Gate valve is our company’s earlier product. During the long period of time, our company has made the gate valve famous in and out with perfect designing and manufacturing techniques and quality system assurance. The manufacturing experience and technique innovation have made the products reach BS, DIN and other international standards.

Metal Seated Gate Valve Features:

-High reliability of strength and rigidity.

-The sealing is copper alloy which is wear-resisting and has long life.

-When opening, no other parts in the way.

-The installation direction is various iwith the same performance.

Product Range:

Standards: BS&DIN

Suitable medium: water, sea water.

Suitable temperature:≤100℃

Material: Ductile iron, GJS500-7. GJS400-15, GGG40,GGG50

GIC Fasteners, a trusted name in the fastener industry, brings over 25 years of unparalleled experience in manufacturing high-quality fasteners. As an ISO 9001:2015 certified company, we adhere to the strictest quality standards, ensuring superior products that meet international specifications. With our vast expertise and commitment to excellence, GIC has established itself as a leading provider of fasteners, catering to diverse industries worldwide. Our dedication to precision, durability, and customer satisfaction sets us apart, making GIC the preferred choice for all your fastening needs.

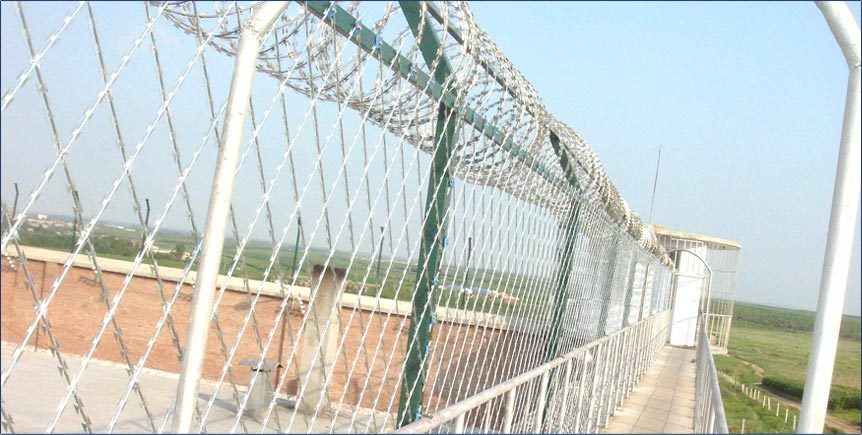

Razor wire is a new type of protective barbed rope. Concertina razor wire is made up with galvanized center wire and outer covered razor in stainless steel or galvanized steel. Razor wire fence has the advantages of beautiful appearance, economy and practicality, has good resistance prevention effect, easy for installation, etc. At present, razor fence has been widely used in many countries’ industrial and mining enterprises, garden apartments, border posts, military fields, prisons, detention centers, government buildings and other national security facilities.

Concertina razor wire fence is a kind of wire fence product made by welding razor wire together. Same as concertina razor wire, this kind of fence also cover densely with razors, this make the fence an not be climbed. Also the steel wire in the razor wire makes the fence very hard to be cut, it is very suitable for prisons, outposts, factory warehouses and other areas requiring high security.

Characteristics of Razor Wire and Razor Wire Fence:

Sharp appearance, good deterrence

Rotatable blades, strong intrusion prevention capability

Corrosion-resistant, long lifespan

Area separation, flexible mobility

Low cost, suitable for large-scale use

Easy installation, easy maintenance

Products name: Stainless steel ferrule mesh, Stainless steel ferrule rope mesh, Stainless steel ferrule cable mesh, X-TEND mesh

Material: High-quality SS 304, 304L, 316, 316L wire ropes and stainless steel ferrules.

Features: light weight, good flexibility, high strength, good transparency, good invisibility. The service life is more than 30 years.

Applications: zoo mesh, animal enclosure, bird aviary, handrail infills, anti-falling safety net, garden fence.

Design and installation: various graphics and structures can be designed, and installation schemes can be provided.

Stainless steel ferrule mesh is also called stainless steel ferrule wire rope mesh. The mainly material is stainless steel cable and stainless steel ferrule. It is produced by putting the ferrules tough the cable first, and then press the ferrule using special molds. This kind of mesh has very beautiful appreance, it also has very good strength and flexibility. We can product various types of ferrule mesh in different cable diameter and mesh opening to meet our clients’ requirement.

Applications

The stainless steel cable mesh, especially the ferrule type mesh, are more used in fields like balustrades on bridges and staircases, large barrier fences, and building facade trellis systems. As an emerging product on architectural decoration and protection, stainless steel rope mesh has provided the mordern architectural decoration and horticulture engineering with a new and stylish element, which are getting more and more appreciated by designeers and clients all over the world.

Officially established in 2014, Da Chu Group located in Wu Han which is the biggest city in Middle of China, with two manufacturing plants.

As a leader in facility maintenance and road safety products, we are home to The Original Bumper Post Sleeve, the strongest industrial, construction and traffic guardrail on the market, and a wide variety of safety handrail systems.

Our patented line of products save time, money, and maintenance by eliminating the need to paint. We continue to be the industry leader in facility maintenance solutions with a long list of acclaimed products which also includes bollard covers, sign bases, handrail, both standard and custom guardrail systems, dock door protection goal posts, highway guardrail, and more. With hundreds of styles available in a variety of sizes and colors, we continually meet the needs of any facility or company.

Da Chu products are designed to be a cost-effective way to improve safety in and around your facility, protecting your most valuable assets – your personnel and machinery – as well as enhancing the overall appearance of your structure.

Since the beginning, our mission has been to provide innovative solutions, superior quality, and excellent customer service. We welcome all the worldwide customers to build cooperation relationship with us for win-win in the future.

More information please click: http://www.dachuguardrail.com

If you are lookimg for Super Duplex Fasteners suppliers so here Explore Middle East FZE company provide you the best quality of Super duplex fasteners. These fasteners contain higher amounts of chromium, molybdenum, nitrogen and tungsten, giving them excellent corrosion resistance properties. Hence Super Duplex Fasteners are suited to deepwater offshore oil production. Promoters have experience of more than 20 years dealing with Exporters, Manufacturers and Suppliers of industrial Metals. For more information visit our site!

The Base Jack Is A Heavy-Duty Adjustable Base Jack That Is Manufactured From High Tensile Steel And Fitted With A “Double Podger” Collar. It Is Used As A Levelling Solution For All Types Of Scaffolding System Such As Ringlock Scaffolding,Cuplock Scaffolding And Kwikstage Scaffolding.

Screw Rod process: raw materials → blanking → pipe cutting/sawing → thread rolling.

In this process, we need to use a pipe cutting machine and a thread rolling machine. The factory currently has two thread rolling machines, a two-axis thread rolling machine, and a three-axis thread rolling machine.

Base Plate process: shearing → blanking → forming (drumming) → punching → welding.

EK manufacturer has shearing machines, forming machines and welding machines to assist in the completion of the bottom plate process.

Screw Nut process: black parts → surface treatment (electro-galvanized/hot-dip galvanized) → screw nuts → broken teeth (spot welding/stamping)

After the nut arrives at the factory, it will first undergo surface treatment, usually electro-galvanized and hot-dip galvanized, then the nut will be screwed onto the screw, and finally the thread will be destroyed on the screw. This process will use spot welding or stamping.

NANJING EK METALWORK CO., LTD Was Established In 2011 In Nanjing. All Parts Of EK Scaffolding Props Are Produced By Ourselves, Which Can Guarantee The Delivery Time And Quality Of Each Order Of Customers.

The Factory Produces Independently, Has Two Welding Robots, Which Can Realize Automatic Welding, And Guarantee The Delivery Time While Increasing Production Capacity.

Customers Can Monitor Product Production In Real Time To Ensure Product Quality.

Special Models Can Be Customized.

The production process of the steel prop is divided into 10 steps.

Material → Inner Tube → Outer Tube → hot dip galvanized → G Pin → Nut → Assemble → Finished Process → Package → Transport

First, the raw materials are purchased. After the raw materials enter the factory, the steel pipes are cut into inner and outer pipes by laser cutting machines and other equipment according to customer needs, Weld the base of the inner and outer tubes by means of welding robots and manual welding.

Next, the inner and outer pipes need to be treated, the common ones are hot-dip galvanizing and painting.

In addition, you need to prepare steel prop accessories, such as G Pin and Nut.The installation step can be carried out after the galvanizing is completed.

After the installation and commissioning of the steel prop is completed, workers will carry out surface treatment, and then pack it into pallets.

An ISO 9001:2008 Certified Company, The Metal Factory is India’s most trusted manufacturer, exporter and supplier of stainless steel tubes (ASTM A 312 304/304L, 316/316L), carbon steel pipes (ASTM A A106, A53, API 5L), alloy steel seamless pipes (ASTM A335 P11, P22), mild steel pipes, industrial steel tubes, galvanized steel pipes and black steel pipes.

We can manufacture and supply steel pipes which can be fabricated to customers design and specification in a variety of length and thickness requirements. We can also offer cold drawn seamless steel tubes to meet the custom design and specifications of our customers. We specialise in the manufacture and supply of cold drawn seamless steel tubes, and large diameter stainless steel welded pipes (100% X-Ray Tested). ISO 9001:2008 Certification ensures consistency in our operations and testing procedures.

Steel Pipes and Steel Tubes supplied by The Metal Factory are used across wide range of industries including food processing, power generation, oil and gas, petrochemicals, petroleum pipelines, medical equipment, biopharma, pharmaceuticals, electrical engineering, fertilizer industry, dairy processing, boiler manufacturing and nuclear energy among others.

METLINE has been proudly servicing the steel pipe industry for over 40 years, as a major supplier and manufacturer of custom size steel pipes and steel tubes. We are the exclusive suppliers of stainless steel welded pipes, stainless steel seamless tubes, stainless steel tubing, alloy steel seamless pipes, boiler steel tubes, heat exchanger tubes, capillary tubes, coiled tubing, and galvanized steel pipes. We are serving all major cities and countries in their needs for steel pipes and steel tubes.

Our products are supplied to all major Industrial areas and cities in India such as Mumbai, Delhi, Bangalore, Hyderabad, Ahmedabad, Chennai, Kolkata, Surat, Pune, Nagpur, Indore, Thane, Bhopal, Visakhapatnam, Vadodra, Nashik, Faridabad, Rajkot, Aurangabad, Ranchi, Coimbatore, Raipur, Mysore, Bhubaneswar, Salem, Bhilai, Bhiwandi, Bikaner, Mangalore, Kochi (Cochin), Bhavnagar, Tirupur, Ankleshwar, Assam, Siliguri, Jamshedpur, Warangal, Nellore, Agartala and Thoothukudi.

Our high quality steel pipes, good customer service, and in house pipes and tubes processing capabilities have made us one of the emerging suppliers for steel pipes and tubes in Middle East countries including Bahrain, Cyprus, Egypt, Iran, Iraq, Israel, Jordan, Kuwait, Lebanon, Oman, Palestine, Qatar, Saudi Arabia, Syria, Turkey, United Arab Emirates and Yemen.

India’s #1 Supplier of Stainless Steel Pipes/Tubes, Chrome Moly Pipes, Black Pipes, Galvanised Pipes, Carbon Steel Pipes

Stainless Steel Pipes, Carbon Steel Tubes, Alloy Steel Tubes, MS Pipes Production and Stock Range

Outside Diameter: 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock, OD Size Steel Tubes available Ex-stock

Thickness Range: 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Type: Seamless / ERW / Welded / Fabricated / CDW

Key Steel Pipes & Tubes Products & Grades

1. Stainless Steel Seamless Pipes & Tubes – 304, 304/L, 316/L, 904L, 310S, 321H, 347H, 446

2. Stainless Steel Welded Pipes & Tubes – 304, 304/L, 316/L, 904L, 310S, 321H, 347H, 446

3. Square Stainless Steel Pipes, Round Stainless Steel Tubes, Rectangular Stainless Steel Pipes & Tubes

4. Carbon Steel Seamless Pipes as per ASTM A 106 Grade B/API 5L Grade B/ASTM A 53 Grade B

5. Carbon Steel Seamless Tubes as per BS 3059, ASTM A 179, ASTM A 192, ASTM A 210 GR.A1

6. Alloy Steel Seamless Pipes as per ASTM A335 Grade P1/ P5/ P9 / P11/ P12 / P22 / P91

7. LTCS Pipe – Low Temperature Carbon Steel Pipes as per ASTM A 333 Grade 6

8. Alloy Steel Seamless Tubes as per ASTM A213 Grade T5/T9/T11/T12/T22/T91

9. ERW Black Pipes as per IS:1239/I, IS: 3589 Grade 330 or Grade 410

10. Galvanised Pipes as per IS:1239/I

11. Square and Rectangular Steel Pipes as per IS: 4923

12. ERW Boiler Tubes: BS 3059, ASTM A 214

13. Air Pre Heater Tubes to BS: 6323 PART V

14. Hydraulic Tubes to DIN 2391 ST. 35, ST. 45 & ST. 52

15. Seamless Heat Exchanger Tubes ASTM A 179

16. CDW TUBES IS: 3074 or BS 980

17. CRCA ERW Tubes to IS 3601 OR IS 3074

18. Stainless Steel Electro polished Pipes Manufacturer/Supplier

19. Alloy Steel Fittings Manufacturer – ASTM A234 WP5, P11, P22, P91

Aluminum sheet supplier RAYIWELL MFG can supply 1050 1060 1070 2024 3003 4017 5052 aluminum plate, anodized aluminum sheet, Brushed aluminum sheet, Mirror finished aluminum sheet, diamond aluminum plate, aluminum tread plate, 5 bars aluminum plate, 3 bars aluminum plate coil at very competitive price

Aluminium Coil or Aluminum Plate Sheet Supplier RAYIWELL MFG can supply Aluminum plate refering to the aluminum material with a thickness of more than 0.2mm to less than 500mm, a width of more than 200mm, and a length of less than 16m. With the progress of large equipment, there are more aluminum plates that can be as wide as 600mm).

Aluminum plate refers to a rectangular plate processed by rolling aluminum ingots, which is divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, medium-thick aluminum plate, and patterned aluminum plate.

Aluminium Coil Aluminum Plate Sheet Supplier RAYIWELL MFG / RUIYI can offer aluminum sheet grade below

1000 series:1050,1060,1070,1080,1100,1145,1200,1235, etc.

2000 series:2014,2017,2018,2024,2025,2219, 2219,2618a etc.

3000 series:3003,3004,3102,3104,3105,3005, etc.

4000 series:4032,4043, 4017, etc

5000 series: 5005,5052,5454,5754,5083,5086,5182,5082, etc.

6000 series:6061,6063,6262,6101, etc

7000 series:7072,7075,7003 etc

8000 series: 8011, etc.

Temper of aluminum sheet: O, H, W, F, T

H:H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H111, H112, H114, H116

T: T0-T651

Size of aluminum sheet

Thickness:0.2-6.0mm

Width:100-2400mm

Length:200-11000mm

Mother coil: CC or DC

Weight: About 2mt per pallet for general size

MOQ: 5ton per size

Protection: paper inter layer, white film, blue film, black-white film, micro bound film, according to your requirement.

Surface: clean and smooth, no bright speck, corrosion, oil, slotted, etc.

Standard product: GBT3880, JIS4000, EN485, ASTM-B209

Delivery time: about 30days after receiving the deposit

Payment: T/T, L/C at sight

Trading terms: FOB, CIF, CFR

Aluminum sheet coils have many applications as below

1. Lighting decorations 2. Solar reflectors 3. Building appearance 4. Interior decoration: ceilings, walls, etc. 5. Furniture, cabinets 6. Elevators 7. Signs, nameplates, bags 8. Car interior and exterior decoration 9. Interior decorations: such as Photo frame 10. Household appliances: refrigerators, microwave ovens, audio equipment, etc. 11. Aerospace and military aspects, such as China’s large aircraft manufacturing, Shenzhou spacecraft series, satellites, etc. 12. Mechanical parts processing 13. Mold manufacturing 14. Chemical or insulation pipe coating. 15. High-quality ship board

Iron Slag Pot for Steel Mill is an essential container for collecting slag generated during steel making. Iron Slag Pot for Steel Mill is made of refractory steel.

Hebei Shineyond Group was established in 1980, with two factories: Hebei Shineyond Metal and Hebei Shineyond Gabion Mesh Factory, which mainly produce iron wire, gabion mesh, fence and undertake domestic construction projects. The factory covers an area of more than 100 Acres, with an annual export volume of 300,000 tons.

Hebei Shineyond has been developing steel trade business since 2010, and established two overseas branches: Sunscope Metals Co., Ltd. and Lucky Timing lnternational Pte.Ltd The company mainly exports Cold-rolled Steel Sheets, Hot-dipped Galvanized Steel Sheets(GI), Galvalume Steel Sheets(GL), Color Coated Steel Sheets(PPGI), Hot Rolled Coils, Wire Rod, Rebars and Steel Sections. Group has cooperated with HBIS, Anfeng, Aosen Steel in China and TATA Steel, Steel Force and Duferco over the world.

Our products are mainly exported to more than 100 countries and regions, such as Europe, South America, Southeast Asia, Central Asia, Africa, etc. They are mainly used in roofing, wall construction, color coated substrates and automobile and home appliance industry.

“Focusing on products and serving with heart” is the core competitiveness of Shineyond. Shineyond Metal is committed to producing high quality products, accepting quality inspection by relevant institutions, providing one-stop service from production to delivery and after-sale.

More information please click:http://www.shineyondmetals.com

What is special about the degreasing process of aluminum alloy castings

Die-Casting Tooling Design is also a processing method, so many parts are obtained by die casting, the performance of the die casting is based on the material composition. Take the aluminum alloy casting with zinc as the main component for example, the parts can only be applied after special treatment.

As the surface of the aluminum alloy casting is a very dense surface layer, inside is the evacuation of porous structure, so in its degreasing is special, can only use alkaline degreasing agent for degreasing. In addition, we have high requirements on the decoration of products, so mechanical polishing is required before degreasing, followed by chemical degreasing and electrolytic degreasing.

Because the polishing paste that aluminium alloy die casting USES contains paraffin in polishing, for emulsive paraffin, the temperature that removes wax water wants to exceed 70 degrees to just have the effect. Generally, wax removal water can only remove wax without degreasing, and chemical degreasing should be carried out again. The chemical activity of zinc alloy is very strong, so the alkalinity of chemical degreasing liquid should not be too strong, or it will corrode the surface of casting. If in this process can be used with ultrasound, the effect will be more ideal. The degreasing process of aluminum alloy castings is very important. The above mentioned operations should be in accordance with the requirements to ensure the quality of the die casting products.

Located in Liaoning province in northeastern China, LianJiang Metals Company have specialized in aluminum and iron casting production since 1997. We are an OEM partnership that manufactures Cast Aluminum and iron parts for clients all over the world and in different industries such as Street Lighting Base, patio furniture & Garden Decoration company.

With over 20 years of casting work experience and expertise, we offer a full range of casting processes including:sand casting,gravity casting,die-casting,vacuum casting

If you want to know more about the product, please click here.

[Aluminum Casting for sale]Complex aluminum casting process

Complex aluminum casting such as Aluminum Casting Gate, it is a new technology, which is based on electromagnetic pump low-pressure casting technology, aluminum smelting and forming compound purification technology and manufacturing core, to produce high-quality aluminum casting modern technology. Electromagnetic pump low-pressure casting metal liquid transfer system has a stable flow, flow control is convenient, ease the process of molten alumina suction and easy to achieve the advantages of using the process automation, which not only improves the casting quality of aluminum casting, but also can improve the working environment. Reduce labor intensity, achieve automation and modern casting production.

Purification of molten enamel alloy castings is an important part of the aluminum smelting and composite purification facilities in addition to aeration and spin foam ceramic filters with high degassing performance, except for metal inclusions. In addition, it USES a new long-life lining material, with an independent insulation/heating system that can be used for mass continuous production, but also for batch production. This technology has high efficiency, long service life, low cost and effective, easy to install, use and flexibility. There are three main aspects to be considered in solving complex problems of quality aluminum casting:

(1) melting and melting of liquid aluminum;

(2) smooth transition aluminum metal halide lamp,

(3) size and stability of the mold and sand core process.

That’s all for the sharing, thanks for your reading, and we also supply Aluminum Patio Furniture for sale, if you have any demand for our products, just feel free to contact us.

Located in Liaoning province in northeastern China, LianJiang Metals Company have specialized in aluminum and iron casting production since 1997. We are an OEM partnership that manufactures Cast Aluminum and iron parts for clients all over the world and in different industries such as Street Lighting Base, patio furniture & Garden Decoration company.

With over 20 years of casting work experience and expertise, we offer a full range of casting processes including:sand casting,gravity casting,die-casting,vacuum casting

If you want to know more about the product, please click here.

Do you want a fresh and new look for your home? Reach Assured Roofing for Roof Restoration Melbourne and be assured of roofing treatments. With us, you will get the ultimate roof protection and a 10-year warranty which is proof of our reliable and honest services. No matter what is the size of the project, we have designed affordable solutions to suit your demand. Our excellent workmanship and high-quality materials provide timely roof repairs and effective roof restorations. If you have noticed cracks or leakage in your roof, call our team to help you with your roof.

Union Steel Industry Co., Ltd as member of United Steel Industry Group, specialized in steel pipe and pipe fittings designing, manufacturing, stocking and exporting in China.

Our products

- SMLS &ERW Steel Pipe(especially processing galvanized/FPE/3LPE/Grooved/pipe & flange welding …etc with very competitive price)

- Tubing&casing (Professional standard API 5CT PSL1/2 J55 K55 P110 Q125….)

- Structure steel profile(Mainly provide international general standards, advantage prices for some EU standards or other standards)

- steel plate &pipe fittings(flange,elbow,reducer,valve..etc)

We basically have steel in stock and support fast delivery:

- Steel pipe : ASTM A53;ASTM A106;ASTM A333;ASTM A500;ASTM A252 ..etc or Equivalent

- Structural steel hollow section: EN 10025、EN 10219 S235/S275/S355..etc or Equivalent

- Steel plate : ASTM A36, ASTM A283, ASTM A572..etc or Equivalent

- We can also provide various conventional stainless steel products.

You can forward needs on alisa@union-steels.com i will provide you best price .

UNS S31254 / Alloy 6Mo / WNR 1.4547 / F44 / 254SMO Super Austenitic Stainless Steel

UNS S31254 is a high corrosion resistant Super Austenitic Stainless Steel and provide excellent corrosion resistance in severe corrosion environments such as high temperature seawater.

We offer a comprehensive selection of seamless/welded stainless steel pipes, including the UNS S31254 super austenitic stainless steel pipe, also known as 254SMo or WNR 1.4547. Made with high-quality materials and under strict manufacturing standards, these pipes are perfect for a variety of applications in seawater handling systems, desalination plant equipment, chemical processing, and flue gas desulphurization units.

UNS S31254 Stainless Steel Pipe Features:

– High corrosion resistance: Made with alloy UNS S31254, these pipes are highly resistant to corrosion in harsh environments, including high chloride and acidic conditions.

– High strength: The WNR 1.4547 pipes are made with a super austenitic stainless steel with high strength, making them durable and reliable for a range of applications.

– Excellent weldability: The 6mo stainless steel pipes are easy to weld and fabricate, making them a versatile solution for complex piping systems.

– Compliant with industry standards: The 254SMO Super Austenitic Stainless Steel pipes meet the manufacturing standards of ASTM A269, ASTM A312, and ASTM A213, ensuring quality and reliability.

UNS S31254 Chemical Composition (%)

| % | C | Mn | P | S | Si | Ni | Cr | Mo | N | Cu |

| Min | 17.5 | 19.5 | 6.0 | 0.18 | 0.50 | |||||

| Max | 0.02 | 1.00 | 0.030 | 0.010 | 0.80 | 18.5 | 20.5 | 6.5 | 0.25 | 1.00 |

254SMO Physical Properties:

| Density | 8.02 Mg/m³ |

| Melting Range | 1360-1405 ℃ |

UNS S31254 Stainless Steel Pipe Applications:

– Seawater handling systems: The UNS 31254 Stainless Steel pipes are ideal for use in seawater handling systems due to their high corrosion resistance and strength.

– Desalination plant equipment: The WNR 1.4547 Stainless Steel tubes are widely used in desalination plant equipment due to their ability to withstand high chloride and saltwater environments.

– Chemical processing: The UNS S31254 pipes are suitable for chemical processing due to their corrosion resistance and thermal stability.

– Flue gas desulphurization unit: The Alloy 6Mo Stainless Steel pipes are ideal for use in flue gas desulphurization units due to their resistance to acids and ability to handle high temperatures.

Manufacturing Standards:

ASTM A213

ASTM A312

ASTM A269

Also individual customer specifications, as a professional UNS 31254 Stainless Steel pipes and tubing supplier, Hengyang is committed to providing high-quality stainless steel pipes to meet the needs of our customers. Contact us today for more information on the UNS S31254 pipe and other products in our collection.

Product Item:HY005

Manufacturing: Cold Rolled/Cold Drawn

Type: Seamless/Welded

Surface: Annealed and Passivated

Application Fields: heat exchanger, boiler, evaporator

Alloy 825/ UNS N08825/ W.Nr.2.4858/ Incoloy® 825

Alloy 825 tube, also known as Incoloy 825 pipe, W.Nr. 2.4858 or UNS N08825, this nickel alloy steel is a combination of nickel, chromium, and iron, with small amounts of molybdenum, copper, and titanium to enhance its resistance to corrosive environments, especially in chloride-containing media. 825 tubing is a durable and reliable material that is widely used in applications that involve harsh environments and high temperatures.

UNS N08825 Chemical Composition:

| % | Ni | Cr | Fe | Mn | C | Cu | Si | S | Al | Ti | Mo |

| Min | 38.0 | 19.5 | 22.0 | 1.5 | 0.6 | 2.5 | |||||

| Max | 46.0 | 23.5 | 1.0 | 0.05 | 3.0 | 0.5 | 0.03 | 0.2 | 1.2 | 3.5 |

Features of Alloy 825 Tube:

- Excellent Corrosion Resistance: Alloy 825 tube is highly resistant to corrosion, pitting, and stress corrosion cracking in various corrosive environments like nitric acid, sulfuric acid, phosphoric acid, and others.

- High-Temperature Strength: The inconel 825 tube can withstand high temperatures up to 550°C (1020°F) and still maintain its excellent mechanical properties.

- Good Weldability: Incoloy 825 pipe can be easily welded with various welding processes, including gas tungsten arc welding, gas metal arc welding, and shielded metal arc welding.

Incoloy® 825 Physical Constants:

| Density | 8.19 Mg/m³ |

| Melting Range | 1370-1400 ℃ |

Alloy 825 Tube Application:

- Chemical Processing Equipment: Alloy 825 tube is used in the chemical processing industry for making process vessels, reactors, tanks, and other equipment that need to be resistant to corrosion.

- Heat Exchanger Tube UNS N08825: Incoloy 825 tubing is commonly used as heat exchanger tubing in various industries like chemical processing, oil and gas, and power generation.

- Pollution Control: Alloy 825 tube is widely used in pollution control systems due to its excellent corrosion resistance, widely used in scrubber systems for removing harmful gas emissions from power plants and other industrial facilities.

- Petroleum Refining: Inconel 825 pipeis used in petroleum refining applications due to its ability to withstand highly corrosive environments, commonly used in heat exchangers, piping systems, and other equipment that comes into contact with sulfuric acid, hydrochloric acid, and other corrosive substances.

- Offshore Oil and Gas Production: The incolony tubeis widely used in offshore and onshore oil and gas production, where corrosion-resistant materials are needed to withstand harsh corrosive environments.

* Marine: W.Nr.2.4858 is used in marine applications, including seawater cooling systems, desalination plants, and offshore platforms.

* Acid Production: 825 pipe is commonly used in the production of acids such as sulfuric acid, phosphoric acid, and nitric acid due to its excellent resistance to corrosion. It is used in heat exchangers, piping systems, and other equipment that come into contact with these corrosive substances.

* Nuclear Fuel Reprocessing: Incoloy 825 seamless pipe is commonly used in nuclear fuel reprocessing applications due to its ability to withstand highly corrosive environments. It is used in equipment such as storage tanks, piping systems, and heat exchangers that come into contact with radioactive materials and corrosive substances.

Alloy 825 is available in wide variety of shapes and forms including pipe, tube, fitting, flange, sheet, plate, round bar, forging stock, flat bar, wire, hexagon. The various forms of UNS N08825 from Hengyang Piping meet different critical standards like ASTM, ASME, DIN, EN, ISO and clients’ specification. For detailed information about customized pipe and fittings, please contact us!

Founded in 2003, Zhongshan GHL Hardware Products Co.,Ltd (formerly known as HOWKEE LOCK) is one of the leading door lock manufacturers with 20 years OEM experience. Covering a production area of 100,000 square feet, we specialize in manufacturing a large variety of door locks, including tubular knobsets, tubular leversets, cylindrical knobsets, cylindrical leversets, deadbolts, combo locks, heavy duty door handle lock, grip handle sets as well as all kinds of door lock accessories. All of our products meet ANSI Grade 3 Standard requirement.

Over the past 20 years, it has been our top priority to make continuous improvement on quality management and control system. Being awarded the ISO 9001 : 2015 certificate, we are dedicated relentlessly to put in place the stringent quality control and inspection process from raw material to final pack products. Samples are taken from each order for cycle test, salt-spray test etc. in our own testing lab before shipment. As a result, our door locks have received high popularity and good reputation among locksmiths, builders, REO contractors, wholesalers and hardware distributors especially in USA, Canada, Australasian Southeast Asian countries.

Our experienced R&D and sales team sincerely welcome any of your OEM and ODM orders and would be greatly honored to continue to serve old and new customers to the highest extent!

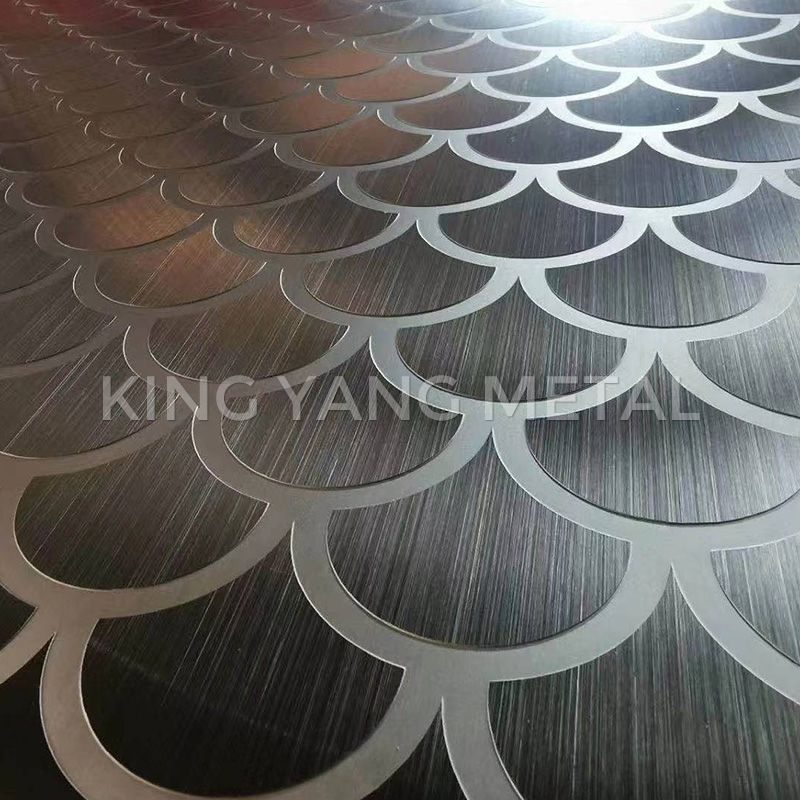

Ky Metal is professional etched stainless steel sheets manufacturer and supplier, offering elevator Etched Stainless Steel Sheet, Wall cladding Etched Stainless Steel Sheet, Stainless Steel Etching Sheets,Decorative SS Etched Sheets, SS Colored Etched Sheets

Etched stainless steel sheets are thin plates of stainless steel that have been chemically treated to produce a pattern or design on the surface. With 8K mirror plate, drawing sheet and sandblasting sheet as the base plate, the surface of the object is further processed after etching. Etching version can be processed by a variety of complex processes such as local blending, wire drawing, gold inlaying and local titanium, to achieve the effect of light and dark patterns and brilliant colors.

Stainless Steel Sheet with Etched Finish is widely used in architectural decoration. Especially in the choice of elevator board, the general use of mirror panel as the elevator bottom sheet, and then according to the needs of the pattern processing, so that the overall effect has a three-dimensional sense, reflect its beautification value.

The installation and use of the elevator should consider its value and safety performance. A variety of different patterns etched out of stainless steel, as well as the use of different colors, so that the elevator space is no longer dull, dull, more lively.