At Aarti Steels Limited, we represent a fully integrated steel manufacturing company with state of art plants located in Punjab and Orissa with an total installed capacity of 3 lakh tonne per annum and 90 MW of Power.

We manufacture total range of Carbon, Alloy and Special Steels conforming to National / International Specifications including customer specific requirements through a dedicated route of steel making i.e. Electric Arc Furnace – Secondary Refining – Vacuum Degassing Route – Con-cast with Electro Magnetic Stirring / Snorkle Casting practices.

Our products hold a formidable status in “Alloy Steel” Industry which is a result of consistency in quality and excellent metallurgical services rendered including after sales service. Our product basket comprises of LONG PRODUCTS with configuration – Rounds, Round Corner Squares (RCS), Wire Rods, Wires whilst we do roll sections in Flats for two wheeler industry and for laminated springs in conventional sizes.

By the dint of adequate representation in “Automotive” Sector of Indian economy, our products are consumed for manufacturing of critical components like Stub Axles, Crank Shafts, Connecting Rods, Crown Wheels, Pinions etc. (to name a few).

To be precise, the steel manufacturing exercise which is quality driven is a perfect blend of Man, Process and Technology.

We are Manufacturer, supplier & Exporter of Alloy Steel Pipe, Alloy Steel Flanges, Alloy Steel Fittings we also supply all types of flanges like slip on flanges, weld neck flanges, blind flanges etc

ALTA SPECIAL STEEL is specialized in supplying and exporting tool steel, mold steel and alloy steel, especially for HOT FORGED BARS

A2, D2/1.2379/SKD11, H13/1.2344/SKD61, O1/1.2510/SKS3, 1.2083/420SSESR, 1.2714, 1.2367, 1.2767, S7, A8 etc.

1) Cold work tool steel A2, D2/1.2379/SKD11, O1/1.2510/SKS3, D3/1.2080, D6/1.2436, , O2/1.2842, S1/1.2550, 1.2767, 1.2328.

2) Hot Work Tool Steel S7, H13/1.2344/SKD61, H11/1.2343, H10/1.2365, H10A/1.2885, H12/1.2606, H21/1.2581, 1.2367, 1.2787, 1.2329.

3) Plastic Mould Steel 420/1.2083/SUS420J2, 1.2316, 1.2085, 1.2713, 1.2714/SKT4, 1.2738.

4) High Speed Steel M2/1.3343/SKH51.

5) Alloy Structure Steel 4140/1.7225/SCM440, 4340/1.6582.

In here, you are gonna to get a source that continuously reliable in Quality, Pricing and Service !

1. Quality assurance

Near 30 years activity in this industry, own a material laboratory and well-equipped facilities e.g. EAF, ESR, LF, VD… we engaged

the most skillful workers from WISCO GROUP, HUBEI XINYEGANG STEEL LTD & DONGBEI SPECIAL STEEL GROUP(Taizhou workshop)

2. Pricing supports

We’d love to support our long term and healthy partners, no matter big or small companies / agents, we do our best service to you.

3. Service – Make you assured with our quality and delivery time

Always worry about the quality risk ? Spend much time and energy on keep tracking where your orders going ? DON’T NEED NOW!

Our sales person always keep you well informed on production and delivery status (not just text, but also real photos).

Most important, we will submit the “Quality Test Report” for your check before shipment.

Give us a ring or write a email to get your most reliable offer and service now ! Sales(at)specialsteel(doc)com

Amanat Steels Pvt. Ltd. was incorporated in year 2009 and is known as a reputed manufacturer and exporter of quality Fittings, Bends, Outlets and Flanges in Stainless Steel, Duplex Steel, Cu-NI, Nickel Alloy, Alloy Steel and Carbon Steel. Our product range includes Copper Nickel Outlets, Monel Outlets, Nickel Outlets, Inconel Outlets, Hastelloy Outlets, Titanium Outlets, Copper Nickel Flanges, Monel Flanges, Inconel Flanges, Hastelloy Flanges, Titanium Flanges and New Items.

Introduction:

Amman Steel Group started in 1978, has made remarkable progress over the past 39 years and it is now the leading steel producers. A group of Company, Amman Steel Corporation was initially a scrap retail and trade organization. Amman Steel Group soon expanded into the biggest integrated steel plant in the private sector in South India. It is one of the largest and most respected companies in South India with 3 Rolling Mill plants in Tamilnadu and 2 Steel making plants one in Puducherry and another in Andhra Pradesh. It is headquartered at Trichirapalli, Tamilnadu.

Ashwin Impex are one of the leading manufacturers, suppliers and exporters of stainless steel, carbon steel, alloy steel, duplex steel, high nickel alloy pipes, tubes, butt weld pipe fittings, flanges, sheets, plates, coils, round bars, rods, forged fittings, fasteners in Mumbai India.

Our Products

Stainless Steel 304 Pipe Fittings

Stainless Steel 304 Flanges

Stainless Steel 304 Fasteners

Stainless Steel 304 Sheets & Plate

Stainless Steel 304L Pipe Fittings

Stainless Steel 304L Flanges

Stainless Steel 304L Fasteners

Stainless Steel 304L Sheets & Plate

Stainless Steel 316 Pipe Fittings

Stainless Steel 316 Flanges

Stainless Steel 316 Fasteners

Stainless Steel 316 Sheets & Plate

Stainless Steel 316L Pipe Fittings

Stainless Steel 316L Flanges

Stainless Steel 316L Fasteners

Stainless Steel 316L Sheets & Plate

more info please visit us http://www.ashwinimpex.com

304 is a chromium-nickel austenitic stainless steel with incredible quality and astonishing utilization assurance as furnished in the reinforced condition with a normal brinell hardness of 175.Characterised by high disintegration insurance all around air damaging circumstances it indicates sublime security from most oxidizing pros, general foodstuffs, purifying courses of action, dyestuffs, most common chemicals, notwithstanding a wide collection of inorganic chemicals furthermore hot oil gases, steam start gases, nitric destructive and to a lesser degree sulphuric destructive.

COGNE began its industrial activity back in 1911. It was called Cogne after the name of the village where iron ore mines have been exploited since the Roman times.

Established in September 2005, Dongguan Yufang Steel Co., Ltd. is located in Dongguan City, covering an area of 23,000 square meters. The superior location provides us with very convenient transportation and good environment.

As a large-scale private enterprise, our company specializes in the domestic and imported special steel and die steel, including plastic die steel, hot work steel, cold work steel, alloy structural steel, bearing steel, high speed tool steel, carbon steel and stainless steel in different specifications. As an authorized dealer of Shanghai Baosteel, TISCO Steel, BUDEUNS, Daido Steel, ASSAB, Sichuan Pangang Steel, Foshan City Mould Steel and Liaoning Yingkou Steel, our company is exploring international markets while developing the markets in China (Guangdong, Tianjin, Shandong, Liaoning and Dalian). We have good cooperative relationships with more than 20 foreign importers in different countries and regions, such as Japan, Korea, India, Malaysia, Brazil, Germany, Belgium and the Middle East.

Our company has introduced large-sized vertical saw machines, horizontal saw machines, milling machines, grinding machines and other advanced equipment. We export our products by wholesalers and retailers and our products can reach the domestic and international quality standards.

We insist on the principles of “reputation first, customer is our God” and “honest, pragmatic spirits are directing our production and sale”, in order to serve our valued customers with convenient, top speed and the best services.

Providing high quality and favorable prices, we are sincerely looking forward to establishing mutually beneficial and long-term relationships with importers from all over the world. Please feel free to contact us for further information!

Double-twist stranding machines, high-performance twisting machines

Double Twist Stranding Machineare effective, compact production units primarily for use in the manufacture of highly flexible braids, bundled braids, for stranding pairs of wires, triples, quadruple designs …

The machine concept differs from the single-twist system in that one rotor turn generates two cable twists / turn. The braid is given the first twist at the stranding point of the system feed. At this point, the stranding material still has twice the length of lay of the desired final geometry. The final braid length of lay with the second stranding twist is only completed at the second turning point, before being introduced back into the static coil former.

BOW DOUBLE TWIST STRANDING MACHINE

Application for:

Multistrand 7 or 19 copper wire, aluminum wire, tinned copper conduct etc. Also multistrand insulated conduct for power cable, data cable, control cable etc. Laying up of 2/3/4 cores of small size building wires.

Bow Double Twist Stranding Machine Description:

Payoff

Double twist stranding machine

PLC control system with color touch screen

Advanced function (Optional):

1:Motorized payoff or back-twist payoff, tension keep stable from start to end.

2:Bow material : carbon fibre

3:Brake: serve motor

4:Motorized driven capstan. Lay length set on touch screen, no need to change gear mechanically.

5:Auto lubrication system: regularly lubricate important parts to prolong machine service life.

COMPUTER SIMULATION OF AN INDUSTRIAL WIRE DRAWING PROCESS

Wire Stranding Machine is an important industrial process. Wires are reduced in diameter through a series of die/capstan combinations which provide the desired reduction steps. Typical wire drawing machines within BICC Cables Ltd use up to twenty-one dies in one line and it is necessary to optimise the die drafting for each machine and final wire diameter to obtain good machine efficiency and high quality product. An important aspect in the manufacturing process is to avoid wire breakages with the resultant loss of production due to short final lengths and the associated time required to restring the drawing machine. In order to optimise the conditions for each machine and wire size, computer simulations of the process are used to predict performance by estimating factors such as the ratio of drawing stress to ultimate tensile stress, drawing force, back tension and heat generated.

A computer simulation of the multi-line wire drawing process for copper wire has been modelled by the Wrexham Technology Centre of BICC Cables Ltd using a bulk model. The redundant work during the drawing process was included by formulation and equations for the redundant deformation were derived that were in good agreement with published experimental work.

A new computer simulation has been developed to predict the performance of wire drawing process. The model uses a one dimensional explicit finite difference method to determine the plastic deformation in the dies. The redundant work formulation was used as in the previous simulation. This paper describes the numerical methods used and compared the results from the new computer simulation with the previous bulk model. Significant differences are predicted in the stress ratios, drawing force and heat generated for process predictions. The new simulation of the plastic deformation in the dies also indicated optimum semi-die angles away from the traditional eight degrees.

7 Wire Tubular Type Stranding Machine

Owing to the vast industry experience and in depth knowledge of this domain, we are offering a huge collection of high quality 7 Wire Tubular Type Stranding Machine. These products are manufactured using optimum quality raw material. These products are easy to install and requires low maintenance. Customers can avail these products from us at market-leading prices

Basket Type Stranding Machine

Basket Type Stranding Machine is mainly used to strand not only copper/aluminum conductor for the electric wire and cable but also the cable core, steel core, and steel rope. Machine’s make-up: pay-off, driving part, cylindrical part, hydraulic brake device, wire –bobbin frame, die-holder, haul-off device, spindle-type take-up/traversing (Φ50 bar traversing) and an electrical control part, etc.

Rigid Stranding Machine

The Rigid Stranding Machine is used for stranding CU, Al wires, and conductors. Stranding unilay and reverse concentric, round, compressed, compacted or sector-shaped ( straight or spiraled) as per customer requirements.

Main features:

Self-supporting rigid rotor design with 1 6 12 18 24 30 36 Bobbin Cage

High efficiency and speed

Bobbins mounted on pintles

A line drive by A.C. or D.C. motors with electronic or mechanical synchronization between line components.

Different braking device for bobbins

Centralized lubricating system for bearing

Disk type Pneumatic brake for Cage.

Machines with or without back twist

MMI /PLC Equipped, optional

Easy Lay Setting

High Speed Tubular Stranding Machine

High Speed Tubular Stranding Machine with back twist, for 1+6 Bobbin copper / aluminum round & compact conductors and steel wire stranding. This strander is for manufacturing high carbon & low carbon steel wire rope, copper & aluminum conductor

Bow Type Stranding Machine

The Bow Type Stranding Machine is suitable for a wide range of productions, obtained with high speed and productivity; the back twist process gives high quality products. The Bow stranders use components made with most modern materials, like carbon fiber for the bows, tungstene carbide for bushes, hardened steel for rollers.The control of tension of the cores is assured with electro-mechanical or pneumatic self compensated brake, with set up by control panel.The safe use is assured with control of bearing temperatures and supports vibration.The machine is protected with a soundproof cover, with pneumatic open, inside fans and lights.Is possible the bobbins side loading with a motorized trolley, that avoids the use of bridge cranes and reduces dramatically the total loading time of the line.

For Cables Industry:

Stranding of conductors made with copper, aluminium, aluminium alloy, aluminium steel reinforced or supported;

Laying up of 2 – 7 round insulated cores for low and medium voltage;

Laying up of 2 – 7 straight sector shaped insulated cores, with the rotating cradles version;

Possible application of fillers and tapes of every type.

Tubular stranding Machine

The Tubular Stranding machine consists of bearing stands made of welded steel for the tube bearings. Up to reel size of 630mm .The stranding rotor is built up from welded tubes with wire guidings outside the tube. The reels are held in cradles, which are positioned inside the tube. A light beam along the complete length of the machine monitors, if the pneumatically (optional)operated reel-pintles are securely closed and the cradles are in safe condition. The machine is equipped with wire break detectors for each segment, pneumatic disk-breaks and individual drives for the Stranding Rotor, the Capstan and the Take-Up. The operator’s desk gives full control over parameters like Rotor-speed, lay-length and production length.

Main Features:

• Machine placed on a Rigide steel frame with rotor support, fixed on the floor for an easy installation

• Tube rotating on encircling bearings or rollers

• Machine able to work in torsion or total back twist with the possibility of partial back twist

• Wire back tension kept constant from full to empty spool payoff

• Wire/strand break detector for each payoff unit(optional)

• Spool loading/unloading by crane

• Pneumatic pintles equipped with safety locking system

• Independent driving motors for tube, capstans and takeup units

• A.C. motors with flux vector control inverter

«Drill Collars and Kellys Plant» Subsidiary Enterprise was founded in 1988. It is unique specialized enterprise utilized high-technological equipment with closed cycle of production from melting to manufacture the ready-made products.

Since the foundation our plant has been manufacturing Drill Collars and Kellys for drilling to extract gas and oil and also for geophysical surveying at all climatic zones.

The production process of manufacturing guaranteers high quality and reliability of our products. Since our enterprise has been working the production acquired wide popularity and confidence of consumers outside Ukraine and has a wide sellers market elsewhere in the CIS and Europe, Asia and North America.

Duexpim is a spanish company established in 1995. For more than 15 years we have been trading stainless steel products in prime and second choice (secondary) around the world.

Our offices are located in Barcelona (Spain), and our stocks are held near the the port of Barcelona. Duexpim is member of the chamber of commerce at Chamber of Commerce in Barcelona

We have a vast experience and knowledge in the steel industry. Our qualified team has has been involved in this field over 30 years, mainly in export stainless steel. We are specialist in supplying stainless steel.

Through our strategic alliances with steel mills and service centers, we can offer a large variety of quality products at most competitive prices.

Duexpim is committed to establish good and long-term business relationship with worldwide customers. We are looking forward to having the opportunity of cooperating with you.

Eu-Metal is an International Trading Company that is today recognized as a professional name dealing in a largest series of Ferrous and Non-ferrous primary and secondary metal products. Eu-Metal chases its goal of establishing long lasting relationship with its customers and suppliers for sourcing and supplying of products and services. We have seen several fluctuations in the international market but our commitment towards quality, on-time delivery and prices have always been rendering us the first choice of clients.

Broadly, Eu-Metal procures products from the suppliers of Europe, America and the South East Asia and gives out these products for the clients of India, Malaysia, Singapore, Pakistan, Vietnam, Indonesia, China, Manila,India,Pakistan,Bangladesh, Turkey,Africa, South America and many others . Our products are supplied to clients at highly competitive prices. Our products are based on the most advanced technology available today. Further, we are all set to enter into new marketplaces for both procurement and the supply of products.

Eu-Metal vast product range covers Cold Rolled Coils, Galvanised coils,Sheets and Plates, Hot Rolled Coils, Sheets and Plates, Electrical Steel-CRGO, CRNGO, EG/ HGD/PPGI/Colour Coils and Sheets, EG Colour Coils, EG Sheet, Tinplate/BP/TFS Sheets and Coils, Stainless Steel Coils and Sheets/Scrap, Stainless Steel Pipes and Tubes, Heavy Melting Scrap, Shredded Scrap, Angles, Channels, H/I Beams, Copper, Zinc, Aluminum and Lead, Wire Rods and Billets, Slabs and Slab Ends.

The Sales/Purchase team of Eu-metal gives you total support as we understand our customers and suppliers very well as the history of the company comes from a steel trading family who has been working from ages in this field and is full of experiences so we know perfectly how to handle our customers and assist them according to their needs

In last, we would like to invites all the suppliers who have products of our interest. We would also like to welcome those customers who find their interest in our products. You can contact us for further information about our company and other products and services offered by us.

|

Euro Fittings manufactures and sells a wide range of buttweld fittings all over the world. To meet your regular needs and ensure you the best quality we offer a state-of-art technology with focused R&D and technical expertise. |

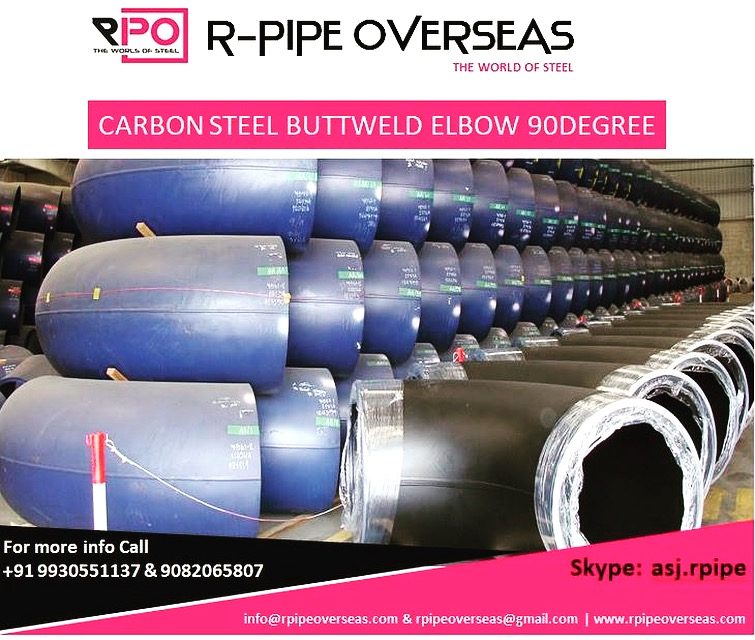

We, R-PIPE OVERSEAS Are BIGGEST STOCKHOLDER & EXPORTER of Pipeline Products and Exporting to More Than 40 Countries Including U.S.A, Europe,

Gulf & Asian Countries And Regions In The World. Our High – Quality Products And Strong International Reputation In The Industries Related To The

Chemicals, Engineering, Pharmaceuticals, Fats & Fertilizers, Sugar Mills & Distilleries, Cement Industries, Ship Builders, Paper Industries, Pumps & Petrochemicals,

Textile, Dairy, Oil & Natural Gas, Allied Industries Organization In Term Of The Specific Materials, Technology Are Highly Valued By Indian & Foreign Customers.

Materials:

PIPES | TUBES | PLATES | SHEETS | FLANGES | FASTENERS | FORGED FITTINGS | BW FITTINGS | ROUNDBARS. IN HIGH NICKEL ALLOYS | DUPLEX STEEL | STAINLESS STEEL | ALLOY STEEL | CARBON STEEL ETC.

REGARDS

ARVIND JAIN – SALES HEAD

R-PIPE OVERSEAS

T: +91 22 6659 5201

M: +91 9930551137

Whatsapp: +91 9082065807

Skype: asj.rpipe

E: info@rpipeoverseas.com & rpipeoverseas@gmail.com

W: http://www.rpipeoverseas.com

A: Shop No. 28, Gr. Flr, 153/154, Shree Ishwaleshwar Siddhesh Deep CHS,

PB Marg, Mumbai – 400008. (INDIA)

GST TIN NO.: 27ALTPJ6984G1ZB

We have cooperated with them for many years,although the amount of the monthly is not particularly large, but very stable.We mainly provide the Forklift Brackets,Forklift Shaft Accessories and other small parts.The quality of our products has been recognized by them..Our products are used in the former more,such as Excavator Parts,Excavator Brackets,Roller accessories,Bulldozer accessories,Construction Machinery Hook, Automobile Casting Parts

HSB was founded in 1910 as a rail re-rolling mill. Throughout our early, formative years, goals were continually reassessed and renewed, with a focus to serve customers with increasingly higher quality products.

Today, HSB’s product focus is Special Bar Quality (SBQ) carbon and alloy steels (rounds) suited to a wide range of market segments, including the automotive, heavy truck, off-road, mining, forging, cold finish and service centre sectors. Classified as a steel mini-mill, HSB currently has a finished annual capacity of approximately 400,000 tons of engineering steels.

Melt Shop

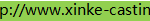

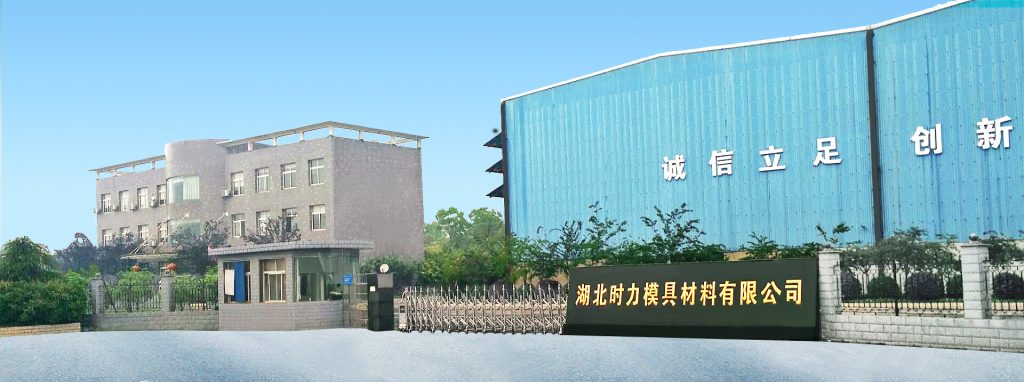

Hubei Shili Mould Material Co.,Ltd is a brand that represents and engages in manufacturing of quality tool steel products. We are highly respected as a reputable tool steel production company in Hubei, China with many years of experience. Since 1994, Hubei shili Mould Material Co., Ltd is considered as one of the oldest mould & die steel manufacturer in Hubei, China. Today, as a high-tech private company, Shili steel possesses the most technically advanced steel rolling production line in China. Over 22 years, we not only supply steel materials but also offer variety steel solutions for worldwide distributors, retailers, manufacturers and the likes. We love to experiment on different tool steel machinery based on customer demand and preference.

Over the past year, Shili manufactures a wide range of products including cold work tool steel, hot work tool steel, plastic mould steel and high-speed steel. Our main products include D2, D3, H11, H13, A2, amongst others.

For better production, Shili has independently researched and developed a production line with a dia850 rolling machine. Consequently, we acquire two patents for innovation and achieve the annual output of 80000 tons.

Furthermore, we dynamic in our procedure and technique which is flexible enough to incorporate the changing demands in the international market. Our services are tailored specifically to meet the needs of our esteemed customers. While many things have changed in the steel industry, our commitment to quality and service remains the same, with our dedication to total customer satisfaction.

We continually work to expand our outreach and business interests, to the delight of our ever increasing customer base. For more details and inquiries, kindly contact us and you could also get in-depth information about our activities right here on the website.