Somos un fabricante profesional de bridas, accesorios de tubería, accesorios forjados en la India, nos especializamos en la fabricación de todos los tamaños, estándar, tipo, etc. Somos capaces de proporcionar una amplia gama de materiales, desde existencias, para satisfacer sus necesidades. Desde material no estándar altamente especializado hasta artículos listos para usar, desde la producción hasta el prototipo, desde mínimos bajos hasta corridas de fábrica, el fabricante de bridas tiene la experiencia para resolver sus requisitos más difíciles.

Metallica Metals is known worldwide as the most competitive group in the world of Stainless Steel having its headquarters in Mumbai – India. It was incorporated in the year 1975 by 3 dynamic leaders named as Mr. Babulal Mehta, Mr. Jugal Mehta & Mr. Vallabhchand Mehta & they are the reason behind the exponential growth of Metallica Metals.

Copper Mould Tube & Plate

We specially in supplying Copper Mould Tube, Crystallizing equipment of continuous casters, Mould cooling jacket, Repair of Metallurgical Copper Mould Tube, etc.

Equipments & Spare parts for Continuous Casting Machine.

- Copper mould tube( square, rectangle and round )

- Crystallizing equipment of continuous casters

- Mould cooling jacket.

- repair of copper tube moulds

The copper alloys chosen for the moulds must maintain their physical properties at the operating temperatures of the continuous casting process.

The temperature gradation from the inner wall of the mould to the outside face of the mould can cause serious distortion problems, and Metallurgical Copper Mould Tube is imperative that the correct alloy is chosen for the various operating conditions.

Square Copper mould tube STANDARD MATERIALS

Phosphorus de-oxidised copper

This alloy has been proven to be excellent for the manufacture of moulds in the continuous casting of billets. The main composition of this alloy are Cu +Ag 99.90min, P0.0015 / 0.040.

Copper -Silver alloy

The addition of a small amount of silver, whilst not increasing the melting point of copper, does increase the recrystallisation temperature by almost 100℃, and also helps to give better thermal conductivity at the operating temperatures.

This alloy is normally used in moulds for the continuous casting of blooms and slabs .In this case, the moulds are much thicker than in the billet moulds, and the moulds temperature can be higher. The main composition of this alloy are Cu+Ag99.90 min. Ag 0.08 / 0.12 O 0.004 / 0.012.

The continuous casting of molten steel into billets, blooms and slab products, has been highly refined over the years into an extremely sophisticated system. The continuous casting process is expected to produce metallurgically sound products at the lower possible cost, and this is being achieved in many steelworks throughout the world.

Copper moulds have played an important role in the development of the continuous casting process. Their funcition is to receive the molten steel and to allow rapid heat transfer from the steel to the cooling water to enable quick solidification.

The mould must exhibit excellent thermal conductivity, be resistant for thermal erosion ,and be resistant to distortion from thermal stress. So far only copper and a few copper alloys meet the above conditions, both economically and technically.

Mould cooling jacket supplier SOLIDIFICATION

The rate of solidification in the continuous casting process dictates the speed of production. The molten steel, which is in contact with the inner faces of the copper mould, starts to sllidify as rapidly as the heat is extracted, forming a shell. The shell increases in thickness as more heat is extracted, and eventually total solidfication is achieved. the process is similar to the solidification of ingots in ingot moulds. In continuous casting, the whole process is speeded up, with the aim to produce and homogeneous shell growth. Consequently, the mould is an important part of the continuous casting process, and the manufactured quality of the mould plays and important role in their length of life.

INNER SURFACE COATINGS

Over the years, Metallurgists and Engineers have been working together to develop better continuous casting moulds. The steel companies require a more economical mould which will give a longer service life. Surface coating of the inner walls of the mould has given the best results to date. Coatings available are Chromium and Nickel plating. Also, a combination of the two give good results on slab casting.

SPECIFICATIONS OF COPPER MOULD

Square 60 x 60 – 350 x 350 (mm)

Rectangle 120 x 160 – 180 x 300 (mm)

Diameter 100-400 (mm)

Size(mm): 90×90, 100×100, 110×110, 115×115, 120×120

130×130, 135×135, 140×140, 143×143, 150×150

155×155, 160×160, 165×165, 175×175, 180×180

200×200, 220×220, 100×170, 100×173, 130×240

150×200, 150×210, 150×220, 160×200, 160×220

150×225, 160×235, 165×225, 175×225, 180×220

200×240, 240×240, 235×235

Radius(mm): 4000, 5000, 5250, 6000, 7000, 7500, 8000, 9000, 10250, 10300, 11000, 12000

Length(mm): 700, 750, 780, 790, 800, 810, 812, 850, 900, 1000

In 1984, Yingkaimo Metal Net Co., Ltd. was founded in Anping County Hebei Province, which is the hometown of wire mesh in China. It has Anping Factory, Dezhou Factory and Dubai Office with more than 500 employees. YKM’s annual value of production is about 50 million US dollars, of which 90% of products delivered to more than 70 countries and regions. It is a high-tech enterprise, also a leading company of industrial cluster enterprises in Hebei Province. YKM brand as a famous brand in Hebei Province has been registered in 17 countries around the world for trademark protection. Nowadays, YKM is one of the most competitive metal wire mesh manufacturers in Asia.

Total area of the two factories is about 156000 square meters with more than 400 sets of manufacturing machines, main machines including international advanced technology Japanese-made RGK, German-made Jager and some Chinese-made machines. Annual production capacity for stainless steel mesh is more than 10 million square meters, with range from 1 mesh to 635 mesh of square mesh and highest dutch weave 2800 mesh. The self-designed two epoxy coating production lines are the most advanced epoxy mesh coating equipment in Asia, its annual output is more than 13 million square meters and it makes YKM to be the R&D and supply center for epoxy mesh.

YKM’s main products are stainless steel wire mesh,epoxy coated wire mesh,nickel wire mesh, copper wire mesh, low-carbon steel wire mesh and all kinds of mesh further-processing products.

More information please view:https://www.china-wiremesh.com/

| Tycoon Piping is well known for his trusted exporters of best precision tubes in the world. We supply both seamless and welded pipes, in a wide range of stainless steel, titanium, nickel and zirconium alloys. Tycoon Piping is the market leader in supplying of Hot Finished structural hollow sections in the UK and almost 25 years of experience in logistics, stockholding, in-house processing, and sector-specific requirements. We provide the best product guarantee to our clients with full satisfaction. |

Galvanized Steel Fiber, an alternate concrete reinforcing material are high tensile galvanized steel wires with hooked ends, glued together by the water-soluble adhesive for compactness and uniform dispersion in concrete, to increase the concrete properties by 3-4 times.

Compared with the normal cold drawn steel fiber,in addition to all the advantage of normal steel fiber(such as excellent tensile strength, bending and shearing strength, high tenacity, resistance against the cracking, impact and fatigue ), this fiber still has a better corrosion resistance when the steel fiber exposure to the air, as there is a zinc thickness on the surface of this fiber.

The concrete with GuangYa steel fiber can be widely used in industrial floor,transportation constructions(roads, bridges, tunnels, airport runways), the concrete prefabricated unit, etc…

Advantage to use the China steel fiber in concrete:

High impact resistance.

Remarkably increased flexural strength.

Improved structural ductility.

Exceptional control over cracking.

Increased durability by providing crack control.

ASTM A453 Specification describes detailed requirements of grade 660 in class A,B,C & D.

ASTM A453 Grade 660

ASTM A453 Grade 660 Class A Specification

ASTM A453 Grade 660 Class B Specification

ASTM A453 Grade 660 Class C Specification

ASTM A453 Grade 660 Class D Specification

ASTM A453 Grade 660 Pdf

ASTM A453 Grade 660 Bars Stock

ASTM A453 Grade 660 Bolts

ASTM A453 Grade 660 Chemical Composition

ASTM A453 Grade 660 Class A Bars Stock

ASTM A453 Grade 660 Class A Bolts

ASTM A453 Grade 660 Class A Countersunk Screws Csk

ASTM A453 Grade 660 Class A Fasteners

ASTM A453 Grade 660 Class A Forgings

ASTM A453 Grade 660 Class A Heavy Hex Bolts

ASTM A453 Grade 660 Class A Heavy Hex Nuts

ASTM A453 Grade 660 Class A Hex Bolts

ASTM A453 Grade 660 Class A Hex Cap Screws

ASTM A453 Grade 660 Class A Keys

ASTM A453 Grade 660 Class A Pins

ASTM A453 Grade 660 Class A Push Bolts Rods

ASTM A453 Grade 660 Class A Rings

ASTM A453 Grade 660 Class A Rods Stock

ASTM A453 Grade 660 Class A Set Screws Grubs

ASTM A453 Grade 660 Class A Socket Head Cap Screws

ASTM A453 Grade 660 Class A Stud Bolt

ASTM A453 Grade 660 Class A U Bolts

ASTM A453 Grade 660 Class A Washers

ASTM A453 Grade 660 Class A Wire Rod Stock

ASTM A453 Grade 660 Class B 12 Point Screws

ASTM A453 Grade 660 Class B Bars Stock

ASTM A453 Grade 660 Class B Bolts

ASTM A453 Grade 660 Class B Countersunk Screws Csk

ASTM A453 Grade 660 Class B Fasteners

ASTM A453 Grade 660 Class B Forgings

ASTM A453 Grade 660 Class B Heavy Hex Bolts

ASTM A453 Grade 660 Class B Heavy Hex Nuts

ASTM A453 Grade 660 Class B Hex Bolts

ASTM A453 Grade 660 Class B Hex Cap Screws

ASTM A453 Grade 660 Class B Keys

ASTM A453 Grade 660 Class B Pins

ASTM A453 Grade 660 Class B Push Bolts Rods

ASTM A453 Grade 660 Class B Rings

ASTM A453 Grade 660 Class B Rods Stock

ASTM A453 Grade 660 Class B Set Screws Grubs

ASTM A453 Grade 660 Class B Socket Head Cap Screws

ASTM A453 Grade 660 Class B Stud Bolt

ASTM A453 Grade 660 Class B U Bolts

ASTM A453 Grade 660 Class B Washers

ASTM A453 Grade 660 Class B Wire Rod Stock

ASTM A453 Grade 660 Class C Bars Stock

ASTM A453 Grade 660 Class C Bolts

ASTM A453 Grade 660 Class C Countersunk Screws Csk

ASTM A453 Grade 660 Class C Fasteners

ASTM A453 Grade 660 Class C Forgings

ASTM A453 Grade 660 Class C Heavy Hex Bolts

ASTM A453 Grade 660 Class C Heavy Hex Nuts

ASTM A453 Grade 660 Class C Hex Bolts

ASTM A453 Grade 660 Class C Hex Cap Screws

ASTM A453 Grade 660 Class C Keys

ASTM A453 Grade 660 Class C Pins

ASTM A453 Grade 660 Class C Push Bolts Rods

ASTM A453 Grade 660 Class C Rings

ASTM A453 Grade 660 Class C Rods Stock

ASTM A453 Grade 660 Class C Set Screws Grubs

ASTM A453 Grade 660 Class C Socket Head Cap Screws

ASTM A453 Grade 660 Class C Stud Bolt

ASTM A453 Grade 660 Class C U Bolts

ASTM A453 Grade 660 Class C Washers

ASTM A453 Grade 660 Class C Wire Rod Stock

API 6A Bolting Torque for Flanges (SI Units)

API 6A Bolting Torque for Flanges (USC Units)

ASTM A453 Grade 660 Class D API 6A Full Thread Stud Bolt

ASTM A453 Grade 660 Class D API 6A Tap End Stud Bolt

ASTM A453 Grade 660 Class D Bars Stock

ASTM A453 Grade 660 Class D Bolts

ASTM A453 Grade 660 Class D Countersunk Screws Csk

ASTM A453 Grade 660 Class D Fasteners

ASTM A453 Grade 660 Class D Forgings

ASTM A453 Grade 660 Class D Heavy Hex Bolts

ASTM A453 Grade 660 Class D Heavy Hex Nuts

ASTM A453 Grade 660 Class D Hex Bolts

ASTM A453 Grade 660 Class D Hex Cap Screws

ASTM A453 Grade 660 Class D Keys

ASTM A453 Grade 660 Class D Pins

ASTM A453 Grade 660 Class D Push Bolts Rods

ASTM A453 Grade 660 Class D Rings

ASTM A453 Grade 660 Class D Rods Stock

ASTM A453 Grade 660 Class D Set Screws Grubs

ASTM A453 Grade 660 Class D Socket Head Cap Screws

ASTM A453 Grade 660 Class D Stud Bolt

ASTM A453 Grade 660 Class D U Bolts

ASTM A453 Grade 660 Class D Washers

ASTM A453 Grade 660 Class D Wire Rod Stock

ASTM A453 Grade 660 Countersunk Csk Screws

ASTM A453 Grade 660 Fasteners

ASTM A453 Grade 660 Forgings

ASTM A453 Grade 660 Heavy Hex Bolts

ASTM A453 Grade 660 Heavy Hex Nuts

ASTM A453 Grade 660 Hex Bolts

ASTM A453 Grade 660 Hex Cap Screws

ASTM A453 Grade 660 Keys

ASTM A453 Grade 660 Mechanical Properties

ASTM A453 Grade 660 Pins

ASTM A453 Grade 660 Push Bolts

ASTM A453 Grade 660 Rings

ASTM A453 Grade 660 Rods

ASTM A453 Grade 660 Set Screws

ASTM A453 Grade 660 Socket Head Cap Screws

ASTM A453 Grade 660 Stud Bolts

ASTM A453 Grade 660 U Bolt

ASTM A453 Grade 660 Washers

ASTM A453 Grade 660 Wire

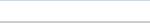

Model No.: LJZ2 -450×3700

PRODUCT DESCRIPTION

Double Head Cutting Saw Equipment Feature

■ Used for aluminum profile cutting.

■ Carbide saw blade give accurate processing and high endurance.

■ The two heads can work independently and simultaneously.

■ Cutting off the required length and two end angles is available by one time processing

Double Head Cutting Saw Technical Parameter

1) Power supply: three phase, four line 380V, 50Hz

2) Saw motor: 1.5Kw x 2, 2,800r/min

3) Pulling motor: 0.55Kw, 1,400r/min

4) Working pressure: 0.4 – 0.6MPa

5) Air consumption: 200L/min

6) Cutting length: max 3,700mm; min. 400mm

7) Cutting width: max 120mm

8) Cutting height: max. 200mm

9) Cutting angle: 0° – 45°

10) Cutter feeding speed: 0 – 3m/min

11) Saw diameter specification: 450mm x 4mm x 30mm-120

12) Overall dimensions: 4,500mm x 1,100mm x 1,400mm

Processing Accuracy

■ Repeat locating length: ≤0.2mm

■ Cutting angle allowance: ±5′

■ Cutting profile surface planeness: ≤0.10mm

■ Cutting profile surface roughness: Ra12.5μm

If you want to know more, you can click here.

Model No.: LJJS-CNC-500×600

PRODUCT DESCRIPTION

CNC Corner Connector Automatic Cutting Saw Equipment Features

■ This machine is mainly for alum windows corner stake cutting, also used for cutting Alum & PVC profiles.

■ PLC auto program controlling, man-machine interface is colored touch screen, input the cutting size and quantity, then it can cut automatically.

■ Automatic feeding system take the linear guiderail and high precision ball screw, driven by stepping motor. High feeding precision and efficiency.

■ Saw blade spindle take special high accuracy spindle, end face and radial runout are less 0.01mm, cutting surface is highly polished.

■ Saw blade feeding system adopts linear guiderail, with high accuracy and high speed (can be stepless speed regulation)

■ Carbide saw blade give accurate processing and high efficiency.

■ Special workpiece clamping system, besides processing common corner stake, it can also process middle frame corner stake.

■ All closed machine body and cover, with good appearance, safe working and low noisy.

CNC Corner Connector Automatic Cutting Saw Technical Parameter

■ Power: 380V 50Hz

■ Motor Rate: 2.2Kw

■ Saw Blade Diameter: Φ500mm

■ R.P.M: 2800r /min

■ Cutting Width: 135mm

■ Automatic Profile Feeding Length: 4-600mm

■ Working air pressure: 0.5-0.8Mpa

■ Weight: 600kg

If you want to know more, you can click here.

Established in 1996, Vintex Steel & Engg. Co. has gained immense expertise in supplying & trading of Stainless steel, carbon steel, ferrous metal etc. The supplier company is located in Mumbai, Maharashtra and is one of the leading sellers of listed products. Buy Stainless steel, carbon steel, ferrous metal in bulk from us for the best quality products and service.

Roopam Steel is top manufacturer & supplier of seamless steel pipe welded tubes in ferrous and non ferrous material, Stockist of high quality tubular piping products and accessories in India. Call us for more Info at +91-22-6639 4333.

Ceramic lined pipe is made through the self-propagating high-temperature synthesis (SHS) technique.

Self-propagating High-temperature Synthetic process

Self-propagating high-temperature synthesis (SHS) is used to describe a process in which the initial reagents (usual powders), when ignited, spontaneously transforms into products due to the exothermic heat of reaction.

The combination of high rigidity of ceramic and high elasticity of steel gives the pipe unmatchable features like abrasion resistant, heat resistant, and corrosion-resistant material for use in the fields of power generation, metallurgy, mining, and chemical industry, etc. It has many advantages over steel pipes, cast stone pipes, and steel-plastic compound pipes.

Usage of Ceramic Lined pipe

The ceramic-lined pipe transportation has been widely used in the industries of electric power, metallurgy, coal, petroleum, chemical engineering, building materials, mechanism, and so on.

The ceramic lined elbow throughout the power, metallurgy, coal, petroleum, chemical, building materials, machinery, and other industries, and high-speed development. When lining the wear-resistant ceramic elbow to deliver high grinding material (such as ash, coal, ore powder, etc.), there is a lining of wear-resistant ceramic elbow wear fast, especially the elbow Wear faster. When lining a ceramic-lined elbow to deliver a highly corrosive gas, liquid or solid, there is a problem that the lined wear-resistant ceramic elbow is corroded and is quickly damaged.

There is a problem that it is expensive to use a heat-resistant steel pipe when the material having a higher temperature is conveyed in the lining of the wear-resistant ceramic elbow. After lining the wear-resistant ceramic elbow, these problems are solved.

The ceramic lined elbow is widely used in wear and tear of mine filling material, ore powder and tailings transportation, coal-fired power plant powder, smelting, ash and other things lined with wear-resistant ceramic elbow are also very appropriate.

The ceramic lined pipe, Elbows, Reducer, Tees, and others manufactured in our factory have been used in over 200 thermal power plants, more than 50 mines, and the industries of coal, building materials, mechanism, petroleum, and so on.

Abrasion

Ceramic layer Ceramic Lined Reducer Pipe with flange reducer Al2O3 content greater than 89%, micro-hardness HV1000-1500, which has high abrasion resistance, wear resistance more than ten times higher than carbon steel after quenching, superior tungsten carbide drill.

Application range

- coal pulverizing system of power plant pipeline, including, powder transmission pipeline, thick powder separator pipeline, coal drop pipe, combustion system of a windpipe, a secondary air pipe, three pipeline and burner pipelines, in addition to ash slagging system the discharge pipe, powder pipe, dry ash conveying pipe;

- Iron and steel plant raw material conveying pipeline, collecting pipe, dust pipe, ash pipe, ash pipe, mixing pipe, grinding export pipeline, coal pipeline, coal pipeline, separator pipe, burner radius pipe, etc.;

- Cement plant selection machine outlet pipe, choose machine inlet pipe, pipe dust pipe, vertical mill outlet pipe, circulating air duct, high-temperature air blower, lower material pipe, etc.;

- Petroleum, chemical, mining, coal, coal washing plant, smelting, paper, aluminum, building materials, powder engineering, food machinery, and other processing and conveying material pipes.

Corrosion

Ceramic materials are neutral, chemically stable, have excellent corrosion resistance and acid resistance, resistant to various inorganic acids, organic acids, organic solvents, and their degree of corrosion of stainless steel is more than ten times.

Temperature

Temperature above 2000celsius degree, long-term work in the range of -50 -900 celsius degree.

Easy welding.

The ceramic adjustable tube can be welded, flanged, flexible connectors, and other fast way links, very easy to install.

Clean and easy maintenance

Smooth walls, can prevent scaling, fouling, and self-cleaning functions. Tightness.

Remarks:

- Under the direction of the arrow diagram for the export direction.

- Bend radius is usually 1.5-5 times the diameter of steel pipe (1.5-5D).

- Othe specifications of the composite pipe can be manufactured according to the user requirements.

- The weight is calculated by theoretics, maybe have some tolerance, and real weight will be weigh-in after they finish.

Hoop strength is the resistance against radial pressure. The strength of the ceramic-lined steel composite pipe is 300 to 500MPa.

Features and Advantages of ceramic lined pipe

Ceramic Liner pipe is a high technology production technology-self-fuel high-temperature clutch synthesis method.

1). High Abrasion Resistant:

Vickers hardness of the corundum lining is HV1100 to1500, as high as that of tungsten-cobalt hard alloys, and the abrasion resistance is 20 times as carbon steel pipes. The composite ceramic-lined steel elbow was used in a mining plant for about fifty thousand hours. The general service life of a common steel elbow is about 700 hours.

2). Corrosion Resistant:

Corundum is a neutral material and is acid-proof and fouling-free.

3). Heat Resistant:

Ceramic lined composite steel pipes can work under circumstances of -50 to 800 Celsius degree.

4). Lower Weight and Convenient Installation:

The ceramic-lined steel pipes are lighter than alloy pipes, cast iron pipes, and cast stone pipes and can be welded or connected through flanges, which reduces the expense of transportation and makes the pipes easier to install.

For the pipes with the same sizes, types, and lengths, the weight of the ceramic pipe is about 1/2 of the wearable cast alloy steel pipe’s, while the cost has reduced 10%~20% per meter.

The weight of ceramic-lined steel pipe is about 1/3 of the cast stone bent pipes, 1/2 of the cast stone straight pipes.

Ceramic (Corundum: a-Al2O3) lined abrasion resistant straight pipe and fittings are lined with highly abrasion-resistant ceramic by SHS ——-Self-propagating High-temperature Synthetic process.

- The ceramic-lined steel composite pipe can be joined by welding the steel pipe layer.

- Ceramic-lined pipes can take place of expensive stainless steel, titanium, nickel, cast stone, or alloy pipes.

- Extended service life can also reduce maintenance costs.

Self-Propagating Ceramic Pipe

Self-propagating ceramic steel pipes create a new generation of abrasion and corrosion-resistant engineering pipelines.

The self-propagating ceramic steel pipe has very good wear resistance, Excellent corrosion resistance, and Excellent thermal resistance performance.

SHS-self-propagating ceramic steel pipe and elbow create a new generation of abrasion and corrosion-resistant engineering pipeline. The composite pipe is composed of three layers: ceramic, intermediate, and steel layers.

The ceramic layer is formed by molten alumina at a temperature above 2500 degrees. The molten alumina produced from the reaction Fe2O3+2Al=2Fe+Al2O3 spreads on the inside wall of the steel pipe under the influence of a centrifugal force, then solidifies, so the ceramic layer has high density and smooth surface and bonds to the steel pipe.

Applicable Industries:

- The pipe needs excellent wear resistance property: Power plant, Mining, Sea Port, Coal Plant, And pipe for transporting the powder, slurry, sand, etc.

- Coal washing plant, pipe for transporting coal and other material.

- Pipe for transporting the melted aluminum.

- Any pipe which needs to wear protection, corrosion protection, etc.

Benefits:

- Excellent wear resistance, Alumina content of the ceramic liner is higher than 95%, Hardness HV1000-1500. The wear protection performance is more than 10 times better than carbon steel after quenching,

- Excellent corrosion resistance, stable chemical properties.

- Excellent thermal resistance performance up to 2000℃ Can be used in the area from-50℃ to 900℃ for a long time.

- Can be connected with another pipe by welding, flange and soft fast connecting, and easy installation.

PRODUCT DETAILS

Barbed wire can be widely used as accessories for woven wire fences to form a fencing system or security system. It is suitable for industry, agriculture, animal husbandry, dwelling house, plantation or fencing.

Barbed wire is a protective net formed by mechanically winding barbed wire around the main wire through various weaving techniques.

Anti-corrosion, anti-aging, high durable. Barbed wire can be used with chain link or other fencing barriers for added security. It can discourage unauthorized entry and is suited to a variety of containment needs.

Mainly serves in isolation and protection of grassland, boundary, railway, highway,prisons, private residence, bank, bill printing factory, and also widely used in military base, industry, agriculture, animal husbandry, plantation for fencing.

Wholesale airport security fence, is mostly made use of in the flight terminal for defense. The main panel and also V panel is welded with 4.0 mm/5.0 mm low carbon steel cable. The surface area therapy of QYM airport fencing is galvanized + electrostatic polyester powder coated or galvanized + PVC layered.

airport fence supplier Material:

Material: Low-Carbon Iron Wire

Application:

Airport, Garden Fence, Residential, etc

Airport Fence Y Type Fence China Specification

| Panel | Mesh | Wire Thickness | Surface Treatment | Panel Width | Folds NOS. | Panel Height | Fence Height |

| Big Panel | 50x100mm 55x100mm |

4.00mm 4.50mm 5.00mm |

Galvanized and Electrostatic polyester coated or PVC coated | 2.50m 3.00m |

4 | 2000mm | 2700mm |

| 5 | 2300mm | 3200mm | |||||

| 6 | 2600mm | 3700mm | |||||

| 2 | 530mm | 2700mm | |||||

| V panel | 630mm | 3200mm | |||||

| 730mm | 3700mm |

Beijing Shenghe Zhongtai Stainless Steel Co.,Ltd was established in 2009 and located in Beijing, China. In the past 9 years, we have focused the Stainless steel material and surface finish. We have passed the ISO9001 test in 2011, and applied the brand of “SUNSONG”in same year. Following the company developed by 2016, we have built our manufacturing base of Hebei Shengnuo Metal Products Co.,Ltd In Hebei province which is the biggest manufacturing base for Stainless steel surface treatment in North of China.

We have imported the advanced cutting equipment to do the coil cutting and flatting. And we have all process machines such as Hairline finish, 8K finish, Bead blasted, Vibration, Anti-finger print, PVD machine and Bending machine, Laser cutting machine.etc. Especially only we could do the surface treatment for the with more than 1500mm.

And our factory covers an area of more than 16000 square meters, introduces advanced equipments such as CNC shearing machine, keyway planer, Bending and laser machine, provides full-service of stainless steel processing. Our annual outputs has exceeded 3000 mts. We are capable to provide one stop services for architecture stainless steel decoration from stainless steel surface treatment, processing, fabrication, assembly and installation.

SUNSONG Decorative Stainless Steel Sheets is neat and beautiful which widely used into kinds of outside decoration of buildings and elevator decoration. We could do many treatment on the Hairline surface such as etching, PVD and so on. The surface would be different and welcomed by customers.

For more, please click here to customize your stainless steel furniture decoration.

Silicon Steel Co. is single source of Industrial Pipe Fittings & Flanges, we are Manufacturer, Supplier, wholesaler, Stockholder & Traders of Pipe Fittings, Forged fittings, Butt weld fittings & Pipe Flanges in INDIA & exporting Pipe fittings & Industrial Flanges to more than 30 countries since 2 decades.

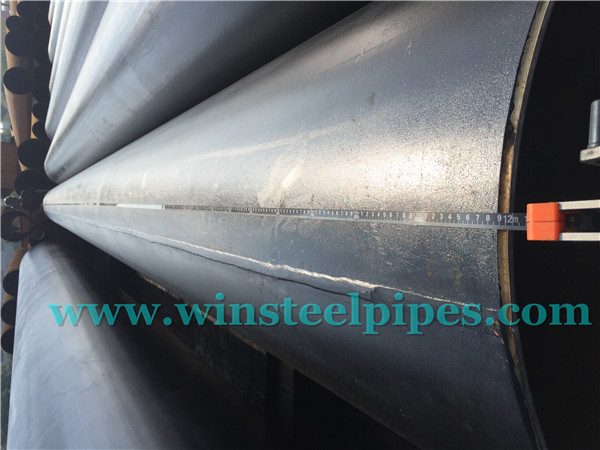

24” steel pipe (609.6 mm steel pipe) is commonly used LSAW pipe in construction usage. Winsteel Group is professional LSAW steel pipe manufacturer. We have got API 5L PSL 1 and PSL 2 certificate, ISO 9001, ISO 14001, OHSAS 18001 certificate, PED and CPR certificate for several years.

As a Concertina Razor Wire Suppliers, share it with you.

Feature

Razor barbed wire, also known as scraper barbed wire, is a new type of protective net product developed with strong protection and isolation capabilities. The sharp knife-shaped thorn is formed into a bellows shape by a double-line buckle, which is both beautiful and chilling. Played a good deterrent effect. At the same time, the product has the advantages of beautiful appearance, good anti-blocking effect and convenient construction.

Concertina Razor Wire

Razor-barbed wire is generally used for protection in prisons. Because the blade is sharp and not easy to touch, it has a certain deterrent effect. The razor-barbed wire has a wide range of uses. It can be used for wall protection of residents and can also be used for enclosure. The anti-theft effect of the barbed wire is better than that of ordinary barbed wire, and the price is not high, so the razor barbed wire is more and more widely used.

Razor wire, also known as razor wire, is a new type of protective product developed with strong protection and isolation capabilities.

Stainless steel barbed wire is different according to the different application areas containing nickel. The effect of using 304 stainless steel in a dry indoor environment is quite good. However, if you want to maintain its appearance outdoors in the countryside and cities, you need to wash it frequently. In heavily polluted industrial areas and coastal areas, the surface will be very dirty and even rusty. However, to obtain the aesthetic effect in the outdoor environment, nickel-containing stainless steel is required. Therefore, 304 stainless steel is widely used in curtain walls, side walls, roofs and other construction purposes. However, 316 stainless steel is best used in severely corrosive industries or marine atmospheres.

Razor nets have been widely used in military powerhouses, prisons, government agencies, banks, and living quarters, private houses, villas, doors and windows, highways, railway guardrails, and borders to protect security in various countries around the world.

Our company also has Concertina Razor Wire for Sale, welcome to contact us.

SHINESTAR STEEL GROUP CO., LTD mainly produce various carbon and alloy steel pipes including oil & gas pipe, pressure pipe, mechanical tubing, and stainless steel tube, etc.

As the most valuable subsidiary under SHINESTAR STEEL GROUP, PRIME STEEL PIPE is the solution provider for the oil, gas, construction, energy and prtrochemical industries.SHINESTAR STEEL GROUP is specialized in manufacturing superior quality steel products, and providing outstanding service for valued clients all over the world.

Hunan Great Steel Pipe Co.,Ltd is specialized in steel pipe & tube production including carbon steel pipe, seamless steel pipe, erw steel pipe, ssaw steel pipe, lsaw steel pipe, etc.