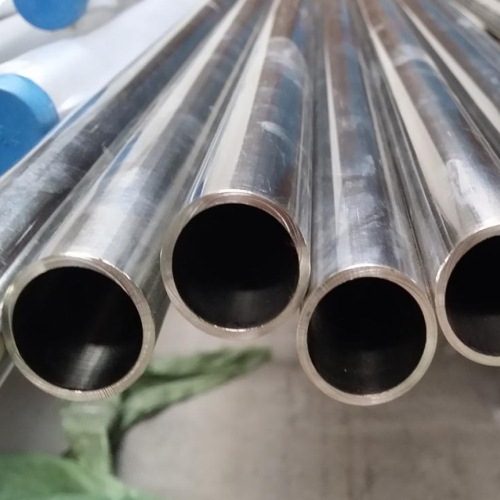

美国联合钢铁工业有限公司(USI Group)是中国最大的钢管集团之一,成立于1989年,海外总部位于新加坡,国内总部位于中国江苏省苏州市苏州工业园区。

USI集团拥有20个分支公司,总资产:10亿美元,员工10000多人,以及6个工厂(分别位于天津,苏州和沧州市),用于生产电焊管(ERW,SSAW和LSAW),无缝碳钢管,镀锌焊接管,方形/矩形钢管,不锈钢管/盘管/板/片,管件,法兰等。

我们先进的设施以及在生产的各个阶段均具有出色的质量控制,可确保产品质量,因为由于我们优质的产品和出色的客户服务,我们赢得了客户的满意并在油气管道行业中享有良好的声誉,我们的客户包括PDVSA,NIOC,中石化,中石油等。

Hebei Fuhua Wanshixing Hardware and Wire Mesh Products Co., Ltd. was established in 2006, has 15 years of history. Our Company covers an area of 33000㎡. There are more than 10 sets razor barbed wire making machines.

Hebei Zhuocui Trading Co., Ltd For Hebei Fuhua Wanshixing Hardware and Wire Mesh Products Co., Ltd. Shijiazhuang office,Our company owns a group of technician and workers specialized trained.The main products: Razor barbed wire, Wall spikes, Chain link fence, Steel grating, Mobile security barriers, temporary fence, etc. Our quality management system has been successfully approved by the ISOQAR to the standard ISO9001:2000.

All the products are exported to Europe, America, Middle East, Southeast Asian and so on. These products enjoy a good reputation from our customers at home and abroad.

Hebei Fuhua Wanshixing always adhere to the principle of “Sincerity First, Customer First”, and strictly complete each order according to customer requirements, ensuring the quality and quantity.

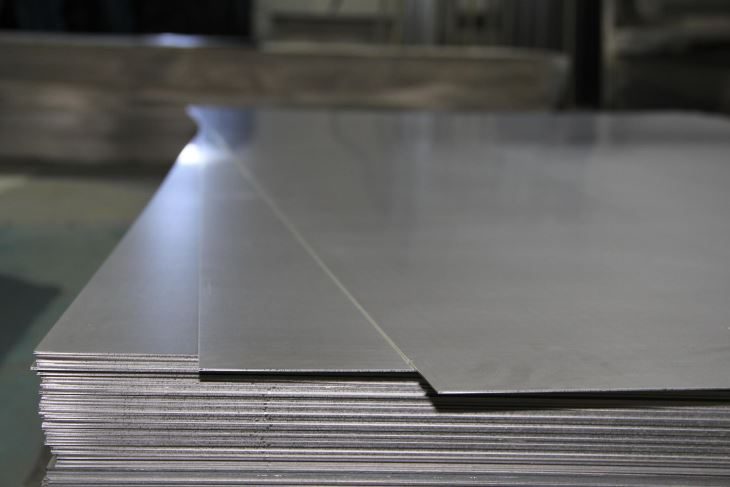

Application:

Hot Rolled Stainless Steel Clad Plate is extensively used in Oil, chemistry, electricity, paper making, alkali production, watering works, vehicles, salt, medicine, food and also public facilities.

Advantage for KLS Stainless Steel Clad Plate:

Stainless steel dressed plate makes the combination far more stronger than that of the surge bonding, more eco-friendly than the explosion bonding, and also the turn-around time is quicker. The toughness of the bonding interface is uniform that makes the anti-corrosion layer totally used, and also hot-rolled cladding modern technology can generate a clad plate with extremely with and also ultra length.

Machining Methods for Stainless Steel Clad Plate China :

Eruptive Clad: Overlap stainless plate on carbon steel plate with a cushion in middle to leave particular space.Explosive material will be paved externally of stainless plate and when eruptive product exploding, high energy can make stainless plate effect carbon steel plate with high speed to joint.In optimal condition, the strength for square mm could get to 400 Mpa.

Thickness Scope:10 mm-300mm.

Warm Rolled Clad: Hot rolled stainless steel dressed plate is rolled of stainless and also carbon steel plates in vacuum condition.In such process, the attired plate and base plate must be in pure clean condition.Besides, for improving the stamina of conbining, there are also a collection of technological approaches with physics and chemical therapies.

Density Scope:0.6 mm-50mm.

Cold Rolled Clad: Cold rolled Stainless dressed plate is made after annealing-pickling-cold rold-mid annealing-pickling manufacturing process to stainless-steel clad plates.This material is with far better yield stamina than exact same grade stainless plate.Min density would get to 0.6 mm.

Galvalume steel is an important alloy material often used in daily life. The galvanized steel sheet is composed of aluminum-zinc alloy structure, which is composed of 55% aluminum, 43.5% zinc and 1.5% silicon solidified at a high temperature of 600℃. Its entire structure is composed of aluminum-iron-silicon-zinc, forming a dense quaternary crystal. Of an alloy.

Characteristics of Galvalume

Hot-dipped Galvalume Steel Coil has many excellent characteristics: strong corrosion resistance, 3 times that of pure galvanized sheet; beautiful spangles on the surface, which can be used as building exterior panels.

Corrosion resistance:

The corrosion resistance of “aluminized zinc steel coil” is mainly due to the protective function of aluminum and aluminum. When zinc is worn, aluminum forms a dense layer of aluminum oxide, which prevents corrosion-resistant substances from further corroding the interior.

Heat resistance:

Hot-dipped Galvalume Steel Coil has good heat resistance and can withstand high temperatures of more than 300 degrees Celsius. It is very similar to the high temperature resistance of aluminized steel plate. It is often used in chimney pipes, ovens, luminaires and fluorescent lampshades.

Heat reflectivity:

The heat reflectivity of Hot-dipped Galvalume Steel Coil is very high, twice that of galvanized steel sheet, and people often use it as a material for heat insulation.

Economical:

Because the density of 55% AL-Zn is lower than that of Zn, the area of the galvanized steel sheet is more than 3% larger than that of the coated steel sheet when the weight is the same and the thickness of the gold plating layer is the same.

Application of Hot-dipped Galvalume Steel Coil

use

The main uses of galvanized products are in two aspects. One is the shell and box of other electrical equipment used in electrical switch cabinets; the other is galvanized steel roofing for steel structure buildings, because of its good anti-corrosion and anti-corrosion properties. In many areas with heavy industrial pollution, aluminum-zinc color panels or aluminum-zinc fingerprint-resistant light panels are directly used on walls or roofs.

Construction: roofs, walls, garages, soundproof walls, pipes and modular houses, etc.

Automobile: muffler, exhaust pipe, wiper attachment, fuel tank, truck box, etc.

Home appliances: refrigerator back panels, gas stoves, air conditioners, electronic microwave ovens, LCD frames, CRT explosion-proof belts, LED backlights, electrical cabinets, etc.

Agricultural: pig houses, chicken houses, granaries, greenhouse pipes, etc.

Others: thermal insulation cover, heat exchanger, dryer, water heater, etc.

Anping TianHui Wire Mesh Products Co., Ltd. is located in anping county, Hebei province, which also be called “Hometown of wire mesh”in china. Started the factory from the year 1986, We are one of the top manufacturers and exporters of Woven wire Mesh, Screens and welded Wire Mesh in China.

We has over 160 sets of wire mesh machines, have around 20000 rolls in stock for stainless steel wire mesh & welded mesh. We have gained a global sales network reaching to the Local market, USA, Middle-East, Europe and Africa etc.

Our company has been based on “good quality, timely delivery, reasonable price, considerate service” the purpose to serve the masses of customers; And is in line with “quality seek survival, prestige seek development” production principles, in our emphasis on product quality at the same time, also actively communicate with the customer, understand customer needs, to realize our shortcomings, and for clients to provide professional and timely after-sales service, won the praise of the vast old and new customers. Our products are widely used in petroleum, textile, metallurgy, construction, farming, machinery, landscape protection, production and manufacturing, and other fields.

Our Main Products: Stainless Steel Wire Mesh, Shale Shaker Screen, Crimped Wire Mesh, Dutch Wire Mesh, Copper Wire Mesh, Brass Wire Mesh, Stainless Steel Welded Wire Mesh, Galvanized Welded Wire Mesh, Filter Discs And Wire Mesh Processed Products.

TIANHUI Sincerely hope to establish long term business relationship with worldwide customers on the basis of sincerity and mutual benefits.

| Standard Reference | Dia Type | Finish | Grade | Raw Material |

| UIC86

4DIN529 |

M20-M36 | Plain & Oiled, Oxide Black, Zinc Plated, Hot Dip Galvanized, etc |

4.6 5.6 8.8 |

Low Carbon Steel Medium Carbon Steel Alloy Steel |

Our hook bolt, anchor bolt, clip bolt have high quality and cheap price. If you have any question on product, we will give the professional answers to your short questions.

Tianjin KXC group founded in 2004, is an ISO 9001 certified company,committed to manufacturing valves, valve parts & related products for water works and water treatment projects.

KXC consists of HY Valves Co. Ltd and KXC Metal Co. Ltd within our own factory and foundry. We have machining center, CNC machines, pressure test machining, electric furnace, mould machine, sand blasting machine, given all of this, our products quality always under good control.

KXC mainly produce gate valve(Resilient seat, Metal seat), butterfly valve(Concentric and Eccentric), check valve, ball valve, globe valve and etc. Supported by our many years’ experience and expertise in this field,

KXC can also offer OEM &ODM valves and parts.KXC philosophy is to offer high cost performance products with optimal service. Welcome to visit our factories and KXC will satisfy you in all respects.

Our products:Rising Stem Globe Valves, Double Eccentric Butterfly Valve

A well screen is a filter device used as the suction portion of a well constructed in a loose or semi-consolidated aquifer. The screen allows water to enter the well from the saturated aquifer, prevents sediment from entering the well, and acts structurally as a support for the aquifer material. When considering well efficiency and the logarithmic cost to the well owner, the importance of having the right screen cannot be overemphasized.

The sieve is resistant to corrosion because it comes into contact with water. In addition, it has high strength and can keep the surrounding structure intact. The openings of the sieve can be small enough to block the large amount of formation around them. The flow of water through the screen will be uniform.

Well screens are recommended for all environmental drilling operations. It helps extend the life of the well and keeps the flow of water unrestricted. Sand and fine powder sand, these fine particles can be filtered out before there is water. Well screens help remove most of this fine material from well water.

Well screens are made from a variety of materials, ranging from rough-hewed hand designs to machine built high-efficiency and long-life models. The value of the screen depends on how much it contributes to the success of the well.

Standard:

- Large open Spaces

- Do not block the slot

- 3.corrosion resistance

- Sufficient column and collapse strength

Functions:

- Easy to develop

- Minimal scaling tendency

- Low head loss through the screen

- Control sand pumping of all types of aquifers

Slot size selection is a critical step to ensure maximum well performance. The screen is usually designed to block 50% of the stratum, and the entry speed for the screen should not exceed 1/10 or 0.1 ft per second. The velocity is calculated by dividing the well production in GPM by the screen open area in square inches.

The gap size of the screen is based on dimensional analysis of the formation sample. After analyzing the composition size of grain in the sample, grain size distribution curve

I can draw it. Several methods can be used to obtain the allocation of information about grain size. The most widely used method is to pass the material through a stacked set of brass or stainless steel sieves. During the screening process, each sieve removes a certain percentage of the whole sample; The best materials are collected in the chassis. Screening analysis not only provides the basis for determining slot sizes, but also other factors that influence screening well design.

BEISAI is large-scale joint-stock group foundry enterprise, divided into Hebei BeiSai Metal Products Co., Ltd and ShiJiaZhuang BeiSai Trade Co., Ltd. which was builded in 2003, located in ShiJiazhuang province City. company net assets is up to CNY 45 Milion, The annual production capacity of 60000 Tons casting iron parts. More than 300 employees here. There are 5 senior casting engineers and 21 technical engineers etc. We have 26 sets of centrifugal casting machines and 5 sets of autoumatic machine painting lines and 3 sets of automatic hydraulic pressure testing machines, we have very perfect testing and checking equipment and testing lab, 100% make sure all products are top-quality.

At present our major products and service is Casting Iron Pipes, Fittings, SS Couplings, Carton Steel Clamps which was used for sewer drainage system of buildings. And Casting iron manhole covers and frame, Casting tree gate and Casting valves , fire protection fittings and connectors, Casting cooking hardware, etc.

We also can produce all kinds of large or small machine casting parts and auto casting parts and pump housing and pump console/ impeller and casting pulley according to the drawing or samples.

All our products are fully meet USA and European and National standard ASTM A888/CISPI301/CSA B70, ASTM-A536, DIN 19522, EN877, BS EN877, ISO6594, BS437, BS416, KSD 4307, EN124:1994, BS 497-1:1976, ISO2531, BS EN545/EN598, AWWAC 151, KSD 4311, AS 2280, GB/T13295, GB/T12772 etc.

C-shaped hooks for hanging posters and signs, store decoration and display items, and for hanging and connecting various items. These CNC Wire hooks wholesale are made of durable 2mm thick metal wire.

Other sizes can be provided on request.

A pack of 100

More information please click here.

3 Type 2 Wall Tie(CE marked)

Product Name: Type 2 Wall Tie(CE Marked)

Item Code: Smart Craftsmen-WTT2

Surface Treatment: Shiny.

Raw Material: Stainless Steel 304( Grade1 4301) or Up on your request.

Package: 250 pieces / Inner Box, 2 or 4 Inner boxes / Master Carton.

Place of Origin: Hebei, China.

Standards: PD 6697 and EN 845-1:2013+A1:2016.

The type 2 wall ties for sale are suitable for general-purpose neckties with a space between 50mm and 150mm, which can be used in European domestic residential and small commercial buildings up to 15 meters high. Smart Craftsmen Type 2 wall ties are CE marked, and the measured dynamic stiffness <113MN/m3 meets the requirements for external masonry walls

Approve the performance requirements of Document E. The test result meets the PD 6697 standard and confirms BS EN 845-1: 2013 + A1: 2016.

benefit

Answer: The specially designed safety end provides an excellent mortar key, which reduces the risk of on-site injury and prevents entanglement.

B: Clear and easy to distinguish packaging, which can be conveniently used on site when different types of wall ties are needed.

C: It is made of corrosion-resistant stainless steel, and high-strength steel wire is cold bridged to minimize heat loss.

D: Multiple drops can prevent water from flowing in any direction where the cable tie is installed.

note

Other special length and wire thickness can be provided according to customer requirements.

Steel grating is generally made of carbon steel, and the surface is hot-dip galvanized, which can prevent oxidation. It can also be made of stainless steel, and the steel grating has the properties of ventilation, lighting, heat dissipation, anti-skid, explosion-proof and so on.

Steel grating is a kind of steel product with square lattice in the middle, which is cross-arranged with flat steel according to a certain spacing and horizontal bars, and welded by pressure welding machine or manually. Steel grating is mainly used as gutter cover. , steel structure platform plate, steel ladder step plate, etc., the cross bar is generally made of twisted square steel.

Advantages of steel grating fence

Material saving: the most material saving method under the same load conditions, correspondingly, the material of the supporting structure can be reduced;

Reduce investment: save material, save labor, save construction period, free of cleaning and maintenance;

Simple construction: on the pre-installed support, it is fixed with bolts or welding, and it can be completed by one person;

Save construction period: the product does not need to be reprocessed on site, and the installation is very fast;

Durable: It has been hot-dip galvanized anti-corrosion treatment before leaving the factory, and has strong impact and heavy pressure resistance;

Modern style: beautiful appearance, standardized design, ventilation and light transmission, giving people an overall smooth modern feeling;

Lightweight structure: less material, light structure, and easy to hoist;

Reduce wind resistance: due to good ventilation, the wind resistance is small in case of strong wind, reducing wind damage;

Anti-contamination: no rain, snow and dust;

Other advantages: ventilation, lighting, heat dissipation, explosion-proof, good anti-skid performance;

Simple design: no need for small support beams, simple structure and simplified design

Acid and alkali corrosion ability: in the range of PH 6 to PH 12.5, a stable protective film is formed on the surface of the zinc layer, and the corrosion resistance is good.

Steel grating use

Steel grating is suitable for alloys, building materials, power stations, boilers, shipbuilding, petrochemical, chemical and general industrial plants, municipal construction and other industries. It has the advantages of ventilation and light transmission, anti-skid, strong bearing capacity, beautiful and durable, easy to clean and easy to install.

Steel grating has been widely used in all walks of life at home and abroad, mainly used as industrial platforms, ladder treads, handrails, passage floors, railway bridge sideways, high-altitude tower platforms, drain covers, well covers, road grilles, three-dimensional It can also be used as a fence for parking lots, institutions, schools, factories, enterprises, sports fields, and garden villas.

Belleville Disc Springs also was called “Disc Springs” “Conical Disc Springs”, include disc spring stacks, Corrosion Resistant Disc Springs, High Temperature / Cryogenic Disc Springs, Disc Springs for Ball Bearing, Disc Springs for Valves. Disc Springs are widely used in petrochemical, electric power, metallurgy, engineering, machine tools, national defense, and other industries.

Bearing Preload Disc Springs manufacturer Description

The Disc Spring concept was first invented by a Frenchman Louis Belleville in 1865. So, disc spring is commonly known as Belleville Springs. And sometimes it also was called “Conical disc springs” “Belleville Disc Springs” or “Belleville Washers”.

Hegong Disc Springs are conically washers and have a rectangular cross-section, which is loaded in the axial direction. It has a small volume and large energy storage compared to traditional helical springs and can be used as a single disc spring or in the stack (stack in parallel, in series or parallel & series combination).

The standards for disc springs mainly include DIN2092 (Calculation) / DIN2093 ( Quality Specifications-Dimensions ) of Germany, JIS B 2706- Japan, GB/T 1972-2005 of China and ISO 19690 : 2017 ( HEGONG SPRING ® is the drafting team member for international standard ISO 19690 : 2017 and Chinese national standard GB/T 1972-2005 ). Among them, DIN2093 is most widely used in the world.

belleville washer design are designed & manufactured according to DIN2092 & DIN2093, working for dynamic or static applications. The engineers of HEGONG SPRING® are pleased to design the springs for the specific applications together with the customer’s R&D department. Be free to contact with our engineers. Tech@DiscSpringsMFG.com.

Generally, disc springs include disc spring stacks, Corrosion Resistant Disc Springs, High Temperature / Cryogenic Disc Springs, Disc Springs for Ball Bearing, Disc Springs for Valves.

Surface Condition And Corrosion Protection:

Polish

Phosphating and oil

Mechanical Zinc Plating

Chemical Nickel Plating

Docromet / Geomet Coating

Electrophoresis

Tolerance:

The Tolerance is according to DIN2093 standards

Belleville Spring Washers exporter Specification:

The following specification table covers the “standard” sizes and some non-standard sizes. HEGONG SPRING ® customizes Belleville Disc Springs as well. The max OD is up to 1000mm. If you require the custom Belleville Disc Springs, please contact our sales engineers.

Wholesale airport security fence, is mostly made use of in the flight terminal for defense. The main panel and also V panel is welded with 4.0 mm/5.0 mm low carbon steel cable. The surface area therapy of QYM airport fencing is galvanized + electrostatic polyester powder coated or galvanized + PVC layered.

airport fence supplier Material:

Material: Low-Carbon Iron Wire

Application:

Airport, Garden Fence, Residential, etc

Airport Fence Y Type Fence China Specification

| Panel | Mesh | Wire Thickness | Surface Treatment | Panel Width | Folds NOS. | Panel Height | Fence Height |

| Big Panel | 50x100mm 55x100mm |

4.00mm 4.50mm 5.00mm |

Galvanized and Electrostatic polyester coated or PVC coated | 2.50m 3.00m |

4 | 2000mm | 2700mm |

| 5 | 2300mm | 3200mm | |||||

| 6 | 2600mm | 3700mm | |||||

| 2 | 530mm | 2700mm | |||||

| V panel | 630mm | 3200mm | |||||

| 730mm | 3700mm |

Beijing Shenghe Zhongtai Stainless Steel Co.,Ltd was established in 2009 and located in Beijing, China. In the past 9 years, we have focused the Stainless steel material and surface finish. We have passed the ISO9001 test in 2011, and applied the brand of “SUNSONG”in same year. Following the company developed by 2016, we have built our manufacturing base of Hebei Shengnuo Metal Products Co.,Ltd In Hebei province which is the biggest manufacturing base for Stainless steel surface treatment in North of China.

We have imported the advanced cutting equipment to do the coil cutting and flatting. And we have all process machines such as Hairline finish, 8K finish, Bead blasted, Vibration, Anti-finger print, PVD machine and Bending machine, Laser cutting machine.etc. Especially only we could do the surface treatment for the with more than 1500mm.

And our factory covers an area of more than 16000 square meters, introduces advanced equipments such as CNC shearing machine, keyway planer, Bending and laser machine, provides full-service of stainless steel processing. Our annual outputs has exceeded 3000 mts. We are capable to provide one stop services for architecture stainless steel decoration from stainless steel surface treatment, processing, fabrication, assembly and installation.

SUNSONG Decorative Stainless Steel Sheets is neat and beautiful which widely used into kinds of outside decoration of buildings and elevator decoration. We could do many treatment on the Hairline surface such as etching, PVD and so on. The surface would be different and welcomed by customers.

For more, please click here to customize your stainless steel furniture decoration.

SHINESTAR STEEL GROUP CO., LTD mainly produce various carbon and alloy steel pipes including oil & gas pipe, pressure pipe, mechanical tubing, and stainless steel tube, etc.

As the most valuable subsidiary under SHINESTAR STEEL GROUP, PRIME STEEL PIPE is the solution provider for the oil, gas, construction, energy and prtrochemical industries.SHINESTAR STEEL GROUP is specialized in manufacturing superior quality steel products, and providing outstanding service for valued clients all over the world.

Hunan Great Steel Pipe Co.,Ltd is specialized in steel pipe & tube production including carbon steel pipe, seamless steel pipe, erw steel pipe, ssaw steel pipe, lsaw steel pipe, etc.

Hunan Great Steel Pipe Co.,Ltd is a world-class production and service provider of seamless pipes and welded pipes as the first subsidiary of Shinestar Group.

Ceramic lined pipe is made through the self-propagating high-temperature synthesis (SHS) technique.

Self-propagating High-temperature Synthetic process

Self-propagating high-temperature synthesis (SHS) is used to describe a process in which the initial reagents (usual powders), when ignited, spontaneously transforms into products due to the exothermic heat of reaction.

The combination of high rigidity of ceramic and high elasticity of steel gives the pipe unmatchable features like abrasion resistant, heat resistant, and corrosion-resistant material for use in the fields of power generation, metallurgy, mining, and chemical industry, etc. It has many advantages over steel pipes, cast stone pipes, and steel-plastic compound pipes.

Usage of Ceramic Lined pipe

The ceramic-lined pipe transportation has been widely used in the industries of electric power, metallurgy, coal, petroleum, chemical engineering, building materials, mechanism, and so on.

The ceramic lined elbow throughout the power, metallurgy, coal, petroleum, chemical, building materials, machinery, and other industries, and high-speed development. When lining the wear-resistant ceramic elbow to deliver high grinding material (such as ash, coal, ore powder, etc.), there is a lining of wear-resistant ceramic elbow wear fast, especially the elbow Wear faster. When lining a ceramic-lined elbow to deliver a highly corrosive gas, liquid or solid, there is a problem that the lined wear-resistant ceramic elbow is corroded and is quickly damaged.

There is a problem that it is expensive to use a heat-resistant steel pipe when the material having a higher temperature is conveyed in the lining of the wear-resistant ceramic elbow. After lining the wear-resistant ceramic elbow, these problems are solved.

The ceramic lined elbow is widely used in wear and tear of mine filling material, ore powder and tailings transportation, coal-fired power plant powder, smelting, ash and other things lined with wear-resistant ceramic elbow are also very appropriate.

The ceramic lined pipe, Elbows, Reducer, Tees, and others manufactured in our factory have been used in over 200 thermal power plants, more than 50 mines, and the industries of coal, building materials, mechanism, petroleum, and so on.

Abrasion

Ceramic layer Ceramic Lined Reducer Pipe with flange reducer Al2O3 content greater than 89%, micro-hardness HV1000-1500, which has high abrasion resistance, wear resistance more than ten times higher than carbon steel after quenching, superior tungsten carbide drill.

Application range

- coal pulverizing system of power plant pipeline, including, powder transmission pipeline, thick powder separator pipeline, coal drop pipe, combustion system of a windpipe, a secondary air pipe, three pipeline and burner pipelines, in addition to ash slagging system the discharge pipe, powder pipe, dry ash conveying pipe;

- Iron and steel plant raw material conveying pipeline, collecting pipe, dust pipe, ash pipe, ash pipe, mixing pipe, grinding export pipeline, coal pipeline, coal pipeline, separator pipe, burner radius pipe, etc.;

- Cement plant selection machine outlet pipe, choose machine inlet pipe, pipe dust pipe, vertical mill outlet pipe, circulating air duct, high-temperature air blower, lower material pipe, etc.;

- Petroleum, chemical, mining, coal, coal washing plant, smelting, paper, aluminum, building materials, powder engineering, food machinery, and other processing and conveying material pipes.

Corrosion

Ceramic materials are neutral, chemically stable, have excellent corrosion resistance and acid resistance, resistant to various inorganic acids, organic acids, organic solvents, and their degree of corrosion of stainless steel is more than ten times.

Temperature

Temperature above 2000celsius degree, long-term work in the range of -50 -900 celsius degree.

Easy welding.

The ceramic adjustable tube can be welded, flanged, flexible connectors, and other fast way links, very easy to install.

Clean and easy maintenance

Smooth walls, can prevent scaling, fouling, and self-cleaning functions. Tightness.

Remarks:

- Under the direction of the arrow diagram for the export direction.

- Bend radius is usually 1.5-5 times the diameter of steel pipe (1.5-5D).

- Othe specifications of the composite pipe can be manufactured according to the user requirements.

- The weight is calculated by theoretics, maybe have some tolerance, and real weight will be weigh-in after they finish.

Hoop strength is the resistance against radial pressure. The strength of the ceramic-lined steel composite pipe is 300 to 500MPa.

Features and Advantages of ceramic lined pipe

Ceramic Liner pipe is a high technology production technology-self-fuel high-temperature clutch synthesis method.

1). High Abrasion Resistant:

Vickers hardness of the corundum lining is HV1100 to1500, as high as that of tungsten-cobalt hard alloys, and the abrasion resistance is 20 times as carbon steel pipes. The composite ceramic-lined steel elbow was used in a mining plant for about fifty thousand hours. The general service life of a common steel elbow is about 700 hours.

2). Corrosion Resistant:

Corundum is a neutral material and is acid-proof and fouling-free.

3). Heat Resistant:

Ceramic lined composite steel pipes can work under circumstances of -50 to 800 Celsius degree.

4). Lower Weight and Convenient Installation:

The ceramic-lined steel pipes are lighter than alloy pipes, cast iron pipes, and cast stone pipes and can be welded or connected through flanges, which reduces the expense of transportation and makes the pipes easier to install.

For the pipes with the same sizes, types, and lengths, the weight of the ceramic pipe is about 1/2 of the wearable cast alloy steel pipe’s, while the cost has reduced 10%~20% per meter.

The weight of ceramic-lined steel pipe is about 1/3 of the cast stone bent pipes, 1/2 of the cast stone straight pipes.

Ceramic (Corundum: a-Al2O3) lined abrasion resistant straight pipe and fittings are lined with highly abrasion-resistant ceramic by SHS ——-Self-propagating High-temperature Synthetic process.

- The ceramic-lined steel composite pipe can be joined by welding the steel pipe layer.

- Ceramic-lined pipes can take place of expensive stainless steel, titanium, nickel, cast stone, or alloy pipes.

- Extended service life can also reduce maintenance costs.

Self-Propagating Ceramic Pipe

Self-propagating ceramic steel pipes create a new generation of abrasion and corrosion-resistant engineering pipelines.

The self-propagating ceramic steel pipe has very good wear resistance, Excellent corrosion resistance, and Excellent thermal resistance performance.

SHS-self-propagating ceramic steel pipe and elbow create a new generation of abrasion and corrosion-resistant engineering pipeline. The composite pipe is composed of three layers: ceramic, intermediate, and steel layers.

The ceramic layer is formed by molten alumina at a temperature above 2500 degrees. The molten alumina produced from the reaction Fe2O3+2Al=2Fe+Al2O3 spreads on the inside wall of the steel pipe under the influence of a centrifugal force, then solidifies, so the ceramic layer has high density and smooth surface and bonds to the steel pipe.

Applicable Industries:

- The pipe needs excellent wear resistance property: Power plant, Mining, Sea Port, Coal Plant, And pipe for transporting the powder, slurry, sand, etc.

- Coal washing plant, pipe for transporting coal and other material.

- Pipe for transporting the melted aluminum.

- Any pipe which needs to wear protection, corrosion protection, etc.

Benefits:

- Excellent wear resistance, Alumina content of the ceramic liner is higher than 95%, Hardness HV1000-1500. The wear protection performance is more than 10 times better than carbon steel after quenching,

- Excellent corrosion resistance, stable chemical properties.

- Excellent thermal resistance performance up to 2000℃ Can be used in the area from-50℃ to 900℃ for a long time.

- Can be connected with another pipe by welding, flange and soft fast connecting, and easy installation.

CRS is a leading manufacturer of thermit welding materials in China, we have more than 30 years experience of designing thermit welding to the rails. Focusing on rail welding used for railroad, metro, tram, crane rails, turnel construction and maintenance.

We have production area of 2500 square meter, with fully automated batching system, sand mould automatic production & drying machines, equipped with full range of raw materials and welding joint testing equipments. Rail aluminum thermit welding material has been promoted and well applied in the railway lines such as the Beijing-Shanghai high-speed railway line, Jinqin passenger line, Daqin line, Tong-Rang line and Tong-huo line. Materials have been exporting to Australia, Indonesia and other countries many years, the products have won praise.

CRS possesses a qualified team of technicians and engineers who have been improving the quality and performance of products, Certified to the ISO9001:2000 standard, CRS’ welding products have been supplied to a wide range of customers worldwide. Thermit products have been passed Chinese rail welding standard TB/T1632-2005 test, Railway Ministry of China, as well as Australia standard AS1085.15-1995 test, Indonesia welding joint inspection test, Taiwan SGS quality inspection test. We are ready to provide technical & operation training, qualification and certificate for customers to ensure a standardized quality and performance of the welding products.

Galvanized Steel Fiber, an alternate concrete reinforcing material are high tensile galvanized steel wires with hooked ends, glued together by the water-soluble adhesive for compactness and uniform dispersion in concrete, to increase the concrete properties by 3-4 times.

Compared with the normal cold drawn steel fiber,in addition to all the advantage of normal steel fiber(such as excellent tensile strength, bending and shearing strength, high tenacity, resistance against the cracking, impact and fatigue ), this fiber still has a better corrosion resistance when the steel fiber exposure to the air, as there is a zinc thickness on the surface of this fiber.

The concrete with GuangYa steel fiber can be widely used in industrial floor,transportation constructions(roads, bridges, tunnels, airport runways), the concrete prefabricated unit, etc…

Advantage to use the China steel fiber in concrete:

High impact resistance.

Remarkably increased flexural strength.

Improved structural ductility.

Exceptional control over cracking.

Increased durability by providing crack control.