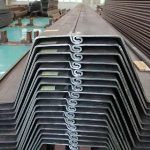

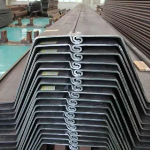

Cold formed steel sheet pile, also known as cold formed sheet pile, is made from steel coils that are passed through different rolls at ambient temperature. Due to their light weight and high cross-sectional modulus, cold-formed profiles are widely used all over the world.

We have different types of cold formed steel sheet piles in our catalog, U-shaped sheet piles and Z-shaped sheet piles. We can offer all steel grades and properties. The most widely used standards are EN 10249-1 and EN 10249-2. Steel grades are S235 JRC, S275 JRC, S355 JOC or others. In North America, construction companies and traders follow ASTM A328 and 328M standards. In many countries, cold formed sheet piles are used for almost all types of projects. In the Philippines, for example, cold formed sheet piles can be found everywhere in Manila, Cebu, Davao, Batangas, General Santos, Cagayan de Oro, etc. Metal interlocking sheet piles, also known as piling sheets or Australian sheet piles, can be made into sheet pile foundations and mined at a lower price.

In many temporary projects, such as bridge piers and abutments, canals, and excavations, you can use cold rolled sections. In permanent applications, such as deep foundations, containment, tunnels, environments, you can also find cold rolled profiles. Cold forming has created many innovations in the pile industry, such as wider, deeper, and multi-thickness sections. This is a great advantage for design houses and customers. Cold-formed sheet piles were introduced more than thirty years ago. There are now more than a dozen plants worldwide producing cold-formed sheet piles compared to the six hot-rolled plants worldwide.

Special shapes and sizes of sheet piles are manufactured to meet the requirements of joints and other similar situations. In fact, cold formed piles never have the tendency to break away from the interlock as many hot rolled steel sheets do under difficult driving conditions. When you have a cofferdam, retaining wall, parking lot, or bulkhead project, you can contact us.

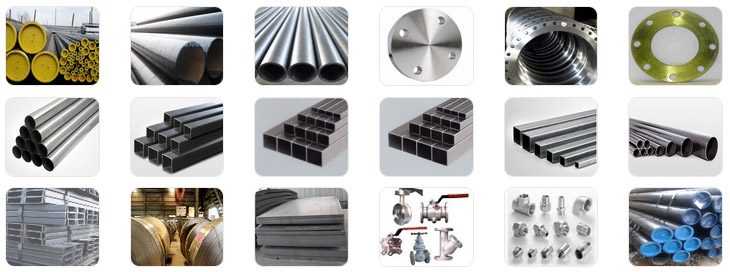

Union Steel Industry Co., Ltd as member of United Steel Industry Group, specialized in steel pipe and pipe fittings designing, manufacturing, stocking and exporting in China.

Our products

- SMLS &ERW Steel Pipe(especially processing galvanized/FPE/3LPE/Grooved/pipe & flange welding …etc with very competitive price)

- Tubing&casing (Professional standard API 5CT PSL1/2 J55 K55 P110 Q125….)

- Structure steel profile(Mainly provide international general standards, advantage prices for some EU standards or other standards)

- steel plate &pipe fittings(flange,elbow,reducer,valve..etc)

We basically have steel in stock and support fast delivery:

- Steel pipe : ASTM A53;ASTM A106;ASTM A333;ASTM A500;ASTM A252 ..etc or Equivalent

- Structural steel hollow section: EN 10025、EN 10219 S235/S275/S355..etc or Equivalent

- Steel plate : ASTM A36, ASTM A283, ASTM A572..etc or Equivalent

- We can also provide various conventional stainless steel products.

You can forward needs on alisa@union-steels.com i will provide you best price .

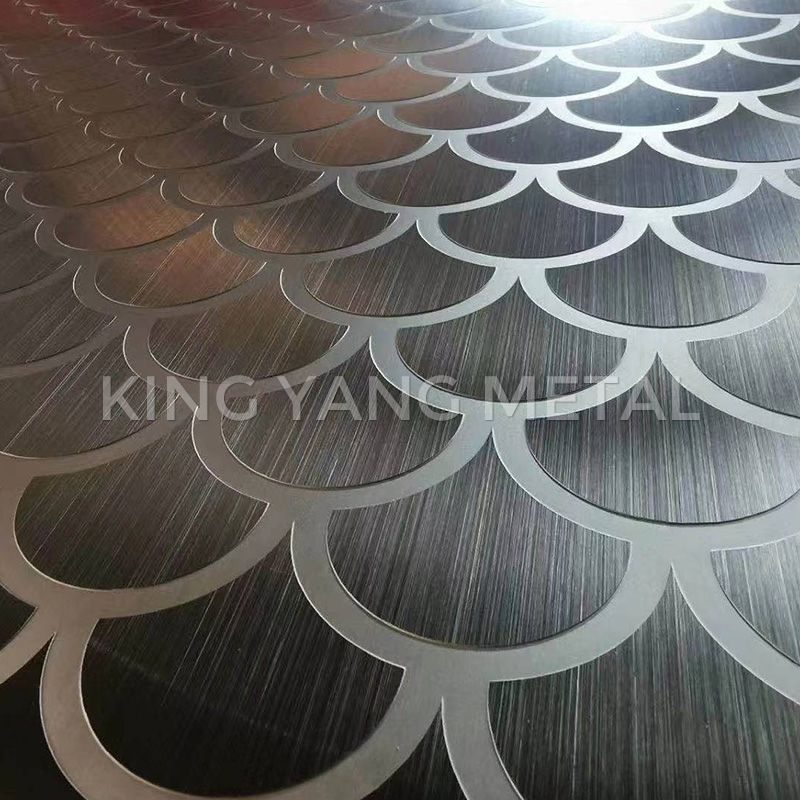

Ky Metal is professional etched stainless steel sheets manufacturer and supplier, offering elevator Etched Stainless Steel Sheet, Wall cladding Etched Stainless Steel Sheet, Stainless Steel Etching Sheets,Decorative SS Etched Sheets, SS Colored Etched Sheets

Etched stainless steel sheets are thin plates of stainless steel that have been chemically treated to produce a pattern or design on the surface. With 8K mirror plate, drawing sheet and sandblasting sheet as the base plate, the surface of the object is further processed after etching. Etching version can be processed by a variety of complex processes such as local blending, wire drawing, gold inlaying and local titanium, to achieve the effect of light and dark patterns and brilliant colors.

Stainless Steel Sheet with Etched Finish is widely used in architectural decoration. Especially in the choice of elevator board, the general use of mirror panel as the elevator bottom sheet, and then according to the needs of the pattern processing, so that the overall effect has a three-dimensional sense, reflect its beautification value.

The installation and use of the elevator should consider its value and safety performance. A variety of different patterns etched out of stainless steel, as well as the use of different colors, so that the elevator space is no longer dull, dull, more lively.

No.8 Mirror stainless steel mirror sheets is kind of mirror stainless steel sheets, like a mirror, through polishing stainless steel surface treatment, mirror effect can be divided into general grinding, fine grinding, super fine grinding, etc. No.8 Mirror stainless steel sheet process, specifications, colors, patterns and so on can largely meet the different needs of each customer. No 8 mirror finish stainless steel sheet is widely used in a variety of decorative design, as building Interior exterior decoration, screen, door, elevator, lift , wall decoration, cover panel, table or decorative surface, as well as stainless steel anchor line, stainless steel TV wall, column edge, etc; It is an essential foundation for high-end architectural decoration projects.

No. 8 mirror stainless steel sheet offers several advantages over other types of stainless steel sheets. Its highly reflective surface creates an aesthetically pleasing finish that is ideal for decorative applications such as architecture, interior design, and signage. The mirror finish also makes the surface easier to clean and maintain, as it resists fingerprints and smudges. In addition, No. 8 mirror stainless steel sheet is durable, corrosion-resistant, and has a long lifespan, making it a cost-effective choice for many applications.

Why choose us as your No.8 Mirror Stainless Steel Sheet Manufacturer?

As a mirror polished stainless steel sheet manufacturer, We are expertise in polishing stainless steel allows us to produce high-quality mirror finishes with consistent reflectivity and smoothness. Our ability to customize the size, thickness, and grade of stainless steel plates ensures that your customers can find the perfect product for their specific needs. Additionally, our experience in the industry allows you to provide competitive pricing and fast turnaround times, making us a reliable and trusted supplier. Overall, our expertise in mirror polished stainless steel plates offers our customers a durable and aesthetically pleasing solution for their decorative and functional needs.

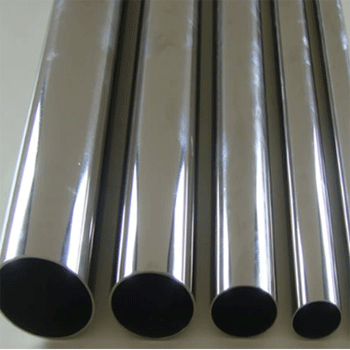

An ISO 9001:2008 Certified Company, The Metal Factory is India’s most trusted manufacturer, exporter and supplier of stainless steel tubes (ASTM A 312 304/304L, 316/316L), carbon steel pipes (ASTM A A106, A53, API 5L), alloy steel seamless pipes (ASTM A335 P11, P22), mild steel pipes, industrial steel tubes, galvanized steel pipes and black steel pipes.

We can manufacture and supply steel pipes which can be fabricated to customers design and specification in a variety of length and thickness requirements. We can also offer cold drawn seamless steel tubes to meet the custom design and specifications of our customers. We specialise in the manufacture and supply of cold drawn seamless steel tubes, and large diameter stainless steel welded pipes (100% X-Ray Tested). ISO 9001:2008 Certification ensures consistency in our operations and testing procedures.

Steel Pipes and Steel Tubes supplied by The Metal Factory are used across wide range of industries including food processing, power generation, oil and gas, petrochemicals, petroleum pipelines, medical equipment, biopharma, pharmaceuticals, electrical engineering, fertilizer industry, dairy processing, boiler manufacturing and nuclear energy among others.

METLINE has been proudly servicing the steel pipe industry for over 40 years, as a major supplier and manufacturer of custom size steel pipes and steel tubes. We are the exclusive suppliers of stainless steel welded pipes, stainless steel seamless tubes, stainless steel tubing, alloy steel seamless pipes, boiler steel tubes, heat exchanger tubes, capillary tubes, coiled tubing, and galvanized steel pipes. We are serving all major cities and countries in their needs for steel pipes and steel tubes.

Our products are supplied to all major Industrial areas and cities in India such as Mumbai, Delhi, Bangalore, Hyderabad, Ahmedabad, Chennai, Kolkata, Surat, Pune, Nagpur, Indore, Thane, Bhopal, Visakhapatnam, Vadodra, Nashik, Faridabad, Rajkot, Aurangabad, Ranchi, Coimbatore, Raipur, Mysore, Bhubaneswar, Salem, Bhilai, Bhiwandi, Bikaner, Mangalore, Kochi (Cochin), Bhavnagar, Tirupur, Ankleshwar, Assam, Siliguri, Jamshedpur, Warangal, Nellore, Agartala and Thoothukudi.

Our high quality steel pipes, good customer service, and in house pipes and tubes processing capabilities have made us one of the emerging suppliers for steel pipes and tubes in Middle East countries including Bahrain, Cyprus, Egypt, Iran, Iraq, Israel, Jordan, Kuwait, Lebanon, Oman, Palestine, Qatar, Saudi Arabia, Syria, Turkey, United Arab Emirates and Yemen.

India’s #1 Supplier of Stainless Steel Pipes/Tubes, Chrome Moly Pipes, Black Pipes, Galvanised Pipes, Carbon Steel Pipes

Stainless Steel Pipes, Carbon Steel Tubes, Alloy Steel Tubes, MS Pipes Production and Stock Range

Outside Diameter: 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock, OD Size Steel Tubes available Ex-stock

Thickness Range: 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Type: Seamless / ERW / Welded / Fabricated / CDW

Key Steel Pipes & Tubes Products & Grades

1. Stainless Steel Seamless Pipes & Tubes – 304, 304/L, 316/L, 904L, 310S, 321H, 347H, 446

2. Stainless Steel Welded Pipes & Tubes – 304, 304/L, 316/L, 904L, 310S, 321H, 347H, 446

3. Square Stainless Steel Pipes, Round Stainless Steel Tubes, Rectangular Stainless Steel Pipes & Tubes

4. Carbon Steel Seamless Pipes as per ASTM A 106 Grade B/API 5L Grade B/ASTM A 53 Grade B

5. Carbon Steel Seamless Tubes as per BS 3059, ASTM A 179, ASTM A 192, ASTM A 210 GR.A1

6. Alloy Steel Seamless Pipes as per ASTM A335 Grade P1/ P5/ P9 / P11/ P12 / P22 / P91

7. LTCS Pipe – Low Temperature Carbon Steel Pipes as per ASTM A 333 Grade 6

8. Alloy Steel Seamless Tubes as per ASTM A213 Grade T5/T9/T11/T12/T22/T91

9. ERW Black Pipes as per IS:1239/I, IS: 3589 Grade 330 or Grade 410

10. Galvanised Pipes as per IS:1239/I

11. Square and Rectangular Steel Pipes as per IS: 4923

12. ERW Boiler Tubes: BS 3059, ASTM A 214

13. Air Pre Heater Tubes to BS: 6323 PART V

14. Hydraulic Tubes to DIN 2391 ST. 35, ST. 45 & ST. 52

15. Seamless Heat Exchanger Tubes ASTM A 179

16. CDW TUBES IS: 3074 or BS 980

17. CRCA ERW Tubes to IS 3601 OR IS 3074

18. Stainless Steel Electro polished Pipes Manufacturer/Supplier

19. Alloy Steel Fittings Manufacturer – ASTM A234 WP5, P11, P22, P91

Changsong industrial equipment (Shandong) Co., Ltd. is an innovative and technological & international industrial solution company, established by the management team of Shandong University MBA graduates. Based on experience and international cooperation with SIEMENS-VAI (Primetals), Xstrata, Glencore, SMS, DME, Koniambo, Metso, Vale, SDEPCI, SDM, WESCO, Hiab and other world-renowned companies, through integration of well-known industrial products and spare parts supply channels of headquarters, our business ranges from supplying Complete sets of metallurgical equipment and spare parts,Bisalloy Shangang, fireproofing of shangang, transportation equipment and facilities. Include steel, casting, forging and other metal materials to supplying high-end mechanical and electrical equipment, and instruments.

We have thousands of sub-vendors for the business of joint manufacturing, we also work as agent of many world-renowned brands, we have broad overseas channels accumulated over the years, working together with our strategic partners to provide lean supply chain services, focusing on high-quality customers, to solve the customer’s urgent, special, small orders. JGPI also help all types of enterprises to develop overseas markets, provide commercial and technological consulting services for domestic and foreign enterprises supporting by various industry associations, research institutions, and teams of expert.

Serving your needs of industry

Meeting your demands of advanced instruments

Providing quality and economic hydraulic parts

Service

- Project routine procurement

- Project supplementary procurement

- Production material procurement

- Spare parts procurement

- Collected manufacturing of equipment

- Repair of equipment

- International marketing

- International consultancy of technology and commerce

- Integrated cooperation of project

We focus on the introduction of advanced products and technology to China, the introduction of creative products and enterprises to overseas markets. We integrate industry and expert resources to provide services in fields of energy, environmental protection, metallurgy, chemical, medical, research and other industries. Our corporate culture:

Customer Value Oriented

Customer Trust as the Goal

Quality and Safety as the Gene

We insist on continuous improvement, prevention, access to the trust of suppliers and customers to jointly ensure the smooth progress of the project, to make the world better through our joint efforts.

Machinery steels are carbon steels suitable for the working parts of the machine in general mechanical engineering industry. Different grades of steel can be applied to components with different level of stress and pressure ranging from moderate to high.All our machinery steel materials are hardened and tempered for oil quenching and water quenching. It is also suitable for flame hardening and induction hardening.

Beijing Shenghe Zhongtai Stainless Steel Co.,Ltd was established in 2009 and located in Beijing, China. In the past 9 years, we have focused the Stainless steel material and surface finish. We have passed the ISO9001 test in 2011, and applied the brand of “SUNSONG”in same year. Following the company developed by 2016, we have built our manufacturing base of Hebei Shengnuo Metal Products Co.,Ltd In Hebei province which is the biggest manufacturing base for Stainless steel surface treatment in North of China.

We have imported the advanced cutting equipment to do the coil cutting and flatting. And we have all process machines such as Hairline finish, 8K finish, Bead blasted, Vibration, Anti-finger print, PVD machine and Bending machine, Laser cutting machine.etc. Especially only we could do the surface treatment for the with more than 1500mm.

And our factory covers an area of more than 16000 square meters, introduces advanced equipments such as CNC shearing machine, keyway planer, Bending and laser machine, provides full-service of stainless steel processing. Our annual outputs has exceeded 3000 mts. We are capable to provide one stop services for architecture stainless steel decoration from stainless steel surface treatment, processing, fabrication, assembly and installation.

SUNSONG Decorative Stainless Steel Sheets is neat and beautiful which widely used into kinds of outside decoration of buildings and elevator decoration. We could do many treatment on the Hairline surface such as etching, PVD and so on. The surface would be different and welcomed by customers.

For more, please click here to customize your stainless steel furniture decoration.

Versatile Overseas Is An ISO 9001:2015 Certified Company And Has A Track Record Of Offering A Wide Range Of Piping Solution At Very Competitive Prices. In A Very Short Period Of Time, We Have Gained An Excellent National And International Reputation.

Galvalume steel is an important alloy material often used in daily life. The galvanized steel sheet is composed of aluminum-zinc alloy structure, which is composed of 55% aluminum, 43.5% zinc and 1.5% silicon solidified at a high temperature of 600℃. Its entire structure is composed of aluminum-iron-silicon-zinc, forming a dense quaternary crystal. Of an alloy.

Characteristics of Galvalume

Hot-dipped Galvalume Steel Coil has many excellent characteristics: strong corrosion resistance, 3 times that of pure galvanized sheet; beautiful spangles on the surface, which can be used as building exterior panels.

Corrosion resistance:

The corrosion resistance of “aluminized zinc steel coil” is mainly due to the protective function of aluminum and aluminum. When zinc is worn, aluminum forms a dense layer of aluminum oxide, which prevents corrosion-resistant substances from further corroding the interior.

Heat resistance:

Hot-dipped Galvalume Steel Coil has good heat resistance and can withstand high temperatures of more than 300 degrees Celsius. It is very similar to the high temperature resistance of aluminized steel plate. It is often used in chimney pipes, ovens, luminaires and fluorescent lampshades.

Heat reflectivity:

The heat reflectivity of Hot-dipped Galvalume Steel Coil is very high, twice that of galvanized steel sheet, and people often use it as a material for heat insulation.

Economical:

Because the density of 55% AL-Zn is lower than that of Zn, the area of the galvanized steel sheet is more than 3% larger than that of the coated steel sheet when the weight is the same and the thickness of the gold plating layer is the same.

Application of Hot-dipped Galvalume Steel Coil

use

The main uses of galvanized products are in two aspects. One is the shell and box of other electrical equipment used in electrical switch cabinets; the other is galvanized steel roofing for steel structure buildings, because of its good anti-corrosion and anti-corrosion properties. In many areas with heavy industrial pollution, aluminum-zinc color panels or aluminum-zinc fingerprint-resistant light panels are directly used on walls or roofs.

Construction: roofs, walls, garages, soundproof walls, pipes and modular houses, etc.

Automobile: muffler, exhaust pipe, wiper attachment, fuel tank, truck box, etc.

Home appliances: refrigerator back panels, gas stoves, air conditioners, electronic microwave ovens, LCD frames, CRT explosion-proof belts, LED backlights, electrical cabinets, etc.

Agricultural: pig houses, chicken houses, granaries, greenhouse pipes, etc.

Others: thermal insulation cover, heat exchanger, dryer, water heater, etc.

ASTM A453 Specification describes detailed requirements of grade 660 in class A,B,C & D.

ASTM A453 Grade 660

ASTM A453 Grade 660 Class A Specification

ASTM A453 Grade 660 Class B Specification

ASTM A453 Grade 660 Class C Specification

ASTM A453 Grade 660 Class D Specification

ASTM A453 Grade 660 Pdf

ASTM A453 Grade 660 Bars Stock

ASTM A453 Grade 660 Bolts

ASTM A453 Grade 660 Chemical Composition

ASTM A453 Grade 660 Class A Bars Stock

ASTM A453 Grade 660 Class A Bolts

ASTM A453 Grade 660 Class A Countersunk Screws Csk

ASTM A453 Grade 660 Class A Fasteners

ASTM A453 Grade 660 Class A Forgings

ASTM A453 Grade 660 Class A Heavy Hex Bolts

ASTM A453 Grade 660 Class A Heavy Hex Nuts

ASTM A453 Grade 660 Class A Hex Bolts

ASTM A453 Grade 660 Class A Hex Cap Screws

ASTM A453 Grade 660 Class A Keys

ASTM A453 Grade 660 Class A Pins

ASTM A453 Grade 660 Class A Push Bolts Rods

ASTM A453 Grade 660 Class A Rings

ASTM A453 Grade 660 Class A Rods Stock

ASTM A453 Grade 660 Class A Set Screws Grubs

ASTM A453 Grade 660 Class A Socket Head Cap Screws

ASTM A453 Grade 660 Class A Stud Bolt

ASTM A453 Grade 660 Class A U Bolts

ASTM A453 Grade 660 Class A Washers

ASTM A453 Grade 660 Class A Wire Rod Stock

ASTM A453 Grade 660 Class B 12 Point Screws

ASTM A453 Grade 660 Class B Bars Stock

ASTM A453 Grade 660 Class B Bolts

ASTM A453 Grade 660 Class B Countersunk Screws Csk

ASTM A453 Grade 660 Class B Fasteners

ASTM A453 Grade 660 Class B Forgings

ASTM A453 Grade 660 Class B Heavy Hex Bolts

ASTM A453 Grade 660 Class B Heavy Hex Nuts

ASTM A453 Grade 660 Class B Hex Bolts

ASTM A453 Grade 660 Class B Hex Cap Screws

ASTM A453 Grade 660 Class B Keys

ASTM A453 Grade 660 Class B Pins

ASTM A453 Grade 660 Class B Push Bolts Rods

ASTM A453 Grade 660 Class B Rings

ASTM A453 Grade 660 Class B Rods Stock

ASTM A453 Grade 660 Class B Set Screws Grubs

ASTM A453 Grade 660 Class B Socket Head Cap Screws

ASTM A453 Grade 660 Class B Stud Bolt

ASTM A453 Grade 660 Class B U Bolts

ASTM A453 Grade 660 Class B Washers

ASTM A453 Grade 660 Class B Wire Rod Stock

ASTM A453 Grade 660 Class C Bars Stock

ASTM A453 Grade 660 Class C Bolts

ASTM A453 Grade 660 Class C Countersunk Screws Csk

ASTM A453 Grade 660 Class C Fasteners

ASTM A453 Grade 660 Class C Forgings

ASTM A453 Grade 660 Class C Heavy Hex Bolts

ASTM A453 Grade 660 Class C Heavy Hex Nuts

ASTM A453 Grade 660 Class C Hex Bolts

ASTM A453 Grade 660 Class C Hex Cap Screws

ASTM A453 Grade 660 Class C Keys

ASTM A453 Grade 660 Class C Pins

ASTM A453 Grade 660 Class C Push Bolts Rods

ASTM A453 Grade 660 Class C Rings

ASTM A453 Grade 660 Class C Rods Stock

ASTM A453 Grade 660 Class C Set Screws Grubs

ASTM A453 Grade 660 Class C Socket Head Cap Screws

ASTM A453 Grade 660 Class C Stud Bolt

ASTM A453 Grade 660 Class C U Bolts

ASTM A453 Grade 660 Class C Washers

ASTM A453 Grade 660 Class C Wire Rod Stock

API 6A Bolting Torque for Flanges (SI Units)

API 6A Bolting Torque for Flanges (USC Units)

ASTM A453 Grade 660 Class D API 6A Full Thread Stud Bolt

ASTM A453 Grade 660 Class D API 6A Tap End Stud Bolt

ASTM A453 Grade 660 Class D Bars Stock

ASTM A453 Grade 660 Class D Bolts

ASTM A453 Grade 660 Class D Countersunk Screws Csk

ASTM A453 Grade 660 Class D Fasteners

ASTM A453 Grade 660 Class D Forgings

ASTM A453 Grade 660 Class D Heavy Hex Bolts

ASTM A453 Grade 660 Class D Heavy Hex Nuts

ASTM A453 Grade 660 Class D Hex Bolts

ASTM A453 Grade 660 Class D Hex Cap Screws

ASTM A453 Grade 660 Class D Keys

ASTM A453 Grade 660 Class D Pins

ASTM A453 Grade 660 Class D Push Bolts Rods

ASTM A453 Grade 660 Class D Rings

ASTM A453 Grade 660 Class D Rods Stock

ASTM A453 Grade 660 Class D Set Screws Grubs

ASTM A453 Grade 660 Class D Socket Head Cap Screws

ASTM A453 Grade 660 Class D Stud Bolt

ASTM A453 Grade 660 Class D U Bolts

ASTM A453 Grade 660 Class D Washers

ASTM A453 Grade 660 Class D Wire Rod Stock

ASTM A453 Grade 660 Countersunk Csk Screws

ASTM A453 Grade 660 Fasteners

ASTM A453 Grade 660 Forgings

ASTM A453 Grade 660 Heavy Hex Bolts

ASTM A453 Grade 660 Heavy Hex Nuts

ASTM A453 Grade 660 Hex Bolts

ASTM A453 Grade 660 Hex Cap Screws

ASTM A453 Grade 660 Keys

ASTM A453 Grade 660 Mechanical Properties

ASTM A453 Grade 660 Pins

ASTM A453 Grade 660 Push Bolts

ASTM A453 Grade 660 Rings

ASTM A453 Grade 660 Rods

ASTM A453 Grade 660 Set Screws

ASTM A453 Grade 660 Socket Head Cap Screws

ASTM A453 Grade 660 Stud Bolts

ASTM A453 Grade 660 U Bolt

ASTM A453 Grade 660 Washers

ASTM A453 Grade 660 Wire

Inner Mongolia Pusheng Iron & Steel Co,.Ltd is a comprehensive company for steel production and trading. Its business includes production, processing, distribution, logistics and import& export of steel. We have been processing and selling high quality , value add steel products to customers throughout all over the world .

Our company lies in Hohhot , inner Mongolia , it is near by BAO STEEL , The superior location provides us with quality products and reasonable prices , By creating long term relationships and building trust with clients and suppliers, Pusheng is able to offer our clients comprehensive and competitive sales packages with quality goods along with excellent customer service, establishing a firm reputation in inner mongolia ’s steel industry.

Our main products : hot rolled steel coils/sheet , cold rolled steel coils/sheet , galvanized steel coils/sheet /pipe , prepainted steel coil, corrugated sheets and tinplate coils,Ms pipe /plate, stainless steel sheet /pipe etc.

Digvijay Metals are one of the leading manufacturers, suppliers and exporters of high quality stainless steel, carbon steel, stainless steel gate roller wheel, duplex steel, super duplex steel, alloy steel, high nickel alloy, inconel, monel, hastelloy, alloy 20, Stainless Steel Architectural Products Manufacturers in India, titanium pipes, tubes, sheets, plates, coils, round bars, rods, flanges, pipe fittings and fasteners in Mumbai, India.

Our Products

Stainless Steel Glass Spigot

Stainless Steel Glass Bracket

Stainless Steel D-Bracket

Stainless Steel Glass Standoff

Stainless Steel Glass Fixing

Stainless Steel Handrail Bracket

Stainless Steel Glass Clamp

Stainless Steel Point Fixing

Stainless Steel Gate Roller Wheel

Stainless Steel Slotted Pipe

Stainless Steel Coated Angle

Stainless Steel Coated Channel

Stainless Steel Coated Profile

Stainless Steel Railing Accessories

Stainless Steel Glass Fittings

Stainless Steel Decorative Profile

Stainless Steel Tile trims

Stainless Steel T Profile

Stainless Steel C Channel

Stainless Steel U Profile

Stainless Steel L Angel

Stainless Steel PVD Coated Profiles

more info visit us http://www.digvijaymentals.com

Application:

Hot Rolled Stainless Steel Clad Plate is extensively used in Oil, chemistry, electricity, paper making, alkali production, watering works, vehicles, salt, medicine, food and also public facilities.

Advantage for KLS Stainless Steel Clad Plate:

Stainless steel dressed plate makes the combination far more stronger than that of the surge bonding, more eco-friendly than the explosion bonding, and also the turn-around time is quicker. The toughness of the bonding interface is uniform that makes the anti-corrosion layer totally used, and also hot-rolled cladding modern technology can generate a clad plate with extremely with and also ultra length.

Machining Methods for Stainless Steel Clad Plate China :

Eruptive Clad: Overlap stainless plate on carbon steel plate with a cushion in middle to leave particular space.Explosive material will be paved externally of stainless plate and when eruptive product exploding, high energy can make stainless plate effect carbon steel plate with high speed to joint.In optimal condition, the strength for square mm could get to 400 Mpa.

Thickness Scope:10 mm-300mm.

Warm Rolled Clad: Hot rolled stainless steel dressed plate is rolled of stainless and also carbon steel plates in vacuum condition.In such process, the attired plate and base plate must be in pure clean condition.Besides, for improving the stamina of conbining, there are also a collection of technological approaches with physics and chemical therapies.

Density Scope:0.6 mm-50mm.

Cold Rolled Clad: Cold rolled Stainless dressed plate is made after annealing-pickling-cold rold-mid annealing-pickling manufacturing process to stainless-steel clad plates.This material is with far better yield stamina than exact same grade stainless plate.Min density would get to 0.6 mm.

Welcome to Asiamet Steel Industries! On behalf of our Team and Management, we would like you to know that we are so grateful of having you. We hope our relationship will be pleasant, profitable and mutually beneficial.

Over 50 Years of Excellence in Steel Business! Asiamet is one of the only suppliers worldwide that offer stainless steel plates, stainless steel coils, stainless steel sheets, carbon steel plates, alloy steel plates in all major alloys from a single source. Asiamet stocks a wide range of sheets and plates, from 0.3mm to 100mm thickness. We specialize in supplying cut to size and shape carbon steel plates, stainless steel sheets, stainless steel plates and stainless steel coils. Asiamet Steel Industries is the local leading stainless steel sheets, plates and coil processor and exporter, based in India. We can offer stainless steel sheets with polished surfaces, 2B finish, No. 4 finish, sating finish, hairline -finish, etching, embossing and various other custom finishes to suit customer requirements. Stainless steel coils can be offered in full standard size coils or in custom widths as strips or sheets in custom length. Asiamet is a specialized supplier of sheets, plates and coils to the defense, aircraft, textiles, aerospace, marine, chemical and oil and gas industries.

Our steel pipes & tubes division is one of the largest manufacturers and importer of steel seamless and welded pipes in India. The management of Asiamet has been serving India and the global market place developed into a large integrated enterprise for processing and marketing of stainless steel sheets, stainless steel plates and stainless steel coils. Our raw materials are sourced directly from popular mills in India and across the world.

As the years have passed our steel business has grown from a local distributor to become one of the leading manufactures, exporters and suppliers of stainless steel, aluminum, carbon steel and alloy steel plates, plates, coils, rods, bars, angles and channels worldwide.

For all your stainless steel sheets, plates and coil requirements contact us on +919619672006 or write to us on sales@asiametsteel.com

We are one of the leading manufacturers, suppliers and exporters of stainless steel sheets, ss sheets, ss plates, ss coils, ss foils, ss polished plates, steel perforated sheets, stainless steel plates, stainless steel coils, stainless steel strips, ss foils, ss shim sheets, steel foils, ss shim sheets, steel polished plates in India.

Ans Pipes Pvt Ltd | ERW, Price list rate Seamless, GI Pipe, Square, Rectangle, Hollow Section , Box Pipe, Crc, MS Pipes TATA Pipe, APL APOLLO, PRAKASH SURYA, ASIAN, HITECH, JINDAL HISSAR in Ahmedabad, Changodar, Gujarat

| STEEL PIPE, STEEL TUBE, BOX SECTION, ERW MS BLACK PIPES, GI PIPE, GALVANISED PIPES, RECTANGULAR PIPES, SQUARE PIPES, BOX PIPES, HOLLOW SECTION, APL APOLLO, JINDAL, TATA, ASIAN, SURYA, WELSPUN, HITECH |

Kamdhenu Group has in its list of manufacturing, marketing, branding and distribution of a diverse range of products including Reinforcement steel Bars, Structural steels, Binding Wire, Colour Coated Sheets, Plywood, and many more. Kamdhenu Group is the largest reinforcement bars manufacturing group in India. The group is manufacturing international quality TMT of Grade bars with best features for construction industry.

Steel, Iron and Steel sector in Turkey is a manufacturer and service provider agreement with the company that operates one of the most fundamental institution for many years. It performs the price, stock and production follow-up of many steel products including flat products, U profile, I steel profile, H profile, Long products such as Ipe Profile, Longitudinal Welded Pipe and Square-Box profile. Iron is needed to produce steel products in Turkey as well as domestic sales network in many countries world and make the sale.

Virgin Engineering is one of the leading and acclaimed company for manufacturing of instrument tube fittings and valves from last 20 years. Based in Mumbai, India and an ISO 9001:2015 certified company has been set the highest standards of customer satisfaction, product development, manufacturing and timely delivery. Visit virginengineers.com for more products details and information.

Vasilios Stavridis G.P specializes in cutting ,slitting and trading steel with the most modern machinery. We have priority the continuous improvement thrοugh the development of machines. The factory have fιve machines which two used to cutting steel(cut to length lines) and the other three slitting lines steel.

The types of steel we use are (for more details, please visit our website ) :

-Hot dip galvanized

-Cold rolled

-P+O

-Hot rolled

-PPG

-Electro-galvanized

Find everything you need : http://www.vstavridis.gr

Hot rolled steel sheet piles are made from hot steel billets that have been gradually shaped and interlocked during the forming process. Hot rolled interlocks tend to be tighter and have better water resistance.

Hot rolled steel sheet piles can be classified by profile and size: U- and Z-shape. Hot rolled profiles can achieve very high modulus by connecting steel tubes, oversized piles or other sheet piles. Tubular combination walls are sheet piles and steel tubes connected by C9 or C6 interlocking devices. hz and hzm oversized piles can also be connected by RZD, RZU, RH 16 and 18 joints. Sheet piles can also be formed as box sheet piles.

Hoesch sheet piles are also interlocking sheet piles, including AU, PU, GU, Larssen profiles, VL sizes, AZ sizes, AS sizes, etc.

There are many steel grades for hot rolled sheet piles: in EN 10248 there are S240GP, S270GP, S320GP, S355GP, S390GP, S430GP, S460AP steel grades. Recently, there are corrosion resistant steel grades for marine applications: MLoCor Blue 320, Blue355, Blue390. american ASTM standards have A36, A 328, A572 grade 42/50/55/60/65, A588 and marine grade A690. in Japan, JIS A 5523 and JIS A 5528 standards have SY295, SY390, SYW295, SYW390.

Steel sheet pile can be divided into cold-formed thin-wall steel sheet pile and hot rolled steel sheet pile according to production technology. In engineering construction, the application scope of cold-formed steel sheet pile is narrow, and it is mostly used as material supplement, while hot-rolled steel sheet pile is always the leading product in engineering application. Based on the advantages of steel sheet pile in construction, the State General Administration of Quality Supervision, Inspection and Quarantine and Standardization Administration issued the “Hot Rolled U-Shaped Steel Sheet Pile” national standard on May 14, 2007, and was formally implemented on December 1, 2007. At the end of the 20th century, Masteel Co., LTD., with the technology and equipment of universal rolling mill production line imported from abroad, produced more than 5,000 tons of 400mm U-shaped steel sheet piles, which were successfully used in the Nenjiang Bridge cofferdam, the 300,000-ton dock of Jingjiang New Century Shipyard and flood control projects in Bangladesh. However, due to low production efficiency, poor economic benefits, little domestic demand and lack of technical experience during the trial production, the production failed to continue. According to statistics, at present, the annual consumption of steel plate pile in China remains at 30,000 tons, only 1%% in the world, and is limited to the permanent engineering of some ports, docks, shipyard construction and other temporary engineering of building bridge cofferdam, foundation pit supporting.