C-shaped hooks for hanging posters and signs, store decoration and display items, and for hanging and connecting various items. These CNC Wire hooks wholesale are made of durable 2mm thick metal wire.

Other sizes can be provided on request.

A pack of 100

More information please click here.

3 Type 2 Wall Tie(CE marked)

Product Name: Type 2 Wall Tie(CE Marked)

Item Code: Smart Craftsmen-WTT2

Surface Treatment: Shiny.

Raw Material: Stainless Steel 304( Grade1 4301) or Up on your request.

Package: 250 pieces / Inner Box, 2 or 4 Inner boxes / Master Carton.

Place of Origin: Hebei, China.

Standards: PD 6697 and EN 845-1:2013+A1:2016.

The type 2 wall ties for sale are suitable for general-purpose neckties with a space between 50mm and 150mm, which can be used in European domestic residential and small commercial buildings up to 15 meters high. Smart Craftsmen Type 2 wall ties are CE marked, and the measured dynamic stiffness <113MN/m3 meets the requirements for external masonry walls

Approve the performance requirements of Document E. The test result meets the PD 6697 standard and confirms BS EN 845-1: 2013 + A1: 2016.

benefit

Answer: The specially designed safety end provides an excellent mortar key, which reduces the risk of on-site injury and prevents entanglement.

B: Clear and easy to distinguish packaging, which can be conveniently used on site when different types of wall ties are needed.

C: It is made of corrosion-resistant stainless steel, and high-strength steel wire is cold bridged to minimize heat loss.

D: Multiple drops can prevent water from flowing in any direction where the cable tie is installed.

note

Other special length and wire thickness can be provided according to customer requirements.

Tianjin KXC group founded in 2004, is an ISO 9001 certified company,committed to manufacturing valves, valve parts & related products for water works and water treatment projects.

KXC consists of HY Valves Co. Ltd and KXC Metal Co. Ltd within our own factory and foundry. We have machining center, CNC machines, pressure test machining, electric furnace, mould machine, sand blasting machine, given all of this, our products quality always under good control.

KXC mainly produce gate valve(Resilient seat, Metal seat), butterfly valve(Concentric and Eccentric), check valve, ball valve, globe valve and etc. Supported by our many years’ experience and expertise in this field,

KXC can also offer OEM &ODM valves and parts.KXC philosophy is to offer high cost performance products with optimal service. Welcome to visit our factories and KXC will satisfy you in all respects.

Our products:Rising Stem Globe Valves, Double Eccentric Butterfly Valve

HOT-DIPPED GALVANIZED STEEL COIL

- INTRODUCTION:

Hot-dipped galvanized steel coil is made from steel plate, which is dipped into the dissolved zinc bath, with a zinc layer on the surface. It mainly adopts the continuous galvanizing production process. That means the cold rolled coils are put into the dissolved zinc bath for continuous galvanizing process.

- EVER-SHINE Steel Coil APPLICATION:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It’s especally useful for countless outdoor and industrial applications.

They are mainly used in building roof, door, window, roller shutter doorand automobile’s vehicle shell, chassis, door, trunk lid, Oil tank, and fender, and also electric equipments, such as refrigerator base and shell and so on.

- SPECIFICATION

| THICKNESS | 0.11mm-5.0mm |

| WIDTH | 600-1250mm Max |

| COATING MASS | 20g-400g/m2 |

| Surface Structure | Zero Spangle,Regular Spangle,Minimized Spangle |

| SURFACE TREATMENT | Chromated/non-Chromated,Oiled/non-Oiled,skinpassed/non-skinpassed |

| COIL INNNER DIAMETER | 508mm or 610mm |

An ISO 9001:2008 Certified Company, The Metal Factory is India’s most trusted manufacturer, exporter and supplier of stainless steel tubes (ASTM A 312 304/304L, 316/316L), carbon steel pipes (ASTM A A106, A53, API 5L), alloy steel seamless pipes (ASTM A335 P11, P22), mild steel pipes, industrial steel tubes, galvanized steel pipes and black steel pipes.

We can manufacture and supply steel pipes which can be fabricated to customers design and specification in a variety of length and thickness requirements. We can also offer cold drawn seamless steel tubes to meet the custom design and specifications of our customers. We specialise in the manufacture and supply of cold drawn seamless steel tubes, and large diameter stainless steel welded pipes (100% X-Ray Tested). ISO 9001:2008 Certification ensures consistency in our operations and testing procedures.

Steel Pipes and Steel Tubes supplied by The Metal Factory are used across wide range of industries including food processing, power generation, oil and gas, petrochemicals, petroleum pipelines, medical equipment, biopharma, pharmaceuticals, electrical engineering, fertilizer industry, dairy processing, boiler manufacturing and nuclear energy among others.

METLINE has been proudly servicing the steel pipe industry for over 40 years, as a major supplier and manufacturer of custom size steel pipes and steel tubes. We are the exclusive suppliers of stainless steel welded pipes, stainless steel seamless tubes, stainless steel tubing, alloy steel seamless pipes, boiler steel tubes, heat exchanger tubes, capillary tubes, coiled tubing, and galvanized steel pipes. We are serving all major cities and countries in their needs for steel pipes and steel tubes.

Our products are supplied to all major Industrial areas and cities in India such as Mumbai, Delhi, Bangalore, Hyderabad, Ahmedabad, Chennai, Kolkata, Surat, Pune, Nagpur, Indore, Thane, Bhopal, Visakhapatnam, Vadodra, Nashik, Faridabad, Rajkot, Aurangabad, Ranchi, Coimbatore, Raipur, Mysore, Bhubaneswar, Salem, Bhilai, Bhiwandi, Bikaner, Mangalore, Kochi (Cochin), Bhavnagar, Tirupur, Ankleshwar, Assam, Siliguri, Jamshedpur, Warangal, Nellore, Agartala and Thoothukudi.

Our high quality steel pipes, good customer service, and in house pipes and tubes processing capabilities have made us one of the emerging suppliers for steel pipes and tubes in Middle East countries including Bahrain, Cyprus, Egypt, Iran, Iraq, Israel, Jordan, Kuwait, Lebanon, Oman, Palestine, Qatar, Saudi Arabia, Syria, Turkey, United Arab Emirates and Yemen.

India’s #1 Supplier of Stainless Steel Pipes/Tubes, Chrome Moly Pipes, Black Pipes, Galvanised Pipes, Carbon Steel Pipes

Stainless Steel Pipes, Carbon Steel Tubes, Alloy Steel Tubes, MS Pipes Production and Stock Range

Outside Diameter: 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock, OD Size Steel Tubes available Ex-stock

Thickness Range: 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Type: Seamless / ERW / Welded / Fabricated / CDW

Key Steel Pipes & Tubes Products & Grades

1. Stainless Steel Seamless Pipes & Tubes – 304, 304/L, 316/L, 904L, 310S, 321H, 347H, 446

2. Stainless Steel Welded Pipes & Tubes – 304, 304/L, 316/L, 904L, 310S, 321H, 347H, 446

3. Square Stainless Steel Pipes, Round Stainless Steel Tubes, Rectangular Stainless Steel Pipes & Tubes

4. Carbon Steel Seamless Pipes as per ASTM A 106 Grade B/API 5L Grade B/ASTM A 53 Grade B

5. Carbon Steel Seamless Tubes as per BS 3059, ASTM A 179, ASTM A 192, ASTM A 210 GR.A1

6. Alloy Steel Seamless Pipes as per ASTM A335 Grade P1/ P5/ P9 / P11/ P12 / P22 / P91

7. LTCS Pipe – Low Temperature Carbon Steel Pipes as per ASTM A 333 Grade 6

8. Alloy Steel Seamless Tubes as per ASTM A213 Grade T5/T9/T11/T12/T22/T91

9. ERW Black Pipes as per IS:1239/I, IS: 3589 Grade 330 or Grade 410

10. Galvanised Pipes as per IS:1239/I

11. Square and Rectangular Steel Pipes as per IS: 4923

12. ERW Boiler Tubes: BS 3059, ASTM A 214

13. Air Pre Heater Tubes to BS: 6323 PART V

14. Hydraulic Tubes to DIN 2391 ST. 35, ST. 45 & ST. 52

15. Seamless Heat Exchanger Tubes ASTM A 179

16. CDW TUBES IS: 3074 or BS 980

17. CRCA ERW Tubes to IS 3601 OR IS 3074

18. Stainless Steel Electro polished Pipes Manufacturer/Supplier

19. Alloy Steel Fittings Manufacturer – ASTM A234 WP5, P11, P22, P91

Ceramic lined pipe is made through the self-propagating high-temperature synthesis (SHS) technique.

Self-propagating High-temperature Synthetic process

Self-propagating high-temperature synthesis (SHS) is used to describe a process in which the initial reagents (usual powders), when ignited, spontaneously transforms into products due to the exothermic heat of reaction.

The combination of high rigidity of ceramic and high elasticity of steel gives the pipe unmatchable features like abrasion resistant, heat resistant, and corrosion-resistant material for use in the fields of power generation, metallurgy, mining, and chemical industry, etc. It has many advantages over steel pipes, cast stone pipes, and steel-plastic compound pipes.

Usage of Ceramic Lined pipe

The ceramic-lined pipe transportation has been widely used in the industries of electric power, metallurgy, coal, petroleum, chemical engineering, building materials, mechanism, and so on.

The ceramic lined elbow throughout the power, metallurgy, coal, petroleum, chemical, building materials, machinery, and other industries, and high-speed development. When lining the wear-resistant ceramic elbow to deliver high grinding material (such as ash, coal, ore powder, etc.), there is a lining of wear-resistant ceramic elbow wear fast, especially the elbow Wear faster. When lining a ceramic-lined elbow to deliver a highly corrosive gas, liquid or solid, there is a problem that the lined wear-resistant ceramic elbow is corroded and is quickly damaged.

There is a problem that it is expensive to use a heat-resistant steel pipe when the material having a higher temperature is conveyed in the lining of the wear-resistant ceramic elbow. After lining the wear-resistant ceramic elbow, these problems are solved.

The ceramic lined elbow is widely used in wear and tear of mine filling material, ore powder and tailings transportation, coal-fired power plant powder, smelting, ash and other things lined with wear-resistant ceramic elbow are also very appropriate.

The ceramic lined pipe, Elbows, Reducer, Tees, and others manufactured in our factory have been used in over 200 thermal power plants, more than 50 mines, and the industries of coal, building materials, mechanism, petroleum, and so on.

Abrasion

Ceramic layer Ceramic Lined Reducer Pipe with flange reducer Al2O3 content greater than 89%, micro-hardness HV1000-1500, which has high abrasion resistance, wear resistance more than ten times higher than carbon steel after quenching, superior tungsten carbide drill.

Application range

- coal pulverizing system of power plant pipeline, including, powder transmission pipeline, thick powder separator pipeline, coal drop pipe, combustion system of a windpipe, a secondary air pipe, three pipeline and burner pipelines, in addition to ash slagging system the discharge pipe, powder pipe, dry ash conveying pipe;

- Iron and steel plant raw material conveying pipeline, collecting pipe, dust pipe, ash pipe, ash pipe, mixing pipe, grinding export pipeline, coal pipeline, coal pipeline, separator pipe, burner radius pipe, etc.;

- Cement plant selection machine outlet pipe, choose machine inlet pipe, pipe dust pipe, vertical mill outlet pipe, circulating air duct, high-temperature air blower, lower material pipe, etc.;

- Petroleum, chemical, mining, coal, coal washing plant, smelting, paper, aluminum, building materials, powder engineering, food machinery, and other processing and conveying material pipes.

Corrosion

Ceramic materials are neutral, chemically stable, have excellent corrosion resistance and acid resistance, resistant to various inorganic acids, organic acids, organic solvents, and their degree of corrosion of stainless steel is more than ten times.

Temperature

Temperature above 2000celsius degree, long-term work in the range of -50 -900 celsius degree.

Easy welding.

The ceramic adjustable tube can be welded, flanged, flexible connectors, and other fast way links, very easy to install.

Clean and easy maintenance

Smooth walls, can prevent scaling, fouling, and self-cleaning functions. Tightness.

Remarks:

- Under the direction of the arrow diagram for the export direction.

- Bend radius is usually 1.5-5 times the diameter of steel pipe (1.5-5D).

- Othe specifications of the composite pipe can be manufactured according to the user requirements.

- The weight is calculated by theoretics, maybe have some tolerance, and real weight will be weigh-in after they finish.

Hoop strength is the resistance against radial pressure. The strength of the ceramic-lined steel composite pipe is 300 to 500MPa.

Features and Advantages of ceramic lined pipe

Ceramic Liner pipe is a high technology production technology-self-fuel high-temperature clutch synthesis method.

1). High Abrasion Resistant:

Vickers hardness of the corundum lining is HV1100 to1500, as high as that of tungsten-cobalt hard alloys, and the abrasion resistance is 20 times as carbon steel pipes. The composite ceramic-lined steel elbow was used in a mining plant for about fifty thousand hours. The general service life of a common steel elbow is about 700 hours.

2). Corrosion Resistant:

Corundum is a neutral material and is acid-proof and fouling-free.

3). Heat Resistant:

Ceramic lined composite steel pipes can work under circumstances of -50 to 800 Celsius degree.

4). Lower Weight and Convenient Installation:

The ceramic-lined steel pipes are lighter than alloy pipes, cast iron pipes, and cast stone pipes and can be welded or connected through flanges, which reduces the expense of transportation and makes the pipes easier to install.

For the pipes with the same sizes, types, and lengths, the weight of the ceramic pipe is about 1/2 of the wearable cast alloy steel pipe’s, while the cost has reduced 10%~20% per meter.

The weight of ceramic-lined steel pipe is about 1/3 of the cast stone bent pipes, 1/2 of the cast stone straight pipes.

Ceramic (Corundum: a-Al2O3) lined abrasion resistant straight pipe and fittings are lined with highly abrasion-resistant ceramic by SHS ——-Self-propagating High-temperature Synthetic process.

- The ceramic-lined steel composite pipe can be joined by welding the steel pipe layer.

- Ceramic-lined pipes can take place of expensive stainless steel, titanium, nickel, cast stone, or alloy pipes.

- Extended service life can also reduce maintenance costs.

Self-Propagating Ceramic Pipe

Self-propagating ceramic steel pipes create a new generation of abrasion and corrosion-resistant engineering pipelines.

The self-propagating ceramic steel pipe has very good wear resistance, Excellent corrosion resistance, and Excellent thermal resistance performance.

SHS-self-propagating ceramic steel pipe and elbow create a new generation of abrasion and corrosion-resistant engineering pipeline. The composite pipe is composed of three layers: ceramic, intermediate, and steel layers.

The ceramic layer is formed by molten alumina at a temperature above 2500 degrees. The molten alumina produced from the reaction Fe2O3+2Al=2Fe+Al2O3 spreads on the inside wall of the steel pipe under the influence of a centrifugal force, then solidifies, so the ceramic layer has high density and smooth surface and bonds to the steel pipe.

Applicable Industries:

- The pipe needs excellent wear resistance property: Power plant, Mining, Sea Port, Coal Plant, And pipe for transporting the powder, slurry, sand, etc.

- Coal washing plant, pipe for transporting coal and other material.

- Pipe for transporting the melted aluminum.

- Any pipe which needs to wear protection, corrosion protection, etc.

Benefits:

- Excellent wear resistance, Alumina content of the ceramic liner is higher than 95%, Hardness HV1000-1500. The wear protection performance is more than 10 times better than carbon steel after quenching,

- Excellent corrosion resistance, stable chemical properties.

- Excellent thermal resistance performance up to 2000℃ Can be used in the area from-50℃ to 900℃ for a long time.

- Can be connected with another pipe by welding, flange and soft fast connecting, and easy installation.

Wir, Fittings und Flansche ist einer der führenden Hersteller Lieferanten und Exporteure von Edelstahl, Kohlenstoffstahl, legiertem Stahl, Duplex-Stahl, Hoch-Nickel-Legierung Stumpfschweißverschraubungen, Flansche, geschmiedete Armaturen, Bleche, Platten, Spulen, Rundstangen, Stangen , Rohre, Rohre, Auslaufarmaturen in Deutschland.

Glued Steel Fiber, an alternate concrete reinforcing material are high tensile steel wires with hooked ends, glued together by the water-soluble adhesive for compactness and uniform dispersion in concrete, to increase the concrete properties by 3-4 times.

steel fiber reinforced concrete supplier improve the mechanical properties concrete and materials such as ductility,

energy absorption, fatigue, and toughness. This fiber helps to controls plastic shrinkage cracking in concrete; helps reduce or eliminate need for conventional reinforcement.

Application of Glued steel fiber reinforced concrete

- For concrete flooring

Industrial floors

Joint-less floors

Floors-on-piles

Lightly loaded floors

Liquid tight floors & composite metal decking

- stainless steel fiber supplierFor Hard Standing & Heavy Duty

Parking lots

Playgrounds

Airport runways

Taxiways

Maintenance hangers

Access roads & workshops

Ports& Containers for port pavements

Container terminals

Bulk storage areas access roads

For army tank movement

- steel fibers for concrete reinforcementOther Applications

Foundations

Traditional cellar and basement walls

Compression layers

Tunnel engineering

Compared with the GuangYa loose steel fiber the operation and advantages of the glued steel fiber:

- Add the steel fiber directly into the belt, the whole row of steel fiber as a whole, evenly dispersed in the concrete corner

- The water-soluble glue begins to dissolve in a row of steel fibers in the premise of the dispersion, it is again dispersed in every corner of the mono filament fiber, showing the perspective in the concrete of the fiber mesh, which plays an integral strengthening.

- Compared with mono-filament fibers, China bonded steel fiberswill not be bundled to ensure that the fibers in concrete do not coalesce and distribute evenly.

Glued steel fibers are loose hook-end fibers that are bonded together in a row. The great difference between loose fiber and glued fiber is that the former is easy to clog and the latter is easy to disperse evenly.

AQE Gate valves are used to limit the flow of fluid flowing straight through the pipeline. This is an effective and reliable way to stop fluid flow. The Slab Gate Valve can be fully opened or fully closed. The slow opening and closing of the valve helps avoid hydraulic hammers, which can damage the pipes connected to the valve. Gate valves are not used for throttling, so do not let them half open. The gate valve has 3 important parts. They are doors, stems and hoods.

The gate can be used in several variations in a gate valve. You may occasionally use knife doors, or if you use crude oil, you may see flat doors. However, in the marine industry, the most common gate is the wedge. This type of gate valve wholesale uses a wedge-shaped metal sheet that can be moved into the valve body to prevent fluid flow. This uses metal-to-metal contact to create a positive pressure seal. However, under extremely low pressure (5 psi or lower), the gate valve may leak a little.

Learn more about AQE valve via https://www.aqemachinery.com/

HENAN FORWARD STEEL EXPORT CO.,LTD

Tel: +86-371-61310228 You also can visit us by sa514steel.com througth google

Address: Tower-A Room 3106 Kai xuan Plaza zhengzhou city of henan province China

http://sa514steel.com

Email: admin@qfsteels.com

SA240 TP310S Stainless, SA240 309S stainless, SA240 316TI stainless, SA240 304H stainless

1. What we do?

HENAN FORWARD STEEL EXPORT CO.,LTD Stainless warehouse provide ASME SA240 Stainless steel plate Bevel,Groove and cutting disc stainless steel machined parts .we have 1000tons tp316L,tp310s,tp304l,tp321, tp304h, tp316h,tp310h, tp321h,2205, S31803, 410, 430, 409, 443, 439, 310SI2, 316TI Stainless steel plate stock.

Besides that, our factory also provide the CNC Cutting platform and water cutting platform. Disc cutting, special parts cutting, stainless steel bevel and stainless steel groove service. Our machined precision to min 0.2 for the surface of machined.

Our cutting service had approved by Mexico and USA, and Canada Project.

2. Our mainly stainless steel grade for ASME SA240

SA240 TP202,SA240 TP201,

SA240 TP304,SA240 TP304L,SA240 TP304H, SA240 TP304N, SA240 TP304LN

SA240 TP316L,SA240 TP316, SA240 TP316H,SA240 TP316N, SA240 TP316LN,SA240 TP316TI

SA240 TP309S, SA240 TP309H,SA240 TP309,SA240 TP309Cb

SA240 TP310S, SA240 TP310, SA240 TP310H

SA240 TP347,SA240 TP347H,

SA240 TP348,SA240 TP348H,

SA240 TP321, SA240 TP321H

SA240 TP317L,SA240 TP317

SA240 TP444,SA240 TP410, SA240 TP430,SA240 TP443, SA240 TP439

3. Products Service of our unitedsteel warehouse.

Stainless steel plate

Stainless disc steel plate.

Stainless steel cutting

Stainless seamless pipe

Stainless seamless Tube

Stainless welded steel pipe

Stainless machined bevel

Stainless machined groove

4. Our Stainless steel thickness

Stainless plates

0.25mm-150mm thickness

Width: 20mm to 2500mm

Length 20mm to 10000mm

Max weight of each plate 6 tons.

Stainless seamless pipe

outer diameter 3.2-200mm,

Wall thickness 0.5-12.7mm

5. Stainless Production time:

5-8days in usual size.

If you need the bevel and groove stainless parts, we need min extra 7days.

6. Stainless Payment Item for HENAN FORWARD STEEL EXPORT CO.,LTD

TT payment Or 30% TT advance and balance should be paid after BL documents.

7. Why you choose us?

a. The faster production time, and most of production, we can control them in one week if the total weight are not large.

b. Better service, we promise that your inquiry will be sent official quotation in 24hours.

c. Faster delivery, we had owned transport truck department and transport stainless to our port in 24hours.

d. Quality promise processing: PMI Test at each stainless steel plates before delivery. We accept the third party inspection, GL. SGS.BV, DNV, LR,ABS and others.

8. Trade Item:

FOB, EXW, CFR AND CIF

Packages by wooden pallet, delivery by containers.

9. How to contact HENAN FORWARD STEEL EXPORT CO.,LTD?

Your can searh our company name from google or visit sa514steel and qfsteels through searching them at google.

Mr David

0086-371-61310228

admin@qfsteels.com

http://sa514steel.com

Anping TianHui Wire Mesh Products Co., Ltd. is located in anping county, Hebei province, which also be called “Hometown of wire mesh”in china. Started the factory from the year 1986, We are one of the top manufacturers and exporters of Woven wire Mesh, Screens and welded Wire Mesh in China.

We has over 160 sets of wire mesh machines, have around 20000 rolls in stock for stainless steel wire mesh & welded mesh. We have gained a global sales network reaching to the Local market, USA, Middle-East, Europe and Africa etc.

Our company has been based on “good quality, timely delivery, reasonable price, considerate service” the purpose to serve the masses of customers; And is in line with “quality seek survival, prestige seek development” production principles, in our emphasis on product quality at the same time, also actively communicate with the customer, understand customer needs, to realize our shortcomings, and for clients to provide professional and timely after-sales service, won the praise of the vast old and new customers. Our products are widely used in petroleum, textile, metallurgy, construction, farming, machinery, landscape protection, production and manufacturing, and other fields.

Our Main Products: Stainless Steel Wire Mesh, Shale Shaker Screen, Crimped Wire Mesh, Dutch Wire Mesh, Copper Wire Mesh, Brass Wire Mesh, Stainless Steel Welded Wire Mesh, Galvanized Welded Wire Mesh, Filter Discs And Wire Mesh Processed Products.

TIANHUI Sincerely hope to establish long term business relationship with worldwide customers on the basis of sincerity and mutual benefits.

Werner Flanges Inc. an ISO 9001:2008 certified Company manufacturing & exporting the finest quality Carbon Steel, Alloy Steel, Stainless Steel Butt Welded Pipe Fittings, High Pressure Forged Fittings & Flanges. Immediate Response, Excellent Quality, Quick Delivery and Customer Satisfaction truly define Werner Flanges Inc.

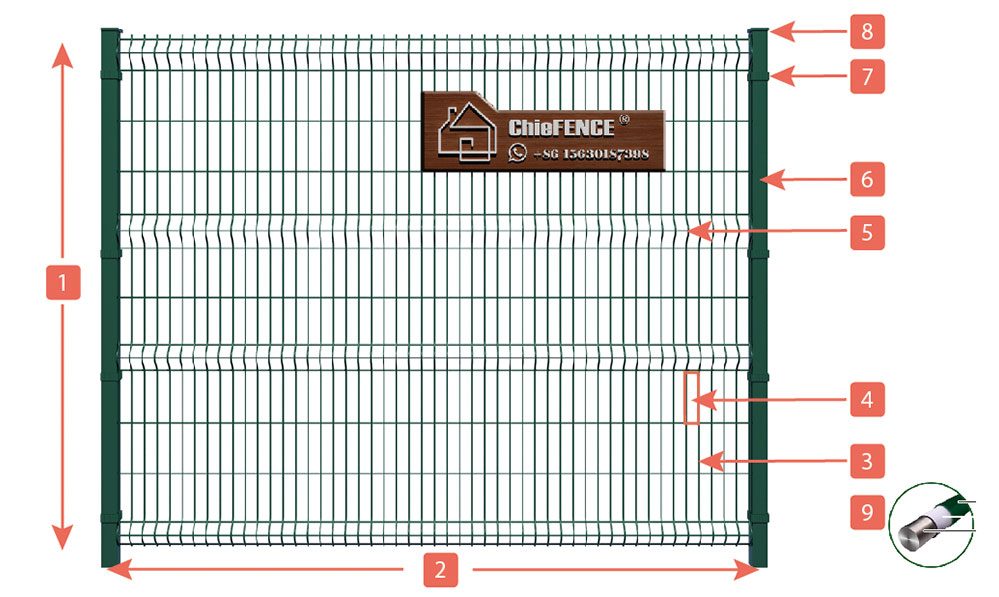

Welded mesh fence likewise called “3D FENCE” “medium-security fencing”. It is an affordable version of steel fence. The panel is bonded with low carbon steel wire. Material Grade: Q195, Surface therapy by Electrostatic polyester powder roaming finishing(Powder-coated) over galvanized products. And after that connect the fencing panels with article by suitable clamps(Clips). Because of its Simple framework, Easy installation and also Beautiful look.More customers regard welded wire mesh security fence as the preferred common protective fence.

Loni ChieFence 3d security fence FEATURES

Lower budget

See-through panel

Anti-rust, Long Service Life

Fast Installation

Customer specs available

Rigidity

In 1984, Yingkaimo Metal Net Co., Ltd. was founded in Anping County Hebei Province, which is the hometown of wire mesh in China. It has Anping Factory, Dezhou Factory and Dubai Office with more than 500 employees. YKM’s annual value of production is about 50 million US dollars, of which 90% of products delivered to more than 70 countries and regions. It is a high-tech enterprise, also a leading company of industrial cluster enterprises in Hebei Province. YKM brand as a famous brand in Hebei Province has been registered in 17 countries around the world for trademark protection. Nowadays, YKM is one of the most competitive metal wire mesh manufacturers in Asia.

Total area of the two factories is about 156000 square meters with more than 400 sets of manufacturing machines, main machines including international advanced technology Japanese-made RGK, German-made Jager and some Chinese-made machines. Annual production capacity for stainless steel mesh is more than 10 million square meters, with range from 1 mesh to 635 mesh of square mesh and highest dutch weave 2800 mesh. The self-designed two epoxy coating production lines are the most advanced epoxy mesh coating equipment in Asia, its annual output is more than 13 million square meters and it makes YKM to be the R&D and supply center for epoxy mesh.

YKM’s main products are stainless steel wire mesh,epoxy coated wire mesh,nickel wire mesh, copper wire mesh, low-carbon steel wire mesh and all kinds of mesh further-processing products.

More information please view:https://www.china-wiremesh.com/

Wholesale airport security fence, is mostly made use of in the flight terminal for defense. The main panel and also V panel is welded with 4.0 mm/5.0 mm low carbon steel cable. The surface area therapy of QYM airport fencing is galvanized + electrostatic polyester powder coated or galvanized + PVC layered.

airport fence supplier Material:

Material: Low-Carbon Iron Wire

Application:

Airport, Garden Fence, Residential, etc

Airport Fence Y Type Fence China Specification

| Panel | Mesh | Wire Thickness | Surface Treatment | Panel Width | Folds NOS. | Panel Height | Fence Height |

| Big Panel | 50x100mm 55x100mm |

4.00mm 4.50mm 5.00mm |

Galvanized and Electrostatic polyester coated or PVC coated | 2.50m 3.00m |

4 | 2000mm | 2700mm |

| 5 | 2300mm | 3200mm | |||||

| 6 | 2600mm | 3700mm | |||||

| 2 | 530mm | 2700mm | |||||

| V panel | 630mm | 3200mm | |||||

| 730mm | 3700mm |

Galvanized Steel Fiber, an alternate concrete reinforcing material are high tensile galvanized steel wires with hooked ends, glued together by the water-soluble adhesive for compactness and uniform dispersion in concrete, to increase the concrete properties by 3-4 times.

Compared with the normal cold drawn steel fiber,in addition to all the advantage of normal steel fiber(such as excellent tensile strength, bending and shearing strength, high tenacity, resistance against the cracking, impact and fatigue ), this fiber still has a better corrosion resistance when the steel fiber exposure to the air, as there is a zinc thickness on the surface of this fiber.

The concrete with GuangYa steel fiber can be widely used in industrial floor,transportation constructions(roads, bridges, tunnels, airport runways), the concrete prefabricated unit, etc…

Advantage to use the China steel fiber in concrete:

High impact resistance.

Remarkably increased flexural strength.

Improved structural ductility.

Exceptional control over cracking.

Increased durability by providing crack control.

Woven Wire Mesh BZ-S001

Material: stainless steel & brass/copper/stainless steel/aluminum

Flexibility: Not flexible

Maximum width: 2.5m

Weight: 7.3kg/m2

Open space: 43%

Surface treatment: PVDF spray paint/PVC coating/electroplating

Stainless Steel Woven Wire Mesh China Detailed instructions

Shade Series BZ woven mesh panels are made of wire or flat steel and the appearance of the mesh is usually rectangular. SHADE series products can adjust the temperature of a building by changing the opening rate and transmission of the mesh. The product can help reduce the energy consumption of buildings and is purchased using different sizes of wire and opening sizes, with a wide range of mesh specifications and appearance. Shade series mesh can be installed as a large area of the facade or used on small areas such as window, partition or handrail filling.

Decorative woven wire mesh wholesale A rainbow of colors

In order to provide customers with more color options, Bzwiremesh can use different processes to make the mesh more colorful.

Bzwiremesh uses paint, fluorocarbon coating, PVC coating or an electroplating process to color the mesh. The usual colors used are gold, champagne, silver, bronze, etc. Color selection can also be made according to the color table provided by the customer.

Bzwiremesh can also produce nets made of brass, copper and other materials with natural colors. By adding brass wire to the BZ stainless steel mesh, the mesh will become a new material.

The “358” in the 358 fence indicates the specific specifications of this type of guardrail: the mesh hole is 76.2mmx12.7mm, namely 3 “x0.5”, and the wire diameter is usually 4.0mm, namely 8#. Of course, 358 guardrail is an expression of the name of this kind of guardrail, and the specific specifications can be adjusted according to the actual needs of customers.

358 Screen general specifications: mesh: 12.7×76.2mm or can be adjusted to 12.5x75mm or 13x75mm according to customer’s actual needs

Wire diameter: 3.0-6.0 mm

Network height: 1.8m, 2.0m, 2.4m, 2.7m, 3.0m, 4.4m, 5.2m

Network width: 2m, 2.5m, 3m.358

Fence net features: strong anti-climbing ability, strengthen the net to increase the extent of its destruction, long use time, durable.

The prison high security protection net in the prison protection net, the use of large diameter high strength alloy steel wire production, with anti-climbing, impact resistance, shear resistance characteristics and good deterrent effect, dedicated to prison detention center, cordon military base and other high security fields.

358 protection net anti-corrosion form: electroplating, hot plating, spraying, dipping, galfan silk.

358 safety net main use: 358 safety net is mainly used in prisons, posts, frontier defense, surrounded areas, military defense and other high risk areas of protection and municipal garden protection net.

The KLS titanium-clad steel plate is a typical metallic laminar composites. It is also referred to as titanium cladding or titanium-steel bimetallics. Normally, they are created by contortion bonding: either hot/cold-roll bonding or explosive bonding. The titanium dressed steel plate gets the inexpensive and high toughness of steel with the superior corrosion resistance of titanium.

The wholesale titanium clad steel plates are widely used in numerous applications as well as services. These include petrochemical & chemical industry especially chloral alkali process, food industry, plant food sector, damp metallurgy, electroplating, vacuum salt production, aquatic engineering, smokeshaft industry, pressure vessels, heat exchangers, desalination industry, and power plant, etc.

Stainless Steel Sprocket Product Description

1. Description: This range of sprockets are made from 304 stainless steel material.

2. Standard: British

3. Feauture:

Corrosion resitance

Good quality

Competitive price

Customized possible

A well screen is a filter device used as the suction portion of a well constructed in a loose or semi-consolidated aquifer. The screen allows water to enter the well from the saturated aquifer, prevents sediment from entering the well, and acts structurally as a support for the aquifer material. When considering well efficiency and the logarithmic cost to the well owner, the importance of having the right screen cannot be overemphasized.

The sieve is resistant to corrosion because it comes into contact with water. In addition, it has high strength and can keep the surrounding structure intact. The openings of the sieve can be small enough to block the large amount of formation around them. The flow of water through the screen will be uniform.

Well screens are recommended for all environmental drilling operations. It helps extend the life of the well and keeps the flow of water unrestricted. Sand and fine powder sand, these fine particles can be filtered out before there is water. Well screens help remove most of this fine material from well water.

Well screens are made from a variety of materials, ranging from rough-hewed hand designs to machine built high-efficiency and long-life models. The value of the screen depends on how much it contributes to the success of the well.

Standard:

- Large open Spaces

- Do not block the slot

- 3.corrosion resistance

- Sufficient column and collapse strength

Functions:

- Easy to develop

- Minimal scaling tendency

- Low head loss through the screen

- Control sand pumping of all types of aquifers

Slot size selection is a critical step to ensure maximum well performance. The screen is usually designed to block 50% of the stratum, and the entry speed for the screen should not exceed 1/10 or 0.1 ft per second. The velocity is calculated by dividing the well production in GPM by the screen open area in square inches.

The gap size of the screen is based on dimensional analysis of the formation sample. After analyzing the composition size of grain in the sample, grain size distribution curve

I can draw it. Several methods can be used to obtain the allocation of information about grain size. The most widely used method is to pass the material through a stacked set of brass or stainless steel sieves. During the screening process, each sieve removes a certain percentage of the whole sample; The best materials are collected in the chassis. Screening analysis not only provides the basis for determining slot sizes, but also other factors that influence screening well design.

We have cooperated with them for many years,although the amount of the monthly is not particularly large, but very stable.We mainly provide the Forklift Brackets,Forklift Shaft Accessories and other small parts.The quality of our products has been recognized by them..Our products are used in the former more,such as Excavator Parts,Excavator Brackets,Roller accessories,Bulldozer accessories,Construction Machinery Hook, Automobile Casting Parts