Our factory is an enterprise manufacturing pipe fittings for more than 30 years. It is supplying Malleable iron fittings, Ductile iron fittings , Gray iron fittings and other steel products, with long history and unchanging faith of producing high quality products.

Main products:Malleable iron pipe fittings, Tube clamps, Air hose couplings, Camlock couplings, Carbon steel pipe nipples, Electric power fittings, Steam couplings, Gas meter connectors etc.

- Founded in 1986, Covering 12,000 square meters, having more than 200 workers. We have a registered capital of 8.88 million, and the annual export volume of 10 million USD.

- As a high-tech enterprise, we have our own R&D team, which can open molds through samples or drawings provided by customers, and even assist customers in developing new products through functional descriptions.

- From purchasing material, casting, annealing, trimming, galvanizing, machining, packing, to exporting, have formed stop production system.

- Various casting techniques: Currently 90% of the products have been changed to coated sand production. And equipped with coated sand production line, which can control the quality requirements of coated sand, and coated sand buried box casting line, further improve the quality of products. Most suitable casting way can be defined according to any products.

- casting surface: our own researched prescription of sand and mold design is used, there’s no joint line, no shift, no sand inclusion, no crack on products, we will satisfy every client.

- Material assurance: on –the –spot sample analysis+ chemical composition analysis after casting, double tests to guarantee stability of material. Electric heating automatic temperature control equipment can precisely control the furnace heats uniformly to ensure product are with the same tenacity.

- Surface treatment: self-color + rust preventing oil, electroplating, hot dip galvanizing, first electroplating and then hot dip galvanizing, first electroplating and then backed galvanizing, first electroplating and then plastic spraying. Different products need different surface treatment, best surface treatment can be defined according to different products.

- Machining technique: we have professional threading machines and CNC lathes to make threads, threads are 100% within specified scope of gauge and plug gauge, included angle of threads is within 90°+-0.5°. High efficiency and high quality producing way make our products have more market value.

- Our certificates: Our factory passed TSE for Turkey, INMETRO for Brazil, and CE, ISO9001:2008, IQNET etc.

- Our clients: Our factory is cooperating with many well-known enterprises, main market for malleable iron pipe fittings is Europe, main market for pipe clamp fittings is U.K., and main market for air hose couplings is USA. There’re also many different kinds of products for specialized application, and are very advantageous in their fields.

Our website:http://www.donghuancast.com

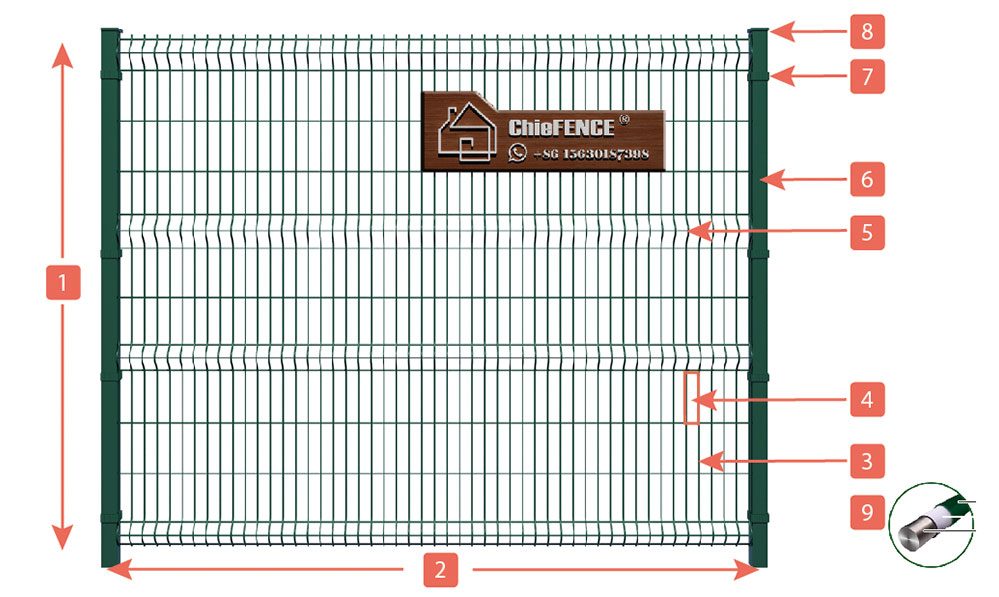

Welded mesh fence likewise called “3D FENCE” “medium-security fencing”. It is an affordable version of steel fence. The panel is bonded with low carbon steel wire. Material Grade: Q195, Surface therapy by Electrostatic polyester powder roaming finishing(Powder-coated) over galvanized products. And after that connect the fencing panels with article by suitable clamps(Clips). Because of its Simple framework, Easy installation and also Beautiful look.More customers regard welded wire mesh security fence as the preferred common protective fence.

Loni ChieFence 3d security fence FEATURES

Lower budget

See-through panel

Anti-rust, Long Service Life

Fast Installation

Customer specs available

Rigidity

Steel grating fence, also known as welded steel grating fence, is the most durable metal grating product. They are made of mild steel. We provide complete solutions for steel grille, pressure lock grille, heavy-duty grille, steel stair treads, wooden board grille, safety grille, trench cover, etc. All gratings are very rugged and suitable for all bearing applications. And all lenticular products are completely recyclable.

Steel grating fence is made by welding with flat steel and bars with certain distances. It goes through cutting, opening, edging and other processes. The products enjoy the feature of high strength, light structure, high bearing, convenience for loading and other properties. The hot dipped zinc coating gives the product excellent anti-corrosion.

The Grating Fence can be customized according to the unique design of a specific building project, and can contain characteristic columns. The integrity of the fused grating material allows it to be cut to Grating Fence of individual shapes, such as bows or wavy tops.

Material specifications

Material: high quality low carbon steel, stainless steel 304 or 316.

Types: plain bar as standard.

Finishes: electric galvanized, hot dipped galvanized, powder coated, according to the difference surface treatment.

Metallica Metals is known worldwide as the most competitive group in the world of Stainless Steel having its headquarters in Mumbai – India. It was incorporated in the year 1975 by 3 dynamic leaders named as Mr. Babulal Mehta, Mr. Jugal Mehta & Mr. Vallabhchand Mehta & they are the reason behind the exponential growth of Metallica Metals.

Product Name: Hot Dipped Galvanized Iron Wire

Item Code: Smart Craftsmen-HDG Wire

Surface Treatment: Electro Galvanized.

Raw Material: SAE1006 SAE1008 Q195 Q235 or Others.

Tensile Strength: 330- 550MPA

Package: Customize.

Place of Origin: Hebei, China.

Loading Port: Tianjin Port

Smart Craftsmen Galvanized iron wire is designed to prevent rust and shiny silver. It is strong, durable and versatile. It has been widely used in landscaping, construction, woven hardware cloth and mesh. Wholesale Galvanized wire is divided into hot-dip galvanized wire and electro-galvanized wire (cold galvanized wire). Galvanized steel wire has good flexibility

Sex and toughness. It has the characteristics of large thickness of galvanized layer and corrosion resistance. Hot-dip galvanized iron wire China is made of low-carbon steel wire, which is drawn, pickled, derusted, annealed and coiled.

Electro-galvanized iron wire is made of selected low-carbon steel through drawing, galvanizing and other processes. Electro-galvanized iron wire has the characteristics of thick galvanized layer, good corrosion resistance and strong galvanized layer.

Material: Uncoated Thick Cast Iron.

The Enameled Cast Iron Covered CasseroleIs Thick And Durable For 60 Years. It Has No Chemical Coating And Is Evenly Heated And Not Sticky.

The Vent Hole Of The Cover Is Effectively Pressed, And The Stainless Steel Bead Screw Is Fixed For A Long Time And Is Not Easy To Loose.

Excellent Thermal Conductivity, Good Heat Preservation, Uniform Heat Conduction, Long Residual Temperature, And Added Flavor To The Stew Ingredients.If you have any question on Weining Enameled Cast Iron Covered. We will give the professional answers to your questions

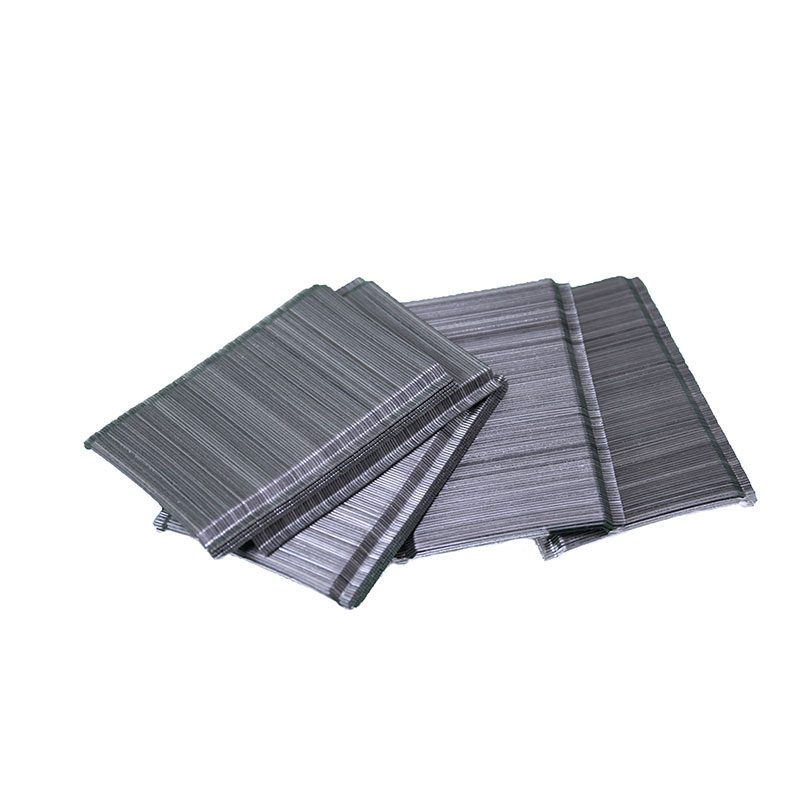

Glued Steel Fiber, an alternate concrete reinforcing material are high tensile steel wires with hooked ends, glued together by the water-soluble adhesive for compactness and uniform dispersion in concrete, to increase the concrete properties by 3-4 times.

steel fiber reinforced concrete supplier improve the mechanical properties concrete and materials such as ductility,

energy absorption, fatigue, and toughness. This fiber helps to controls plastic shrinkage cracking in concrete; helps reduce or eliminate need for conventional reinforcement.

Application of Glued steel fiber reinforced concrete

- For concrete flooring

Industrial floors

Joint-less floors

Floors-on-piles

Lightly loaded floors

Liquid tight floors & composite metal decking

- stainless steel fiber supplierFor Hard Standing & Heavy Duty

Parking lots

Playgrounds

Airport runways

Taxiways

Maintenance hangers

Access roads & workshops

Ports& Containers for port pavements

Container terminals

Bulk storage areas access roads

For army tank movement

- steel fibers for concrete reinforcementOther Applications

Foundations

Traditional cellar and basement walls

Compression layers

Tunnel engineering

Compared with the GuangYa loose steel fiber the operation and advantages of the glued steel fiber:

- Add the steel fiber directly into the belt, the whole row of steel fiber as a whole, evenly dispersed in the concrete corner

- The water-soluble glue begins to dissolve in a row of steel fibers in the premise of the dispersion, it is again dispersed in every corner of the mono filament fiber, showing the perspective in the concrete of the fiber mesh, which plays an integral strengthening.

- Compared with mono-filament fibers, China bonded steel fiberswill not be bundled to ensure that the fibers in concrete do not coalesce and distribute evenly.

Glued steel fibers are loose hook-end fibers that are bonded together in a row. The great difference between loose fiber and glued fiber is that the former is easy to clog and the latter is easy to disperse evenly.

Rafit Metal & Alloys produces and Exports impeccable and super compound darting which incorporates: Hex screw, Hex Nuts, Stud fasteners, Threaded Bars, Washers, Hex attachments and so forth according to guidelines ASTM, ASME, DIN and UNI. The application enterprises are oil and Gas, Chemical, Petrochemical, Power and Energy and Marine industries(On Shore/Offshore).

Copper Mould Tube & Plate

We specially in supplying Copper Mould Tube, Crystallizing equipment of continuous casters, Mould cooling jacket, Repair of Metallurgical Copper Mould Tube, etc.

Equipments & Spare parts for Continuous Casting Machine.

- Copper mould tube( square, rectangle and round )

- Crystallizing equipment of continuous casters

- Mould cooling jacket.

- repair of copper tube moulds

The copper alloys chosen for the moulds must maintain their physical properties at the operating temperatures of the continuous casting process.

The temperature gradation from the inner wall of the mould to the outside face of the mould can cause serious distortion problems, and Metallurgical Copper Mould Tube is imperative that the correct alloy is chosen for the various operating conditions.

Square Copper mould tube STANDARD MATERIALS

Phosphorus de-oxidised copper

This alloy has been proven to be excellent for the manufacture of moulds in the continuous casting of billets. The main composition of this alloy are Cu +Ag 99.90min, P0.0015 / 0.040.

Copper -Silver alloy

The addition of a small amount of silver, whilst not increasing the melting point of copper, does increase the recrystallisation temperature by almost 100℃, and also helps to give better thermal conductivity at the operating temperatures.

This alloy is normally used in moulds for the continuous casting of blooms and slabs .In this case, the moulds are much thicker than in the billet moulds, and the moulds temperature can be higher. The main composition of this alloy are Cu+Ag99.90 min. Ag 0.08 / 0.12 O 0.004 / 0.012.

The continuous casting of molten steel into billets, blooms and slab products, has been highly refined over the years into an extremely sophisticated system. The continuous casting process is expected to produce metallurgically sound products at the lower possible cost, and this is being achieved in many steelworks throughout the world.

Copper moulds have played an important role in the development of the continuous casting process. Their funcition is to receive the molten steel and to allow rapid heat transfer from the steel to the cooling water to enable quick solidification.

The mould must exhibit excellent thermal conductivity, be resistant for thermal erosion ,and be resistant to distortion from thermal stress. So far only copper and a few copper alloys meet the above conditions, both economically and technically.

Mould cooling jacket supplier SOLIDIFICATION

The rate of solidification in the continuous casting process dictates the speed of production. The molten steel, which is in contact with the inner faces of the copper mould, starts to sllidify as rapidly as the heat is extracted, forming a shell. The shell increases in thickness as more heat is extracted, and eventually total solidfication is achieved. the process is similar to the solidification of ingots in ingot moulds. In continuous casting, the whole process is speeded up, with the aim to produce and homogeneous shell growth. Consequently, the mould is an important part of the continuous casting process, and the manufactured quality of the mould plays and important role in their length of life.

INNER SURFACE COATINGS

Over the years, Metallurgists and Engineers have been working together to develop better continuous casting moulds. The steel companies require a more economical mould which will give a longer service life. Surface coating of the inner walls of the mould has given the best results to date. Coatings available are Chromium and Nickel plating. Also, a combination of the two give good results on slab casting.

SPECIFICATIONS OF COPPER MOULD

Square 60 x 60 – 350 x 350 (mm)

Rectangle 120 x 160 – 180 x 300 (mm)

Diameter 100-400 (mm)

Size(mm): 90×90, 100×100, 110×110, 115×115, 120×120

130×130, 135×135, 140×140, 143×143, 150×150

155×155, 160×160, 165×165, 175×175, 180×180

200×200, 220×220, 100×170, 100×173, 130×240

150×200, 150×210, 150×220, 160×200, 160×220

150×225, 160×235, 165×225, 175×225, 180×220

200×240, 240×240, 235×235

Radius(mm): 4000, 5000, 5250, 6000, 7000, 7500, 8000, 9000, 10250, 10300, 11000, 12000

Length(mm): 700, 750, 780, 790, 800, 810, 812, 850, 900, 1000

We Are Counted Among The Best Manufacturer, Exporter Stockist & Supplier. We Export 60% Of Our Range Of Flanges, Outlets, Pipe Fittings And Forged Fittings To Many Countries Like Usa, Uk, Italy, Malaysia, Gulf Etc. We Would Appreciate To Get Your Esteemed Enquires And Look Forward To The Pleasure Receiving Your Valuable Response.

HOT-DIPPED GALVANIZED STEEL COIL

- INTRODUCTION:

Hot-dipped galvanized steel coil is made from steel plate, which is dipped into the dissolved zinc bath, with a zinc layer on the surface. It mainly adopts the continuous galvanizing production process. That means the cold rolled coils are put into the dissolved zinc bath for continuous galvanizing process.

- EVER-SHINE Steel Coil APPLICATION:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It’s especally useful for countless outdoor and industrial applications.

They are mainly used in building roof, door, window, roller shutter doorand automobile’s vehicle shell, chassis, door, trunk lid, Oil tank, and fender, and also electric equipments, such as refrigerator base and shell and so on.

- SPECIFICATION

| THICKNESS | 0.11mm-5.0mm |

| WIDTH | 600-1250mm Max |

| COATING MASS | 20g-400g/m2 |

| Surface Structure | Zero Spangle,Regular Spangle,Minimized Spangle |

| SURFACE TREATMENT | Chromated/non-Chromated,Oiled/non-Oiled,skinpassed/non-skinpassed |

| COIL INNNER DIAMETER | 508mm or 610mm |

Who We Are

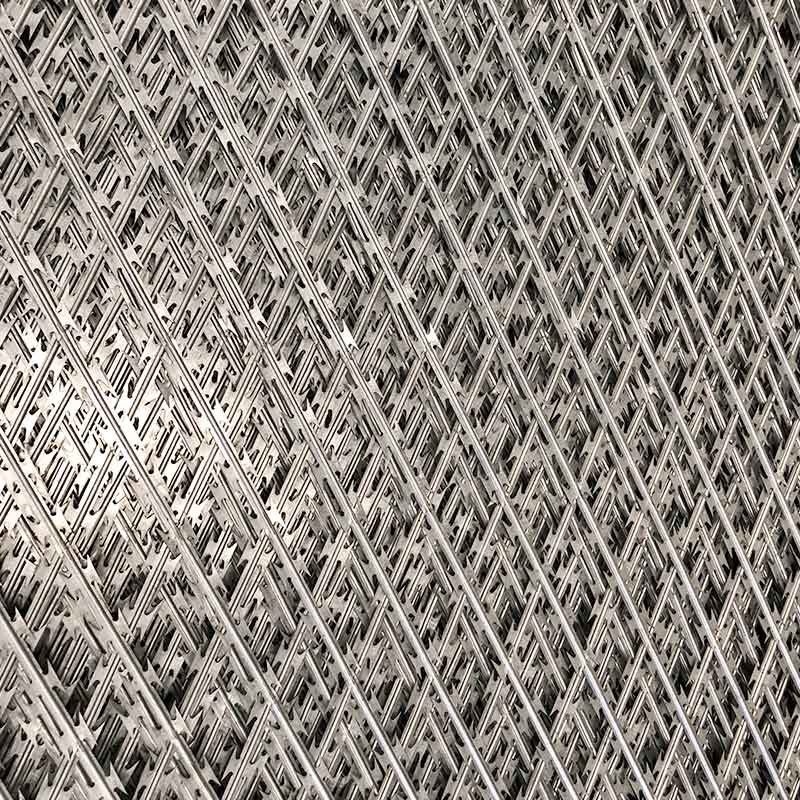

Ares Engineering is the expert in the manufacturing metal decorative wire mesh for architectural application. With the most advanced facility, we have the most modern and productive mill in China. Our products―whether they’re expanded metal mesh, laser cut sheet, perforated sheet or stainless steel decorative wire mesh―seamlessly blend form and function, challenging the status-quo. Through consistent growth and innovation we strive for the highest quality products at an unbeatable value.

As a major manufacturer and supplier of metal mesh products, we are committed to quality. Our investment in personnel and equipment provides you–customers with innovative and value-based products that meet or exceed your design expectations. From concept to completion, our team of experts and 35 years of experience in metal products can help you choose the mesh that suits your needs.

Our People

At Ares engineering, we are extremely proud of our employees and our commitment to them. Everyone is full of enthusiasm, diligence, dedication, and always strive to pursue the highest quality craftsmanship. They are the heart of our company and the reason why we are able to provide you with high-quality metal mesh products.

We have professional sales staff, engineers, designer, mesh worker, painting technical worker, quality inspector, customer service representatives, and all of the creative, inventive individuals here at Ares that continue to push the boundaries of what metal mesh can be.

With a professional team of product advisors, we are able to guide you in product selection. If your product requires design and technical support, we can provide suitable suggestions, alternatively we can provide price information, availability and lead times.

Company Profile

Ares engineering has been the leading manufacturer of metal mesh products. We are well respected in the industry for being trustworthy in quality and service.

Ares was built as DBL Expanded Metal Mesh Factory in 1986, which only produce the expanded metal mesh at first. With time goes by, our founder introduced many advanced equipment and enlarge our production range, including not only stretched mesh machines, but also punching machines, laser cutting machines, cutting machines, and decorative wire mesh machines. Then we renamed the company name as Anping County Huijin Wire Mesh Co., Ltd on 2008. Next year, we started the Production of Aluminum Expanded Curtain Wall Panel and Ceiling System and applied for a patented technology.

With the continuous increase of decorative mesh projects, we invested the international-standard PVDF and Powder Coating Painting line, which can control quality well.

On 2019, we set up Branch Company- Hebei Ares Building Decoration Engineering Co., Ltd. The main purpose of the branch establishment is separating projects from traditional businesses, assembling a dedicated project team which can provide solutions and professional service for metal decorative mesh projects.

Now in its 36th year of operation, Ares Engineering looks towards the future. With mechanical and technological advancements, we now offer a wider range of patterns than ever before. New partnerships have allowed us to not only offer new types of products, but to provide technical and design suggestion of projects. Though Ares Engineering continues to build and grow, Quality & To meet and exceed customers\\’ expectations will always remain the fundamental core of our business.

Now in its 36th year of operation, Ares Engineering looks towards the future. With mechanical and technological advancements, we now offer a wider range of patterns than ever before. New partnerships have allowed us to not only offer new types of products, but to provide technical and design suggestion of projects. Though Ares Engineering continues to build and grow, Quality & To meet and exceed customers\\’ expectations will always remain the fundamental core of our business.

History

1986: Built DBL Expanded Metal Mesh Factory

2008: Renamed as Anping County Huijin Wire Mesh Co., Ltd

2009: Started the Production of Aluminum Expanded Curtain Wall Panel and Ceiling System and applied for a patented technology

2012: Invested the international-standard PVDF and Powder Coating Painting line

2019 by now: Set up Branch Company- Hebei Ares Building Decoration Engineering Co., Ltd. Focus on providing solutions and supplying products for metal decorative mesh projects.

Our website:http://www.aresmaterial.com

Roopam Steel is top manufacturer & supplier of seamless steel pipe welded tubes in ferrous and non ferrous material, Stockist of high quality tubular piping products and accessories in India. Call us for more Info at +91-22-6639 4333.

What is Gate valves

Gate valves are widely used for all types of applications and are suitable for both above-ground and underground installation. Not least for underground installations it is paramount to choose the right type of valve to avoid high replacement costs.

Gate valves are used to shut off the flow of liquids rather than for flow regulation. When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low flow resistance. The size of the open flow path generally varies in a nonlinear manner as the gate is moved. This means that the flow rate does not change evenly with stem travel. Depending on the construction, a partially open gate can vibrate from the fluid flow

Gate valves are mostly used with larger pipe diameters (from 2″ to the largest pipelines) since they are less complex to construct than other types of valves in large sizes.

Main gate valve parts of a gate valve are: body, seat, gate, stem, bonnet and actuator. The main operation mechanism is very simple. When the handwheel is turned, it rotates the stem, which is translated into the vertical movement of a gate via threads.

There are three ways to classify the gate valve.

Types of Disk

Solid taper wedge

Flexible wedge

Split wedge or Parallel disks Valve

Types of Body Bonnet Joint

Screwed Bonnet

Bolted-Bonnet

Welded-Bonnet

Pressure-Seal Bonnet

Types of Stem movement

Rising Stem or OS & Y Type (Outside Stem and Screw Type)

Non-rising Stem type

Gate valvesare used in almost all fluid services such as air, fuel gas, feedwater, steam, lube oil, hydrocarbon, and all most any services.

Some special gate valve is used in slurry and powder product also such as knife gate valve

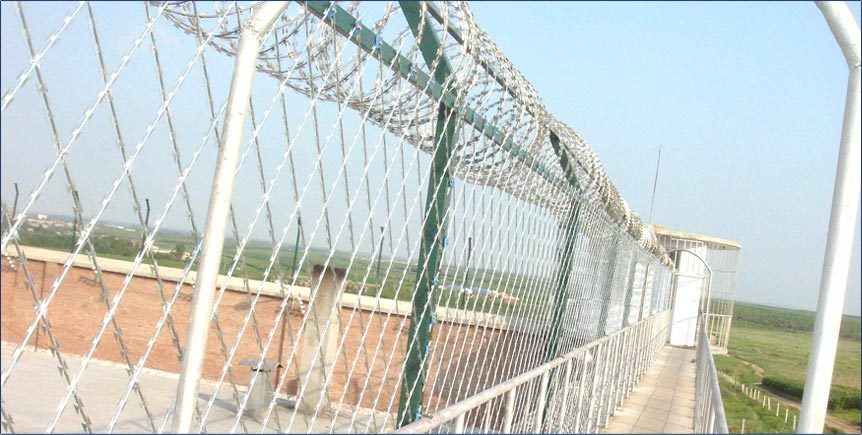

Razor wire is a new type of protective barbed rope. Concertina razor wire is made up with galvanized center wire and outer covered razor in stainless steel or galvanized steel. Razor wire fence has the advantages of beautiful appearance, economy and practicality, has good resistance prevention effect, easy for installation, etc. At present, razor fence has been widely used in many countries’ industrial and mining enterprises, garden apartments, border posts, military fields, prisons, detention centers, government buildings and other national security facilities.

Concertina razor wire fence is a kind of wire fence product made by welding razor wire together. Same as concertina razor wire, this kind of fence also cover densely with razors, this make the fence an not be climbed. Also the steel wire in the razor wire makes the fence very hard to be cut, it is very suitable for prisons, outposts, factory warehouses and other areas requiring high security.

Characteristics of Razor Wire and Razor Wire Fence:

Sharp appearance, good deterrence

Rotatable blades, strong intrusion prevention capability

Corrosion-resistant, long lifespan

Area separation, flexible mobility

Low cost, suitable for large-scale use

Easy installation, easy maintenance

Stainless Steel Sprocket Product Description

1. Description: This range of sprockets are made from 304 stainless steel material.

2. Standard: British

3. Feauture:

Corrosion resitance

Good quality

Competitive price

Customized possible

Nansteel Manufacturing Co.,Ltd manufacture and supply differenet steel products, like

seamless steel pipe, carbon steel pipe, stainless steel pipe, casing etc.For

more,visit:https://www.nan-steel.com/

| Product: | Seamless Stainless Steel Pipe, Stainless Steel Seamless Pipe |

| Size: | OD: 3-2500 mm |

| WT: 1.0-150 mm | |

| LENGTH: 5.8/6/11.8/12m | |

| Pipe Standard: | ASTM A213, ASTM A312, ASTM A269, ASTM A778, ASTM A789 |

| DIN 17456,DIN 17457,DIN | |

| EN 10216, BS 3605, JIS 3459, JIS3463, GOS T9941 | |

| Material: | 304/L,316/L,201,202,301,347/H,316Ti,309s,310s |

| Process: | Cold drawn, Cold rolled, Precision Rolled |

| Finish: | Annealed & pickled, bright annealing, polished |

| Standard Reference | Dia Type | Finish | Grade | Raw Material |

| UIC86

4DIN529 |

M20-M36 | Plain & Oiled, Oxide Black, Zinc Plated, Hot Dip Galvanized, etc |

4.6 5.6 8.8 |

Low Carbon Steel Medium Carbon Steel Alloy Steel |

Our hook bolt, anchor bolt, clip bolt have high quality and cheap price. If you have any question on product, we will give the professional answers to your short questions.

Welded razor mesh is a multi-functional, high security mesh fencing made of straight-blade netting welded together, packaging into a roll form for transport.

Model: BTO-22, BTO-28, BTO-30, BTO-60, BTO-65

Brand: YUJUN

Code: 73144900

Welded Razor Mesh Specification:

Color: GREEN, WHITE

razor wire security fencing Size: 75mm X 150mm, 150mm X 300mm, 177mm X 400mm, do as required

Material: galvanized, stainless steel

Welded stainless steel razor wire Description

Welded razor mesh is a multi-functional, high security mesh fencing made of straight-blade netting welded together, packaging into a roll form for transport. Razor wire mesh is used in operations to pave the field after the installation of a blade barrier. This product can protect you and your property, and ensures the safety of the protective barriers.

This YUJUN razor wire security fence product is almost impossible to climb or cut off with the standard tools, also it has a neat appearance.

Razor mesh is installed in various parts of the world’s airports, military bases, water substation, the border fence, oil depots, factories and so on.

Razor mesh security fence China the benefits

1 it is almost impossible to climb

2 high-strength steel core very difficult to cut off

3 powerful security fence barriers neat appearance

4 no secondary use, so he will not be stolen

5 extremely simple to install, needs three to four to install molding.

More information please click here.

Somos un fabricante profesional de bridas, accesorios de tubería, accesorios forjados en la India, nos especializamos en la fabricación de todos los tamaños, estándar, tipo, etc. Somos capaces de proporcionar una amplia gama de materiales, desde existencias, para satisfacer sus necesidades. Desde material no estándar altamente especializado hasta artículos listos para usar, desde la producción hasta el prototipo, desde mínimos bajos hasta corridas de fábrica, el fabricante de bridas tiene la experiencia para resolver sus requisitos más difíciles.