Werner Flanges Inc. an ISO 9001:2008 certified Company manufacturing & exporting the finest quality Carbon Steel, Alloy Steel, Stainless Steel Butt Welded Pipe Fittings, High Pressure Forged Fittings & Flanges. Immediate Response, Excellent Quality, Quick Delivery and Customer Satisfaction truly define Werner Flanges Inc.

As the most valuable subsidiary under SHINESTAR STEEL GROUP, PRIME STEEL PIPE is the solution provider for the oil, gas, construction, energy and prtrochemical industries.SHINESTAR STEEL GROUP is specialized in manufacturing superior quality steel products, and providing outstanding service for valued clients all over the world.

Hunan Great Steel Pipe Co.,Ltd is specialized in steel pipe & tube production including carbon steel pipe, seamless steel pipe, erw steel pipe, ssaw steel pipe, lsaw steel pipe, etc.

Hunan Great Steel Pipe Co.,Ltd is a world-class production and service provider of seamless pipes and welded pipes as the first subsidiary of Shinestar Group.

Roopam Steel is top manufacturer & supplier of seamless steel pipe welded tubes in ferrous and non ferrous material, Stockist of high quality tubular piping products and accessories in India. Call us for more Info at +91-22-6639 4333.

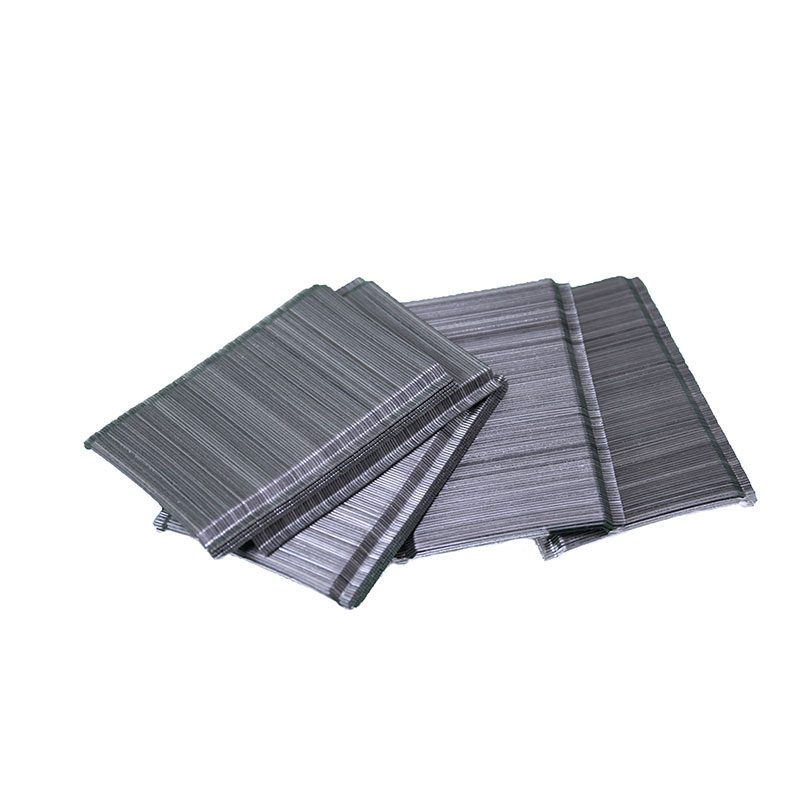

Glued Steel Fiber, an alternate concrete reinforcing material are high tensile steel wires with hooked ends, glued together by the water-soluble adhesive for compactness and uniform dispersion in concrete, to increase the concrete properties by 3-4 times.

steel fiber reinforced concrete supplier improve the mechanical properties concrete and materials such as ductility,

energy absorption, fatigue, and toughness. This fiber helps to controls plastic shrinkage cracking in concrete; helps reduce or eliminate need for conventional reinforcement.

Application of Glued steel fiber reinforced concrete

- For concrete flooring

Industrial floors

Joint-less floors

Floors-on-piles

Lightly loaded floors

Liquid tight floors & composite metal decking

- stainless steel fiber supplierFor Hard Standing & Heavy Duty

Parking lots

Playgrounds

Airport runways

Taxiways

Maintenance hangers

Access roads & workshops

Ports& Containers for port pavements

Container terminals

Bulk storage areas access roads

For army tank movement

- steel fibers for concrete reinforcementOther Applications

Foundations

Traditional cellar and basement walls

Compression layers

Tunnel engineering

Compared with the GuangYa loose steel fiber the operation and advantages of the glued steel fiber:

- Add the steel fiber directly into the belt, the whole row of steel fiber as a whole, evenly dispersed in the concrete corner

- The water-soluble glue begins to dissolve in a row of steel fibers in the premise of the dispersion, it is again dispersed in every corner of the mono filament fiber, showing the perspective in the concrete of the fiber mesh, which plays an integral strengthening.

- Compared with mono-filament fibers, China bonded steel fiberswill not be bundled to ensure that the fibers in concrete do not coalesce and distribute evenly.

Glued steel fibers are loose hook-end fibers that are bonded together in a row. The great difference between loose fiber and glued fiber is that the former is easy to clog and the latter is easy to disperse evenly.

Product Item:HY005

Manufacturing: Cold Rolled/Cold Drawn

Type: Seamless/Welded

Surface: Annealed and Passivated

Application Fields: heat exchanger, boiler, evaporator

Alloy 825/ UNS N08825/ W.Nr.2.4858/ Incoloy® 825

Alloy 825 tube, also known as Incoloy 825 pipe, W.Nr. 2.4858 or UNS N08825, this nickel alloy steel is a combination of nickel, chromium, and iron, with small amounts of molybdenum, copper, and titanium to enhance its resistance to corrosive environments, especially in chloride-containing media. 825 tubing is a durable and reliable material that is widely used in applications that involve harsh environments and high temperatures.

UNS N08825 Chemical Composition:

| % | Ni | Cr | Fe | Mn | C | Cu | Si | S | Al | Ti | Mo |

| Min | 38.0 | 19.5 | 22.0 | 1.5 | 0.6 | 2.5 | |||||

| Max | 46.0 | 23.5 | 1.0 | 0.05 | 3.0 | 0.5 | 0.03 | 0.2 | 1.2 | 3.5 |

Features of Alloy 825 Tube:

- Excellent Corrosion Resistance: Alloy 825 tube is highly resistant to corrosion, pitting, and stress corrosion cracking in various corrosive environments like nitric acid, sulfuric acid, phosphoric acid, and others.

- High-Temperature Strength: The inconel 825 tube can withstand high temperatures up to 550°C (1020°F) and still maintain its excellent mechanical properties.

- Good Weldability: Incoloy 825 pipe can be easily welded with various welding processes, including gas tungsten arc welding, gas metal arc welding, and shielded metal arc welding.

Incoloy® 825 Physical Constants:

| Density | 8.19 Mg/m³ |

| Melting Range | 1370-1400 ℃ |

Alloy 825 Tube Application:

- Chemical Processing Equipment: Alloy 825 tube is used in the chemical processing industry for making process vessels, reactors, tanks, and other equipment that need to be resistant to corrosion.

- Heat Exchanger Tube UNS N08825: Incoloy 825 tubing is commonly used as heat exchanger tubing in various industries like chemical processing, oil and gas, and power generation.

- Pollution Control: Alloy 825 tube is widely used in pollution control systems due to its excellent corrosion resistance, widely used in scrubber systems for removing harmful gas emissions from power plants and other industrial facilities.

- Petroleum Refining: Inconel 825 pipeis used in petroleum refining applications due to its ability to withstand highly corrosive environments, commonly used in heat exchangers, piping systems, and other equipment that comes into contact with sulfuric acid, hydrochloric acid, and other corrosive substances.

- Offshore Oil and Gas Production: The incolony tubeis widely used in offshore and onshore oil and gas production, where corrosion-resistant materials are needed to withstand harsh corrosive environments.

* Marine: W.Nr.2.4858 is used in marine applications, including seawater cooling systems, desalination plants, and offshore platforms.

* Acid Production: 825 pipe is commonly used in the production of acids such as sulfuric acid, phosphoric acid, and nitric acid due to its excellent resistance to corrosion. It is used in heat exchangers, piping systems, and other equipment that come into contact with these corrosive substances.

* Nuclear Fuel Reprocessing: Incoloy 825 seamless pipe is commonly used in nuclear fuel reprocessing applications due to its ability to withstand highly corrosive environments. It is used in equipment such as storage tanks, piping systems, and heat exchangers that come into contact with radioactive materials and corrosive substances.

Alloy 825 is available in wide variety of shapes and forms including pipe, tube, fitting, flange, sheet, plate, round bar, forging stock, flat bar, wire, hexagon. The various forms of UNS N08825 from Hengyang Piping meet different critical standards like ASTM, ASME, DIN, EN, ISO and clients’ specification. For detailed information about customized pipe and fittings, please contact us!

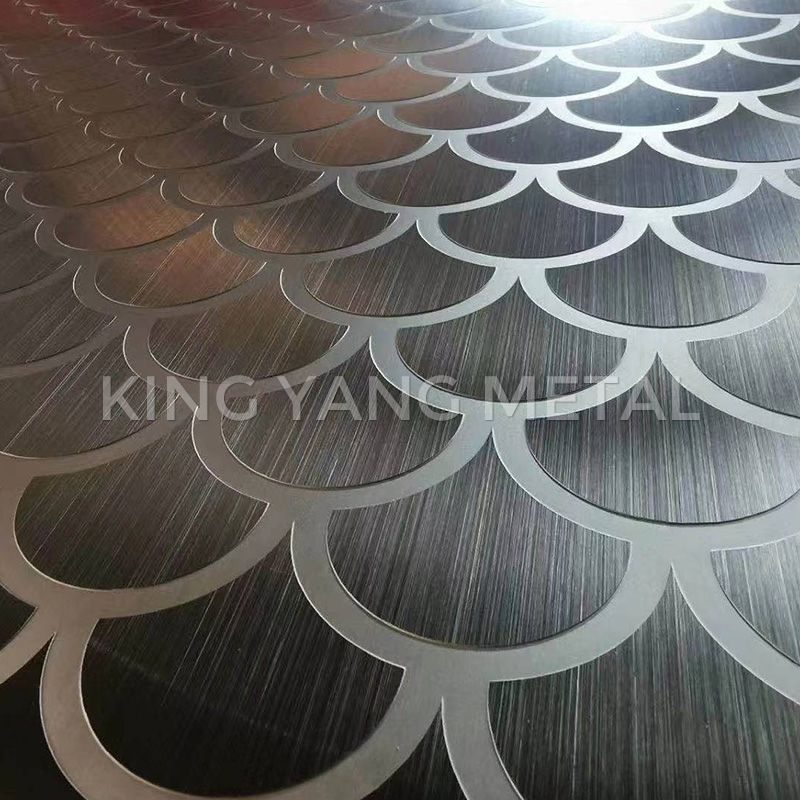

Ky Metal is professional etched stainless steel sheets manufacturer and supplier, offering elevator Etched Stainless Steel Sheet, Wall cladding Etched Stainless Steel Sheet, Stainless Steel Etching Sheets,Decorative SS Etched Sheets, SS Colored Etched Sheets

Etched stainless steel sheets are thin plates of stainless steel that have been chemically treated to produce a pattern or design on the surface. With 8K mirror plate, drawing sheet and sandblasting sheet as the base plate, the surface of the object is further processed after etching. Etching version can be processed by a variety of complex processes such as local blending, wire drawing, gold inlaying and local titanium, to achieve the effect of light and dark patterns and brilliant colors.

Stainless Steel Sheet with Etched Finish is widely used in architectural decoration. Especially in the choice of elevator board, the general use of mirror panel as the elevator bottom sheet, and then according to the needs of the pattern processing, so that the overall effect has a three-dimensional sense, reflect its beautification value.

The installation and use of the elevator should consider its value and safety performance. A variety of different patterns etched out of stainless steel, as well as the use of different colors, so that the elevator space is no longer dull, dull, more lively.

Copper Mould Tube & Plate

We specially in supplying Copper Mould Tube, Crystallizing equipment of continuous casters, Mould cooling jacket, Repair of Metallurgical Copper Mould Tube, etc.

Equipments & Spare parts for Continuous Casting Machine.

- Copper mould tube( square, rectangle and round )

- Crystallizing equipment of continuous casters

- Mould cooling jacket.

- repair of copper tube moulds

The copper alloys chosen for the moulds must maintain their physical properties at the operating temperatures of the continuous casting process.

The temperature gradation from the inner wall of the mould to the outside face of the mould can cause serious distortion problems, and Metallurgical Copper Mould Tube is imperative that the correct alloy is chosen for the various operating conditions.

Square Copper mould tube STANDARD MATERIALS

Phosphorus de-oxidised copper

This alloy has been proven to be excellent for the manufacture of moulds in the continuous casting of billets. The main composition of this alloy are Cu +Ag 99.90min, P0.0015 / 0.040.

Copper -Silver alloy

The addition of a small amount of silver, whilst not increasing the melting point of copper, does increase the recrystallisation temperature by almost 100℃, and also helps to give better thermal conductivity at the operating temperatures.

This alloy is normally used in moulds for the continuous casting of blooms and slabs .In this case, the moulds are much thicker than in the billet moulds, and the moulds temperature can be higher. The main composition of this alloy are Cu+Ag99.90 min. Ag 0.08 / 0.12 O 0.004 / 0.012.

The continuous casting of molten steel into billets, blooms and slab products, has been highly refined over the years into an extremely sophisticated system. The continuous casting process is expected to produce metallurgically sound products at the lower possible cost, and this is being achieved in many steelworks throughout the world.

Copper moulds have played an important role in the development of the continuous casting process. Their funcition is to receive the molten steel and to allow rapid heat transfer from the steel to the cooling water to enable quick solidification.

The mould must exhibit excellent thermal conductivity, be resistant for thermal erosion ,and be resistant to distortion from thermal stress. So far only copper and a few copper alloys meet the above conditions, both economically and technically.

Mould cooling jacket supplier SOLIDIFICATION

The rate of solidification in the continuous casting process dictates the speed of production. The molten steel, which is in contact with the inner faces of the copper mould, starts to sllidify as rapidly as the heat is extracted, forming a shell. The shell increases in thickness as more heat is extracted, and eventually total solidfication is achieved. the process is similar to the solidification of ingots in ingot moulds. In continuous casting, the whole process is speeded up, with the aim to produce and homogeneous shell growth. Consequently, the mould is an important part of the continuous casting process, and the manufactured quality of the mould plays and important role in their length of life.

INNER SURFACE COATINGS

Over the years, Metallurgists and Engineers have been working together to develop better continuous casting moulds. The steel companies require a more economical mould which will give a longer service life. Surface coating of the inner walls of the mould has given the best results to date. Coatings available are Chromium and Nickel plating. Also, a combination of the two give good results on slab casting.

SPECIFICATIONS OF COPPER MOULD

Square 60 x 60 – 350 x 350 (mm)

Rectangle 120 x 160 – 180 x 300 (mm)

Diameter 100-400 (mm)

Size(mm): 90×90, 100×100, 110×110, 115×115, 120×120

130×130, 135×135, 140×140, 143×143, 150×150

155×155, 160×160, 165×165, 175×175, 180×180

200×200, 220×220, 100×170, 100×173, 130×240

150×200, 150×210, 150×220, 160×200, 160×220

150×225, 160×235, 165×225, 175×225, 180×220

200×240, 240×240, 235×235

Radius(mm): 4000, 5000, 5250, 6000, 7000, 7500, 8000, 9000, 10250, 10300, 11000, 12000

Length(mm): 700, 750, 780, 790, 800, 810, 812, 850, 900, 1000

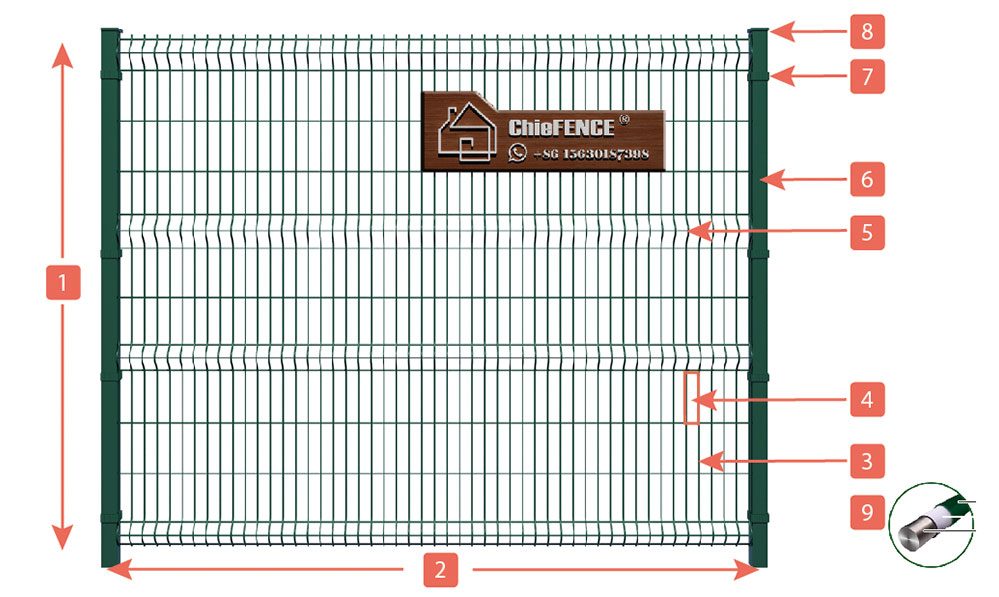

Welded mesh fence likewise called “3D FENCE” “medium-security fencing”. It is an affordable version of steel fence. The panel is bonded with low carbon steel wire. Material Grade: Q195, Surface therapy by Electrostatic polyester powder roaming finishing(Powder-coated) over galvanized products. And after that connect the fencing panels with article by suitable clamps(Clips). Because of its Simple framework, Easy installation and also Beautiful look.More customers regard welded wire mesh security fence as the preferred common protective fence.

Loni ChieFence 3d security fence FEATURES

Lower budget

See-through panel

Anti-rust, Long Service Life

Fast Installation

Customer specs available

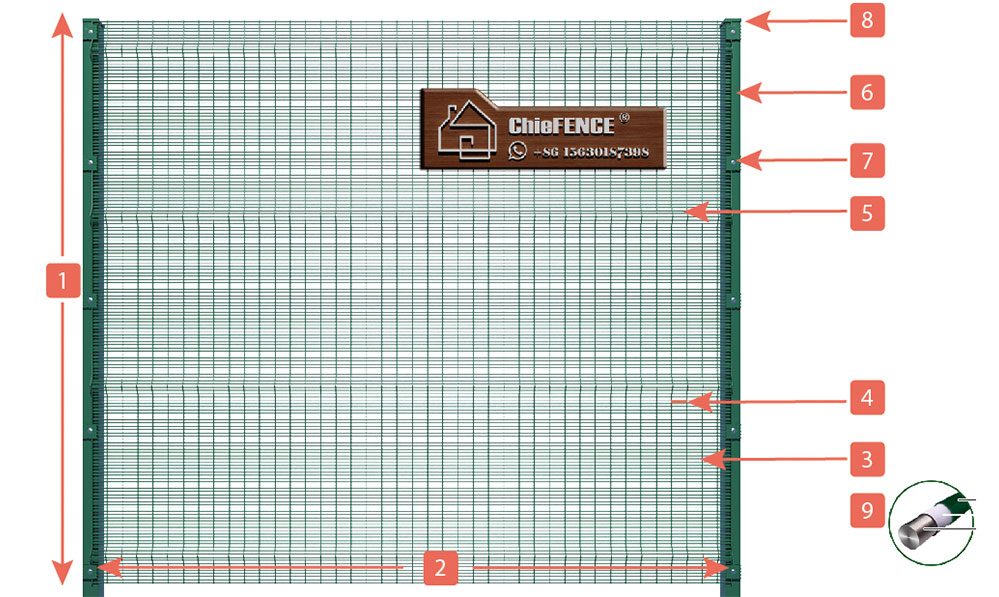

Rigidity

High security fencing also called ‘358 FENCE’ ‘3510 fencing’ ‘antifinger fencing’ ‘clearvu fencing’. It is a high cost version of Loni ChieFence 358 anti climb mesh. The panel is welded with reduced carbon steel cable , Material Grade: Q195, Surface treatment by Electrostatic polyester powder roaming finish(Powder-coated) over galvanized materials. And after that attach the fencing panels with message by suitable clamps(Clips). As a result of the 12.7 * 76.2 mm small mesh dimension, it is anti cut & anti finger climb.

358 high security fence China FEATURES

Anti climb

See-through panel

Anti-rust,Long Service Life

Fast Installation

Customer specs available

Rigidity

Learn more about our wire mesh via https://www.chiefence.com/

Belleville Disc Springs also was called “Disc Springs” “Conical Disc Springs”, include disc spring stacks, Corrosion Resistant Disc Springs, High Temperature / Cryogenic Disc Springs, Disc Springs for Ball Bearing, Disc Springs for Valves. Disc Springs are widely used in petrochemical, electric power, metallurgy, engineering, machine tools, national defense, and other industries.

Bearing Preload Disc Springs manufacturer Description

The Disc Spring concept was first invented by a Frenchman Louis Belleville in 1865. So, disc spring is commonly known as Belleville Springs. And sometimes it also was called “Conical disc springs” “Belleville Disc Springs” or “Belleville Washers”.

Hegong Disc Springs are conically washers and have a rectangular cross-section, which is loaded in the axial direction. It has a small volume and large energy storage compared to traditional helical springs and can be used as a single disc spring or in the stack (stack in parallel, in series or parallel & series combination).

The standards for disc springs mainly include DIN2092 (Calculation) / DIN2093 ( Quality Specifications-Dimensions ) of Germany, JIS B 2706- Japan, GB/T 1972-2005 of China and ISO 19690 : 2017 ( HEGONG SPRING ® is the drafting team member for international standard ISO 19690 : 2017 and Chinese national standard GB/T 1972-2005 ). Among them, DIN2093 is most widely used in the world.

belleville washer design are designed & manufactured according to DIN2092 & DIN2093, working for dynamic or static applications. The engineers of HEGONG SPRING® are pleased to design the springs for the specific applications together with the customer’s R&D department. Be free to contact with our engineers. Tech@DiscSpringsMFG.com.

Generally, disc springs include disc spring stacks, Corrosion Resistant Disc Springs, High Temperature / Cryogenic Disc Springs, Disc Springs for Ball Bearing, Disc Springs for Valves.

Surface Condition And Corrosion Protection:

Polish

Phosphating and oil

Mechanical Zinc Plating

Chemical Nickel Plating

Docromet / Geomet Coating

Electrophoresis

Tolerance:

The Tolerance is according to DIN2093 standards

Belleville Spring Washers exporter Specification:

The following specification table covers the “standard” sizes and some non-standard sizes. HEGONG SPRING ® customizes Belleville Disc Springs as well. The max OD is up to 1000mm. If you require the custom Belleville Disc Springs, please contact our sales engineers.

HENAN FORWARD STEEL EXPORT CO.,LTD

Tel: +86-371-61310228 You also can visit us by sa514steel.com througth google

Address: Tower-A Room 3106 Kai xuan Plaza zhengzhou city of henan province China

http://sa514steel.com

Email: admin@qfsteels.com

SA240 TP310S Stainless, SA240 309S stainless, SA240 316TI stainless, SA240 304H stainless

1. What we do?

HENAN FORWARD STEEL EXPORT CO.,LTD Stainless warehouse provide ASME SA240 Stainless steel plate Bevel,Groove and cutting disc stainless steel machined parts .we have 1000tons tp316L,tp310s,tp304l,tp321, tp304h, tp316h,tp310h, tp321h,2205, S31803, 410, 430, 409, 443, 439, 310SI2, 316TI Stainless steel plate stock.

Besides that, our factory also provide the CNC Cutting platform and water cutting platform. Disc cutting, special parts cutting, stainless steel bevel and stainless steel groove service. Our machined precision to min 0.2 for the surface of machined.

Our cutting service had approved by Mexico and USA, and Canada Project.

2. Our mainly stainless steel grade for ASME SA240

SA240 TP202,SA240 TP201,

SA240 TP304,SA240 TP304L,SA240 TP304H, SA240 TP304N, SA240 TP304LN

SA240 TP316L,SA240 TP316, SA240 TP316H,SA240 TP316N, SA240 TP316LN,SA240 TP316TI

SA240 TP309S, SA240 TP309H,SA240 TP309,SA240 TP309Cb

SA240 TP310S, SA240 TP310, SA240 TP310H

SA240 TP347,SA240 TP347H,

SA240 TP348,SA240 TP348H,

SA240 TP321, SA240 TP321H

SA240 TP317L,SA240 TP317

SA240 TP444,SA240 TP410, SA240 TP430,SA240 TP443, SA240 TP439

3. Products Service of our unitedsteel warehouse.

Stainless steel plate

Stainless disc steel plate.

Stainless steel cutting

Stainless seamless pipe

Stainless seamless Tube

Stainless welded steel pipe

Stainless machined bevel

Stainless machined groove

4. Our Stainless steel thickness

Stainless plates

0.25mm-150mm thickness

Width: 20mm to 2500mm

Length 20mm to 10000mm

Max weight of each plate 6 tons.

Stainless seamless pipe

outer diameter 3.2-200mm,

Wall thickness 0.5-12.7mm

5. Stainless Production time:

5-8days in usual size.

If you need the bevel and groove stainless parts, we need min extra 7days.

6. Stainless Payment Item for HENAN FORWARD STEEL EXPORT CO.,LTD

TT payment Or 30% TT advance and balance should be paid after BL documents.

7. Why you choose us?

a. The faster production time, and most of production, we can control them in one week if the total weight are not large.

b. Better service, we promise that your inquiry will be sent official quotation in 24hours.

c. Faster delivery, we had owned transport truck department and transport stainless to our port in 24hours.

d. Quality promise processing: PMI Test at each stainless steel plates before delivery. We accept the third party inspection, GL. SGS.BV, DNV, LR,ABS and others.

8. Trade Item:

FOB, EXW, CFR AND CIF

Packages by wooden pallet, delivery by containers.

9. How to contact HENAN FORWARD STEEL EXPORT CO.,LTD?

Your can searh our company name from google or visit sa514steel and qfsteels through searching them at google.

Mr David

0086-371-61310228

admin@qfsteels.com

http://sa514steel.com

Hebei Deko Commercial Co., Ltd. (hereinafter referred to as the “DEKO”), the company is located in China’s “Land of Casting” Hebei province, DEKO mainly supplies products involved in municipal engineering and road construction and related products, such as Ductile iron Pipe, Pipe Fitting, Valve, Manhole covers, Gratings, Public Illumination, Urban Furnishing, Flange and Pipe Repair Clamp etc…. we can also produce according to the drawings and samples provided by customers, our products have been exported to Europe, Africa, Asia, Middle East and Southeast Asia etc… providing import and export business for domestic and foreign customers.

DEKO has its own fully automatic vertical production line and now we have reached a strategic cooperation with several manufacturers and become the only designated agent service by manufacturers and can be better provide customers with the best prices, excellent product quality, DEKO’s aim is: to supply the required products and high quality service for every customers and maintain long-term and stable cooperation.

At Wonderful, we use advanced equipment to provide you with various exactness cnc machining service, including milling, turning, EDM, wire cutting, EDM and so on. Using our 3-axis, 4-axis and 5-axis CNC machining centers, our skilled machinists can use a variety of plastic and metal materials to manufacture turning and milling parts. Our CNC machining center can not only produce perfect samples for you, but also customize more small batch products for you, making us a one-stop service provider for your advanced design and small batch product needs.https://www.wdfprecision.com/

Somos un fabricante profesional de bridas, accesorios de tubería, accesorios forjados en la India, nos especializamos en la fabricación de todos los tamaños, estándar, tipo, etc. Somos capaces de proporcionar una amplia gama de materiales, desde existencias, para satisfacer sus necesidades. Desde material no estándar altamente especializado hasta artículos listos para usar, desde la producción hasta el prototipo, desde mínimos bajos hasta corridas de fábrica, el fabricante de bridas tiene la experiencia para resolver sus requisitos más difíciles.

Products name: Stainless steel ferrule mesh, Stainless steel ferrule rope mesh, Stainless steel ferrule cable mesh, X-TEND mesh

Material: High-quality SS 304, 304L, 316, 316L wire ropes and stainless steel ferrules.

Features: light weight, good flexibility, high strength, good transparency, good invisibility. The service life is more than 30 years.

Applications: zoo mesh, animal enclosure, bird aviary, handrail infills, anti-falling safety net, garden fence.

Design and installation: various graphics and structures can be designed, and installation schemes can be provided.

Stainless steel ferrule mesh is also called stainless steel ferrule wire rope mesh. The mainly material is stainless steel cable and stainless steel ferrule. It is produced by putting the ferrules tough the cable first, and then press the ferrule using special molds. This kind of mesh has very beautiful appreance, it also has very good strength and flexibility. We can product various types of ferrule mesh in different cable diameter and mesh opening to meet our clients’ requirement.

Applications

The stainless steel cable mesh, especially the ferrule type mesh, are more used in fields like balustrades on bridges and staircases, large barrier fences, and building facade trellis systems. As an emerging product on architectural decoration and protection, stainless steel rope mesh has provided the mordern architectural decoration and horticulture engineering with a new and stylish element, which are getting more and more appreciated by designeers and clients all over the world.

Product Name: Hot Dipped Galvanized Iron Wire

Item Code: Smart Craftsmen-HDG Wire

Surface Treatment: Electro Galvanized.

Raw Material: SAE1006 SAE1008 Q195 Q235 or Others.

Tensile Strength: 330- 550MPA

Package: Customize.

Place of Origin: Hebei, China.

Loading Port: Tianjin Port

Smart Craftsmen Galvanized iron wire is designed to prevent rust and shiny silver. It is strong, durable and versatile. It has been widely used in landscaping, construction, woven hardware cloth and mesh. Wholesale Galvanized wire is divided into hot-dip galvanized wire and electro-galvanized wire (cold galvanized wire). Galvanized steel wire has good flexibility

Sex and toughness. It has the characteristics of large thickness of galvanized layer and corrosion resistance. Hot-dip galvanized iron wire China is made of low-carbon steel wire, which is drawn, pickled, derusted, annealed and coiled.

Electro-galvanized iron wire is made of selected low-carbon steel through drawing, galvanizing and other processes. Electro-galvanized iron wire has the characteristics of thick galvanized layer, good corrosion resistance and strong galvanized layer.

Ceramic lined pipe is made through the self-propagating high-temperature synthesis (SHS) technique.

Self-propagating High-temperature Synthetic process

Self-propagating high-temperature synthesis (SHS) is used to describe a process in which the initial reagents (usual powders), when ignited, spontaneously transforms into products due to the exothermic heat of reaction.

The combination of high rigidity of ceramic and high elasticity of steel gives the pipe unmatchable features like abrasion resistant, heat resistant, and corrosion-resistant material for use in the fields of power generation, metallurgy, mining, and chemical industry, etc. It has many advantages over steel pipes, cast stone pipes, and steel-plastic compound pipes.

Usage of Ceramic Lined pipe

The ceramic-lined pipe transportation has been widely used in the industries of electric power, metallurgy, coal, petroleum, chemical engineering, building materials, mechanism, and so on.

The ceramic lined elbow throughout the power, metallurgy, coal, petroleum, chemical, building materials, machinery, and other industries, and high-speed development. When lining the wear-resistant ceramic elbow to deliver high grinding material (such as ash, coal, ore powder, etc.), there is a lining of wear-resistant ceramic elbow wear fast, especially the elbow Wear faster. When lining a ceramic-lined elbow to deliver a highly corrosive gas, liquid or solid, there is a problem that the lined wear-resistant ceramic elbow is corroded and is quickly damaged.

There is a problem that it is expensive to use a heat-resistant steel pipe when the material having a higher temperature is conveyed in the lining of the wear-resistant ceramic elbow. After lining the wear-resistant ceramic elbow, these problems are solved.

The ceramic lined elbow is widely used in wear and tear of mine filling material, ore powder and tailings transportation, coal-fired power plant powder, smelting, ash and other things lined with wear-resistant ceramic elbow are also very appropriate.

The ceramic lined pipe, Elbows, Reducer, Tees, and others manufactured in our factory have been used in over 200 thermal power plants, more than 50 mines, and the industries of coal, building materials, mechanism, petroleum, and so on.

Abrasion

Ceramic layer Ceramic Lined Reducer Pipe with flange reducer Al2O3 content greater than 89%, micro-hardness HV1000-1500, which has high abrasion resistance, wear resistance more than ten times higher than carbon steel after quenching, superior tungsten carbide drill.

Application range

- coal pulverizing system of power plant pipeline, including, powder transmission pipeline, thick powder separator pipeline, coal drop pipe, combustion system of a windpipe, a secondary air pipe, three pipeline and burner pipelines, in addition to ash slagging system the discharge pipe, powder pipe, dry ash conveying pipe;

- Iron and steel plant raw material conveying pipeline, collecting pipe, dust pipe, ash pipe, ash pipe, mixing pipe, grinding export pipeline, coal pipeline, coal pipeline, separator pipe, burner radius pipe, etc.;

- Cement plant selection machine outlet pipe, choose machine inlet pipe, pipe dust pipe, vertical mill outlet pipe, circulating air duct, high-temperature air blower, lower material pipe, etc.;

- Petroleum, chemical, mining, coal, coal washing plant, smelting, paper, aluminum, building materials, powder engineering, food machinery, and other processing and conveying material pipes.

Corrosion

Ceramic materials are neutral, chemically stable, have excellent corrosion resistance and acid resistance, resistant to various inorganic acids, organic acids, organic solvents, and their degree of corrosion of stainless steel is more than ten times.

Temperature

Temperature above 2000celsius degree, long-term work in the range of -50 -900 celsius degree.

Easy welding.

The ceramic adjustable tube can be welded, flanged, flexible connectors, and other fast way links, very easy to install.

Clean and easy maintenance

Smooth walls, can prevent scaling, fouling, and self-cleaning functions. Tightness.

Remarks:

- Under the direction of the arrow diagram for the export direction.

- Bend radius is usually 1.5-5 times the diameter of steel pipe (1.5-5D).

- Othe specifications of the composite pipe can be manufactured according to the user requirements.

- The weight is calculated by theoretics, maybe have some tolerance, and real weight will be weigh-in after they finish.

Hoop strength is the resistance against radial pressure. The strength of the ceramic-lined steel composite pipe is 300 to 500MPa.

Features and Advantages of ceramic lined pipe

Ceramic Liner pipe is a high technology production technology-self-fuel high-temperature clutch synthesis method.

1). High Abrasion Resistant:

Vickers hardness of the corundum lining is HV1100 to1500, as high as that of tungsten-cobalt hard alloys, and the abrasion resistance is 20 times as carbon steel pipes. The composite ceramic-lined steel elbow was used in a mining plant for about fifty thousand hours. The general service life of a common steel elbow is about 700 hours.

2). Corrosion Resistant:

Corundum is a neutral material and is acid-proof and fouling-free.

3). Heat Resistant:

Ceramic lined composite steel pipes can work under circumstances of -50 to 800 Celsius degree.

4). Lower Weight and Convenient Installation:

The ceramic-lined steel pipes are lighter than alloy pipes, cast iron pipes, and cast stone pipes and can be welded or connected through flanges, which reduces the expense of transportation and makes the pipes easier to install.

For the pipes with the same sizes, types, and lengths, the weight of the ceramic pipe is about 1/2 of the wearable cast alloy steel pipe’s, while the cost has reduced 10%~20% per meter.

The weight of ceramic-lined steel pipe is about 1/3 of the cast stone bent pipes, 1/2 of the cast stone straight pipes.

Ceramic (Corundum: a-Al2O3) lined abrasion resistant straight pipe and fittings are lined with highly abrasion-resistant ceramic by SHS ——-Self-propagating High-temperature Synthetic process.

- The ceramic-lined steel composite pipe can be joined by welding the steel pipe layer.

- Ceramic-lined pipes can take place of expensive stainless steel, titanium, nickel, cast stone, or alloy pipes.

- Extended service life can also reduce maintenance costs.

Self-Propagating Ceramic Pipe

Self-propagating ceramic steel pipes create a new generation of abrasion and corrosion-resistant engineering pipelines.

The self-propagating ceramic steel pipe has very good wear resistance, Excellent corrosion resistance, and Excellent thermal resistance performance.

SHS-self-propagating ceramic steel pipe and elbow create a new generation of abrasion and corrosion-resistant engineering pipeline. The composite pipe is composed of three layers: ceramic, intermediate, and steel layers.

The ceramic layer is formed by molten alumina at a temperature above 2500 degrees. The molten alumina produced from the reaction Fe2O3+2Al=2Fe+Al2O3 spreads on the inside wall of the steel pipe under the influence of a centrifugal force, then solidifies, so the ceramic layer has high density and smooth surface and bonds to the steel pipe.

Applicable Industries:

- The pipe needs excellent wear resistance property: Power plant, Mining, Sea Port, Coal Plant, And pipe for transporting the powder, slurry, sand, etc.

- Coal washing plant, pipe for transporting coal and other material.

- Pipe for transporting the melted aluminum.

- Any pipe which needs to wear protection, corrosion protection, etc.

Benefits:

- Excellent wear resistance, Alumina content of the ceramic liner is higher than 95%, Hardness HV1000-1500. The wear protection performance is more than 10 times better than carbon steel after quenching,

- Excellent corrosion resistance, stable chemical properties.

- Excellent thermal resistance performance up to 2000℃ Can be used in the area from-50℃ to 900℃ for a long time.

- Can be connected with another pipe by welding, flange and soft fast connecting, and easy installation.

No.8 Mirror stainless steel mirror sheets is kind of mirror stainless steel sheets, like a mirror, through polishing stainless steel surface treatment, mirror effect can be divided into general grinding, fine grinding, super fine grinding, etc. No.8 Mirror stainless steel sheet process, specifications, colors, patterns and so on can largely meet the different needs of each customer. No 8 mirror finish stainless steel sheet is widely used in a variety of decorative design, as building Interior exterior decoration, screen, door, elevator, lift , wall decoration, cover panel, table or decorative surface, as well as stainless steel anchor line, stainless steel TV wall, column edge, etc; It is an essential foundation for high-end architectural decoration projects.

No. 8 mirror stainless steel sheet offers several advantages over other types of stainless steel sheets. Its highly reflective surface creates an aesthetically pleasing finish that is ideal for decorative applications such as architecture, interior design, and signage. The mirror finish also makes the surface easier to clean and maintain, as it resists fingerprints and smudges. In addition, No. 8 mirror stainless steel sheet is durable, corrosion-resistant, and has a long lifespan, making it a cost-effective choice for many applications.

Why choose us as your No.8 Mirror Stainless Steel Sheet Manufacturer?

As a mirror polished stainless steel sheet manufacturer, We are expertise in polishing stainless steel allows us to produce high-quality mirror finishes with consistent reflectivity and smoothness. Our ability to customize the size, thickness, and grade of stainless steel plates ensures that your customers can find the perfect product for their specific needs. Additionally, our experience in the industry allows you to provide competitive pricing and fast turnaround times, making us a reliable and trusted supplier. Overall, our expertise in mirror polished stainless steel plates offers our customers a durable and aesthetically pleasing solution for their decorative and functional needs.

Steel grating is generally made of carbon steel, and the surface is hot-dip galvanized, which can prevent oxidation. It can also be made of stainless steel, and the steel grating has the properties of ventilation, lighting, heat dissipation, anti-skid, explosion-proof and so on.

Steel grating is a kind of steel product with square lattice in the middle, which is cross-arranged with flat steel according to a certain spacing and horizontal bars, and welded by pressure welding machine or manually. Steel grating is mainly used as gutter cover. , steel structure platform plate, steel ladder step plate, etc., the cross bar is generally made of twisted square steel.

Advantages of steel grating fence

Material saving: the most material saving method under the same load conditions, correspondingly, the material of the supporting structure can be reduced;

Reduce investment: save material, save labor, save construction period, free of cleaning and maintenance;

Simple construction: on the pre-installed support, it is fixed with bolts or welding, and it can be completed by one person;

Save construction period: the product does not need to be reprocessed on site, and the installation is very fast;

Durable: It has been hot-dip galvanized anti-corrosion treatment before leaving the factory, and has strong impact and heavy pressure resistance;

Modern style: beautiful appearance, standardized design, ventilation and light transmission, giving people an overall smooth modern feeling;

Lightweight structure: less material, light structure, and easy to hoist;

Reduce wind resistance: due to good ventilation, the wind resistance is small in case of strong wind, reducing wind damage;

Anti-contamination: no rain, snow and dust;

Other advantages: ventilation, lighting, heat dissipation, explosion-proof, good anti-skid performance;

Simple design: no need for small support beams, simple structure and simplified design

Acid and alkali corrosion ability: in the range of PH 6 to PH 12.5, a stable protective film is formed on the surface of the zinc layer, and the corrosion resistance is good.

Steel grating use

Steel grating is suitable for alloys, building materials, power stations, boilers, shipbuilding, petrochemical, chemical and general industrial plants, municipal construction and other industries. It has the advantages of ventilation and light transmission, anti-skid, strong bearing capacity, beautiful and durable, easy to clean and easy to install.

Steel grating has been widely used in all walks of life at home and abroad, mainly used as industrial platforms, ladder treads, handrails, passage floors, railway bridge sideways, high-altitude tower platforms, drain covers, well covers, road grilles, three-dimensional It can also be used as a fence for parking lots, institutions, schools, factories, enterprises, sports fields, and garden villas.