As a Concertina Razor Wire Suppliers, share it with you.

Feature

Razor barbed wire, also known as scraper barbed wire, is a new type of protective net product developed with strong protection and isolation capabilities. The sharp knife-shaped thorn is formed into a bellows shape by a double-line buckle, which is both beautiful and chilling. Played a good deterrent effect. At the same time, the product has the advantages of beautiful appearance, good anti-blocking effect and convenient construction.

Concertina Razor Wire

Razor-barbed wire is generally used for protection in prisons. Because the blade is sharp and not easy to touch, it has a certain deterrent effect. The razor-barbed wire has a wide range of uses. It can be used for wall protection of residents and can also be used for enclosure. The anti-theft effect of the barbed wire is better than that of ordinary barbed wire, and the price is not high, so the razor barbed wire is more and more widely used.

Razor wire, also known as razor wire, is a new type of protective product developed with strong protection and isolation capabilities.

Stainless steel barbed wire is different according to the different application areas containing nickel. The effect of using 304 stainless steel in a dry indoor environment is quite good. However, if you want to maintain its appearance outdoors in the countryside and cities, you need to wash it frequently. In heavily polluted industrial areas and coastal areas, the surface will be very dirty and even rusty. However, to obtain the aesthetic effect in the outdoor environment, nickel-containing stainless steel is required. Therefore, 304 stainless steel is widely used in curtain walls, side walls, roofs and other construction purposes. However, 316 stainless steel is best used in severely corrosive industries or marine atmospheres.

Razor nets have been widely used in military powerhouses, prisons, government agencies, banks, and living quarters, private houses, villas, doors and windows, highways, railway guardrails, and borders to protect security in various countries around the world.

Our company also has Concertina Razor Wire for Sale, welcome to contact us.

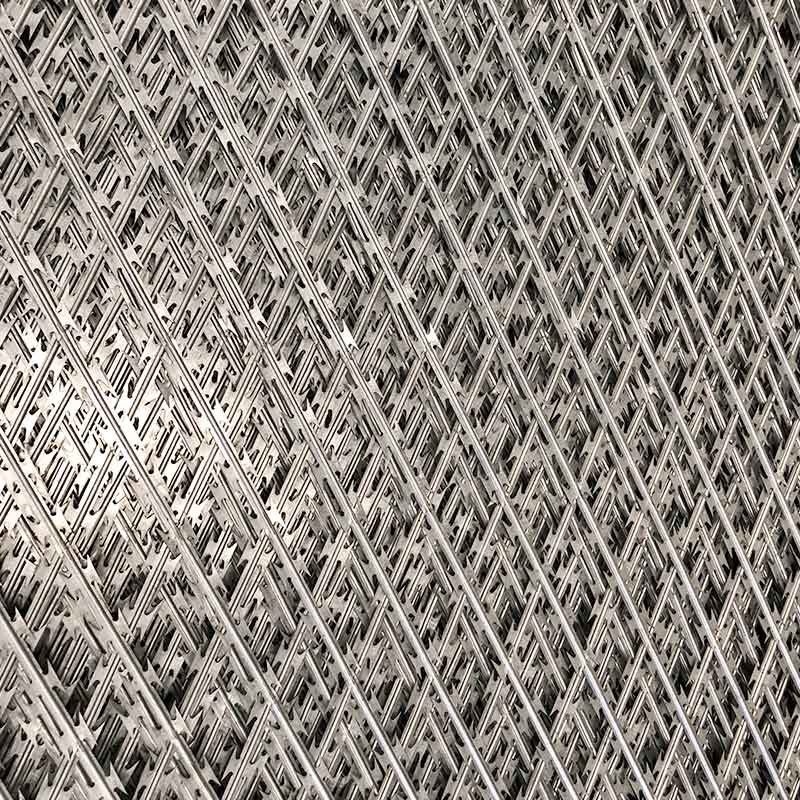

Woven Wire Mesh BZ-S001

Material: stainless steel & brass/copper/stainless steel/aluminum

Flexibility: Not flexible

Maximum width: 2.5m

Weight: 7.3kg/m2

Open space: 43%

Surface treatment: PVDF spray paint/PVC coating/electroplating

Stainless Steel Woven Wire Mesh China Detailed instructions

Shade Series BZ woven mesh panels are made of wire or flat steel and the appearance of the mesh is usually rectangular. SHADE series products can adjust the temperature of a building by changing the opening rate and transmission of the mesh. The product can help reduce the energy consumption of buildings and is purchased using different sizes of wire and opening sizes, with a wide range of mesh specifications and appearance. Shade series mesh can be installed as a large area of the facade or used on small areas such as window, partition or handrail filling.

Decorative woven wire mesh wholesale A rainbow of colors

In order to provide customers with more color options, Bzwiremesh can use different processes to make the mesh more colorful.

Bzwiremesh uses paint, fluorocarbon coating, PVC coating or an electroplating process to color the mesh. The usual colors used are gold, champagne, silver, bronze, etc. Color selection can also be made according to the color table provided by the customer.

Bzwiremesh can also produce nets made of brass, copper and other materials with natural colors. By adding brass wire to the BZ stainless steel mesh, the mesh will become a new material.

C-shaped hooks for hanging posters and signs, store decoration and display items, and for hanging and connecting various items. These CNC Wire hooks wholesale are made of durable 2mm thick metal wire.

Other sizes can be provided on request.

A pack of 100

More information please click here.

3 Type 2 Wall Tie(CE marked)

Product Name: Type 2 Wall Tie(CE Marked)

Item Code: Smart Craftsmen-WTT2

Surface Treatment: Shiny.

Raw Material: Stainless Steel 304( Grade1 4301) or Up on your request.

Package: 250 pieces / Inner Box, 2 or 4 Inner boxes / Master Carton.

Place of Origin: Hebei, China.

Standards: PD 6697 and EN 845-1:2013+A1:2016.

The type 2 wall ties for sale are suitable for general-purpose neckties with a space between 50mm and 150mm, which can be used in European domestic residential and small commercial buildings up to 15 meters high. Smart Craftsmen Type 2 wall ties are CE marked, and the measured dynamic stiffness <113MN/m3 meets the requirements for external masonry walls

Approve the performance requirements of Document E. The test result meets the PD 6697 standard and confirms BS EN 845-1: 2013 + A1: 2016.

benefit

Answer: The specially designed safety end provides an excellent mortar key, which reduces the risk of on-site injury and prevents entanglement.

B: Clear and easy to distinguish packaging, which can be conveniently used on site when different types of wall ties are needed.

C: It is made of corrosion-resistant stainless steel, and high-strength steel wire is cold bridged to minimize heat loss.

D: Multiple drops can prevent water from flowing in any direction where the cable tie is installed.

note

Other special length and wire thickness can be provided according to customer requirements.

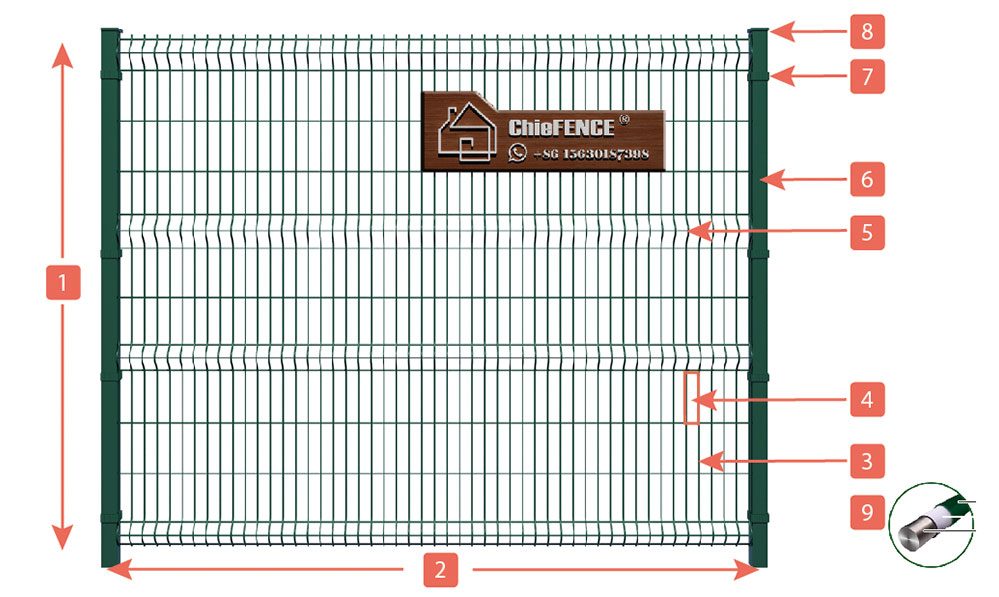

The “358” in the 358 fence indicates the specific specifications of this type of guardrail: the mesh hole is 76.2mmx12.7mm, namely 3 “x0.5”, and the wire diameter is usually 4.0mm, namely 8#. Of course, 358 guardrail is an expression of the name of this kind of guardrail, and the specific specifications can be adjusted according to the actual needs of customers.

358 Screen general specifications: mesh: 12.7×76.2mm or can be adjusted to 12.5x75mm or 13x75mm according to customer’s actual needs

Wire diameter: 3.0-6.0 mm

Network height: 1.8m, 2.0m, 2.4m, 2.7m, 3.0m, 4.4m, 5.2m

Network width: 2m, 2.5m, 3m.358

Fence net features: strong anti-climbing ability, strengthen the net to increase the extent of its destruction, long use time, durable.

The prison high security protection net in the prison protection net, the use of large diameter high strength alloy steel wire production, with anti-climbing, impact resistance, shear resistance characteristics and good deterrent effect, dedicated to prison detention center, cordon military base and other high security fields.

358 protection net anti-corrosion form: electroplating, hot plating, spraying, dipping, galfan silk.

358 safety net main use: 358 safety net is mainly used in prisons, posts, frontier defense, surrounded areas, military defense and other high risk areas of protection and municipal garden protection net.

Roopam Steel is top manufacturer & supplier of seamless steel pipe welded tubes in ferrous and non ferrous material, Stockist of high quality tubular piping products and accessories in India. Call us for more Info at +91-22-6639 4333.

HOT-DIPPED GALVANIZED STEEL COIL

- INTRODUCTION:

Hot-dipped galvanized steel coil is made from steel plate, which is dipped into the dissolved zinc bath, with a zinc layer on the surface. It mainly adopts the continuous galvanizing production process. That means the cold rolled coils are put into the dissolved zinc bath for continuous galvanizing process.

- EVER-SHINE Steel Coil APPLICATION:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It’s especally useful for countless outdoor and industrial applications.

They are mainly used in building roof, door, window, roller shutter doorand automobile’s vehicle shell, chassis, door, trunk lid, Oil tank, and fender, and also electric equipments, such as refrigerator base and shell and so on.

- SPECIFICATION

| THICKNESS | 0.11mm-5.0mm |

| WIDTH | 600-1250mm Max |

| COATING MASS | 20g-400g/m2 |

| Surface Structure | Zero Spangle,Regular Spangle,Minimized Spangle |

| SURFACE TREATMENT | Chromated/non-Chromated,Oiled/non-Oiled,skinpassed/non-skinpassed |

| COIL INNNER DIAMETER | 508mm or 610mm |

Copper Mould Tube & Plate

We specially in supplying Copper Mould Tube, Crystallizing equipment of continuous casters, Mould cooling jacket, Repair of Metallurgical Copper Mould Tube, etc.

Equipments & Spare parts for Continuous Casting Machine.

- Copper mould tube( square, rectangle and round )

- Crystallizing equipment of continuous casters

- Mould cooling jacket.

- repair of copper tube moulds

The copper alloys chosen for the moulds must maintain their physical properties at the operating temperatures of the continuous casting process.

The temperature gradation from the inner wall of the mould to the outside face of the mould can cause serious distortion problems, and Metallurgical Copper Mould Tube is imperative that the correct alloy is chosen for the various operating conditions.

Square Copper mould tube STANDARD MATERIALS

Phosphorus de-oxidised copper

This alloy has been proven to be excellent for the manufacture of moulds in the continuous casting of billets. The main composition of this alloy are Cu +Ag 99.90min, P0.0015 / 0.040.

Copper -Silver alloy

The addition of a small amount of silver, whilst not increasing the melting point of copper, does increase the recrystallisation temperature by almost 100℃, and also helps to give better thermal conductivity at the operating temperatures.

This alloy is normally used in moulds for the continuous casting of blooms and slabs .In this case, the moulds are much thicker than in the billet moulds, and the moulds temperature can be higher. The main composition of this alloy are Cu+Ag99.90 min. Ag 0.08 / 0.12 O 0.004 / 0.012.

The continuous casting of molten steel into billets, blooms and slab products, has been highly refined over the years into an extremely sophisticated system. The continuous casting process is expected to produce metallurgically sound products at the lower possible cost, and this is being achieved in many steelworks throughout the world.

Copper moulds have played an important role in the development of the continuous casting process. Their funcition is to receive the molten steel and to allow rapid heat transfer from the steel to the cooling water to enable quick solidification.

The mould must exhibit excellent thermal conductivity, be resistant for thermal erosion ,and be resistant to distortion from thermal stress. So far only copper and a few copper alloys meet the above conditions, both economically and technically.

Mould cooling jacket supplier SOLIDIFICATION

The rate of solidification in the continuous casting process dictates the speed of production. The molten steel, which is in contact with the inner faces of the copper mould, starts to sllidify as rapidly as the heat is extracted, forming a shell. The shell increases in thickness as more heat is extracted, and eventually total solidfication is achieved. the process is similar to the solidification of ingots in ingot moulds. In continuous casting, the whole process is speeded up, with the aim to produce and homogeneous shell growth. Consequently, the mould is an important part of the continuous casting process, and the manufactured quality of the mould plays and important role in their length of life.

INNER SURFACE COATINGS

Over the years, Metallurgists and Engineers have been working together to develop better continuous casting moulds. The steel companies require a more economical mould which will give a longer service life. Surface coating of the inner walls of the mould has given the best results to date. Coatings available are Chromium and Nickel plating. Also, a combination of the two give good results on slab casting.

SPECIFICATIONS OF COPPER MOULD

Square 60 x 60 – 350 x 350 (mm)

Rectangle 120 x 160 – 180 x 300 (mm)

Diameter 100-400 (mm)

Size(mm): 90×90, 100×100, 110×110, 115×115, 120×120

130×130, 135×135, 140×140, 143×143, 150×150

155×155, 160×160, 165×165, 175×175, 180×180

200×200, 220×220, 100×170, 100×173, 130×240

150×200, 150×210, 150×220, 160×200, 160×220

150×225, 160×235, 165×225, 175×225, 180×220

200×240, 240×240, 235×235

Radius(mm): 4000, 5000, 5250, 6000, 7000, 7500, 8000, 9000, 10250, 10300, 11000, 12000

Length(mm): 700, 750, 780, 790, 800, 810, 812, 850, 900, 1000

Stainless Steel Sprocket Product Description

1. Description: This range of sprockets are made from 304 stainless steel material.

2. Standard: British

3. Feauture:

Corrosion resitance

Good quality

Competitive price

Customized possible

We Are Counted Among The Best Manufacturer, Exporter Stockist & Supplier. We Export 60% Of Our Range Of Flanges, Outlets, Pipe Fittings And Forged Fittings To Many Countries Like Usa, Uk, Italy, Malaysia, Gulf Etc.

CRS is a leading manufacturer of thermit welding materials in China, we have more than 30 years experience of designing thermit welding to the rails. Focusing on rail welding used for railroad, metro, tram, crane rails, turnel construction and maintenance.

We have production area of 2500 square meter, with fully automated batching system, sand mould automatic production & drying machines, equipped with full range of raw materials and welding joint testing equipments. Rail aluminum thermit welding material has been promoted and well applied in the railway lines such as the Beijing-Shanghai high-speed railway line, Jinqin passenger line, Daqin line, Tong-Rang line and Tong-huo line. Materials have been exporting to Australia, Indonesia and other countries many years, the products have won praise.

CRS possesses a qualified team of technicians and engineers who have been improving the quality and performance of products, Certified to the ISO9001:2000 standard, CRS’ welding products have been supplied to a wide range of customers worldwide. Thermit products have been passed Chinese rail welding standard TB/T1632-2005 test, Railway Ministry of China, as well as Australia standard AS1085.15-1995 test, Indonesia welding joint inspection test, Taiwan SGS quality inspection test. We are ready to provide technical & operation training, qualification and certificate for customers to ensure a standardized quality and performance of the welding products.

Glued Steel Fiber, an alternate concrete reinforcing material are high tensile steel wires with hooked ends, glued together by the water-soluble adhesive for compactness and uniform dispersion in concrete, to increase the concrete properties by 3-4 times.

steel fiber reinforced concrete supplier improve the mechanical properties concrete and materials such as ductility,

energy absorption, fatigue, and toughness. This fiber helps to controls plastic shrinkage cracking in concrete; helps reduce or eliminate need for conventional reinforcement.

Application of Glued steel fiber reinforced concrete

- For concrete flooring

Industrial floors

Joint-less floors

Floors-on-piles

Lightly loaded floors

Liquid tight floors & composite metal decking

- stainless steel fiber supplierFor Hard Standing & Heavy Duty

Parking lots

Playgrounds

Airport runways

Taxiways

Maintenance hangers

Access roads & workshops

Ports& Containers for port pavements

Container terminals

Bulk storage areas access roads

For army tank movement

- steel fibers for concrete reinforcementOther Applications

Foundations

Traditional cellar and basement walls

Compression layers

Tunnel engineering

Compared with the GuangYa loose steel fiber the operation and advantages of the glued steel fiber:

- Add the steel fiber directly into the belt, the whole row of steel fiber as a whole, evenly dispersed in the concrete corner

- The water-soluble glue begins to dissolve in a row of steel fibers in the premise of the dispersion, it is again dispersed in every corner of the mono filament fiber, showing the perspective in the concrete of the fiber mesh, which plays an integral strengthening.

- Compared with mono-filament fibers, China bonded steel fiberswill not be bundled to ensure that the fibers in concrete do not coalesce and distribute evenly.

Glued steel fibers are loose hook-end fibers that are bonded together in a row. The great difference between loose fiber and glued fiber is that the former is easy to clog and the latter is easy to disperse evenly.

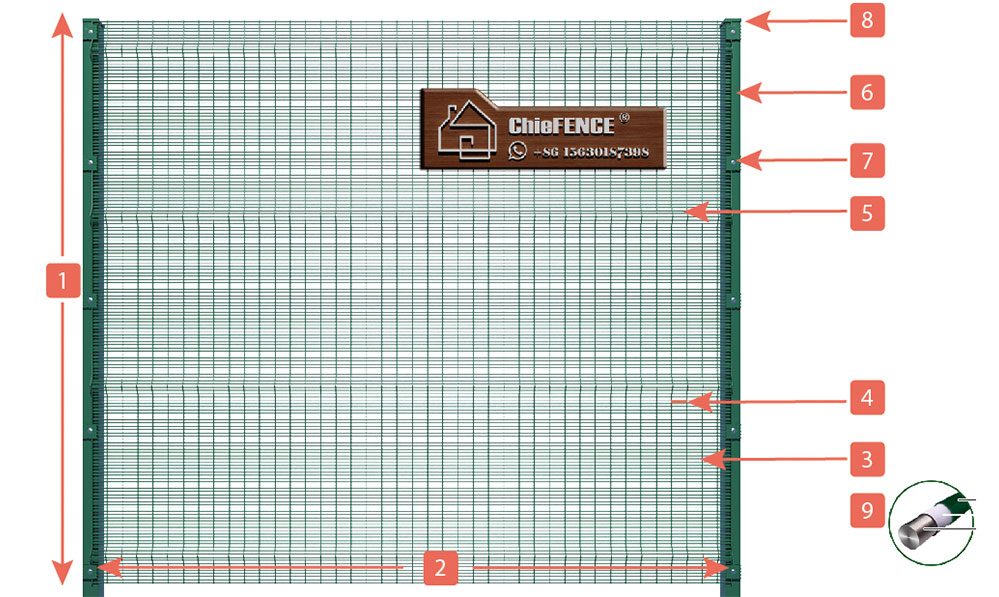

Welded mesh fence likewise called “3D FENCE” “medium-security fencing”. It is an affordable version of steel fence. The panel is bonded with low carbon steel wire. Material Grade: Q195, Surface therapy by Electrostatic polyester powder roaming finishing(Powder-coated) over galvanized products. And after that connect the fencing panels with article by suitable clamps(Clips). Because of its Simple framework, Easy installation and also Beautiful look.More customers regard welded wire mesh security fence as the preferred common protective fence.

Loni ChieFence 3d security fence FEATURES

Lower budget

See-through panel

Anti-rust, Long Service Life

Fast Installation

Customer specs available

Rigidity

| Standard Reference | Dia Type | Finish | Grade | Raw Material |

| UIC86

4DIN529 |

M20-M36 | Plain & Oiled, Oxide Black, Zinc Plated, Hot Dip Galvanized, etc |

4.6 5.6 8.8 |

Low Carbon Steel Medium Carbon Steel Alloy Steel |

Our hook bolt, anchor bolt, clip bolt have high quality and cheap price. If you have any question on product, we will give the professional answers to your short questions.

Jade Special Metals is India’s 10th largest supplier, trader & Exporter of Stainless Steel, Carbon steel pipes and round bar. We are specialised in Stocking & Distributing various Stainless Steel, carbon steel pipes, round bar & sheet plates to worldwide for specific & urgent requirements.

UNS S31254 / Alloy 6Mo / WNR 1.4547 / F44 / 254SMO Super Austenitic Stainless Steel

UNS S31254 is a high corrosion resistant Super Austenitic Stainless Steel and provide excellent corrosion resistance in severe corrosion environments such as high temperature seawater.

We offer a comprehensive selection of seamless/welded stainless steel pipes, including the UNS S31254 super austenitic stainless steel pipe, also known as 254SMo or WNR 1.4547. Made with high-quality materials and under strict manufacturing standards, these pipes are perfect for a variety of applications in seawater handling systems, desalination plant equipment, chemical processing, and flue gas desulphurization units.

UNS S31254 Stainless Steel Pipe Features:

– High corrosion resistance: Made with alloy UNS S31254, these pipes are highly resistant to corrosion in harsh environments, including high chloride and acidic conditions.

– High strength: The WNR 1.4547 pipes are made with a super austenitic stainless steel with high strength, making them durable and reliable for a range of applications.

– Excellent weldability: The 6mo stainless steel pipes are easy to weld and fabricate, making them a versatile solution for complex piping systems.

– Compliant with industry standards: The 254SMO Super Austenitic Stainless Steel pipes meet the manufacturing standards of ASTM A269, ASTM A312, and ASTM A213, ensuring quality and reliability.

UNS S31254 Chemical Composition (%)

| % | C | Mn | P | S | Si | Ni | Cr | Mo | N | Cu |

| Min | 17.5 | 19.5 | 6.0 | 0.18 | 0.50 | |||||

| Max | 0.02 | 1.00 | 0.030 | 0.010 | 0.80 | 18.5 | 20.5 | 6.5 | 0.25 | 1.00 |

254SMO Physical Properties:

| Density | 8.02 Mg/m³ |

| Melting Range | 1360-1405 ℃ |

UNS S31254 Stainless Steel Pipe Applications:

– Seawater handling systems: The UNS 31254 Stainless Steel pipes are ideal for use in seawater handling systems due to their high corrosion resistance and strength.

– Desalination plant equipment: The WNR 1.4547 Stainless Steel tubes are widely used in desalination plant equipment due to their ability to withstand high chloride and saltwater environments.

– Chemical processing: The UNS S31254 pipes are suitable for chemical processing due to their corrosion resistance and thermal stability.

– Flue gas desulphurization unit: The Alloy 6Mo Stainless Steel pipes are ideal for use in flue gas desulphurization units due to their resistance to acids and ability to handle high temperatures.

Manufacturing Standards:

ASTM A213

ASTM A312

ASTM A269

Also individual customer specifications, as a professional UNS 31254 Stainless Steel pipes and tubing supplier, Hengyang is committed to providing high-quality stainless steel pipes to meet the needs of our customers. Contact us today for more information on the UNS S31254 pipe and other products in our collection.

Ceramic lined pipe is made through the self-propagating high-temperature synthesis (SHS) technique.

Self-propagating High-temperature Synthetic process

Self-propagating high-temperature synthesis (SHS) is used to describe a process in which the initial reagents (usual powders), when ignited, spontaneously transforms into products due to the exothermic heat of reaction.

The combination of high rigidity of ceramic and high elasticity of steel gives the pipe unmatchable features like abrasion resistant, heat resistant, and corrosion-resistant material for use in the fields of power generation, metallurgy, mining, and chemical industry, etc. It has many advantages over steel pipes, cast stone pipes, and steel-plastic compound pipes.

Usage of Ceramic Lined pipe

The ceramic-lined pipe transportation has been widely used in the industries of electric power, metallurgy, coal, petroleum, chemical engineering, building materials, mechanism, and so on.

The ceramic lined elbow throughout the power, metallurgy, coal, petroleum, chemical, building materials, machinery, and other industries, and high-speed development. When lining the wear-resistant ceramic elbow to deliver high grinding material (such as ash, coal, ore powder, etc.), there is a lining of wear-resistant ceramic elbow wear fast, especially the elbow Wear faster. When lining a ceramic-lined elbow to deliver a highly corrosive gas, liquid or solid, there is a problem that the lined wear-resistant ceramic elbow is corroded and is quickly damaged.

There is a problem that it is expensive to use a heat-resistant steel pipe when the material having a higher temperature is conveyed in the lining of the wear-resistant ceramic elbow. After lining the wear-resistant ceramic elbow, these problems are solved.

The ceramic lined elbow is widely used in wear and tear of mine filling material, ore powder and tailings transportation, coal-fired power plant powder, smelting, ash and other things lined with wear-resistant ceramic elbow are also very appropriate.

The ceramic lined pipe, Elbows, Reducer, Tees, and others manufactured in our factory have been used in over 200 thermal power plants, more than 50 mines, and the industries of coal, building materials, mechanism, petroleum, and so on.

Abrasion

Ceramic layer Ceramic Lined Reducer Pipe with flange reducer Al2O3 content greater than 89%, micro-hardness HV1000-1500, which has high abrasion resistance, wear resistance more than ten times higher than carbon steel after quenching, superior tungsten carbide drill.

Application range

- coal pulverizing system of power plant pipeline, including, powder transmission pipeline, thick powder separator pipeline, coal drop pipe, combustion system of a windpipe, a secondary air pipe, three pipeline and burner pipelines, in addition to ash slagging system the discharge pipe, powder pipe, dry ash conveying pipe;

- Iron and steel plant raw material conveying pipeline, collecting pipe, dust pipe, ash pipe, ash pipe, mixing pipe, grinding export pipeline, coal pipeline, coal pipeline, separator pipe, burner radius pipe, etc.;

- Cement plant selection machine outlet pipe, choose machine inlet pipe, pipe dust pipe, vertical mill outlet pipe, circulating air duct, high-temperature air blower, lower material pipe, etc.;

- Petroleum, chemical, mining, coal, coal washing plant, smelting, paper, aluminum, building materials, powder engineering, food machinery, and other processing and conveying material pipes.

Corrosion

Ceramic materials are neutral, chemically stable, have excellent corrosion resistance and acid resistance, resistant to various inorganic acids, organic acids, organic solvents, and their degree of corrosion of stainless steel is more than ten times.

Temperature

Temperature above 2000celsius degree, long-term work in the range of -50 -900 celsius degree.

Easy welding.

The ceramic adjustable tube can be welded, flanged, flexible connectors, and other fast way links, very easy to install.

Clean and easy maintenance

Smooth walls, can prevent scaling, fouling, and self-cleaning functions. Tightness.

Remarks:

- Under the direction of the arrow diagram for the export direction.

- Bend radius is usually 1.5-5 times the diameter of steel pipe (1.5-5D).

- Othe specifications of the composite pipe can be manufactured according to the user requirements.

- The weight is calculated by theoretics, maybe have some tolerance, and real weight will be weigh-in after they finish.

Hoop strength is the resistance against radial pressure. The strength of the ceramic-lined steel composite pipe is 300 to 500MPa.

Features and Advantages of ceramic lined pipe

Ceramic Liner pipe is a high technology production technology-self-fuel high-temperature clutch synthesis method.

1). High Abrasion Resistant:

Vickers hardness of the corundum lining is HV1100 to1500, as high as that of tungsten-cobalt hard alloys, and the abrasion resistance is 20 times as carbon steel pipes. The composite ceramic-lined steel elbow was used in a mining plant for about fifty thousand hours. The general service life of a common steel elbow is about 700 hours.

2). Corrosion Resistant:

Corundum is a neutral material and is acid-proof and fouling-free.

3). Heat Resistant:

Ceramic lined composite steel pipes can work under circumstances of -50 to 800 Celsius degree.

4). Lower Weight and Convenient Installation:

The ceramic-lined steel pipes are lighter than alloy pipes, cast iron pipes, and cast stone pipes and can be welded or connected through flanges, which reduces the expense of transportation and makes the pipes easier to install.

For the pipes with the same sizes, types, and lengths, the weight of the ceramic pipe is about 1/2 of the wearable cast alloy steel pipe’s, while the cost has reduced 10%~20% per meter.

The weight of ceramic-lined steel pipe is about 1/3 of the cast stone bent pipes, 1/2 of the cast stone straight pipes.

Ceramic (Corundum: a-Al2O3) lined abrasion resistant straight pipe and fittings are lined with highly abrasion-resistant ceramic by SHS ——-Self-propagating High-temperature Synthetic process.

- The ceramic-lined steel composite pipe can be joined by welding the steel pipe layer.

- Ceramic-lined pipes can take place of expensive stainless steel, titanium, nickel, cast stone, or alloy pipes.

- Extended service life can also reduce maintenance costs.

Self-Propagating Ceramic Pipe

Self-propagating ceramic steel pipes create a new generation of abrasion and corrosion-resistant engineering pipelines.

The self-propagating ceramic steel pipe has very good wear resistance, Excellent corrosion resistance, and Excellent thermal resistance performance.

SHS-self-propagating ceramic steel pipe and elbow create a new generation of abrasion and corrosion-resistant engineering pipeline. The composite pipe is composed of three layers: ceramic, intermediate, and steel layers.

The ceramic layer is formed by molten alumina at a temperature above 2500 degrees. The molten alumina produced from the reaction Fe2O3+2Al=2Fe+Al2O3 spreads on the inside wall of the steel pipe under the influence of a centrifugal force, then solidifies, so the ceramic layer has high density and smooth surface and bonds to the steel pipe.

Applicable Industries:

- The pipe needs excellent wear resistance property: Power plant, Mining, Sea Port, Coal Plant, And pipe for transporting the powder, slurry, sand, etc.

- Coal washing plant, pipe for transporting coal and other material.

- Pipe for transporting the melted aluminum.

- Any pipe which needs to wear protection, corrosion protection, etc.

Benefits:

- Excellent wear resistance, Alumina content of the ceramic liner is higher than 95%, Hardness HV1000-1500. The wear protection performance is more than 10 times better than carbon steel after quenching,

- Excellent corrosion resistance, stable chemical properties.

- Excellent thermal resistance performance up to 2000℃ Can be used in the area from-50℃ to 900℃ for a long time.

- Can be connected with another pipe by welding, flange and soft fast connecting, and easy installation.

Product Item:HY005

Manufacturing: Cold Rolled/Cold Drawn

Type: Seamless/Welded

Surface: Annealed and Passivated

Application Fields: heat exchanger, boiler, evaporator

Alloy 825/ UNS N08825/ W.Nr.2.4858/ Incoloy® 825

Alloy 825 tube, also known as Incoloy 825 pipe, W.Nr. 2.4858 or UNS N08825, this nickel alloy steel is a combination of nickel, chromium, and iron, with small amounts of molybdenum, copper, and titanium to enhance its resistance to corrosive environments, especially in chloride-containing media. 825 tubing is a durable and reliable material that is widely used in applications that involve harsh environments and high temperatures.

UNS N08825 Chemical Composition:

| % | Ni | Cr | Fe | Mn | C | Cu | Si | S | Al | Ti | Mo |

| Min | 38.0 | 19.5 | 22.0 | 1.5 | 0.6 | 2.5 | |||||

| Max | 46.0 | 23.5 | 1.0 | 0.05 | 3.0 | 0.5 | 0.03 | 0.2 | 1.2 | 3.5 |

Features of Alloy 825 Tube:

- Excellent Corrosion Resistance: Alloy 825 tube is highly resistant to corrosion, pitting, and stress corrosion cracking in various corrosive environments like nitric acid, sulfuric acid, phosphoric acid, and others.

- High-Temperature Strength: The inconel 825 tube can withstand high temperatures up to 550°C (1020°F) and still maintain its excellent mechanical properties.

- Good Weldability: Incoloy 825 pipe can be easily welded with various welding processes, including gas tungsten arc welding, gas metal arc welding, and shielded metal arc welding.

Incoloy® 825 Physical Constants:

| Density | 8.19 Mg/m³ |

| Melting Range | 1370-1400 ℃ |

Alloy 825 Tube Application:

- Chemical Processing Equipment: Alloy 825 tube is used in the chemical processing industry for making process vessels, reactors, tanks, and other equipment that need to be resistant to corrosion.

- Heat Exchanger Tube UNS N08825: Incoloy 825 tubing is commonly used as heat exchanger tubing in various industries like chemical processing, oil and gas, and power generation.

- Pollution Control: Alloy 825 tube is widely used in pollution control systems due to its excellent corrosion resistance, widely used in scrubber systems for removing harmful gas emissions from power plants and other industrial facilities.

- Petroleum Refining: Inconel 825 pipeis used in petroleum refining applications due to its ability to withstand highly corrosive environments, commonly used in heat exchangers, piping systems, and other equipment that comes into contact with sulfuric acid, hydrochloric acid, and other corrosive substances.

- Offshore Oil and Gas Production: The incolony tubeis widely used in offshore and onshore oil and gas production, where corrosion-resistant materials are needed to withstand harsh corrosive environments.

* Marine: W.Nr.2.4858 is used in marine applications, including seawater cooling systems, desalination plants, and offshore platforms.

* Acid Production: 825 pipe is commonly used in the production of acids such as sulfuric acid, phosphoric acid, and nitric acid due to its excellent resistance to corrosion. It is used in heat exchangers, piping systems, and other equipment that come into contact with these corrosive substances.

* Nuclear Fuel Reprocessing: Incoloy 825 seamless pipe is commonly used in nuclear fuel reprocessing applications due to its ability to withstand highly corrosive environments. It is used in equipment such as storage tanks, piping systems, and heat exchangers that come into contact with radioactive materials and corrosive substances.

Alloy 825 is available in wide variety of shapes and forms including pipe, tube, fitting, flange, sheet, plate, round bar, forging stock, flat bar, wire, hexagon. The various forms of UNS N08825 from Hengyang Piping meet different critical standards like ASTM, ASME, DIN, EN, ISO and clients’ specification. For detailed information about customized pipe and fittings, please contact us!

BEISAI is large-scale joint-stock group foundry enterprise, divided into Hebei BeiSai Metal Products Co., Ltd and ShiJiaZhuang BeiSai Trade Co., Ltd. which was builded in 2003, located in ShiJiazhuang province City. company net assets is up to CNY 45 Milion, The annual production capacity of 60000 Tons casting iron parts. More than 300 employees here. There are 5 senior casting engineers and 21 technical engineers etc. We have 26 sets of centrifugal casting machines and 5 sets of autoumatic machine painting lines and 3 sets of automatic hydraulic pressure testing machines, we have very perfect testing and checking equipment and testing lab, 100% make sure all products are top-quality.

At present our major products and service is Casting Iron Pipes, Fittings, SS Couplings, Carton Steel Clamps which was used for sewer drainage system of buildings. And Casting iron manhole covers and frame, Casting tree gate and Casting valves , fire protection fittings and connectors, Casting cooking hardware, etc.

We also can produce all kinds of large or small machine casting parts and auto casting parts and pump housing and pump console/ impeller and casting pulley according to the drawing or samples.

All our products are fully meet USA and European and National standard ASTM A888/CISPI301/CSA B70, ASTM-A536, DIN 19522, EN877, BS EN877, ISO6594, BS437, BS416, KSD 4307, EN124:1994, BS 497-1:1976, ISO2531, BS EN545/EN598, AWWAC 151, KSD 4311, AS 2280, GB/T13295, GB/T12772 etc.

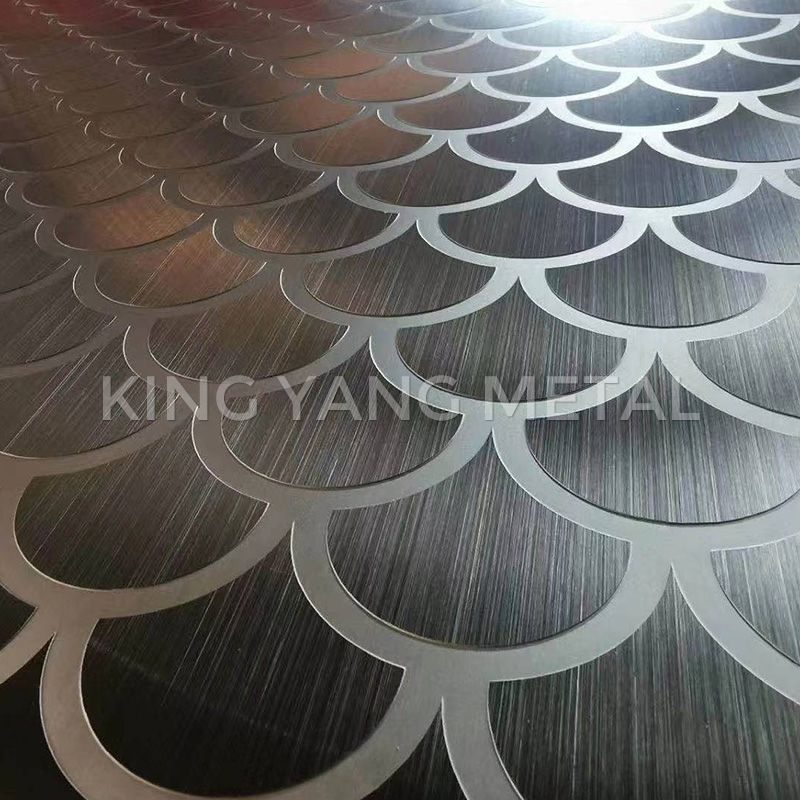

Ky Metal is professional etched stainless steel sheets manufacturer and supplier, offering elevator Etched Stainless Steel Sheet, Wall cladding Etched Stainless Steel Sheet, Stainless Steel Etching Sheets,Decorative SS Etched Sheets, SS Colored Etched Sheets

Etched stainless steel sheets are thin plates of stainless steel that have been chemically treated to produce a pattern or design on the surface. With 8K mirror plate, drawing sheet and sandblasting sheet as the base plate, the surface of the object is further processed after etching. Etching version can be processed by a variety of complex processes such as local blending, wire drawing, gold inlaying and local titanium, to achieve the effect of light and dark patterns and brilliant colors.

Stainless Steel Sheet with Etched Finish is widely used in architectural decoration. Especially in the choice of elevator board, the general use of mirror panel as the elevator bottom sheet, and then according to the needs of the pattern processing, so that the overall effect has a three-dimensional sense, reflect its beautification value.

The installation and use of the elevator should consider its value and safety performance. A variety of different patterns etched out of stainless steel, as well as the use of different colors, so that the elevator space is no longer dull, dull, more lively.

High security fencing also called ‘358 FENCE’ ‘3510 fencing’ ‘antifinger fencing’ ‘clearvu fencing’. It is a high cost version of Loni ChieFence 358 anti climb mesh. The panel is welded with reduced carbon steel cable , Material Grade: Q195, Surface treatment by Electrostatic polyester powder roaming finish(Powder-coated) over galvanized materials. And after that attach the fencing panels with message by suitable clamps(Clips). As a result of the 12.7 * 76.2 mm small mesh dimension, it is anti cut & anti finger climb.

358 high security fence China FEATURES

Anti climb

See-through panel

Anti-rust,Long Service Life

Fast Installation

Customer specs available

Rigidity

Learn more about our wire mesh via https://www.chiefence.com/

Rajveer Stainless And Alloys is 2008 certified and the largest Flanges Manufacturer company in India deals with the Star Export House & Manufacturer of Steel Flanges Since 2004. We manufacture BLRF Flanges, SORF Flanges, WNRF Flanges according to a number of internationally recognized standards including DIN, ANSI/ASTM, BS, JIS, GB, etc. Our professionals have more than 40 years of familiarity and experience. We are also the premier supplier of metals solutions around the world, revolutionizing the supply chains of the industries we serve also focus on the respective vendors who will be there for all your needs.