line;auto-control cuting machine vertically and horizontally;24 sets of PC control fading-fire bright fnish facility, With advanced equipments and excellent technology we have an annual output of 350, 000 tons hot-rolled steel strip and 250, 000 tons cold-rolled steel strip. The main grade Of our products includes: carbon steel (Q195、Q215、Q235), Structural alloy steel, silica steel and stainless steel.

The production lines of hot-rolled steel strip adopted the international advanced continuous rolling technique. The machine set adopted the advanced technology and equipments, such as all-digital and all- network technology control and electric closed loop. The electrical controlled system adopted the up-to- date SIEMENS S7-400 PLC Artificial Intelligent control system it not only satisfied the craft demand of on-the-spot production, but also provided flexible and convenient man-machine operation interface for productive operation. The DCS plan organized by computer network fully reflected the thinking of modern computer control of decentralized control and centralized management.

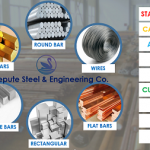

Changshu Fengyang Special Steel Co., Ltd. is a company specializing in steel products. We are an agent of XingCheng, Tangsteel, Wisco, Masteel and other major domestic steel providers.

Main products: spring steel, alloy steel, strip, tube, marine material, cold rolled steel, cold rolled steel strip, section steel, galvanized steel, stainless steel, billet, wire, etc.

Relying on the powerful economic strength and business capability and the good relationships with many domestically famous steelwork companies, we …

Relying on the powerful economic strength and business capability and the good relationships with many domestically famous steelwork companies, we adhere to “Customers First” principle. We ensure to provide customers with worry-free products.

Listed on the Nasdaq Capital Market, Sutor Technology Group Limited is a high-tech manufacturer of fine finished steel products used by steel fabricators and other applications in China.

Utilizing its fully automated facilities, state-of-the-art technology and a world-class manufacturing concept, SUTOR has grown to six integrated steel sheet and six steel pipe production lines with total production capacity of approximately 4.05million metric tons. SUTOR specializes in manufacturing and developing diversified high-end finished steel products, including hot-dipped galvanized steel, pre-painted galvanized steel, acid-pickled steel, cold-rolled steel , welded steel pipe products, and high-precision auto body sheet products. SUTOR has also established a vertically integrated business model that provides processing, distribution and customized logistic solutions.

Sutor’s diversified lines of products are used in a variety of industries including solar energy, household appliances, medical instruments, IT, building & construction and automobiles. The company benefits directly from the increasing demand for its products due to on-going urbanization and industrial upgrading in China.

Wuxi Baile Steel Products Co., Ltd. is a Sino-foreign joint venture, and a large-scale iron and steel enterprise to produce hot rolled steel strip and cold rolled steel strip. With advanced equipments and excellent technology, we have an annual output of 400,000 tons high-quality hot-rolled steel strip and 200,000 tons cold-rolled steel strip, the annual sales volume is USD 2.62 millions. The main grade of our products includes: carbon steel(Q195Q215Q235), structural alloy steel, silica steel and stainless steel.

Wuxi Baile Steel Products Co., Ltd. is situated in the region of Shitangwan Industrial Park, the Northwest Suburb, and Wuxi with advantageous geographical position and convenient communication. Hu-Ning Express Way is on the north and Hu-Ning Railway, Jing-Hang Canal, No.312 National Way are on the south and Xi-Cheng Canal is on the east. The land area of the company is more than 300,000 M2, in which, the building area is 100,000 M2. There are 600 workers and staff members, including 75 various engineers, technicians and administrators with senior professional titles.

The main production equipment includes one advanced hot-rolled steel strip production line; 350450550680850 etc. 25 sets of cold-rolled steel strip reversible rolling machines; 800HC rolling machines; 5 sets of pickle line; auto-control slitting machine vertically and horizontally; 25 sets of annealing equipment, ammonia decomposition; stove of arising coal gas.

The productive craft of hot-rolled steel strip adopted the international advanced continuous rolling technology. The machine set adopted the advanced technology and equipments, such as all-digital and all-network technology control and electric closed loop. The electrical controlled system adopted the up-to-date SIEMENS S7-400 PLC Artificial Intelligent Control System (S7-400 is the quickest CPU in PLC of S7 series with DP port series), it not only satisfied the craft demand of on-the-spot production, but also provided flexible and convenient man-machine operation interface for productive operation. The DCS plan organized by computer network fully reflected the thinking of modern computer control of decentralized control and centralized management. The key of this technical reform depended on micro-tension control and closed loop control, making the automatic plan have advantage and quickness and raising output and quality.

We concept is: Quality Products, Competitive Price, and Reliable Service.