HENAN FORWARD STEEL EXPORT CO.,LTD

Tel: +86-371-61310228 You also can visit us by sa514steel.com througth google

Address: Tower-A Room 3106 Kai xuan Plaza zhengzhou city of henan province China

http://sa514steel.com

Email: admin@qfsteels.com

SA240 TP310S Stainless, SA240 309S stainless, SA240 316TI stainless, SA240 304H stainless

1. What we do?

HENAN FORWARD STEEL EXPORT CO.,LTD Stainless warehouse provide ASME SA240 Stainless steel plate Bevel,Groove and cutting disc stainless steel machined parts .we have 1000tons tp316L,tp310s,tp304l,tp321, tp304h, tp316h,tp310h, tp321h,2205, S31803, 410, 430, 409, 443, 439, 310SI2, 316TI Stainless steel plate stock.

Besides that, our factory also provide the CNC Cutting platform and water cutting platform. Disc cutting, special parts cutting, stainless steel bevel and stainless steel groove service. Our machined precision to min 0.2 for the surface of machined.

Our cutting service had approved by Mexico and USA, and Canada Project.

2. Our mainly stainless steel grade for ASME SA240

SA240 TP202,SA240 TP201,

SA240 TP304,SA240 TP304L,SA240 TP304H, SA240 TP304N, SA240 TP304LN

SA240 TP316L,SA240 TP316, SA240 TP316H,SA240 TP316N, SA240 TP316LN,SA240 TP316TI

SA240 TP309S, SA240 TP309H,SA240 TP309,SA240 TP309Cb

SA240 TP310S, SA240 TP310, SA240 TP310H

SA240 TP347,SA240 TP347H,

SA240 TP348,SA240 TP348H,

SA240 TP321, SA240 TP321H

SA240 TP317L,SA240 TP317

SA240 TP444,SA240 TP410, SA240 TP430,SA240 TP443, SA240 TP439

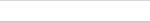

3. Products Service of our unitedsteel warehouse.

Stainless steel plate

Stainless disc steel plate.

Stainless steel cutting

Stainless seamless pipe

Stainless seamless Tube

Stainless welded steel pipe

Stainless machined bevel

Stainless machined groove

4. Our Stainless steel thickness

Stainless plates

0.25mm-150mm thickness

Width: 20mm to 2500mm

Length 20mm to 10000mm

Max weight of each plate 6 tons.

Stainless seamless pipe

outer diameter 3.2-200mm,

Wall thickness 0.5-12.7mm

5. Stainless Production time:

5-8days in usual size.

If you need the bevel and groove stainless parts, we need min extra 7days.

6. Stainless Payment Item for HENAN FORWARD STEEL EXPORT CO.,LTD

TT payment Or 30% TT advance and balance should be paid after BL documents.

7. Why you choose us?

a. The faster production time, and most of production, we can control them in one week if the total weight are not large.

b. Better service, we promise that your inquiry will be sent official quotation in 24hours.

c. Faster delivery, we had owned transport truck department and transport stainless to our port in 24hours.

d. Quality promise processing: PMI Test at each stainless steel plates before delivery. We accept the third party inspection, GL. SGS.BV, DNV, LR,ABS and others.

8. Trade Item:

FOB, EXW, CFR AND CIF

Packages by wooden pallet, delivery by containers.

9. How to contact HENAN FORWARD STEEL EXPORT CO.,LTD?

Your can searh our company name from google or visit sa514steel and qfsteels through searching them at google.

Mr David

0086-371-61310228

admin@qfsteels.com

http://sa514steel.com

Steel grating is generally made of carbon steel, and the surface is hot-dip galvanized, which can prevent oxidation. It can also be made of stainless steel, and the steel grating has the properties of ventilation, lighting, heat dissipation, anti-skid, explosion-proof and so on.

Steel grating is a kind of steel product with square lattice in the middle, which is cross-arranged with flat steel according to a certain spacing and horizontal bars, and welded by pressure welding machine or manually. Steel grating is mainly used as gutter cover. , steel structure platform plate, steel ladder step plate, etc., the cross bar is generally made of twisted square steel.

Advantages of steel grating fence

Material saving: the most material saving method under the same load conditions, correspondingly, the material of the supporting structure can be reduced;

Reduce investment: save material, save labor, save construction period, free of cleaning and maintenance;

Simple construction: on the pre-installed support, it is fixed with bolts or welding, and it can be completed by one person;

Save construction period: the product does not need to be reprocessed on site, and the installation is very fast;

Durable: It has been hot-dip galvanized anti-corrosion treatment before leaving the factory, and has strong impact and heavy pressure resistance;

Modern style: beautiful appearance, standardized design, ventilation and light transmission, giving people an overall smooth modern feeling;

Lightweight structure: less material, light structure, and easy to hoist;

Reduce wind resistance: due to good ventilation, the wind resistance is small in case of strong wind, reducing wind damage;

Anti-contamination: no rain, snow and dust;

Other advantages: ventilation, lighting, heat dissipation, explosion-proof, good anti-skid performance;

Simple design: no need for small support beams, simple structure and simplified design

Acid and alkali corrosion ability: in the range of PH 6 to PH 12.5, a stable protective film is formed on the surface of the zinc layer, and the corrosion resistance is good.

Steel grating use

Steel grating is suitable for alloys, building materials, power stations, boilers, shipbuilding, petrochemical, chemical and general industrial plants, municipal construction and other industries. It has the advantages of ventilation and light transmission, anti-skid, strong bearing capacity, beautiful and durable, easy to clean and easy to install.

Steel grating has been widely used in all walks of life at home and abroad, mainly used as industrial platforms, ladder treads, handrails, passage floors, railway bridge sideways, high-altitude tower platforms, drain covers, well covers, road grilles, three-dimensional It can also be used as a fence for parking lots, institutions, schools, factories, enterprises, sports fields, and garden villas.

Bath Handle Pull YD-BHP12

Item no.: YD-BHP12

Description: Door Handle Pull

Sanitary Hardware Material: Aluminium/zinc alloy

Size: available, customized

Usage: bath hardware, furniture hardware

Process: die casting, machining, surface treatment

Surface: PVD finished, satin nickel, black, mirror finished, bronze, customized

Rajveer Stainless And Alloys is 2008 certified and the largest Flanges Manufacturer company in India deals with the Star Export House & Manufacturer of Steel Flanges Since 2004. We manufacture BLRF Flanges, SORF Flanges, WNRF Flanges according to a number of internationally recognized standards including DIN, ANSI/ASTM, BS, JIS, GB, etc. Our professionals have more than 40 years of familiarity and experience. We are also the premier supplier of metals solutions around the world, revolutionizing the supply chains of the industries we serve also focus on the respective vendors who will be there for all your needs.

Ductile iron Drainage pipe is available in a range of diameters from 80mm to 1600mm and are suitable for both potable water transmission and distribution (in accordance with BS EN 545) and sewerage (in accordance with BS EN 598).

China tongmao ductile pipe is available in a range of diameters from 80mm to 1600mm and are suitable for both potable water transmission and distribution (in accordance with BS EN 545) and sewerage (in accordance with BS EN 598).

Ductile iron Drainage pipe is simple to joint, can be laid in all weather conditions and often without the need for selected backfill. Its high safety factor and ability to accommodate ground movement make it the ideal pipeline material for a wide range of applications.

ductile iron pipeline wholesale have a number of advantages over other pipe materials:

Easy to install

Full range of accessories are widely available

Suited to a host of applications both above and below ground

Strength of the material allows it to withstand significant internal pressure and also makes it less susceptible to impact damage

It has the nature of iron, the performance of steel, excellent corrosion resistance, good ductility and easy installation.

The main components are carbon, silicon, manganese, sulfur, phosphorus and magnesium.

The ductile iron pipe price list is very reasonable.

Cast iron pipe drain pipe、the cast iron sewage pipe and the cast iron gas pipe are widely used.

The wall thickness of the 150mm cast iron pipe is 6mm.

Tianjin KXC group founded in 2004, is an ISO 9001 certified company,committed to manufacturing valves, valve parts & related products for water works and water treatment projects.

KXC consists of HY Valves Co. Ltd and KXC Metal Co. Ltd within our own factory and foundry. We have machining center, CNC machines, pressure test machining, electric furnace, mould machine, sand blasting machine, given all of this, our products quality always under good control.

KXC mainly produce gate valve(Resilient seat, Metal seat), butterfly valve(Concentric and Eccentric), check valve, ball valve, globe valve and etc. Supported by our many years’ experience and expertise in this field,

KXC can also offer OEM &ODM valves and parts.KXC philosophy is to offer high cost performance products with optimal service. Welcome to visit our factories and KXC will satisfy you in all respects.

Our products:Rising Stem Globe Valves, Double Eccentric Butterfly Valve

Galvalume steel is an important alloy material often used in daily life. The galvanized steel sheet is composed of aluminum-zinc alloy structure, which is composed of 55% aluminum, 43.5% zinc and 1.5% silicon solidified at a high temperature of 600℃. Its entire structure is composed of aluminum-iron-silicon-zinc, forming a dense quaternary crystal. Of an alloy.

Characteristics of Galvalume

Hot-dipped Galvalume Steel Coil has many excellent characteristics: strong corrosion resistance, 3 times that of pure galvanized sheet; beautiful spangles on the surface, which can be used as building exterior panels.

Corrosion resistance:

The corrosion resistance of “aluminized zinc steel coil” is mainly due to the protective function of aluminum and aluminum. When zinc is worn, aluminum forms a dense layer of aluminum oxide, which prevents corrosion-resistant substances from further corroding the interior.

Heat resistance:

Hot-dipped Galvalume Steel Coil has good heat resistance and can withstand high temperatures of more than 300 degrees Celsius. It is very similar to the high temperature resistance of aluminized steel plate. It is often used in chimney pipes, ovens, luminaires and fluorescent lampshades.

Heat reflectivity:

The heat reflectivity of Hot-dipped Galvalume Steel Coil is very high, twice that of galvanized steel sheet, and people often use it as a material for heat insulation.

Economical:

Because the density of 55% AL-Zn is lower than that of Zn, the area of the galvanized steel sheet is more than 3% larger than that of the coated steel sheet when the weight is the same and the thickness of the gold plating layer is the same.

Application of Hot-dipped Galvalume Steel Coil

use

The main uses of galvanized products are in two aspects. One is the shell and box of other electrical equipment used in electrical switch cabinets; the other is galvanized steel roofing for steel structure buildings, because of its good anti-corrosion and anti-corrosion properties. In many areas with heavy industrial pollution, aluminum-zinc color panels or aluminum-zinc fingerprint-resistant light panels are directly used on walls or roofs.

Construction: roofs, walls, garages, soundproof walls, pipes and modular houses, etc.

Automobile: muffler, exhaust pipe, wiper attachment, fuel tank, truck box, etc.

Home appliances: refrigerator back panels, gas stoves, air conditioners, electronic microwave ovens, LCD frames, CRT explosion-proof belts, LED backlights, electrical cabinets, etc.

Agricultural: pig houses, chicken houses, granaries, greenhouse pipes, etc.

Others: thermal insulation cover, heat exchanger, dryer, water heater, etc.

| Standard Reference | Dia Type | Finish | Grade | Raw Material |

| UIC86

4DIN529 |

M20-M36 | Plain & Oiled, Oxide Black, Zinc Plated, Hot Dip Galvanized, etc |

4.6 5.6 8.8 |

Low Carbon Steel Medium Carbon Steel Alloy Steel |

Our hook bolt, anchor bolt, clip bolt have high quality and cheap price. If you have any question on product, we will give the professional answers to your short questions.

Woven Wire Mesh BZ-S001

Material: stainless steel & brass/copper/stainless steel/aluminum

Flexibility: Not flexible

Maximum width: 2.5m

Weight: 7.3kg/m2

Open space: 43%

Surface treatment: PVDF spray paint/PVC coating/electroplating

Stainless Steel Woven Wire Mesh China Detailed instructions

Shade Series BZ woven mesh panels are made of wire or flat steel and the appearance of the mesh is usually rectangular. SHADE series products can adjust the temperature of a building by changing the opening rate and transmission of the mesh. The product can help reduce the energy consumption of buildings and is purchased using different sizes of wire and opening sizes, with a wide range of mesh specifications and appearance. Shade series mesh can be installed as a large area of the facade or used on small areas such as window, partition or handrail filling.

Decorative woven wire mesh wholesale A rainbow of colors

In order to provide customers with more color options, Bzwiremesh can use different processes to make the mesh more colorful.

Bzwiremesh uses paint, fluorocarbon coating, PVC coating or an electroplating process to color the mesh. The usual colors used are gold, champagne, silver, bronze, etc. Color selection can also be made according to the color table provided by the customer.

Bzwiremesh can also produce nets made of brass, copper and other materials with natural colors. By adding brass wire to the BZ stainless steel mesh, the mesh will become a new material.

Roopam Steel is top manufacturer & supplier of seamless steel pipe welded tubes in ferrous and non ferrous material, Stockist of high quality tubular piping products and accessories in India. Call us for more Info at +91-22-6639 4333.

The “358” in the 358 fence indicates the specific specifications of this type of guardrail: the mesh hole is 76.2mmx12.7mm, namely 3 “x0.5”, and the wire diameter is usually 4.0mm, namely 8#. Of course, 358 guardrail is an expression of the name of this kind of guardrail, and the specific specifications can be adjusted according to the actual needs of customers.

358 Screen general specifications: mesh: 12.7×76.2mm or can be adjusted to 12.5x75mm or 13x75mm according to customer’s actual needs

Wire diameter: 3.0-6.0 mm

Network height: 1.8m, 2.0m, 2.4m, 2.7m, 3.0m, 4.4m, 5.2m

Network width: 2m, 2.5m, 3m.358

Fence net features: strong anti-climbing ability, strengthen the net to increase the extent of its destruction, long use time, durable.

The prison high security protection net in the prison protection net, the use of large diameter high strength alloy steel wire production, with anti-climbing, impact resistance, shear resistance characteristics and good deterrent effect, dedicated to prison detention center, cordon military base and other high security fields.

358 protection net anti-corrosion form: electroplating, hot plating, spraying, dipping, galfan silk.

358 safety net main use: 358 safety net is mainly used in prisons, posts, frontier defense, surrounded areas, military defense and other high risk areas of protection and municipal garden protection net.

Anping TianHui Wire Mesh Products Co., Ltd. is located in anping county, Hebei province, which also be called “Hometown of wire mesh”in china. Started the factory from the year 1986, We are one of the top manufacturers and exporters of Woven wire Mesh, Screens and welded Wire Mesh in China.

We has over 160 sets of wire mesh machines, have around 20000 rolls in stock for stainless steel wire mesh & welded mesh. We have gained a global sales network reaching to the Local market, USA, Middle-East, Europe and Africa etc.

Our company has been based on “good quality, timely delivery, reasonable price, considerate service” the purpose to serve the masses of customers; And is in line with “quality seek survival, prestige seek development” production principles, in our emphasis on product quality at the same time, also actively communicate with the customer, understand customer needs, to realize our shortcomings, and for clients to provide professional and timely after-sales service, won the praise of the vast old and new customers. Our products are widely used in petroleum, textile, metallurgy, construction, farming, machinery, landscape protection, production and manufacturing, and other fields.

Our Main Products: Stainless Steel Wire Mesh, Shale Shaker Screen, Crimped Wire Mesh, Dutch Wire Mesh, Copper Wire Mesh, Brass Wire Mesh, Stainless Steel Welded Wire Mesh, Galvanized Welded Wire Mesh, Filter Discs And Wire Mesh Processed Products.

TIANHUI Sincerely hope to establish long term business relationship with worldwide customers on the basis of sincerity and mutual benefits.

Copper Mould Tube & Plate

We specially in supplying Copper Mould Tube, Crystallizing equipment of continuous casters, Mould cooling jacket, Repair of Metallurgical Copper Mould Tube, etc.

Equipments & Spare parts for Continuous Casting Machine.

- Copper mould tube( square, rectangle and round )

- Crystallizing equipment of continuous casters

- Mould cooling jacket.

- repair of copper tube moulds

The copper alloys chosen for the moulds must maintain their physical properties at the operating temperatures of the continuous casting process.

The temperature gradation from the inner wall of the mould to the outside face of the mould can cause serious distortion problems, and Metallurgical Copper Mould Tube is imperative that the correct alloy is chosen for the various operating conditions.

Square Copper mould tube STANDARD MATERIALS

Phosphorus de-oxidised copper

This alloy has been proven to be excellent for the manufacture of moulds in the continuous casting of billets. The main composition of this alloy are Cu +Ag 99.90min, P0.0015 / 0.040.

Copper -Silver alloy

The addition of a small amount of silver, whilst not increasing the melting point of copper, does increase the recrystallisation temperature by almost 100℃, and also helps to give better thermal conductivity at the operating temperatures.

This alloy is normally used in moulds for the continuous casting of blooms and slabs .In this case, the moulds are much thicker than in the billet moulds, and the moulds temperature can be higher. The main composition of this alloy are Cu+Ag99.90 min. Ag 0.08 / 0.12 O 0.004 / 0.012.

The continuous casting of molten steel into billets, blooms and slab products, has been highly refined over the years into an extremely sophisticated system. The continuous casting process is expected to produce metallurgically sound products at the lower possible cost, and this is being achieved in many steelworks throughout the world.

Copper moulds have played an important role in the development of the continuous casting process. Their funcition is to receive the molten steel and to allow rapid heat transfer from the steel to the cooling water to enable quick solidification.

The mould must exhibit excellent thermal conductivity, be resistant for thermal erosion ,and be resistant to distortion from thermal stress. So far only copper and a few copper alloys meet the above conditions, both economically and technically.

Mould cooling jacket supplier SOLIDIFICATION

The rate of solidification in the continuous casting process dictates the speed of production. The molten steel, which is in contact with the inner faces of the copper mould, starts to sllidify as rapidly as the heat is extracted, forming a shell. The shell increases in thickness as more heat is extracted, and eventually total solidfication is achieved. the process is similar to the solidification of ingots in ingot moulds. In continuous casting, the whole process is speeded up, with the aim to produce and homogeneous shell growth. Consequently, the mould is an important part of the continuous casting process, and the manufactured quality of the mould plays and important role in their length of life.

INNER SURFACE COATINGS

Over the years, Metallurgists and Engineers have been working together to develop better continuous casting moulds. The steel companies require a more economical mould which will give a longer service life. Surface coating of the inner walls of the mould has given the best results to date. Coatings available are Chromium and Nickel plating. Also, a combination of the two give good results on slab casting.

SPECIFICATIONS OF COPPER MOULD

Square 60 x 60 – 350 x 350 (mm)

Rectangle 120 x 160 – 180 x 300 (mm)

Diameter 100-400 (mm)

Size(mm): 90×90, 100×100, 110×110, 115×115, 120×120

130×130, 135×135, 140×140, 143×143, 150×150

155×155, 160×160, 165×165, 175×175, 180×180

200×200, 220×220, 100×170, 100×173, 130×240

150×200, 150×210, 150×220, 160×200, 160×220

150×225, 160×235, 165×225, 175×225, 180×220

200×240, 240×240, 235×235

Radius(mm): 4000, 5000, 5250, 6000, 7000, 7500, 8000, 9000, 10250, 10300, 11000, 12000

Length(mm): 700, 750, 780, 790, 800, 810, 812, 850, 900, 1000

A well screen is a filter device used as the suction portion of a well constructed in a loose or semi-consolidated aquifer. The screen allows water to enter the well from the saturated aquifer, prevents sediment from entering the well, and acts structurally as a support for the aquifer material. When considering well efficiency and the logarithmic cost to the well owner, the importance of having the right screen cannot be overemphasized.

The sieve is resistant to corrosion because it comes into contact with water. In addition, it has high strength and can keep the surrounding structure intact. The openings of the sieve can be small enough to block the large amount of formation around them. The flow of water through the screen will be uniform.

Well screens are recommended for all environmental drilling operations. It helps extend the life of the well and keeps the flow of water unrestricted. Sand and fine powder sand, these fine particles can be filtered out before there is water. Well screens help remove most of this fine material from well water.

Well screens are made from a variety of materials, ranging from rough-hewed hand designs to machine built high-efficiency and long-life models. The value of the screen depends on how much it contributes to the success of the well.

Standard:

- Large open Spaces

- Do not block the slot

- 3.corrosion resistance

- Sufficient column and collapse strength

Functions:

- Easy to develop

- Minimal scaling tendency

- Low head loss through the screen

- Control sand pumping of all types of aquifers

Slot size selection is a critical step to ensure maximum well performance. The screen is usually designed to block 50% of the stratum, and the entry speed for the screen should not exceed 1/10 or 0.1 ft per second. The velocity is calculated by dividing the well production in GPM by the screen open area in square inches.

The gap size of the screen is based on dimensional analysis of the formation sample. After analyzing the composition size of grain in the sample, grain size distribution curve

I can draw it. Several methods can be used to obtain the allocation of information about grain size. The most widely used method is to pass the material through a stacked set of brass or stainless steel sieves. During the screening process, each sieve removes a certain percentage of the whole sample; The best materials are collected in the chassis. Screening analysis not only provides the basis for determining slot sizes, but also other factors that influence screening well design.

HOT-DIPPED GALVANIZED STEEL COIL

- INTRODUCTION:

Hot-dipped galvanized steel coil is made from steel plate, which is dipped into the dissolved zinc bath, with a zinc layer on the surface. It mainly adopts the continuous galvanizing production process. That means the cold rolled coils are put into the dissolved zinc bath for continuous galvanizing process.

- EVER-SHINE Steel Coil APPLICATION:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It’s especally useful for countless outdoor and industrial applications.

They are mainly used in building roof, door, window, roller shutter doorand automobile’s vehicle shell, chassis, door, trunk lid, Oil tank, and fender, and also electric equipments, such as refrigerator base and shell and so on.

- SPECIFICATION

| THICKNESS | 0.11mm-5.0mm |

| WIDTH | 600-1250mm Max |

| COATING MASS | 20g-400g/m2 |

| Surface Structure | Zero Spangle,Regular Spangle,Minimized Spangle |

| SURFACE TREATMENT | Chromated/non-Chromated,Oiled/non-Oiled,skinpassed/non-skinpassed |

| COIL INNNER DIAMETER | 508mm or 610mm |

We Are Counted Among The Best Manufacturer, Exporter Stockist & Supplier. We Export 60% Of Our Range Of Flanges, Outlets, Pipe Fittings And Forged Fittings To Many Countries Like Usa, Uk, Italy, Malaysia, Gulf Etc.

Stainless Steel Sprocket Product Description

1. Description: This range of sprockets are made from 304 stainless steel material.

2. Standard: British

3. Feauture:

Corrosion resitance

Good quality

Competitive price

Customized possible

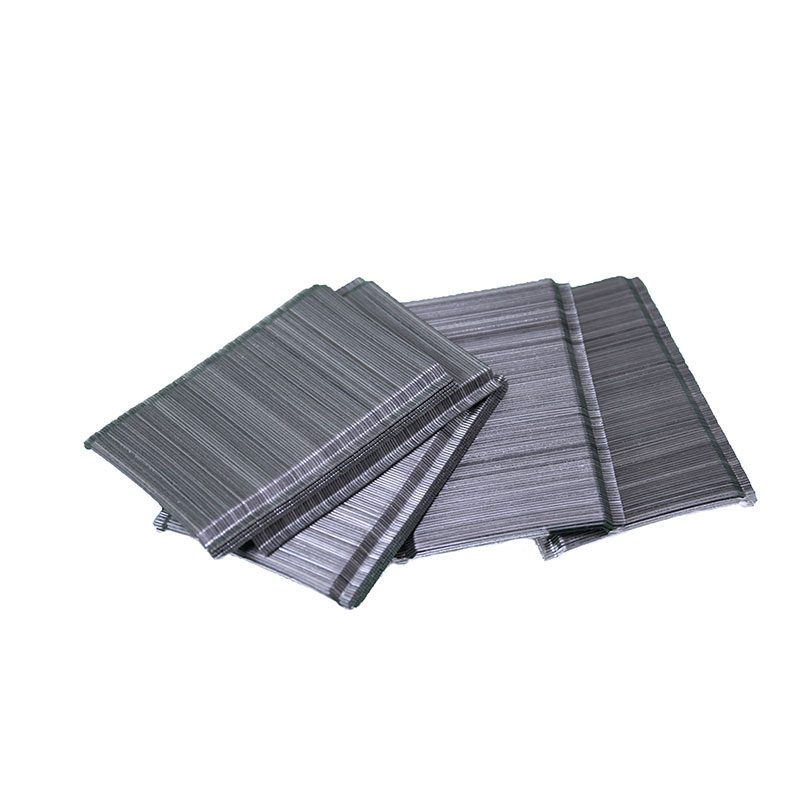

Glued Steel Fiber, an alternate concrete reinforcing material are high tensile steel wires with hooked ends, glued together by the water-soluble adhesive for compactness and uniform dispersion in concrete, to increase the concrete properties by 3-4 times.

steel fiber reinforced concrete supplier improve the mechanical properties concrete and materials such as ductility,

energy absorption, fatigue, and toughness. This fiber helps to controls plastic shrinkage cracking in concrete; helps reduce or eliminate need for conventional reinforcement.

Application of Glued steel fiber reinforced concrete

- For concrete flooring

Industrial floors

Joint-less floors

Floors-on-piles

Lightly loaded floors

Liquid tight floors & composite metal decking

- stainless steel fiber supplierFor Hard Standing & Heavy Duty

Parking lots

Playgrounds

Airport runways

Taxiways

Maintenance hangers

Access roads & workshops

Ports& Containers for port pavements

Container terminals

Bulk storage areas access roads

For army tank movement

- steel fibers for concrete reinforcementOther Applications

Foundations

Traditional cellar and basement walls

Compression layers

Tunnel engineering

Compared with the GuangYa loose steel fiber the operation and advantages of the glued steel fiber:

- Add the steel fiber directly into the belt, the whole row of steel fiber as a whole, evenly dispersed in the concrete corner

- The water-soluble glue begins to dissolve in a row of steel fibers in the premise of the dispersion, it is again dispersed in every corner of the mono filament fiber, showing the perspective in the concrete of the fiber mesh, which plays an integral strengthening.

- Compared with mono-filament fibers, China bonded steel fiberswill not be bundled to ensure that the fibers in concrete do not coalesce and distribute evenly.

Glued steel fibers are loose hook-end fibers that are bonded together in a row. The great difference between loose fiber and glued fiber is that the former is easy to clog and the latter is easy to disperse evenly.

UNS S31254 / Alloy 6Mo / WNR 1.4547 / F44 / 254SMO Super Austenitic Stainless Steel

UNS S31254 is a high corrosion resistant Super Austenitic Stainless Steel and provide excellent corrosion resistance in severe corrosion environments such as high temperature seawater.

We offer a comprehensive selection of seamless/welded stainless steel pipes, including the UNS S31254 super austenitic stainless steel pipe, also known as 254SMo or WNR 1.4547. Made with high-quality materials and under strict manufacturing standards, these pipes are perfect for a variety of applications in seawater handling systems, desalination plant equipment, chemical processing, and flue gas desulphurization units.

UNS S31254 Stainless Steel Pipe Features:

– High corrosion resistance: Made with alloy UNS S31254, these pipes are highly resistant to corrosion in harsh environments, including high chloride and acidic conditions.

– High strength: The WNR 1.4547 pipes are made with a super austenitic stainless steel with high strength, making them durable and reliable for a range of applications.

– Excellent weldability: The 6mo stainless steel pipes are easy to weld and fabricate, making them a versatile solution for complex piping systems.

– Compliant with industry standards: The 254SMO Super Austenitic Stainless Steel pipes meet the manufacturing standards of ASTM A269, ASTM A312, and ASTM A213, ensuring quality and reliability.

UNS S31254 Chemical Composition (%)

| % | C | Mn | P | S | Si | Ni | Cr | Mo | N | Cu |

| Min | 17.5 | 19.5 | 6.0 | 0.18 | 0.50 | |||||

| Max | 0.02 | 1.00 | 0.030 | 0.010 | 0.80 | 18.5 | 20.5 | 6.5 | 0.25 | 1.00 |

254SMO Physical Properties:

| Density | 8.02 Mg/m³ |

| Melting Range | 1360-1405 ℃ |

UNS S31254 Stainless Steel Pipe Applications:

– Seawater handling systems: The UNS 31254 Stainless Steel pipes are ideal for use in seawater handling systems due to their high corrosion resistance and strength.

– Desalination plant equipment: The WNR 1.4547 Stainless Steel tubes are widely used in desalination plant equipment due to their ability to withstand high chloride and saltwater environments.

– Chemical processing: The UNS S31254 pipes are suitable for chemical processing due to their corrosion resistance and thermal stability.

– Flue gas desulphurization unit: The Alloy 6Mo Stainless Steel pipes are ideal for use in flue gas desulphurization units due to their resistance to acids and ability to handle high temperatures.

Manufacturing Standards:

ASTM A213

ASTM A312

ASTM A269

Also individual customer specifications, as a professional UNS 31254 Stainless Steel pipes and tubing supplier, Hengyang is committed to providing high-quality stainless steel pipes to meet the needs of our customers. Contact us today for more information on the UNS S31254 pipe and other products in our collection.

Jade Special Metals is India’s 10th largest supplier, trader & Exporter of Stainless Steel, Carbon steel pipes and round bar. We are specialised in Stocking & Distributing various Stainless Steel, carbon steel pipes, round bar & sheet plates to worldwide for specific & urgent requirements.