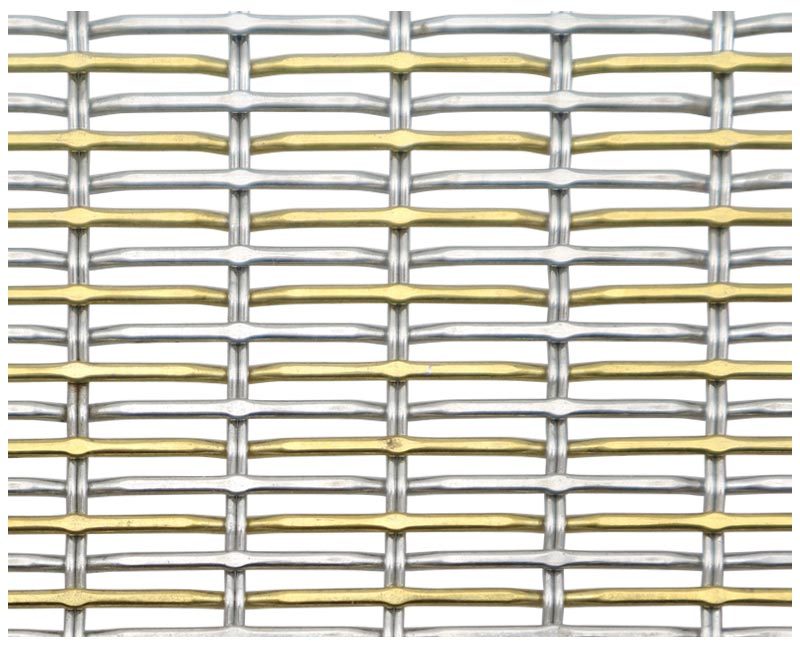

Steel grating is generally made of carbon steel, and the surface is hot-dip galvanized, which can prevent oxidation. It can also be made of stainless steel, and the steel grating has the properties of ventilation, lighting, heat dissipation, anti-skid, explosion-proof and so on.

Steel grating is a kind of steel product with square lattice in the middle, which is cross-arranged with flat steel according to a certain spacing and horizontal bars, and welded by pressure welding machine or manually. Steel grating is mainly used as gutter cover. , steel structure platform plate, steel ladder step plate, etc., the cross bar is generally made of twisted square steel.

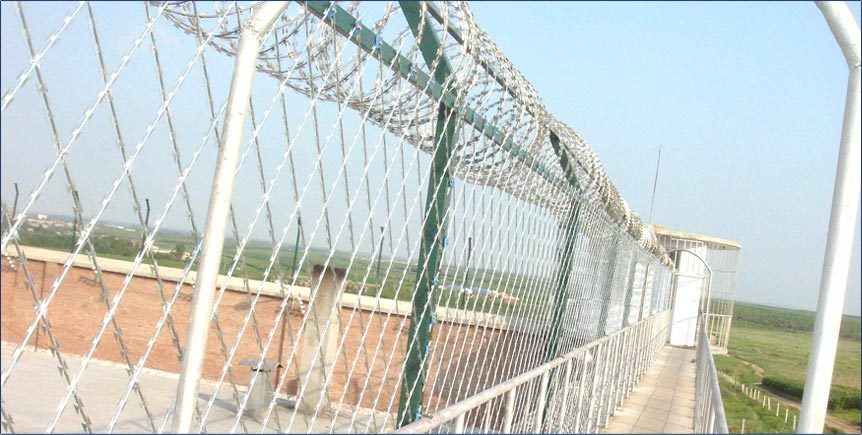

Advantages of steel grating fence

Material saving: the most material saving method under the same load conditions, correspondingly, the material of the supporting structure can be reduced;

Reduce investment: save material, save labor, save construction period, free of cleaning and maintenance;

Simple construction: on the pre-installed support, it is fixed with bolts or welding, and it can be completed by one person;

Save construction period: the product does not need to be reprocessed on site, and the installation is very fast;

Durable: It has been hot-dip galvanized anti-corrosion treatment before leaving the factory, and has strong impact and heavy pressure resistance;

Modern style: beautiful appearance, standardized design, ventilation and light transmission, giving people an overall smooth modern feeling;

Lightweight structure: less material, light structure, and easy to hoist;

Reduce wind resistance: due to good ventilation, the wind resistance is small in case of strong wind, reducing wind damage;

Anti-contamination: no rain, snow and dust;

Other advantages: ventilation, lighting, heat dissipation, explosion-proof, good anti-skid performance;

Simple design: no need for small support beams, simple structure and simplified design

Acid and alkali corrosion ability: in the range of PH 6 to PH 12.5, a stable protective film is formed on the surface of the zinc layer, and the corrosion resistance is good.

Steel grating use

Steel grating is suitable for alloys, building materials, power stations, boilers, shipbuilding, petrochemical, chemical and general industrial plants, municipal construction and other industries. It has the advantages of ventilation and light transmission, anti-skid, strong bearing capacity, beautiful and durable, easy to clean and easy to install.

Steel grating has been widely used in all walks of life at home and abroad, mainly used as industrial platforms, ladder treads, handrails, passage floors, railway bridge sideways, high-altitude tower platforms, drain covers, well covers, road grilles, three-dimensional It can also be used as a fence for parking lots, institutions, schools, factories, enterprises, sports fields, and garden villas.

The KLS titanium-clad steel plate is a typical metallic laminar composites. It is also referred to as titanium cladding or titanium-steel bimetallics. Normally, they are created by contortion bonding: either hot/cold-roll bonding or explosive bonding. The titanium dressed steel plate gets the inexpensive and high toughness of steel with the superior corrosion resistance of titanium.

The wholesale titanium clad steel plates are widely used in numerous applications as well as services. These include petrochemical & chemical industry especially chloral alkali process, food industry, plant food sector, damp metallurgy, electroplating, vacuum salt production, aquatic engineering, smokeshaft industry, pressure vessels, heat exchangers, desalination industry, and power plant, etc.

We have cooperated with them for many years,although the amount of the monthly is not particularly large, but very stable.We mainly provide the Forklift Brackets,Forklift Shaft Accessories and other small parts.The quality of our products has been recognized by them..Our products are used in the former more,such as Excavator Parts,Excavator Brackets,Roller accessories,Bulldozer accessories,Construction Machinery Hook, Automobile Casting Parts

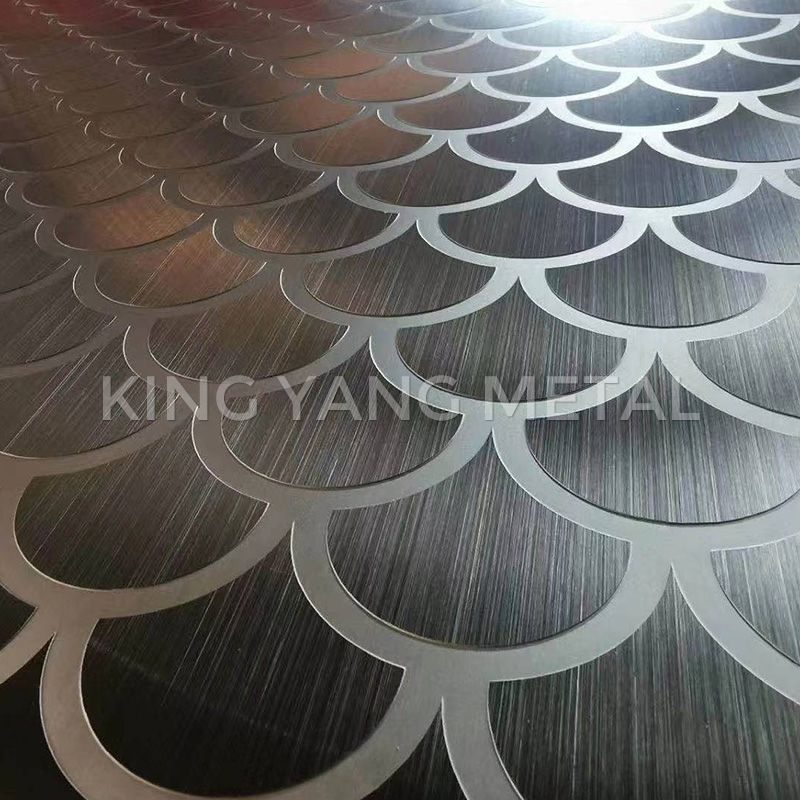

Beijing Shenghe Zhongtai Stainless Steel Co.,Ltd was established in 2009 and located in Beijing, China. In the past 9 years, we have focused the Stainless steel material and surface finish. We have passed the ISO9001 test in 2011, and applied the brand of “SUNSONG”in same year. Following the company developed by 2016, we have built our manufacturing base of Hebei Shengnuo Metal Products Co.,Ltd In Hebei province which is the biggest manufacturing base for Stainless steel surface treatment in North of China.

We have imported the advanced cutting equipment to do the coil cutting and flatting. And we have all process machines such as Hairline finish, 8K finish, Bead blasted, Vibration, Anti-finger print, PVD machine and Bending machine, Laser cutting machine.etc. Especially only we could do the surface treatment for the with more than 1500mm.

And our factory covers an area of more than 16000 square meters, introduces advanced equipments such as CNC shearing machine, keyway planer, Bending and laser machine, provides full-service of stainless steel processing. Our annual outputs has exceeded 3000 mts. We are capable to provide one stop services for architecture stainless steel decoration from stainless steel surface treatment, processing, fabrication, assembly and installation.

SUNSONG Decorative Stainless Steel Sheets is neat and beautiful which widely used into kinds of outside decoration of buildings and elevator decoration. We could do many treatment on the Hairline surface such as etching, PVD and so on. The surface would be different and welcomed by customers.

For more, please click here to customize your stainless steel furniture decoration.

Stainless Steel 304 Buttweld Pipe Fittings are made up of the most commonly used 304 stainless steel material. Buttweld is the most common type of welding applied to fix pipes, fittings and other components together.

We Are Counted Among The Best Manufacturer, Exporter Stockist & Supplier. We Export 60% Of Our Range Of Flanges, Outlets, Pipe Fittings And Forged Fittings To Many Countries Like Usa, Uk, Italy, Malaysia, Gulf Etc.

A well screen is a filter device used as the suction portion of a well constructed in a loose or semi-consolidated aquifer. The screen allows water to enter the well from the saturated aquifer, prevents sediment from entering the well, and acts structurally as a support for the aquifer material. When considering well efficiency and the logarithmic cost to the well owner, the importance of having the right screen cannot be overemphasized.

The sieve is resistant to corrosion because it comes into contact with water. In addition, it has high strength and can keep the surrounding structure intact. The openings of the sieve can be small enough to block the large amount of formation around them. The flow of water through the screen will be uniform.

Well screens are recommended for all environmental drilling operations. It helps extend the life of the well and keeps the flow of water unrestricted. Sand and fine powder sand, these fine particles can be filtered out before there is water. Well screens help remove most of this fine material from well water.

Well screens are made from a variety of materials, ranging from rough-hewed hand designs to machine built high-efficiency and long-life models. The value of the screen depends on how much it contributes to the success of the well.

Standard:

- Large open Spaces

- Do not block the slot

- 3.corrosion resistance

- Sufficient column and collapse strength

Functions:

- Easy to develop

- Minimal scaling tendency

- Low head loss through the screen

- Control sand pumping of all types of aquifers

Slot size selection is a critical step to ensure maximum well performance. The screen is usually designed to block 50% of the stratum, and the entry speed for the screen should not exceed 1/10 or 0.1 ft per second. The velocity is calculated by dividing the well production in GPM by the screen open area in square inches.

The gap size of the screen is based on dimensional analysis of the formation sample. After analyzing the composition size of grain in the sample, grain size distribution curve

I can draw it. Several methods can be used to obtain the allocation of information about grain size. The most widely used method is to pass the material through a stacked set of brass or stainless steel sieves. During the screening process, each sieve removes a certain percentage of the whole sample; The best materials are collected in the chassis. Screening analysis not only provides the basis for determining slot sizes, but also other factors that influence screening well design.

We, Reliable Overseas, are one of the leading wholesalers, exporters, and traders of Stainless Steel Pipes, Nickel Pipes, Inconel Pipes, and much more, established in 2010. Backed by an efficient team of qualified professionals, we are offering all these products in different stipulations.

ASTM A453 Specification describes detailed requirements of grade 660 in class A,B,C & D.

ASTM A453 Grade 660

ASTM A453 Grade 660 Class A Specification

ASTM A453 Grade 660 Class B Specification

ASTM A453 Grade 660 Class C Specification

ASTM A453 Grade 660 Class D Specification

ASTM A453 Grade 660 Pdf

ASTM A453 Grade 660 Bars Stock

ASTM A453 Grade 660 Bolts

ASTM A453 Grade 660 Chemical Composition

ASTM A453 Grade 660 Class A Bars Stock

ASTM A453 Grade 660 Class A Bolts

ASTM A453 Grade 660 Class A Countersunk Screws Csk

ASTM A453 Grade 660 Class A Fasteners

ASTM A453 Grade 660 Class A Forgings

ASTM A453 Grade 660 Class A Heavy Hex Bolts

ASTM A453 Grade 660 Class A Heavy Hex Nuts

ASTM A453 Grade 660 Class A Hex Bolts

ASTM A453 Grade 660 Class A Hex Cap Screws

ASTM A453 Grade 660 Class A Keys

ASTM A453 Grade 660 Class A Pins

ASTM A453 Grade 660 Class A Push Bolts Rods

ASTM A453 Grade 660 Class A Rings

ASTM A453 Grade 660 Class A Rods Stock

ASTM A453 Grade 660 Class A Set Screws Grubs

ASTM A453 Grade 660 Class A Socket Head Cap Screws

ASTM A453 Grade 660 Class A Stud Bolt

ASTM A453 Grade 660 Class A U Bolts

ASTM A453 Grade 660 Class A Washers

ASTM A453 Grade 660 Class A Wire Rod Stock

ASTM A453 Grade 660 Class B 12 Point Screws

ASTM A453 Grade 660 Class B Bars Stock

ASTM A453 Grade 660 Class B Bolts

ASTM A453 Grade 660 Class B Countersunk Screws Csk

ASTM A453 Grade 660 Class B Fasteners

ASTM A453 Grade 660 Class B Forgings

ASTM A453 Grade 660 Class B Heavy Hex Bolts

ASTM A453 Grade 660 Class B Heavy Hex Nuts

ASTM A453 Grade 660 Class B Hex Bolts

ASTM A453 Grade 660 Class B Hex Cap Screws

ASTM A453 Grade 660 Class B Keys

ASTM A453 Grade 660 Class B Pins

ASTM A453 Grade 660 Class B Push Bolts Rods

ASTM A453 Grade 660 Class B Rings

ASTM A453 Grade 660 Class B Rods Stock

ASTM A453 Grade 660 Class B Set Screws Grubs

ASTM A453 Grade 660 Class B Socket Head Cap Screws

ASTM A453 Grade 660 Class B Stud Bolt

ASTM A453 Grade 660 Class B U Bolts

ASTM A453 Grade 660 Class B Washers

ASTM A453 Grade 660 Class B Wire Rod Stock

ASTM A453 Grade 660 Class C Bars Stock

ASTM A453 Grade 660 Class C Bolts

ASTM A453 Grade 660 Class C Countersunk Screws Csk

ASTM A453 Grade 660 Class C Fasteners

ASTM A453 Grade 660 Class C Forgings

ASTM A453 Grade 660 Class C Heavy Hex Bolts

ASTM A453 Grade 660 Class C Heavy Hex Nuts

ASTM A453 Grade 660 Class C Hex Bolts

ASTM A453 Grade 660 Class C Hex Cap Screws

ASTM A453 Grade 660 Class C Keys

ASTM A453 Grade 660 Class C Pins

ASTM A453 Grade 660 Class C Push Bolts Rods

ASTM A453 Grade 660 Class C Rings

ASTM A453 Grade 660 Class C Rods Stock

ASTM A453 Grade 660 Class C Set Screws Grubs

ASTM A453 Grade 660 Class C Socket Head Cap Screws

ASTM A453 Grade 660 Class C Stud Bolt

ASTM A453 Grade 660 Class C U Bolts

ASTM A453 Grade 660 Class C Washers

ASTM A453 Grade 660 Class C Wire Rod Stock

API 6A Bolting Torque for Flanges (SI Units)

API 6A Bolting Torque for Flanges (USC Units)

ASTM A453 Grade 660 Class D API 6A Full Thread Stud Bolt

ASTM A453 Grade 660 Class D API 6A Tap End Stud Bolt

ASTM A453 Grade 660 Class D Bars Stock

ASTM A453 Grade 660 Class D Bolts

ASTM A453 Grade 660 Class D Countersunk Screws Csk

ASTM A453 Grade 660 Class D Fasteners

ASTM A453 Grade 660 Class D Forgings

ASTM A453 Grade 660 Class D Heavy Hex Bolts

ASTM A453 Grade 660 Class D Heavy Hex Nuts

ASTM A453 Grade 660 Class D Hex Bolts

ASTM A453 Grade 660 Class D Hex Cap Screws

ASTM A453 Grade 660 Class D Keys

ASTM A453 Grade 660 Class D Pins

ASTM A453 Grade 660 Class D Push Bolts Rods

ASTM A453 Grade 660 Class D Rings

ASTM A453 Grade 660 Class D Rods Stock

ASTM A453 Grade 660 Class D Set Screws Grubs

ASTM A453 Grade 660 Class D Socket Head Cap Screws

ASTM A453 Grade 660 Class D Stud Bolt

ASTM A453 Grade 660 Class D U Bolts

ASTM A453 Grade 660 Class D Washers

ASTM A453 Grade 660 Class D Wire Rod Stock

ASTM A453 Grade 660 Countersunk Csk Screws

ASTM A453 Grade 660 Fasteners

ASTM A453 Grade 660 Forgings

ASTM A453 Grade 660 Heavy Hex Bolts

ASTM A453 Grade 660 Heavy Hex Nuts

ASTM A453 Grade 660 Hex Bolts

ASTM A453 Grade 660 Hex Cap Screws

ASTM A453 Grade 660 Keys

ASTM A453 Grade 660 Mechanical Properties

ASTM A453 Grade 660 Pins

ASTM A453 Grade 660 Push Bolts

ASTM A453 Grade 660 Rings

ASTM A453 Grade 660 Rods

ASTM A453 Grade 660 Set Screws

ASTM A453 Grade 660 Socket Head Cap Screws

ASTM A453 Grade 660 Stud Bolts

ASTM A453 Grade 660 U Bolt

ASTM A453 Grade 660 Washers

ASTM A453 Grade 660 Wire

Jade Special Metals is India’s 10th largest supplier, trader & Exporter of Stainless Steel, Carbon steel pipes and round bar. We are specialised in Stocking & Distributing various Stainless Steel, carbon steel pipes, round bar & sheet plates to worldwide for specific & urgent requirements.

Product Name: Hot Dipped Galvanized Iron Wire

Item Code: Smart Craftsmen-HDG Wire

Surface Treatment: Electro Galvanized.

Raw Material: SAE1006 SAE1008 Q195 Q235 or Others.

Tensile Strength: 330- 550MPA

Package: Customize.

Place of Origin: Hebei, China.

Loading Port: Tianjin Port

Smart Craftsmen Galvanized iron wire is designed to prevent rust and shiny silver. It is strong, durable and versatile. It has been widely used in landscaping, construction, woven hardware cloth and mesh. Wholesale Galvanized wire is divided into hot-dip galvanized wire and electro-galvanized wire (cold galvanized wire). Galvanized steel wire has good flexibility

Sex and toughness. It has the characteristics of large thickness of galvanized layer and corrosion resistance. Hot-dip galvanized iron wire China is made of low-carbon steel wire, which is drawn, pickled, derusted, annealed and coiled.

Electro-galvanized iron wire is made of selected low-carbon steel through drawing, galvanizing and other processes. Electro-galvanized iron wire has the characteristics of thick galvanized layer, good corrosion resistance and strong galvanized layer.

UNS S31254 / Alloy 6Mo / WNR 1.4547 / F44 / 254SMO Super Austenitic Stainless Steel

UNS S31254 is a high corrosion resistant Super Austenitic Stainless Steel and provide excellent corrosion resistance in severe corrosion environments such as high temperature seawater.

We offer a comprehensive selection of seamless/welded stainless steel pipes, including the UNS S31254 super austenitic stainless steel pipe, also known as 254SMo or WNR 1.4547. Made with high-quality materials and under strict manufacturing standards, these pipes are perfect for a variety of applications in seawater handling systems, desalination plant equipment, chemical processing, and flue gas desulphurization units.

UNS S31254 Stainless Steel Pipe Features:

– High corrosion resistance: Made with alloy UNS S31254, these pipes are highly resistant to corrosion in harsh environments, including high chloride and acidic conditions.

– High strength: The WNR 1.4547 pipes are made with a super austenitic stainless steel with high strength, making them durable and reliable for a range of applications.

– Excellent weldability: The 6mo stainless steel pipes are easy to weld and fabricate, making them a versatile solution for complex piping systems.

– Compliant with industry standards: The 254SMO Super Austenitic Stainless Steel pipes meet the manufacturing standards of ASTM A269, ASTM A312, and ASTM A213, ensuring quality and reliability.

UNS S31254 Chemical Composition (%)

| % | C | Mn | P | S | Si | Ni | Cr | Mo | N | Cu |

| Min | 17.5 | 19.5 | 6.0 | 0.18 | 0.50 | |||||

| Max | 0.02 | 1.00 | 0.030 | 0.010 | 0.80 | 18.5 | 20.5 | 6.5 | 0.25 | 1.00 |

254SMO Physical Properties:

| Density | 8.02 Mg/m³ |

| Melting Range | 1360-1405 ℃ |

UNS S31254 Stainless Steel Pipe Applications:

– Seawater handling systems: The UNS 31254 Stainless Steel pipes are ideal for use in seawater handling systems due to their high corrosion resistance and strength.

– Desalination plant equipment: The WNR 1.4547 Stainless Steel tubes are widely used in desalination plant equipment due to their ability to withstand high chloride and saltwater environments.

– Chemical processing: The UNS S31254 pipes are suitable for chemical processing due to their corrosion resistance and thermal stability.

– Flue gas desulphurization unit: The Alloy 6Mo Stainless Steel pipes are ideal for use in flue gas desulphurization units due to their resistance to acids and ability to handle high temperatures.

Manufacturing Standards:

ASTM A213

ASTM A312

ASTM A269

Also individual customer specifications, as a professional UNS 31254 Stainless Steel pipes and tubing supplier, Hengyang is committed to providing high-quality stainless steel pipes to meet the needs of our customers. Contact us today for more information on the UNS S31254 pipe and other products in our collection.

Door Handle YD-DHA01

Item no.: YD-DHA01

Description: door handle

- Suitable for uPVC doors, composite doors and wooden doors

- Reversible for right and left handed doors

- Sprung handles

- Youding Door HardwareSuitable for the most popular door locks with 92mm lock centres and 122mm fixing centres

Material: Zinc alloy, Stainless steel frame

Process: die casting, machining, surface treatment

Surface: PVD finished, satin finished, black painting, satin nickel, mirror finished, customized.

Door and window handles from YOUDING is with guarantee based on competitive price. Welcome inquiry.

Ky Metal is professional etched stainless steel sheets manufacturer and supplier, offering elevator Etched Stainless Steel Sheet, Wall cladding Etched Stainless Steel Sheet, Stainless Steel Etching Sheets,Decorative SS Etched Sheets, SS Colored Etched Sheets

Etched stainless steel sheets are thin plates of stainless steel that have been chemically treated to produce a pattern or design on the surface. With 8K mirror plate, drawing sheet and sandblasting sheet as the base plate, the surface of the object is further processed after etching. Etching version can be processed by a variety of complex processes such as local blending, wire drawing, gold inlaying and local titanium, to achieve the effect of light and dark patterns and brilliant colors.

Stainless Steel Sheet with Etched Finish is widely used in architectural decoration. Especially in the choice of elevator board, the general use of mirror panel as the elevator bottom sheet, and then according to the needs of the pattern processing, so that the overall effect has a three-dimensional sense, reflect its beautification value.

The installation and use of the elevator should consider its value and safety performance. A variety of different patterns etched out of stainless steel, as well as the use of different colors, so that the elevator space is no longer dull, dull, more lively.

Material: Uncoated Thick Cast Iron.

The Enameled Cast Iron Covered CasseroleIs Thick And Durable For 60 Years. It Has No Chemical Coating And Is Evenly Heated And Not Sticky.

The Vent Hole Of The Cover Is Effectively Pressed, And The Stainless Steel Bead Screw Is Fixed For A Long Time And Is Not Easy To Loose.

Excellent Thermal Conductivity, Good Heat Preservation, Uniform Heat Conduction, Long Residual Temperature, And Added Flavor To The Stew Ingredients.If you have any question on Weining Enameled Cast Iron Covered. We will give the professional answers to your questions

Fujian Dongya Machinery Co., Ltd. was founded in 1988 in China West Strait Economic Zone, Putian, Fujian, China. It covers an area of 127,050㎡, with capital assets of 430 million RMB and registered capital of 116 million RMB. It has 1,120 employees, including 130 experienced engineers and management staff with senior professional titles.

For over 30 years, DY piston rings produced by Fujian Dongya Machinery Co.Ltd., provide companies such as Dachangjiang Group, Zongshen Power, Longcin General Motors, Lifan Technology, Qianjiang Motorcycle, Honda Power, Sundiro Honda, CFmoto Power, QS Suzuki, Briggs & Stratton, STIHL,etc. for motorcycles, general-purpose engine, drones, and outboard engine manufacturers general support.

Piston ring products are widely exported to all over the world such as Europe, USA, Middle East, South America, Africa, and Southeast Asia, with good global reputation for its high quality and market share.

Somos un fabricante profesional de bridas, accesorios de tubería, accesorios forjados en la India, nos especializamos en la fabricación de todos los tamaños, estándar, tipo, etc. Somos capaces de proporcionar una amplia gama de materiales, desde existencias, para satisfacer sus necesidades. Desde material no estándar altamente especializado hasta artículos listos para usar, desde la producción hasta el prototipo, desde mínimos bajos hasta corridas de fábrica, el fabricante de bridas tiene la experiencia para resolver sus requisitos más difíciles.

At Wonderful, we use advanced equipment to provide you with various exactness cnc machining service, including milling, turning, EDM, wire cutting, EDM and so on. Using our 3-axis, 4-axis and 5-axis CNC machining centers, our skilled machinists can use a variety of plastic and metal materials to manufacture turning and milling parts. Our CNC machining center can not only produce perfect samples for you, but also customize more small batch products for you, making us a one-stop service provider for your advanced design and small batch product needs.https://www.wdfprecision.com/

Hebei Abter Steel Pipe Co.,Ltd is a professional steel exporter in China. We specialize in the production of steel product, including stainless steel, galvanized steel, pre-painted steel and carbon steel pipes, ceramic lined composite steel pipe and fittings,elbow, bending and the related products, covering pipe & tube , fitting, bar etc. Based on the standing better and faster service,we have been the best partner both of the steel factories and suppliers.

We offer perfect service to the mills and bring in the highest quality levels at the most competitive price for our customers. Our entire operations are focused on the precise demands of our customers needs.

Our production bases cover most of China, with a production capacity of 300,000 MT annually, Size range from O.D: 8–141mm, W.T.0.8–12mm. (cold drawn tube). O.D 141mm–610mm, W.T :5–25mm(hot rolled pipe). With a strict quality assurance system to the manufacturing process, including steel making and finished products inspection.

Factory and industrial products

In addition to our steel products for construction, we also offer a variety of steel fabrication products for use in industry. We provide local factories with steel cutting, fabricating, and distributing pipe fittings anc composite pipes.

Our versatility ensures we will be able to provide you with the steel products you require to to complete a project, from start to finish.

Our team

Our team are highly trained and experienced in servicing and producing all types of steel supplies. Whether you’ve got a large construction project, or need parts for industrial machinery, our team of steel fabrication consultants will ensure that your project is provided with the parts you need, when you need them.

We Are Counted Among The Best Manufacturer, Exporter Stockist & Supplier. We Export 60% Of Our Range Of Flanges, Outlets, Pipe Fittings And Forged Fittings To Many Countries Like Usa, Uk, Italy, Malaysia, Gulf Etc. We Would Appreciate To Get Your Esteemed Enquires And Look Forward To The Pleasure Receiving Your Valuable Response.

Product Item:HY005

Manufacturing: Cold Rolled/Cold Drawn

Type: Seamless/Welded

Surface: Annealed and Passivated

Application Fields: heat exchanger, boiler, evaporator

Alloy 825/ UNS N08825/ W.Nr.2.4858/ Incoloy® 825

Alloy 825 tube, also known as Incoloy 825 pipe, W.Nr. 2.4858 or UNS N08825, this nickel alloy steel is a combination of nickel, chromium, and iron, with small amounts of molybdenum, copper, and titanium to enhance its resistance to corrosive environments, especially in chloride-containing media. 825 tubing is a durable and reliable material that is widely used in applications that involve harsh environments and high temperatures.

UNS N08825 Chemical Composition:

| % | Ni | Cr | Fe | Mn | C | Cu | Si | S | Al | Ti | Mo |

| Min | 38.0 | 19.5 | 22.0 | 1.5 | 0.6 | 2.5 | |||||

| Max | 46.0 | 23.5 | 1.0 | 0.05 | 3.0 | 0.5 | 0.03 | 0.2 | 1.2 | 3.5 |

Features of Alloy 825 Tube:

- Excellent Corrosion Resistance: Alloy 825 tube is highly resistant to corrosion, pitting, and stress corrosion cracking in various corrosive environments like nitric acid, sulfuric acid, phosphoric acid, and others.

- High-Temperature Strength: The inconel 825 tube can withstand high temperatures up to 550°C (1020°F) and still maintain its excellent mechanical properties.

- Good Weldability: Incoloy 825 pipe can be easily welded with various welding processes, including gas tungsten arc welding, gas metal arc welding, and shielded metal arc welding.

Incoloy® 825 Physical Constants:

| Density | 8.19 Mg/m³ |

| Melting Range | 1370-1400 ℃ |

Alloy 825 Tube Application:

- Chemical Processing Equipment: Alloy 825 tube is used in the chemical processing industry for making process vessels, reactors, tanks, and other equipment that need to be resistant to corrosion.

- Heat Exchanger Tube UNS N08825: Incoloy 825 tubing is commonly used as heat exchanger tubing in various industries like chemical processing, oil and gas, and power generation.

- Pollution Control: Alloy 825 tube is widely used in pollution control systems due to its excellent corrosion resistance, widely used in scrubber systems for removing harmful gas emissions from power plants and other industrial facilities.

- Petroleum Refining: Inconel 825 pipeis used in petroleum refining applications due to its ability to withstand highly corrosive environments, commonly used in heat exchangers, piping systems, and other equipment that comes into contact with sulfuric acid, hydrochloric acid, and other corrosive substances.

- Offshore Oil and Gas Production: The incolony tubeis widely used in offshore and onshore oil and gas production, where corrosion-resistant materials are needed to withstand harsh corrosive environments.

* Marine: W.Nr.2.4858 is used in marine applications, including seawater cooling systems, desalination plants, and offshore platforms.

* Acid Production: 825 pipe is commonly used in the production of acids such as sulfuric acid, phosphoric acid, and nitric acid due to its excellent resistance to corrosion. It is used in heat exchangers, piping systems, and other equipment that come into contact with these corrosive substances.

* Nuclear Fuel Reprocessing: Incoloy 825 seamless pipe is commonly used in nuclear fuel reprocessing applications due to its ability to withstand highly corrosive environments. It is used in equipment such as storage tanks, piping systems, and heat exchangers that come into contact with radioactive materials and corrosive substances.

Alloy 825 is available in wide variety of shapes and forms including pipe, tube, fitting, flange, sheet, plate, round bar, forging stock, flat bar, wire, hexagon. The various forms of UNS N08825 from Hengyang Piping meet different critical standards like ASTM, ASME, DIN, EN, ISO and clients’ specification. For detailed information about customized pipe and fittings, please contact us!