Steel grating is generally made of carbon steel, and the surface is hot-dip galvanized, which can prevent oxidation. It can also be made of stainless steel, and the steel grating has the properties of ventilation, lighting, heat dissipation, anti-skid, explosion-proof and so on.

Steel grating is a kind of steel product with square lattice in the middle, which is cross-arranged with flat steel according to a certain spacing and horizontal bars, and welded by pressure welding machine or manually. Steel grating is mainly used as gutter cover. , steel structure platform plate, steel ladder step plate, etc., the cross bar is generally made of twisted square steel.

Advantages of steel grating fence

Material saving: the most material saving method under the same load conditions, correspondingly, the material of the supporting structure can be reduced;

Reduce investment: save material, save labor, save construction period, free of cleaning and maintenance;

Simple construction: on the pre-installed support, it is fixed with bolts or welding, and it can be completed by one person;

Save construction period: the product does not need to be reprocessed on site, and the installation is very fast;

Durable: It has been hot-dip galvanized anti-corrosion treatment before leaving the factory, and has strong impact and heavy pressure resistance;

Modern style: beautiful appearance, standardized design, ventilation and light transmission, giving people an overall smooth modern feeling;

Lightweight structure: less material, light structure, and easy to hoist;

Reduce wind resistance: due to good ventilation, the wind resistance is small in case of strong wind, reducing wind damage;

Anti-contamination: no rain, snow and dust;

Other advantages: ventilation, lighting, heat dissipation, explosion-proof, good anti-skid performance;

Simple design: no need for small support beams, simple structure and simplified design

Acid and alkali corrosion ability: in the range of PH 6 to PH 12.5, a stable protective film is formed on the surface of the zinc layer, and the corrosion resistance is good.

Steel grating use

Steel grating is suitable for alloys, building materials, power stations, boilers, shipbuilding, petrochemical, chemical and general industrial plants, municipal construction and other industries. It has the advantages of ventilation and light transmission, anti-skid, strong bearing capacity, beautiful and durable, easy to clean and easy to install.

Steel grating has been widely used in all walks of life at home and abroad, mainly used as industrial platforms, ladder treads, handrails, passage floors, railway bridge sideways, high-altitude tower platforms, drain covers, well covers, road grilles, three-dimensional It can also be used as a fence for parking lots, institutions, schools, factories, enterprises, sports fields, and garden villas.

C-shaped hooks for hanging posters and signs, store decoration and display items, and for hanging and connecting various items. These CNC Wire hooks wholesale are made of durable 2mm thick metal wire.

Other sizes can be provided on request.

A pack of 100

More information please click here.

3 Type 2 Wall Tie(CE marked)

Product Name: Type 2 Wall Tie(CE Marked)

Item Code: Smart Craftsmen-WTT2

Surface Treatment: Shiny.

Raw Material: Stainless Steel 304( Grade1 4301) or Up on your request.

Package: 250 pieces / Inner Box, 2 or 4 Inner boxes / Master Carton.

Place of Origin: Hebei, China.

Standards: PD 6697 and EN 845-1:2013+A1:2016.

The type 2 wall ties for sale are suitable for general-purpose neckties with a space between 50mm and 150mm, which can be used in European domestic residential and small commercial buildings up to 15 meters high. Smart Craftsmen Type 2 wall ties are CE marked, and the measured dynamic stiffness <113MN/m3 meets the requirements for external masonry walls

Approve the performance requirements of Document E. The test result meets the PD 6697 standard and confirms BS EN 845-1: 2013 + A1: 2016.

benefit

Answer: The specially designed safety end provides an excellent mortar key, which reduces the risk of on-site injury and prevents entanglement.

B: Clear and easy to distinguish packaging, which can be conveniently used on site when different types of wall ties are needed.

C: It is made of corrosion-resistant stainless steel, and high-strength steel wire is cold bridged to minimize heat loss.

D: Multiple drops can prevent water from flowing in any direction where the cable tie is installed.

note

Other special length and wire thickness can be provided according to customer requirements.

Belleville Disc Springs also was called “Disc Springs” “Conical Disc Springs”, include disc spring stacks, Corrosion Resistant Disc Springs, High Temperature / Cryogenic Disc Springs, Disc Springs for Ball Bearing, Disc Springs for Valves. Disc Springs are widely used in petrochemical, electric power, metallurgy, engineering, machine tools, national defense, and other industries.

Bearing Preload Disc Springs manufacturer Description

The Disc Spring concept was first invented by a Frenchman Louis Belleville in 1865. So, disc spring is commonly known as Belleville Springs. And sometimes it also was called “Conical disc springs” “Belleville Disc Springs” or “Belleville Washers”.

Hegong Disc Springs are conically washers and have a rectangular cross-section, which is loaded in the axial direction. It has a small volume and large energy storage compared to traditional helical springs and can be used as a single disc spring or in the stack (stack in parallel, in series or parallel & series combination).

The standards for disc springs mainly include DIN2092 (Calculation) / DIN2093 ( Quality Specifications-Dimensions ) of Germany, JIS B 2706- Japan, GB/T 1972-2005 of China and ISO 19690 : 2017 ( HEGONG SPRING ® is the drafting team member for international standard ISO 19690 : 2017 and Chinese national standard GB/T 1972-2005 ). Among them, DIN2093 is most widely used in the world.

belleville washer design are designed & manufactured according to DIN2092 & DIN2093, working for dynamic or static applications. The engineers of HEGONG SPRING® are pleased to design the springs for the specific applications together with the customer’s R&D department. Be free to contact with our engineers. Tech@DiscSpringsMFG.com.

Generally, disc springs include disc spring stacks, Corrosion Resistant Disc Springs, High Temperature / Cryogenic Disc Springs, Disc Springs for Ball Bearing, Disc Springs for Valves.

Surface Condition And Corrosion Protection:

Polish

Phosphating and oil

Mechanical Zinc Plating

Chemical Nickel Plating

Docromet / Geomet Coating

Electrophoresis

Tolerance:

The Tolerance is according to DIN2093 standards

Belleville Spring Washers exporter Specification:

The following specification table covers the “standard” sizes and some non-standard sizes. HEGONG SPRING ® customizes Belleville Disc Springs as well. The max OD is up to 1000mm. If you require the custom Belleville Disc Springs, please contact our sales engineers.

| Standard Reference | Dia Type | Finish | Grade | Raw Material |

| UIC86

4DIN529 |

M20-M36 | Plain & Oiled, Oxide Black, Zinc Plated, Hot Dip Galvanized, etc |

4.6 5.6 8.8 |

Low Carbon Steel Medium Carbon Steel Alloy Steel |

Our hook bolt, anchor bolt, clip bolt have high quality and cheap price. If you have any question on product, we will give the professional answers to your short questions.

SHINESTAR STEEL GROUP CO., LTD mainly produce various carbon and alloy steel pipes including oil & gas pipe, pressure pipe, mechanical tubing, and stainless steel tube, etc.

As the most valuable subsidiary under SHINESTAR STEEL GROUP, PRIME STEEL PIPE is the solution provider for the oil, gas, construction, energy and prtrochemical industries.SHINESTAR STEEL GROUP is specialized in manufacturing superior quality steel products, and providing outstanding service for valued clients all over the world.

Hunan Great Steel Pipe Co.,Ltd is specialized in steel pipe & tube production including carbon steel pipe, seamless steel pipe, erw steel pipe, ssaw steel pipe, lsaw steel pipe, etc.

Hunan Great Steel Pipe Co.,Ltd is a world-class production and service provider of seamless pipes and welded pipes as the first subsidiary of Shinestar Group.

- 起源地;原产地:

-

中国天津

- 品牌:

-

国际商业中心

- 应用:

-

制作管道、切割片材、制作小工具、制作波纹板、制作容器、制作栅栏

- 类型:

-

钢卷

- 厚度:

-

0.21-0.50mm

- 标准:

-

爱思

- 宽度:

-

1501-2000MM

- 长度:

-

按要求

- 证书:

-

API、 SNI、 BIS、 SASO 、SABS 、sirm、 tisi

- 年级:

-

镀铝锌硅,SGCC,DX51D

- 涂层:

-

AZ121-Z150

- 宽容:

-

±10%

- 加工服务:

-

焊接、冲孔、切割、弯曲、开卷

- 铝含量:

-

55%

- 亮片类型:

-

零亮片

- 涂油或不涂油:

-

轻微上油

- 硬度:

-

全硬

- 交货时间:

-

15-21 天

- 产品名称:

-

镀铝硅

- 最小起订量:

-

1吨

- 表面:

-

低碳钢素面,热浸镀锌,彩色涂层

Established in 1996, Vintex Steel & Engg. Co. has gained immense expertise in supplying & trading of Stainless steel, carbon steel, ferrous metal etc. The supplier company is located in Mumbai, Maharashtra and is one of the leading sellers of listed products. Buy Stainless steel, carbon steel, ferrous metal in bulk from us for the best quality products and service.

Shijiazhuang Ruite Pump Co., Ltd. is one of the high-enterprises integrating research, design, production and sales systems, produces slurry pumps, dredge pumps, gravel pumps, desulphurization pumps and pump parts. Our standard TAH(R) slurry pump, THH slurry pump, TSP(R) Vertical slurry pump, TG(H) gravel pump and all spare parts are interchangeable with Warman (weir) slurry pumps and spares. Meanwhile, Custom slurry pumps and spare parts are welcome. We will open mold and manufacure as your design drawing or samples. With more than 20years of accumulation and development, our factory was founded in 2003, the covering area is more than 3000 square meters, the registered capital is 50 millions. Our slurry pumps are mainly used in coal, mining, FGD in power station, metallurgy, dredging, petro-leum, chemical industry, building material, paper and other industries.

First-rate goods ! Reliable quality! Our Ruite pump have won well-deserved reputation at home and abroad. Our slurry pumps have been exported to Russia, South Africa, Zambia, Australia, Indonesia, Canada, Peru, Chile, Italy, France, Thailand, Singapore, Vietnam, Philippines, Mexico, Saudi Arabia, UAE…more than 37 countries. The professional pre-service, in-service and after-service provide customer perfect slurry solution.

Roopam Steel is top manufacturer & supplier of seamless steel pipe welded tubes in ferrous and non ferrous material, Stockist of high quality tubular piping products and accessories in India. Call us for more Info at +91-22-6639 4333.

Galvalume steel is an important alloy material often used in daily life. The galvanized steel sheet is composed of aluminum-zinc alloy structure, which is composed of 55% aluminum, 43.5% zinc and 1.5% silicon solidified at a high temperature of 600℃. Its entire structure is composed of aluminum-iron-silicon-zinc, forming a dense quaternary crystal. Of an alloy.

Characteristics of Galvalume

Hot-dipped Galvalume Steel Coil has many excellent characteristics: strong corrosion resistance, 3 times that of pure galvanized sheet; beautiful spangles on the surface, which can be used as building exterior panels.

Corrosion resistance:

The corrosion resistance of “aluminized zinc steel coil” is mainly due to the protective function of aluminum and aluminum. When zinc is worn, aluminum forms a dense layer of aluminum oxide, which prevents corrosion-resistant substances from further corroding the interior.

Heat resistance:

Hot-dipped Galvalume Steel Coil has good heat resistance and can withstand high temperatures of more than 300 degrees Celsius. It is very similar to the high temperature resistance of aluminized steel plate. It is often used in chimney pipes, ovens, luminaires and fluorescent lampshades.

Heat reflectivity:

The heat reflectivity of Hot-dipped Galvalume Steel Coil is very high, twice that of galvanized steel sheet, and people often use it as a material for heat insulation.

Economical:

Because the density of 55% AL-Zn is lower than that of Zn, the area of the galvanized steel sheet is more than 3% larger than that of the coated steel sheet when the weight is the same and the thickness of the gold plating layer is the same.

Application of Hot-dipped Galvalume Steel Coil

use

The main uses of galvanized products are in two aspects. One is the shell and box of other electrical equipment used in electrical switch cabinets; the other is galvanized steel roofing for steel structure buildings, because of its good anti-corrosion and anti-corrosion properties. In many areas with heavy industrial pollution, aluminum-zinc color panels or aluminum-zinc fingerprint-resistant light panels are directly used on walls or roofs.

Construction: roofs, walls, garages, soundproof walls, pipes and modular houses, etc.

Automobile: muffler, exhaust pipe, wiper attachment, fuel tank, truck box, etc.

Home appliances: refrigerator back panels, gas stoves, air conditioners, electronic microwave ovens, LCD frames, CRT explosion-proof belts, LED backlights, electrical cabinets, etc.

Agricultural: pig houses, chicken houses, granaries, greenhouse pipes, etc.

Others: thermal insulation cover, heat exchanger, dryer, water heater, etc.

Ductile iron Drainage pipe is available in a range of diameters from 80mm to 1600mm and are suitable for both potable water transmission and distribution (in accordance with BS EN 545) and sewerage (in accordance with BS EN 598).

China tongmao ductile pipe is available in a range of diameters from 80mm to 1600mm and are suitable for both potable water transmission and distribution (in accordance with BS EN 545) and sewerage (in accordance with BS EN 598).

Ductile iron Drainage pipe is simple to joint, can be laid in all weather conditions and often without the need for selected backfill. Its high safety factor and ability to accommodate ground movement make it the ideal pipeline material for a wide range of applications.

ductile iron pipeline wholesale have a number of advantages over other pipe materials:

Easy to install

Full range of accessories are widely available

Suited to a host of applications both above and below ground

Strength of the material allows it to withstand significant internal pressure and also makes it less susceptible to impact damage

It has the nature of iron, the performance of steel, excellent corrosion resistance, good ductility and easy installation.

The main components are carbon, silicon, manganese, sulfur, phosphorus and magnesium.

The ductile iron pipe price list is very reasonable.

Cast iron pipe drain pipe、the cast iron sewage pipe and the cast iron gas pipe are widely used.

The wall thickness of the 150mm cast iron pipe is 6mm.

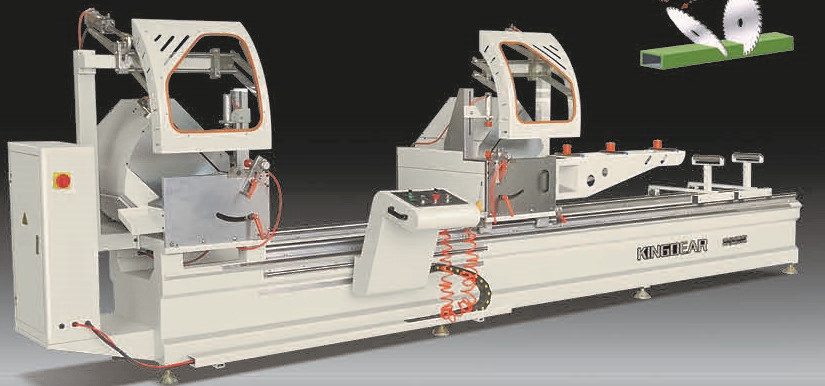

Model No.: LJZ2 -450×3700

PRODUCT DESCRIPTION

Double Head Cutting Saw Equipment Feature

■ Used for aluminum profile cutting.

■ Carbide saw blade give accurate processing and high endurance.

■ The two heads can work independently and simultaneously.

■ Cutting off the required length and two end angles is available by one time processing

Double Head Cutting Saw Technical Parameter

1) Power supply: three phase, four line 380V, 50Hz

2) Saw motor: 1.5Kw x 2, 2,800r/min

3) Pulling motor: 0.55Kw, 1,400r/min

4) Working pressure: 0.4 – 0.6MPa

5) Air consumption: 200L/min

6) Cutting length: max 3,700mm; min. 400mm

7) Cutting width: max 120mm

8) Cutting height: max. 200mm

9) Cutting angle: 0° – 45°

10) Cutter feeding speed: 0 – 3m/min

11) Saw diameter specification: 450mm x 4mm x 30mm-120

12) Overall dimensions: 4,500mm x 1,100mm x 1,400mm

Processing Accuracy

■ Repeat locating length: ≤0.2mm

■ Cutting angle allowance: ±5′

■ Cutting profile surface planeness: ≤0.10mm

■ Cutting profile surface roughness: Ra12.5μm

If you want to know more, you can click here.

Model No.: LJJS-CNC-500×600

PRODUCT DESCRIPTION

CNC Corner Connector Automatic Cutting Saw Equipment Features

■ This machine is mainly for alum windows corner stake cutting, also used for cutting Alum & PVC profiles.

■ PLC auto program controlling, man-machine interface is colored touch screen, input the cutting size and quantity, then it can cut automatically.

■ Automatic feeding system take the linear guiderail and high precision ball screw, driven by stepping motor. High feeding precision and efficiency.

■ Saw blade spindle take special high accuracy spindle, end face and radial runout are less 0.01mm, cutting surface is highly polished.

■ Saw blade feeding system adopts linear guiderail, with high accuracy and high speed (can be stepless speed regulation)

■ Carbide saw blade give accurate processing and high efficiency.

■ Special workpiece clamping system, besides processing common corner stake, it can also process middle frame corner stake.

■ All closed machine body and cover, with good appearance, safe working and low noisy.

CNC Corner Connector Automatic Cutting Saw Technical Parameter

■ Power: 380V 50Hz

■ Motor Rate: 2.2Kw

■ Saw Blade Diameter: Φ500mm

■ R.P.M: 2800r /min

■ Cutting Width: 135mm

■ Automatic Profile Feeding Length: 4-600mm

■ Working air pressure: 0.5-0.8Mpa

■ Weight: 600kg

If you want to know more, you can click here.

Bath Handle Pull YD-BHP12

Item no.: YD-BHP12

Description: Door Handle Pull

Sanitary Hardware Material: Aluminium/zinc alloy

Size: available, customized

Usage: bath hardware, furniture hardware

Process: die casting, machining, surface treatment

Surface: PVD finished, satin nickel, black, mirror finished, bronze, customized

Different from Studded T post , T post replaces studs with holes. It’s consistent holes spacing for convenient and firm wire attachment. Customers can choose different sizes, lengths, and number of holes according to their requirement. Our posts range from lengths of 1.35m to 2.1m and weights of 1.1kg to 2.0kg per linear foot.

L-posts are one of the best options for securing fences. L posts are made of high-quality low-carbon steel. Compared with studded T posts, L posts use consistent holes to attach various fence wires firmly. With high strength, corrosion and rust resistance, easy installation, and a long service life, L fence posts are widely used in gardens or farms to fix fences firmly or to fix plants, such as tomatoes, grapes, trees, and so on. L Post is popular in Germany.

Product Parameters

| Specification | 30 mm × 30 mm,40 mm × 40 mm,50 mm × 50 mm etc. |

| Length | 1.35m / 1.6m /1.8m /2.1m or as request |

| Surface Treatment | Electrostatic spraying,Galvanized |

| Package | 5pcs/bundle,200pcs/pallet |

High carbon steel (or Spring Steel) can be hardened substantially and is used for high tensile applications such as springs, brush, Upholstered furniture, duct, auto parts.

With the increasing of carbon content, the wire becomes stronger and harder. There are four types of carbon steel including low (mild) carbon steel, medium-carbon steel, high carbon steel wire and very high- carbon steel wire.

Steel wire is a kind of multifunctional wire. High-strength materials make it withstand heavy things like hanging wire without being damaged.

Crafted from premium quality materials, our high carbon steel wire is engineered to withstand demanding environments and heavy-duty usage. Its high carbon content ensures superior strength and resilience, making it suitable for applications that require durability and longevity. Count on our wire to tackle even the toughest tasks with ease.

With its versatile nature, our high carbon steel wire can be used in various industries and projects. It serves as a vital component in fencing systems, providing reliable support and security. Additionally, it finds application in manufacturing, construction, agriculture, and many other sectors. Whatever your project demands, our high carbon steel wire is up to the challenge.

Installation and handling are made effortless with our high carbon steel wire. Its flexible yet sturdy construction allows for easy manipulation and shaping, ensuring a hassle-free installation process. The wire’s uniform thickness and smooth surface provide a seamless experience, whether you’re working with automated machinery or performing manual tasks.

Copper Mould Tube & Plate

We specially in supplying Copper Mould Tube, Crystallizing equipment of continuous casters, Mould cooling jacket, Repair of Metallurgical Copper Mould Tube, etc.

Equipments & Spare parts for Continuous Casting Machine.

- Copper mould tube( square, rectangle and round )

- Crystallizing equipment of continuous casters

- Mould cooling jacket.

- repair of copper tube moulds

The copper alloys chosen for the moulds must maintain their physical properties at the operating temperatures of the continuous casting process.

The temperature gradation from the inner wall of the mould to the outside face of the mould can cause serious distortion problems, and Metallurgical Copper Mould Tube is imperative that the correct alloy is chosen for the various operating conditions.

Square Copper mould tube STANDARD MATERIALS

Phosphorus de-oxidised copper

This alloy has been proven to be excellent for the manufacture of moulds in the continuous casting of billets. The main composition of this alloy are Cu +Ag 99.90min, P0.0015 / 0.040.

Copper -Silver alloy

The addition of a small amount of silver, whilst not increasing the melting point of copper, does increase the recrystallisation temperature by almost 100℃, and also helps to give better thermal conductivity at the operating temperatures.

This alloy is normally used in moulds for the continuous casting of blooms and slabs .In this case, the moulds are much thicker than in the billet moulds, and the moulds temperature can be higher. The main composition of this alloy are Cu+Ag99.90 min. Ag 0.08 / 0.12 O 0.004 / 0.012.

The continuous casting of molten steel into billets, blooms and slab products, has been highly refined over the years into an extremely sophisticated system. The continuous casting process is expected to produce metallurgically sound products at the lower possible cost, and this is being achieved in many steelworks throughout the world.

Copper moulds have played an important role in the development of the continuous casting process. Their funcition is to receive the molten steel and to allow rapid heat transfer from the steel to the cooling water to enable quick solidification.

The mould must exhibit excellent thermal conductivity, be resistant for thermal erosion ,and be resistant to distortion from thermal stress. So far only copper and a few copper alloys meet the above conditions, both economically and technically.

Mould cooling jacket supplier SOLIDIFICATION

The rate of solidification in the continuous casting process dictates the speed of production. The molten steel, which is in contact with the inner faces of the copper mould, starts to sllidify as rapidly as the heat is extracted, forming a shell. The shell increases in thickness as more heat is extracted, and eventually total solidfication is achieved. the process is similar to the solidification of ingots in ingot moulds. In continuous casting, the whole process is speeded up, with the aim to produce and homogeneous shell growth. Consequently, the mould is an important part of the continuous casting process, and the manufactured quality of the mould plays and important role in their length of life.

INNER SURFACE COATINGS

Over the years, Metallurgists and Engineers have been working together to develop better continuous casting moulds. The steel companies require a more economical mould which will give a longer service life. Surface coating of the inner walls of the mould has given the best results to date. Coatings available are Chromium and Nickel plating. Also, a combination of the two give good results on slab casting.

SPECIFICATIONS OF COPPER MOULD

Square 60 x 60 – 350 x 350 (mm)

Rectangle 120 x 160 – 180 x 300 (mm)

Diameter 100-400 (mm)

Size(mm): 90×90, 100×100, 110×110, 115×115, 120×120

130×130, 135×135, 140×140, 143×143, 150×150

155×155, 160×160, 165×165, 175×175, 180×180

200×200, 220×220, 100×170, 100×173, 130×240

150×200, 150×210, 150×220, 160×200, 160×220

150×225, 160×235, 165×225, 175×225, 180×220

200×240, 240×240, 235×235

Radius(mm): 4000, 5000, 5250, 6000, 7000, 7500, 8000, 9000, 10250, 10300, 11000, 12000

Length(mm): 700, 750, 780, 790, 800, 810, 812, 850, 900, 1000

HOT-DIPPED GALVANIZED STEEL COIL

- INTRODUCTION:

Hot-dipped galvanized steel coil is made from steel plate, which is dipped into the dissolved zinc bath, with a zinc layer on the surface. It mainly adopts the continuous galvanizing production process. That means the cold rolled coils are put into the dissolved zinc bath for continuous galvanizing process.

- EVER-SHINE Steel Coil APPLICATION:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It’s especally useful for countless outdoor and industrial applications.

They are mainly used in building roof, door, window, roller shutter doorand automobile’s vehicle shell, chassis, door, trunk lid, Oil tank, and fender, and also electric equipments, such as refrigerator base and shell and so on.

- SPECIFICATION

| THICKNESS | 0.11mm-5.0mm |

| WIDTH | 600-1250mm Max |

| COATING MASS | 20g-400g/m2 |

| Surface Structure | Zero Spangle,Regular Spangle,Minimized Spangle |

| SURFACE TREATMENT | Chromated/non-Chromated,Oiled/non-Oiled,skinpassed/non-skinpassed |

| COIL INNNER DIAMETER | 508mm or 610mm |