Double-twist stranding machines, high-performance twisting machines

Double Twist Stranding Machineare effective, compact production units primarily for use in the manufacture of highly flexible braids, bundled braids, for stranding pairs of wires, triples, quadruple designs …

The machine concept differs from the single-twist system in that one rotor turn generates two cable twists / turn. The braid is given the first twist at the stranding point of the system feed. At this point, the stranding material still has twice the length of lay of the desired final geometry. The final braid length of lay with the second stranding twist is only completed at the second turning point, before being introduced back into the static coil former.

BOW DOUBLE TWIST STRANDING MACHINE

Application for:

Multistrand 7 or 19 copper wire, aluminum wire, tinned copper conduct etc. Also multistrand insulated conduct for power cable, data cable, control cable etc. Laying up of 2/3/4 cores of small size building wires.

Bow Double Twist Stranding Machine Description:

Payoff

Double twist stranding machine

PLC control system with color touch screen

Advanced function (Optional):

1:Motorized payoff or back-twist payoff, tension keep stable from start to end.

2:Bow material : carbon fibre

3:Brake: serve motor

4:Motorized driven capstan. Lay length set on touch screen, no need to change gear mechanically.

5:Auto lubrication system: regularly lubricate important parts to prolong machine service life.

COMPUTER SIMULATION OF AN INDUSTRIAL WIRE DRAWING PROCESS

Wire Stranding Machine is an important industrial process. Wires are reduced in diameter through a series of die/capstan combinations which provide the desired reduction steps. Typical wire drawing machines within BICC Cables Ltd use up to twenty-one dies in one line and it is necessary to optimise the die drafting for each machine and final wire diameter to obtain good machine efficiency and high quality product. An important aspect in the manufacturing process is to avoid wire breakages with the resultant loss of production due to short final lengths and the associated time required to restring the drawing machine. In order to optimise the conditions for each machine and wire size, computer simulations of the process are used to predict performance by estimating factors such as the ratio of drawing stress to ultimate tensile stress, drawing force, back tension and heat generated.

A computer simulation of the multi-line wire drawing process for copper wire has been modelled by the Wrexham Technology Centre of BICC Cables Ltd using a bulk model. The redundant work during the drawing process was included by formulation and equations for the redundant deformation were derived that were in good agreement with published experimental work.

A new computer simulation has been developed to predict the performance of wire drawing process. The model uses a one dimensional explicit finite difference method to determine the plastic deformation in the dies. The redundant work formulation was used as in the previous simulation. This paper describes the numerical methods used and compared the results from the new computer simulation with the previous bulk model. Significant differences are predicted in the stress ratios, drawing force and heat generated for process predictions. The new simulation of the plastic deformation in the dies also indicated optimum semi-die angles away from the traditional eight degrees.

7 Wire Tubular Type Stranding Machine

Owing to the vast industry experience and in depth knowledge of this domain, we are offering a huge collection of high quality 7 Wire Tubular Type Stranding Machine. These products are manufactured using optimum quality raw material. These products are easy to install and requires low maintenance. Customers can avail these products from us at market-leading prices

Basket Type Stranding Machine

Basket Type Stranding Machine is mainly used to strand not only copper/aluminum conductor for the electric wire and cable but also the cable core, steel core, and steel rope. Machine’s make-up: pay-off, driving part, cylindrical part, hydraulic brake device, wire –bobbin frame, die-holder, haul-off device, spindle-type take-up/traversing (Φ50 bar traversing) and an electrical control part, etc.

Rigid Stranding Machine

The Rigid Stranding Machine is used for stranding CU, Al wires, and conductors. Stranding unilay and reverse concentric, round, compressed, compacted or sector-shaped ( straight or spiraled) as per customer requirements.

Main features:

Self-supporting rigid rotor design with 1 6 12 18 24 30 36 Bobbin Cage

High efficiency and speed

Bobbins mounted on pintles

A line drive by A.C. or D.C. motors with electronic or mechanical synchronization between line components.

Different braking device for bobbins

Centralized lubricating system for bearing

Disk type Pneumatic brake for Cage.

Machines with or without back twist

MMI /PLC Equipped, optional

Easy Lay Setting

High Speed Tubular Stranding Machine

High Speed Tubular Stranding Machine with back twist, for 1+6 Bobbin copper / aluminum round & compact conductors and steel wire stranding. This strander is for manufacturing high carbon & low carbon steel wire rope, copper & aluminum conductor

Bow Type Stranding Machine

The Bow Type Stranding Machine is suitable for a wide range of productions, obtained with high speed and productivity; the back twist process gives high quality products. The Bow stranders use components made with most modern materials, like carbon fiber for the bows, tungstene carbide for bushes, hardened steel for rollers.The control of tension of the cores is assured with electro-mechanical or pneumatic self compensated brake, with set up by control panel.The safe use is assured with control of bearing temperatures and supports vibration.The machine is protected with a soundproof cover, with pneumatic open, inside fans and lights.Is possible the bobbins side loading with a motorized trolley, that avoids the use of bridge cranes and reduces dramatically the total loading time of the line.

For Cables Industry:

Stranding of conductors made with copper, aluminium, aluminium alloy, aluminium steel reinforced or supported;

Laying up of 2 – 7 round insulated cores for low and medium voltage;

Laying up of 2 – 7 straight sector shaped insulated cores, with the rotating cradles version;

Possible application of fillers and tapes of every type.

Tubular stranding Machine

The Tubular Stranding machine consists of bearing stands made of welded steel for the tube bearings. Up to reel size of 630mm .The stranding rotor is built up from welded tubes with wire guidings outside the tube. The reels are held in cradles, which are positioned inside the tube. A light beam along the complete length of the machine monitors, if the pneumatically (optional)operated reel-pintles are securely closed and the cradles are in safe condition. The machine is equipped with wire break detectors for each segment, pneumatic disk-breaks and individual drives for the Stranding Rotor, the Capstan and the Take-Up. The operator’s desk gives full control over parameters like Rotor-speed, lay-length and production length.

Main Features:

• Machine placed on a Rigide steel frame with rotor support, fixed on the floor for an easy installation

• Tube rotating on encircling bearings or rollers

• Machine able to work in torsion or total back twist with the possibility of partial back twist

• Wire back tension kept constant from full to empty spool payoff

• Wire/strand break detector for each payoff unit(optional)

• Spool loading/unloading by crane

• Pneumatic pintles equipped with safety locking system

• Independent driving motors for tube, capstans and takeup units

• A.C. motors with flux vector control inverter

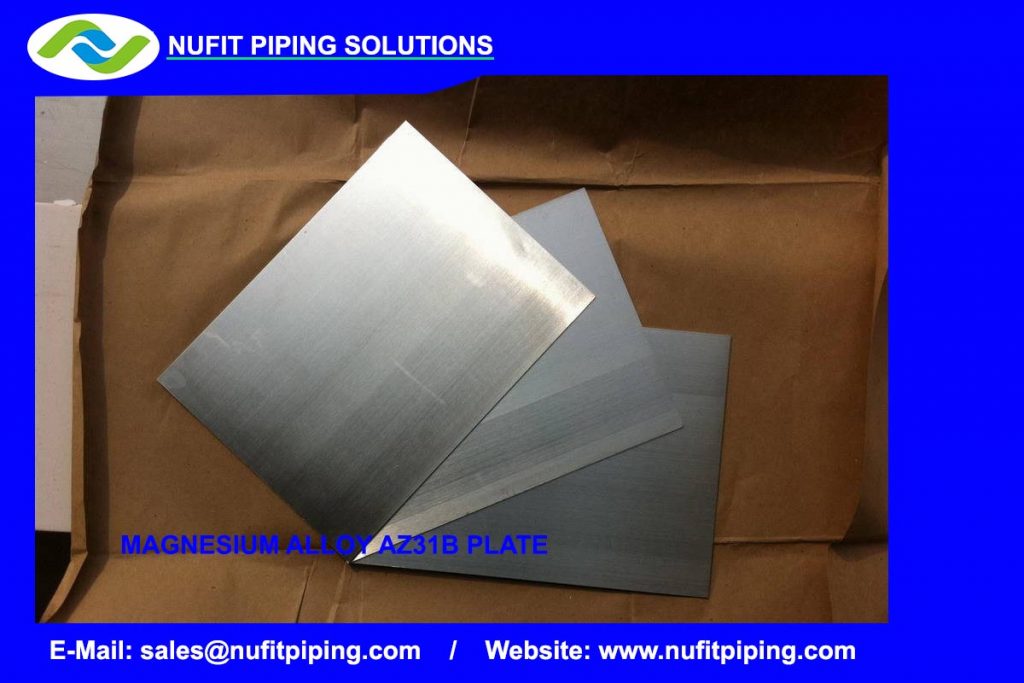

UNS S31254 / Alloy 6Mo / WNR 1.4547 / F44 / 254SMO Super Austenitic Stainless Steel

UNS S31254 is a high corrosion resistant Super Austenitic Stainless Steel and provide excellent corrosion resistance in severe corrosion environments such as high temperature seawater.

We offer a comprehensive selection of seamless/welded stainless steel pipes, including the UNS S31254 super austenitic stainless steel pipe, also known as 254SMo or WNR 1.4547. Made with high-quality materials and under strict manufacturing standards, these pipes are perfect for a variety of applications in seawater handling systems, desalination plant equipment, chemical processing, and flue gas desulphurization units.

UNS S31254 Stainless Steel Pipe Features:

– High corrosion resistance: Made with alloy UNS S31254, these pipes are highly resistant to corrosion in harsh environments, including high chloride and acidic conditions.

– High strength: The WNR 1.4547 pipes are made with a super austenitic stainless steel with high strength, making them durable and reliable for a range of applications.

– Excellent weldability: The 6mo stainless steel pipes are easy to weld and fabricate, making them a versatile solution for complex piping systems.

– Compliant with industry standards: The 254SMO Super Austenitic Stainless Steel pipes meet the manufacturing standards of ASTM A269, ASTM A312, and ASTM A213, ensuring quality and reliability.

UNS S31254 Chemical Composition (%)

| % | C | Mn | P | S | Si | Ni | Cr | Mo | N | Cu |

| Min | 17.5 | 19.5 | 6.0 | 0.18 | 0.50 | |||||

| Max | 0.02 | 1.00 | 0.030 | 0.010 | 0.80 | 18.5 | 20.5 | 6.5 | 0.25 | 1.00 |

254SMO Physical Properties:

| Density | 8.02 Mg/m³ |

| Melting Range | 1360-1405 ℃ |

UNS S31254 Stainless Steel Pipe Applications:

– Seawater handling systems: The UNS 31254 Stainless Steel pipes are ideal for use in seawater handling systems due to their high corrosion resistance and strength.

– Desalination plant equipment: The WNR 1.4547 Stainless Steel tubes are widely used in desalination plant equipment due to their ability to withstand high chloride and saltwater environments.

– Chemical processing: The UNS S31254 pipes are suitable for chemical processing due to their corrosion resistance and thermal stability.

– Flue gas desulphurization unit: The Alloy 6Mo Stainless Steel pipes are ideal for use in flue gas desulphurization units due to their resistance to acids and ability to handle high temperatures.

Manufacturing Standards:

ASTM A213

ASTM A312

ASTM A269

Also individual customer specifications, as a professional UNS 31254 Stainless Steel pipes and tubing supplier, Hengyang is committed to providing high-quality stainless steel pipes to meet the needs of our customers. Contact us today for more information on the UNS S31254 pipe and other products in our collection.

Beijing Shenghe Zhongtai Stainless Steel Co.,Ltd was established in 2009 and located in Beijing, China. In the past 9 years, we have focused the Stainless steel material and surface finish. We have passed the ISO9001 test in 2011, and applied the brand of “SUNSONG”in same year. Following the company developed by 2016, we have built our manufacturing base of Hebei Shengnuo Metal Products Co.,Ltd In Hebei province which is the biggest manufacturing base for Stainless steel surface treatment in North of China.

We have imported the advanced cutting equipment to do the coil cutting and flatting. And we have all process machines such as Hairline finish, 8K finish, Bead blasted, Vibration, Anti-finger print, PVD machine and Bending machine, Laser cutting machine.etc. Especially only we could do the surface treatment for the with more than 1500mm.

And our factory covers an area of more than 16000 square meters, introduces advanced equipments such as CNC shearing machine, keyway planer, Bending and laser machine, provides full-service of stainless steel processing. Our annual outputs has exceeded 3000 mts. We are capable to provide one stop services for architecture stainless steel decoration from stainless steel surface treatment, processing, fabrication, assembly and installation.

SUNSONG Decorative Stainless Steel Sheets is neat and beautiful which widely used into kinds of outside decoration of buildings and elevator decoration. We could do many treatment on the Hairline surface such as etching, PVD and so on. The surface would be different and welcomed by customers.

For more, please click here to customize your stainless steel furniture decoration.

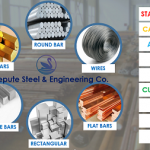

We Are Counted Among The Best Manufacturer, Exporter Stockist & Supplier. We Export 60% Of Our Range Of Flanges, Outlets, Pipe Fittings And Forged Fittings To Many Countries Like Usa, Uk, Italy, Malaysia, Gulf Etc.

Stainless Steel Sprocket Product Description

1. Description: This range of sprockets are made from 304 stainless steel material.

2. Standard: British

3. Feauture:

Corrosion resitance

Good quality

Competitive price

Customized possible

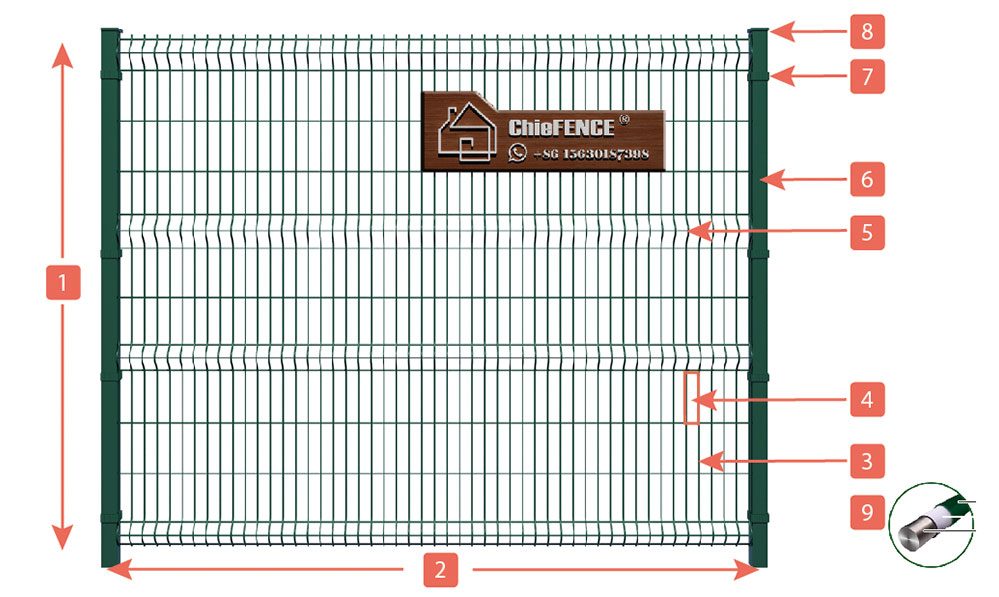

The “358” in the 358 fence indicates the specific specifications of this type of guardrail: the mesh hole is 76.2mmx12.7mm, namely 3 “x0.5”, and the wire diameter is usually 4.0mm, namely 8#. Of course, 358 guardrail is an expression of the name of this kind of guardrail, and the specific specifications can be adjusted according to the actual needs of customers.

358 Screen general specifications: mesh: 12.7×76.2mm or can be adjusted to 12.5x75mm or 13x75mm according to customer’s actual needs

Wire diameter: 3.0-6.0 mm

Network height: 1.8m, 2.0m, 2.4m, 2.7m, 3.0m, 4.4m, 5.2m

Network width: 2m, 2.5m, 3m.358

Fence net features: strong anti-climbing ability, strengthen the net to increase the extent of its destruction, long use time, durable.

The prison high security protection net in the prison protection net, the use of large diameter high strength alloy steel wire production, with anti-climbing, impact resistance, shear resistance characteristics and good deterrent effect, dedicated to prison detention center, cordon military base and other high security fields.

358 protection net anti-corrosion form: electroplating, hot plating, spraying, dipping, galfan silk.

358 safety net main use: 358 safety net is mainly used in prisons, posts, frontier defense, surrounded areas, military defense and other high risk areas of protection and municipal garden protection net.

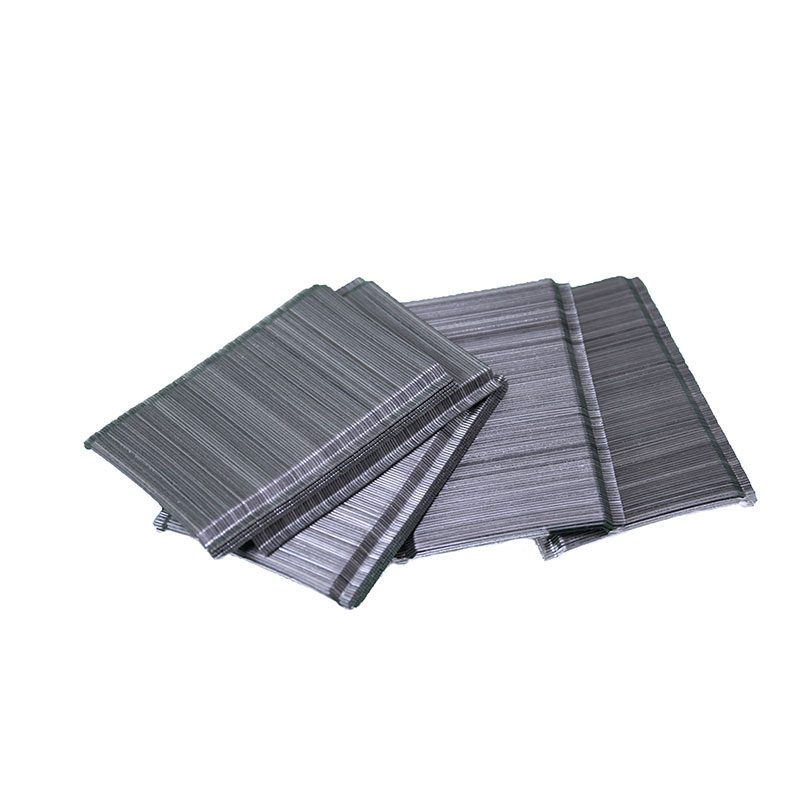

Galvanized Steel Fiber, an alternate concrete reinforcing material are high tensile galvanized steel wires with hooked ends, glued together by the water-soluble adhesive for compactness and uniform dispersion in concrete, to increase the concrete properties by 3-4 times.

Compared with the normal cold drawn steel fiber,in addition to all the advantage of normal steel fiber(such as excellent tensile strength, bending and shearing strength, high tenacity, resistance against the cracking, impact and fatigue ), this fiber still has a better corrosion resistance when the steel fiber exposure to the air, as there is a zinc thickness on the surface of this fiber.

The concrete with GuangYa steel fiber can be widely used in industrial floor,transportation constructions(roads, bridges, tunnels, airport runways), the concrete prefabricated unit, etc…

Advantage to use the China steel fiber in concrete:

High impact resistance.

Remarkably increased flexural strength.

Improved structural ductility.

Exceptional control over cracking.

Increased durability by providing crack control.

Welded mesh fence likewise called “3D FENCE” “medium-security fencing”. It is an affordable version of steel fence. The panel is bonded with low carbon steel wire. Material Grade: Q195, Surface therapy by Electrostatic polyester powder roaming finishing(Powder-coated) over galvanized products. And after that connect the fencing panels with article by suitable clamps(Clips). Because of its Simple framework, Easy installation and also Beautiful look.More customers regard welded wire mesh security fence as the preferred common protective fence.

Loni ChieFence 3d security fence FEATURES

Lower budget

See-through panel

Anti-rust, Long Service Life

Fast Installation

Customer specs available

Rigidity

Woven Wire Mesh BZ-S001

Material: stainless steel & brass/copper/stainless steel/aluminum

Flexibility: Not flexible

Maximum width: 2.5m

Weight: 7.3kg/m2

Open space: 43%

Surface treatment: PVDF spray paint/PVC coating/electroplating

Stainless Steel Woven Wire Mesh China Detailed instructions

Shade Series BZ woven mesh panels are made of wire or flat steel and the appearance of the mesh is usually rectangular. SHADE series products can adjust the temperature of a building by changing the opening rate and transmission of the mesh. The product can help reduce the energy consumption of buildings and is purchased using different sizes of wire and opening sizes, with a wide range of mesh specifications and appearance. Shade series mesh can be installed as a large area of the facade or used on small areas such as window, partition or handrail filling.

Decorative woven wire mesh wholesale A rainbow of colors

In order to provide customers with more color options, Bzwiremesh can use different processes to make the mesh more colorful.

Bzwiremesh uses paint, fluorocarbon coating, PVC coating or an electroplating process to color the mesh. The usual colors used are gold, champagne, silver, bronze, etc. Color selection can also be made according to the color table provided by the customer.

Bzwiremesh can also produce nets made of brass, copper and other materials with natural colors. By adding brass wire to the BZ stainless steel mesh, the mesh will become a new material.

In 1984, Yingkaimo Metal Net Co., Ltd. was founded in Anping County Hebei Province, which is the hometown of wire mesh in China. It has Anping Factory, Dezhou Factory and Dubai Office with more than 500 employees. YKM’s annual value of production is about 50 million US dollars, of which 90% of products delivered to more than 70 countries and regions. It is a high-tech enterprise, also a leading company of industrial cluster enterprises in Hebei Province. YKM brand as a famous brand in Hebei Province has been registered in 17 countries around the world for trademark protection. Nowadays, YKM is one of the most competitive metal wire mesh manufacturers in Asia.

Total area of the two factories is about 156000 square meters with more than 400 sets of manufacturing machines, main machines including international advanced technology Japanese-made RGK, German-made Jager and some Chinese-made machines. Annual production capacity for stainless steel mesh is more than 10 million square meters, with range from 1 mesh to 635 mesh of square mesh and highest dutch weave 2800 mesh. The self-designed two epoxy coating production lines are the most advanced epoxy mesh coating equipment in Asia, its annual output is more than 13 million square meters and it makes YKM to be the R&D and supply center for epoxy mesh.

YKM’s main products are stainless steel wire mesh,epoxy coated wire mesh,nickel wire mesh, copper wire mesh, low-carbon steel wire mesh and all kinds of mesh further-processing products.

More information please view:https://www.china-wiremesh.com/

Wholesale airport security fence, is mostly made use of in the flight terminal for defense. The main panel and also V panel is welded with 4.0 mm/5.0 mm low carbon steel cable. The surface area therapy of QYM airport fencing is galvanized + electrostatic polyester powder coated or galvanized + PVC layered.

airport fence supplier Material:

Material: Low-Carbon Iron Wire

Application:

Airport, Garden Fence, Residential, etc

Airport Fence Y Type Fence China Specification

| Panel | Mesh | Wire Thickness | Surface Treatment | Panel Width | Folds NOS. | Panel Height | Fence Height |

| Big Panel | 50x100mm 55x100mm |

4.00mm 4.50mm 5.00mm |

Galvanized and Electrostatic polyester coated or PVC coated | 2.50m 3.00m |

4 | 2000mm | 2700mm |

| 5 | 2300mm | 3200mm | |||||

| 6 | 2600mm | 3700mm | |||||

| 2 | 530mm | 2700mm | |||||

| V panel | 630mm | 3200mm | |||||

| 730mm | 3700mm |

Glued Steel Fiber, an alternate concrete reinforcing material are high tensile steel wires with hooked ends, glued together by the water-soluble adhesive for compactness and uniform dispersion in concrete, to increase the concrete properties by 3-4 times.

steel fiber reinforced concrete supplier improve the mechanical properties concrete and materials such as ductility,

energy absorption, fatigue, and toughness. This fiber helps to controls plastic shrinkage cracking in concrete; helps reduce or eliminate need for conventional reinforcement.

Application of Glued steel fiber reinforced concrete

- For concrete flooring

Industrial floors

Joint-less floors

Floors-on-piles

Lightly loaded floors

Liquid tight floors & composite metal decking

- stainless steel fiber supplierFor Hard Standing & Heavy Duty

Parking lots

Playgrounds

Airport runways

Taxiways

Maintenance hangers

Access roads & workshops

Ports& Containers for port pavements

Container terminals

Bulk storage areas access roads

For army tank movement

- steel fibers for concrete reinforcementOther Applications

Foundations

Traditional cellar and basement walls

Compression layers

Tunnel engineering

Compared with the GuangYa loose steel fiber the operation and advantages of the glued steel fiber:

- Add the steel fiber directly into the belt, the whole row of steel fiber as a whole, evenly dispersed in the concrete corner

- The water-soluble glue begins to dissolve in a row of steel fibers in the premise of the dispersion, it is again dispersed in every corner of the mono filament fiber, showing the perspective in the concrete of the fiber mesh, which plays an integral strengthening.

- Compared with mono-filament fibers, China bonded steel fiberswill not be bundled to ensure that the fibers in concrete do not coalesce and distribute evenly.

Glued steel fibers are loose hook-end fibers that are bonded together in a row. The great difference between loose fiber and glued fiber is that the former is easy to clog and the latter is easy to disperse evenly.

Ceramic lined pipe is made through the self-propagating high-temperature synthesis (SHS) technique.

Self-propagating High-temperature Synthetic process

Self-propagating high-temperature synthesis (SHS) is used to describe a process in which the initial reagents (usual powders), when ignited, spontaneously transforms into products due to the exothermic heat of reaction.

The combination of high rigidity of ceramic and high elasticity of steel gives the pipe unmatchable features like abrasion resistant, heat resistant, and corrosion-resistant material for use in the fields of power generation, metallurgy, mining, and chemical industry, etc. It has many advantages over steel pipes, cast stone pipes, and steel-plastic compound pipes.

Usage of Ceramic Lined pipe

The ceramic-lined pipe transportation has been widely used in the industries of electric power, metallurgy, coal, petroleum, chemical engineering, building materials, mechanism, and so on.

The ceramic lined elbow throughout the power, metallurgy, coal, petroleum, chemical, building materials, machinery, and other industries, and high-speed development. When lining the wear-resistant ceramic elbow to deliver high grinding material (such as ash, coal, ore powder, etc.), there is a lining of wear-resistant ceramic elbow wear fast, especially the elbow Wear faster. When lining a ceramic-lined elbow to deliver a highly corrosive gas, liquid or solid, there is a problem that the lined wear-resistant ceramic elbow is corroded and is quickly damaged.

There is a problem that it is expensive to use a heat-resistant steel pipe when the material having a higher temperature is conveyed in the lining of the wear-resistant ceramic elbow. After lining the wear-resistant ceramic elbow, these problems are solved.

The ceramic lined elbow is widely used in wear and tear of mine filling material, ore powder and tailings transportation, coal-fired power plant powder, smelting, ash and other things lined with wear-resistant ceramic elbow are also very appropriate.

The ceramic lined pipe, Elbows, Reducer, Tees, and others manufactured in our factory have been used in over 200 thermal power plants, more than 50 mines, and the industries of coal, building materials, mechanism, petroleum, and so on.

Abrasion

Ceramic layer Ceramic Lined Reducer Pipe with flange reducer Al2O3 content greater than 89%, micro-hardness HV1000-1500, which has high abrasion resistance, wear resistance more than ten times higher than carbon steel after quenching, superior tungsten carbide drill.

Application range

- coal pulverizing system of power plant pipeline, including, powder transmission pipeline, thick powder separator pipeline, coal drop pipe, combustion system of a windpipe, a secondary air pipe, three pipeline and burner pipelines, in addition to ash slagging system the discharge pipe, powder pipe, dry ash conveying pipe;

- Iron and steel plant raw material conveying pipeline, collecting pipe, dust pipe, ash pipe, ash pipe, mixing pipe, grinding export pipeline, coal pipeline, coal pipeline, separator pipe, burner radius pipe, etc.;

- Cement plant selection machine outlet pipe, choose machine inlet pipe, pipe dust pipe, vertical mill outlet pipe, circulating air duct, high-temperature air blower, lower material pipe, etc.;

- Petroleum, chemical, mining, coal, coal washing plant, smelting, paper, aluminum, building materials, powder engineering, food machinery, and other processing and conveying material pipes.

Corrosion

Ceramic materials are neutral, chemically stable, have excellent corrosion resistance and acid resistance, resistant to various inorganic acids, organic acids, organic solvents, and their degree of corrosion of stainless steel is more than ten times.

Temperature

Temperature above 2000celsius degree, long-term work in the range of -50 -900 celsius degree.

Easy welding.

The ceramic adjustable tube can be welded, flanged, flexible connectors, and other fast way links, very easy to install.

Clean and easy maintenance

Smooth walls, can prevent scaling, fouling, and self-cleaning functions. Tightness.

Remarks:

- Under the direction of the arrow diagram for the export direction.

- Bend radius is usually 1.5-5 times the diameter of steel pipe (1.5-5D).

- Othe specifications of the composite pipe can be manufactured according to the user requirements.

- The weight is calculated by theoretics, maybe have some tolerance, and real weight will be weigh-in after they finish.

Hoop strength is the resistance against radial pressure. The strength of the ceramic-lined steel composite pipe is 300 to 500MPa.

Features and Advantages of ceramic lined pipe

Ceramic Liner pipe is a high technology production technology-self-fuel high-temperature clutch synthesis method.

1). High Abrasion Resistant:

Vickers hardness of the corundum lining is HV1100 to1500, as high as that of tungsten-cobalt hard alloys, and the abrasion resistance is 20 times as carbon steel pipes. The composite ceramic-lined steel elbow was used in a mining plant for about fifty thousand hours. The general service life of a common steel elbow is about 700 hours.

2). Corrosion Resistant:

Corundum is a neutral material and is acid-proof and fouling-free.

3). Heat Resistant:

Ceramic lined composite steel pipes can work under circumstances of -50 to 800 Celsius degree.

4). Lower Weight and Convenient Installation:

The ceramic-lined steel pipes are lighter than alloy pipes, cast iron pipes, and cast stone pipes and can be welded or connected through flanges, which reduces the expense of transportation and makes the pipes easier to install.

For the pipes with the same sizes, types, and lengths, the weight of the ceramic pipe is about 1/2 of the wearable cast alloy steel pipe’s, while the cost has reduced 10%~20% per meter.

The weight of ceramic-lined steel pipe is about 1/3 of the cast stone bent pipes, 1/2 of the cast stone straight pipes.

Ceramic (Corundum: a-Al2O3) lined abrasion resistant straight pipe and fittings are lined with highly abrasion-resistant ceramic by SHS ——-Self-propagating High-temperature Synthetic process.

- The ceramic-lined steel composite pipe can be joined by welding the steel pipe layer.

- Ceramic-lined pipes can take place of expensive stainless steel, titanium, nickel, cast stone, or alloy pipes.

- Extended service life can also reduce maintenance costs.

Self-Propagating Ceramic Pipe

Self-propagating ceramic steel pipes create a new generation of abrasion and corrosion-resistant engineering pipelines.

The self-propagating ceramic steel pipe has very good wear resistance, Excellent corrosion resistance, and Excellent thermal resistance performance.

SHS-self-propagating ceramic steel pipe and elbow create a new generation of abrasion and corrosion-resistant engineering pipeline. The composite pipe is composed of three layers: ceramic, intermediate, and steel layers.

The ceramic layer is formed by molten alumina at a temperature above 2500 degrees. The molten alumina produced from the reaction Fe2O3+2Al=2Fe+Al2O3 spreads on the inside wall of the steel pipe under the influence of a centrifugal force, then solidifies, so the ceramic layer has high density and smooth surface and bonds to the steel pipe.

Applicable Industries:

- The pipe needs excellent wear resistance property: Power plant, Mining, Sea Port, Coal Plant, And pipe for transporting the powder, slurry, sand, etc.

- Coal washing plant, pipe for transporting coal and other material.

- Pipe for transporting the melted aluminum.

- Any pipe which needs to wear protection, corrosion protection, etc.

Benefits:

- Excellent wear resistance, Alumina content of the ceramic liner is higher than 95%, Hardness HV1000-1500. The wear protection performance is more than 10 times better than carbon steel after quenching,

- Excellent corrosion resistance, stable chemical properties.

- Excellent thermal resistance performance up to 2000℃ Can be used in the area from-50℃ to 900℃ for a long time.

- Can be connected with another pipe by welding, flange and soft fast connecting, and easy installation.

HOT-DIPPED GALVANIZED STEEL COIL

- INTRODUCTION:

Hot-dipped galvanized steel coil is made from steel plate, which is dipped into the dissolved zinc bath, with a zinc layer on the surface. It mainly adopts the continuous galvanizing production process. That means the cold rolled coils are put into the dissolved zinc bath for continuous galvanizing process.

- EVER-SHINE Steel Coil APPLICATION:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It’s especally useful for countless outdoor and industrial applications.

They are mainly used in building roof, door, window, roller shutter doorand automobile’s vehicle shell, chassis, door, trunk lid, Oil tank, and fender, and also electric equipments, such as refrigerator base and shell and so on.

- SPECIFICATION

| THICKNESS | 0.11mm-5.0mm |

| WIDTH | 600-1250mm Max |

| COATING MASS | 20g-400g/m2 |

| Surface Structure | Zero Spangle,Regular Spangle,Minimized Spangle |

| SURFACE TREATMENT | Chromated/non-Chromated,Oiled/non-Oiled,skinpassed/non-skinpassed |

| COIL INNNER DIAMETER | 508mm or 610mm |

Copper Mould Tube & Plate

We specially in supplying Copper Mould Tube, Crystallizing equipment of continuous casters, Mould cooling jacket, Repair of Metallurgical Copper Mould Tube, etc.

Equipments & Spare parts for Continuous Casting Machine.

- Copper mould tube( square, rectangle and round )

- Crystallizing equipment of continuous casters

- Mould cooling jacket.

- repair of copper tube moulds

The copper alloys chosen for the moulds must maintain their physical properties at the operating temperatures of the continuous casting process.

The temperature gradation from the inner wall of the mould to the outside face of the mould can cause serious distortion problems, and Metallurgical Copper Mould Tube is imperative that the correct alloy is chosen for the various operating conditions.

Square Copper mould tube STANDARD MATERIALS

Phosphorus de-oxidised copper

This alloy has been proven to be excellent for the manufacture of moulds in the continuous casting of billets. The main composition of this alloy are Cu +Ag 99.90min, P0.0015 / 0.040.

Copper -Silver alloy

The addition of a small amount of silver, whilst not increasing the melting point of copper, does increase the recrystallisation temperature by almost 100℃, and also helps to give better thermal conductivity at the operating temperatures.

This alloy is normally used in moulds for the continuous casting of blooms and slabs .In this case, the moulds are much thicker than in the billet moulds, and the moulds temperature can be higher. The main composition of this alloy are Cu+Ag99.90 min. Ag 0.08 / 0.12 O 0.004 / 0.012.

The continuous casting of molten steel into billets, blooms and slab products, has been highly refined over the years into an extremely sophisticated system. The continuous casting process is expected to produce metallurgically sound products at the lower possible cost, and this is being achieved in many steelworks throughout the world.

Copper moulds have played an important role in the development of the continuous casting process. Their funcition is to receive the molten steel and to allow rapid heat transfer from the steel to the cooling water to enable quick solidification.

The mould must exhibit excellent thermal conductivity, be resistant for thermal erosion ,and be resistant to distortion from thermal stress. So far only copper and a few copper alloys meet the above conditions, both economically and technically.

Mould cooling jacket supplier SOLIDIFICATION

The rate of solidification in the continuous casting process dictates the speed of production. The molten steel, which is in contact with the inner faces of the copper mould, starts to sllidify as rapidly as the heat is extracted, forming a shell. The shell increases in thickness as more heat is extracted, and eventually total solidfication is achieved. the process is similar to the solidification of ingots in ingot moulds. In continuous casting, the whole process is speeded up, with the aim to produce and homogeneous shell growth. Consequently, the mould is an important part of the continuous casting process, and the manufactured quality of the mould plays and important role in their length of life.

INNER SURFACE COATINGS

Over the years, Metallurgists and Engineers have been working together to develop better continuous casting moulds. The steel companies require a more economical mould which will give a longer service life. Surface coating of the inner walls of the mould has given the best results to date. Coatings available are Chromium and Nickel plating. Also, a combination of the two give good results on slab casting.

SPECIFICATIONS OF COPPER MOULD

Square 60 x 60 – 350 x 350 (mm)

Rectangle 120 x 160 – 180 x 300 (mm)

Diameter 100-400 (mm)

Size(mm): 90×90, 100×100, 110×110, 115×115, 120×120

130×130, 135×135, 140×140, 143×143, 150×150

155×155, 160×160, 165×165, 175×175, 180×180

200×200, 220×220, 100×170, 100×173, 130×240

150×200, 150×210, 150×220, 160×200, 160×220

150×225, 160×235, 165×225, 175×225, 180×220

200×240, 240×240, 235×235

Radius(mm): 4000, 5000, 5250, 6000, 7000, 7500, 8000, 9000, 10250, 10300, 11000, 12000

Length(mm): 700, 750, 780, 790, 800, 810, 812, 850, 900, 1000

Stainless Steel 304 Buttweld Pipe Fittings are made up of the most commonly used 304 stainless steel material. Buttweld is the most common type of welding applied to fix pipes, fittings and other components together.

We have cooperated with them for many years,although the amount of the monthly is not particularly large, but very stable.We mainly provide the Forklift Brackets,Forklift Shaft Accessories and other small parts.The quality of our products has been recognized by them..Our products are used in the former more,such as Excavator Parts,Excavator Brackets,Roller accessories,Bulldozer accessories,Construction Machinery Hook, Automobile Casting Parts

Roopam Steel is top manufacturer & supplier of seamless steel pipe welded tubes in ferrous and non ferrous material, Stockist of high quality tubular piping products and accessories in India. Call us for more Info at +91-22-6639 4333.

Shijiazhuang Ruite Pump Co., Ltd. is one of the high-enterprises integrating research, design, production and sales systems, produces slurry pumps, dredge pumps, gravel pumps, desulphurization pumps and pump parts. Our standard TAH(R) slurry pump, THH slurry pump, TSP(R) Vertical slurry pump, TG(H) gravel pump and all spare parts are interchangeable with Warman (weir) slurry pumps and spares. Meanwhile, Custom slurry pumps and spare parts are welcome. We will open mold and manufacure as your design drawing or samples. With more than 20years of accumulation and development, our factory was founded in 2003, the covering area is more than 3000 square meters, the registered capital is 50 millions. Our slurry pumps are mainly used in coal, mining, FGD in power station, metallurgy, dredging, petro-leum, chemical industry, building material, paper and other industries.

First-rate goods ! Reliable quality! Our Ruite pump have won well-deserved reputation at home and abroad. Our slurry pumps have been exported to Russia, South Africa, Zambia, Australia, Indonesia, Canada, Peru, Chile, Italy, France, Thailand, Singapore, Vietnam, Philippines, Mexico, Saudi Arabia, UAE…more than 37 countries. The professional pre-service, in-service and after-service provide customer perfect slurry solution.

Ductile iron Drainage pipe is available in a range of diameters from 80mm to 1600mm and are suitable for both potable water transmission and distribution (in accordance with BS EN 545) and sewerage (in accordance with BS EN 598).

China tongmao ductile pipe is available in a range of diameters from 80mm to 1600mm and are suitable for both potable water transmission and distribution (in accordance with BS EN 545) and sewerage (in accordance with BS EN 598).

Ductile iron Drainage pipe is simple to joint, can be laid in all weather conditions and often without the need for selected backfill. Its high safety factor and ability to accommodate ground movement make it the ideal pipeline material for a wide range of applications.

ductile iron pipeline wholesale have a number of advantages over other pipe materials:

Easy to install

Full range of accessories are widely available

Suited to a host of applications both above and below ground

Strength of the material allows it to withstand significant internal pressure and also makes it less susceptible to impact damage

It has the nature of iron, the performance of steel, excellent corrosion resistance, good ductility and easy installation.

The main components are carbon, silicon, manganese, sulfur, phosphorus and magnesium.

The ductile iron pipe price list is very reasonable.

Cast iron pipe drain pipe、the cast iron sewage pipe and the cast iron gas pipe are widely used.

The wall thickness of the 150mm cast iron pipe is 6mm.

Bath Handle Pull YD-BHP12

Item no.: YD-BHP12

Description: Door Handle Pull

Sanitary Hardware Material: Aluminium/zinc alloy

Size: available, customized

Usage: bath hardware, furniture hardware

Process: die casting, machining, surface treatment

Surface: PVD finished, satin nickel, black, mirror finished, bronze, customized