Introduction

pre disposal waste aluminum is a common name for recycled aluminum.

After pretreatment, part of the recovered aluminum will be cold-processed to turn it into powder aluminum, while the other part will be recycled by means of heavy medium dressing and parabolic dressing.

recycled aluminum Processing method

The purpose of the pre-disposal of waste aluminum is to get rid of other metals and impurities mixed in the waste aluminum; to classify the waste aluminum according to its composition, so that the alloy components in the waste aluminum can be used to the maximum extent; and to dispose of the oil, oxide and paint on the surface of the waste aluminum.At the end of the pre-treatment, the waste aluminum is disposed into the burden suitable for the furnace conditions, and the fourth is to make the aluminum (including alumina) that is guessed correctly by the waste aluminum get the most economical and reasonable use.

The pre-disposal skills of ALUMINUM SCRAP supplier are very brief and backward. Even in large recycled aluminum plants, the pre-disposal skills of waste aluminum are not relatively advanced.In terms of the disposal method for recovery and recycling of waste aluminum of a single type, waste aluminum of a single type or no other impurities is usually not pre-disposed in a disorderly manner, but only classified according to the type and composition of the waste and accumulated independently.A single type of aluminium scrap when use only check assay gives a composition, can know the composition of batch, is high-quality recycled aluminium material, usually need not to make any advance disposal charging melting, in a certain aluminum alloy melting, can choose the corresponding components and types of aluminium scrap directly participate in reverberatory furnace smelting, and can be easily melting into the corresponding trademark of aluminum alloy.Some waste aluminum containing high copper and zinc can also be used as the central alloy for adjusting the composition of aluminum alloy in the smelting process.In the enterprise that chooses small reverberatory furnace or crucible furnace, want to want according to need to break large volume waste aluminium (shear or other method) the material that accords with furnace standard is quick.It is worth mentioning that a small number of non-aluminum metals will be mechanically contained in some single type of China scrap aluminum, such as scrap steel parts such as screws on the Windows and doors of scrap aluminum, although the content is very small, but will seriously affect the quality of the alloy, so it must be separated before smelting.

Heavy medium dressing

That is, the method of heavy media heavy selection is used to separate the heavy non-ferrous metals, such as copper, whose density is higher than that of aluminum, which USES the principle that the density of aluminum is smaller than that of other heavy non-ferrous metals, so that the waste aluminum floats on the medium, while the heavy non-ferrous metal sinks on the bottom, achieving the purpose of separation.But the key is to screen a medium that is denser than aluminum and less than copper, and that medium is not water or any other liquid, definitely a fluid.When the fluid is doing reciprocating motion, the waste aluminum is floating on the top of the medium is separated.

metallurgical accessories Parabolic dressing

By using the principle that objects of basically the same volume fall at different points when they are thrown out by the same force, various waste non-ferrous metals with different densities in the scrap aluminum can be separated.When the same force is used to shoot an object with different density but basically the same volume along a straight line, various objects move along the direction of the parabola and have different landing points.The simplest experiment can be carried out on a horizontal conveyor belt. When the mixed wastes run at high speed along the conveyor belt, the waste aluminum is thrown out along a straight line at the end of the operation. Due to the different gravity of various wastes, the waste aluminum falls to the ground at different points, so as to achieve the purpose of waste aluminum separation.In this way, recycled aluminum, copper, lead and other wastes can be separated evenly.The equipment manufactured according to this principle has been adopted in foreign countries and is in the research stage at home.

Threeway Steel co.,ltd is a world-class steel pipe provider, one of the largest subsidiary in Shinestar Holdings Group Co.,ltd. As the companys largest export base, we are committed to provide professional one-stop procurement service for customers with excellent quality, competitive price, convenient transportation and timely delivery. At present, customers have been all over world. Including Singapore, Vietnam, Egypt, Nigeria, Arabia, United Arab Emirates, Kuwait, Oman, Mexico, Columbia, Australia etc.In the future,Threeway steel co.,ltd devotes to bring unexpected special experience for worldwide customers by the excellent strength and abundant experience.

Hebei Fuhua Wanshixing Hardware and Wire Mesh Products Co., Ltd. was established in 2006, has 15 years of history. Our Company covers an area of 33000㎡. There are more than 10 sets razor barbed wire making machines.

Hebei Zhuocui Trading Co., Ltd For Hebei Fuhua Wanshixing Hardware and Wire Mesh Products Co., Ltd. Shijiazhuang office,Our company owns a group of technician and workers specialized trained.The main products: Razor barbed wire, Wall spikes, Chain link fence, Steel grating, Mobile security barriers, temporary fence, etc. Our quality management system has been successfully approved by the ISOQAR to the standard ISO9001:2000.

All the products are exported to Europe, America, Middle East, Southeast Asian and so on. These products enjoy a good reputation from our customers at home and abroad.

Hebei Fuhua Wanshixing always adhere to the principle of “Sincerity First, Customer First”, and strictly complete each order according to customer requirements, ensuring the quality and quantity.

Gate valve is our company’s earlier product. During the long period of time, our company has made the gate valve famous in and out with perfect designing and manufacturing techniques and quality system assurance. The manufacturing experience and technique innovation have made the products reach BS, DIN and other international standards.

Metal Seated Gate Valve Features:

-High reliability of strength and rigidity.

-The sealing is copper alloy which is wear-resisting and has long life.

-When opening, no other parts in the way.

-The installation direction is various iwith the same performance.

Product Range:

Standards: BS&DIN

Suitable medium: water, sea water.

Suitable temperature:≤100℃

Material: Ductile iron, GJS500-7. GJS400-15, GGG40,GGG50

Standard Reference: AS1085.10-20002, DIN, ISO-9001

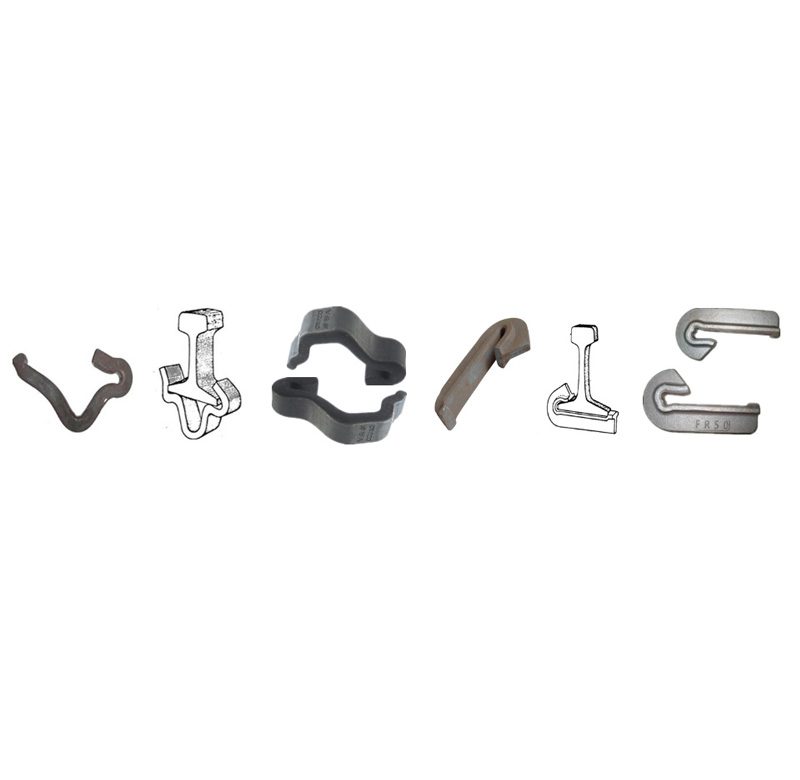

China Rail Anchor Surface Treatment: Plain / Oxide Black / Zinc Plated / Normal Painting / Sandblasting, etc

Raw Material: 60Si2MnA / 45# / QT500-7

Production Engineering: Forging ,Casting

Our company supply track fasteners, which include rail clamp, rail anchor, rail clip. Our products have high quality and competitive prices, please feel free to contact us.

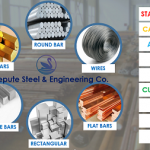

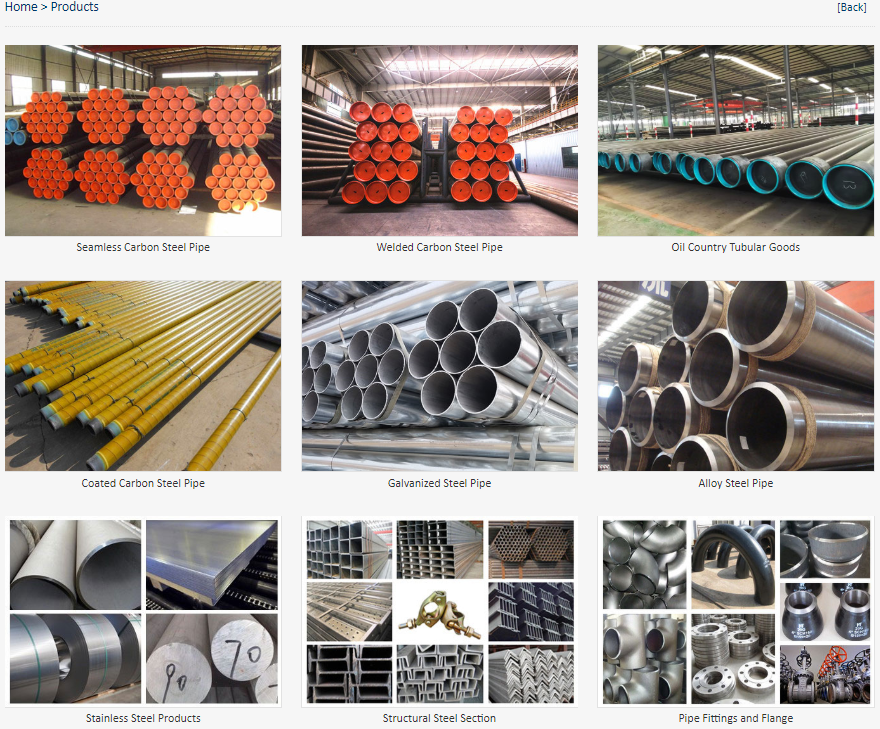

Hebei Abter Steel Pipe Co.,Ltd is a professional steel exporter in China. We specialize in the production of steel product, including stainless steel, galvanized steel, pre-painted steel and carbon steel pipes, ceramic lined composite steel pipe and fittings,elbow, bending and the related products, covering pipe & tube , fitting, bar etc. Based on the standing better and faster service,we have been the best partner both of the steel factories and suppliers.

We offer perfect service to the mills and bring in the highest quality levels at the most competitive price for our customers. Our entire operations are focused on the precise demands of our customers needs.

Our production bases cover most of China, with a production capacity of 300,000 MT annually, Size range from O.D: 8–141mm, W.T.0.8–12mm. (cold drawn tube). O.D 141mm–610mm, W.T :5–25mm(hot rolled pipe). With a strict quality assurance system to the manufacturing process, including steel making and finished products inspection.

Factory and industrial products

In addition to our steel products for construction, we also offer a variety of steel fabrication products for use in industry. We provide local factories with steel cutting, fabricating, and distributing pipe fittings anc composite pipes.

Our versatility ensures we will be able to provide you with the steel products you require to to complete a project, from start to finish.

Our team

Our team are highly trained and experienced in servicing and producing all types of steel supplies. Whether you’ve got a large construction project, or need parts for industrial machinery, our team of steel fabrication consultants will ensure that your project is provided with the parts you need, when you need them.

A well screen is a filter device used as the suction portion of a well constructed in a loose or semi-consolidated aquifer. The screen allows water to enter the well from the saturated aquifer, prevents sediment from entering the well, and acts structurally as a support for the aquifer material. When considering well efficiency and the logarithmic cost to the well owner, the importance of having the right screen cannot be overemphasized.

The sieve is resistant to corrosion because it comes into contact with water. In addition, it has high strength and can keep the surrounding structure intact. The openings of the sieve can be small enough to block the large amount of formation around them. The flow of water through the screen will be uniform.

Well screens are recommended for all environmental drilling operations. It helps extend the life of the well and keeps the flow of water unrestricted. Sand and fine powder sand, these fine particles can be filtered out before there is water. Well screens help remove most of this fine material from well water.

Well screens are made from a variety of materials, ranging from rough-hewed hand designs to machine built high-efficiency and long-life models. The value of the screen depends on how much it contributes to the success of the well.

Standard:

- Large open Spaces

- Do not block the slot

- 3.corrosion resistance

- Sufficient column and collapse strength

Functions:

- Easy to develop

- Minimal scaling tendency

- Low head loss through the screen

- Control sand pumping of all types of aquifers

Slot size selection is a critical step to ensure maximum well performance. The screen is usually designed to block 50% of the stratum, and the entry speed for the screen should not exceed 1/10 or 0.1 ft per second. The velocity is calculated by dividing the well production in GPM by the screen open area in square inches.

The gap size of the screen is based on dimensional analysis of the formation sample. After analyzing the composition size of grain in the sample, grain size distribution curve

I can draw it. Several methods can be used to obtain the allocation of information about grain size. The most widely used method is to pass the material through a stacked set of brass or stainless steel sieves. During the screening process, each sieve removes a certain percentage of the whole sample; The best materials are collected in the chassis. Screening analysis not only provides the basis for determining slot sizes, but also other factors that influence screening well design.

What is Gate valves

Gate valves are widely used for all types of applications and are suitable for both above-ground and underground installation. Not least for underground installations it is paramount to choose the right type of valve to avoid high replacement costs.

Gate valves are used to shut off the flow of liquids rather than for flow regulation. When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low flow resistance. The size of the open flow path generally varies in a nonlinear manner as the gate is moved. This means that the flow rate does not change evenly with stem travel. Depending on the construction, a partially open gate can vibrate from the fluid flow

Gate valves are mostly used with larger pipe diameters (from 2″ to the largest pipelines) since they are less complex to construct than other types of valves in large sizes.

Main gate valve parts of a gate valve are: body, seat, gate, stem, bonnet and actuator. The main operation mechanism is very simple. When the handwheel is turned, it rotates the stem, which is translated into the vertical movement of a gate via threads.

There are three ways to classify the gate valve.

Types of Disk

Solid taper wedge

Flexible wedge

Split wedge or Parallel disks Valve

Types of Body Bonnet Joint

Screwed Bonnet

Bolted-Bonnet

Welded-Bonnet

Pressure-Seal Bonnet

Types of Stem movement

Rising Stem or OS & Y Type (Outside Stem and Screw Type)

Non-rising Stem type

Gate valvesare used in almost all fluid services such as air, fuel gas, feedwater, steam, lube oil, hydrocarbon, and all most any services.

Some special gate valve is used in slurry and powder product also such as knife gate valve

Anping TianHui Wire Mesh Products Co., Ltd. is located in anping county, Hebei province, which also be called “Hometown of wire mesh”in china. Started the factory from the year 1986, We are one of the top manufacturers and exporters of Woven wire Mesh, Screens and welded Wire Mesh in China.

We has over 160 sets of wire mesh machines, have around 20000 rolls in stock for stainless steel wire mesh & welded mesh. We have gained a global sales network reaching to the Local market, USA, Middle-East, Europe and Africa etc.

Our company has been based on “good quality, timely delivery, reasonable price, considerate service” the purpose to serve the masses of customers; And is in line with “quality seek survival, prestige seek development” production principles, in our emphasis on product quality at the same time, also actively communicate with the customer, understand customer needs, to realize our shortcomings, and for clients to provide professional and timely after-sales service, won the praise of the vast old and new customers. Our products are widely used in petroleum, textile, metallurgy, construction, farming, machinery, landscape protection, production and manufacturing, and other fields.

Our Main Products: Stainless Steel Wire Mesh, Shale Shaker Screen, Crimped Wire Mesh, Dutch Wire Mesh, Copper Wire Mesh, Brass Wire Mesh, Stainless Steel Welded Wire Mesh, Galvanized Welded Wire Mesh, Filter Discs And Wire Mesh Processed Products.

TIANHUI Sincerely hope to establish long term business relationship with worldwide customers on the basis of sincerity and mutual benefits.

Tianjin KXC group founded in 2004, is an ISO 9001 certified company,committed to manufacturing valves, valve parts & related products for water works and water treatment projects.

KXC consists of HY Valves Co. Ltd and KXC Metal Co. Ltd within our own factory and foundry. We have machining center, CNC machines, pressure test machining, electric furnace, mould machine, sand blasting machine, given all of this, our products quality always under good control.

KXC mainly produce gate valve(Resilient seat, Metal seat), butterfly valve(Concentric and Eccentric), check valve, ball valve, globe valve and etc. Supported by our many years’ experience and expertise in this field,

KXC can also offer OEM &ODM valves and parts.KXC philosophy is to offer high cost performance products with optimal service. Welcome to visit our factories and KXC will satisfy you in all respects.

Our products:Rising Stem Globe Valves, Double Eccentric Butterfly Valve

BEISAI is large-scale joint-stock group foundry enterprise, divided into Hebei BeiSai Metal Products Co., Ltd and ShiJiaZhuang BeiSai Trade Co., Ltd. which was builded in 2003, located in ShiJiazhuang province City. company net assets is up to CNY 45 Milion, The annual production capacity of 60000 Tons casting iron parts. More than 300 employees here. There are 5 senior casting engineers and 21 technical engineers etc. We have 26 sets of centrifugal casting machines and 5 sets of autoumatic machine painting lines and 3 sets of automatic hydraulic pressure testing machines, we have very perfect testing and checking equipment and testing lab, 100% make sure all products are top-quality.

At present our major products and service is Casting Iron Pipes, Fittings, SS Couplings, Carton Steel Clamps which was used for sewer drainage system of buildings. And Casting iron manhole covers and frame, Casting tree gate and Casting valves , fire protection fittings and connectors, Casting cooking hardware, etc.

We also can produce all kinds of large or small machine casting parts and auto casting parts and pump housing and pump console/ impeller and casting pulley according to the drawing or samples.

All our products are fully meet USA and European and National standard ASTM A888/CISPI301/CSA B70, ASTM-A536, DIN 19522, EN877, BS EN877, ISO6594, BS437, BS416, KSD 4307, EN124:1994, BS 497-1:1976, ISO2531, BS EN545/EN598, AWWAC 151, KSD 4311, AS 2280, GB/T13295, GB/T12772 etc.

Expanded metal, also known as metal mesh, refers to any type of metal raw material that can expand in response to different climate changes. This expansion capability makes it ideal for many functions, and it also helps reduce wear on components made with this metal structure. Expanded metal can be used to make many different types of objects, including metal grinders, wall art, furniture and other objects, where the ability to cope with climate change helps protect the integrity of the finished product.

One of the most common examples of such metal products is expanded metal sheets. These sheets can be scored and peeled to create perforation designs, which can then be used to create many different metal products. This method can be used to create mesh designs and is often found in outdoor furniture made entirely or partially of metal parts. The same technique can also be used to create large panels for use as wall art, room dividers, and metal products with similar functionality and decoration. Although expanded metal can expand and contract when exposed to different weather conditions, it is very durable and very suitable for use in many different products.

Expanded metals can also be used to increase the strength of many construction projects. By including metal sheets or even metal strips in the masonry work, it can help maintain the integrity of the masonry over a long period of time. The same method can be used to provide additional strength to plaster and other types of concrete structures. When used to create perforated or diamond-shaped grids, expanded metal can be effectively used to create cages or other enclosures, ideal for everything from animal kennel spaces to storage areas for holding various supplies. One of the advantages of constructing these types of enclosures with expanded metal is that it allows air to circulate freely and improves visibility.

Today, many other applications for metal expansion are also adopted. This includes creating expanded metal fencing that are both decorative and durable. The metal can be used to make grills suitable for outdoor use and various forms of indoor cooking equipment. Many companies use expanded metal to create a variety of products that can be used by individual consumers and business operations, making this metal one of the most widely used material categories today.

美国联合钢铁工业有限公司(USI Group)是中国最大的钢管集团之一,成立于1989年,海外总部位于新加坡,国内总部位于中国江苏省苏州市苏州工业园区。

USI集团拥有20个分支公司,总资产:10亿美元,员工10000多人,以及6个工厂(分别位于天津,苏州和沧州市),用于生产电焊管(ERW,SSAW和LSAW),无缝碳钢管,镀锌焊接管,方形/矩形钢管,不锈钢管/盘管/板/片,管件,法兰等。

我们先进的设施以及在生产的各个阶段均具有出色的质量控制,可确保产品质量,因为由于我们优质的产品和出色的客户服务,我们赢得了客户的满意并在油气管道行业中享有良好的声誉,我们的客户包括PDVSA,NIOC,中石化,中石油等。

CRS is a leading manufacturer of thermit welding materials in China, we have more than 30 years experience of designing thermit welding to the rails. Focusing on rail welding used for railroad, metro, tram, crane rails, turnel construction and maintenance.

We have production area of 2500 square meter, with fully automated batching system, sand mould automatic production & drying machines, equipped with full range of raw materials and welding joint testing equipments. Rail aluminum thermit welding material has been promoted and well applied in the railway lines such as the Beijing-Shanghai high-speed railway line, Jinqin passenger line, Daqin line, Tong-Rang line and Tong-huo line. Materials have been exporting to Australia, Indonesia and other countries many years, the products have won praise.

CRS possesses a qualified team of technicians and engineers who have been improving the quality and performance of products, Certified to the ISO9001:2000 standard, CRS’ welding products have been supplied to a wide range of customers worldwide. Thermit products have been passed Chinese rail welding standard TB/T1632-2005 test, Railway Ministry of China, as well as Australia standard AS1085.15-1995 test, Indonesia welding joint inspection test, Taiwan SGS quality inspection test. We are ready to provide technical & operation training, qualification and certificate for customers to ensure a standardized quality and performance of the welding products.

Galvalume steel is an important alloy material often used in daily life. The galvanized steel sheet is composed of aluminum-zinc alloy structure, which is composed of 55% aluminum, 43.5% zinc and 1.5% silicon solidified at a high temperature of 600℃. Its entire structure is composed of aluminum-iron-silicon-zinc, forming a dense quaternary crystal. Of an alloy.

Characteristics of Galvalume

Hot-dipped Galvalume Steel Coil has many excellent characteristics: strong corrosion resistance, 3 times that of pure galvanized sheet; beautiful spangles on the surface, which can be used as building exterior panels.

Corrosion resistance:

The corrosion resistance of “aluminized zinc steel coil” is mainly due to the protective function of aluminum and aluminum. When zinc is worn, aluminum forms a dense layer of aluminum oxide, which prevents corrosion-resistant substances from further corroding the interior.

Heat resistance:

Hot-dipped Galvalume Steel Coil has good heat resistance and can withstand high temperatures of more than 300 degrees Celsius. It is very similar to the high temperature resistance of aluminized steel plate. It is often used in chimney pipes, ovens, luminaires and fluorescent lampshades.

Heat reflectivity:

The heat reflectivity of Hot-dipped Galvalume Steel Coil is very high, twice that of galvanized steel sheet, and people often use it as a material for heat insulation.

Economical:

Because the density of 55% AL-Zn is lower than that of Zn, the area of the galvanized steel sheet is more than 3% larger than that of the coated steel sheet when the weight is the same and the thickness of the gold plating layer is the same.

Application of Hot-dipped Galvalume Steel Coil

use

The main uses of galvanized products are in two aspects. One is the shell and box of other electrical equipment used in electrical switch cabinets; the other is galvanized steel roofing for steel structure buildings, because of its good anti-corrosion and anti-corrosion properties. In many areas with heavy industrial pollution, aluminum-zinc color panels or aluminum-zinc fingerprint-resistant light panels are directly used on walls or roofs.

Construction: roofs, walls, garages, soundproof walls, pipes and modular houses, etc.

Automobile: muffler, exhaust pipe, wiper attachment, fuel tank, truck box, etc.

Home appliances: refrigerator back panels, gas stoves, air conditioners, electronic microwave ovens, LCD frames, CRT explosion-proof belts, LED backlights, electrical cabinets, etc.

Agricultural: pig houses, chicken houses, granaries, greenhouse pipes, etc.

Others: thermal insulation cover, heat exchanger, dryer, water heater, etc.

AQE Gate valves are used to limit the flow of fluid flowing straight through the pipeline. This is an effective and reliable way to stop fluid flow. The Slab Gate Valve can be fully opened or fully closed. The slow opening and closing of the valve helps avoid hydraulic hammers, which can damage the pipes connected to the valve. Gate valves are not used for throttling, so do not let them half open. The gate valve has 3 important parts. They are doors, stems and hoods.

The gate can be used in several variations in a gate valve. You may occasionally use knife doors, or if you use crude oil, you may see flat doors. However, in the marine industry, the most common gate is the wedge. This type of gate valve wholesale uses a wedge-shaped metal sheet that can be moved into the valve body to prevent fluid flow. This uses metal-to-metal contact to create a positive pressure seal. However, under extremely low pressure (5 psi or lower), the gate valve may leak a little.

Learn more about AQE valve via https://www.aqemachinery.com/

Hebei Huahui Valve Co.,Ltd (Botou Yaxing Fluid Equipment Co.,ltd) was established in 2003, specialize in designing and manufacturing various kinds of high quality valves and accessories, such as: Gate valve, Butterfly valve, Check valve, Strainer, Hudraulic control valve(float valve, pressure reducing valve, pressure relief valve,flow control valve),HVAC balancing valve,Air release valve,Rubber flexible joint and Stainless steel flexible joint,Pipe fittings(unicersal coupling, flange adaptor, repair clamp, saddle…) etc, which used in water supply and sewage system\ fire fighting system, and heating ventilation air conditioning system.

Hebei Huahui Valve Co.,Ltd is located in Botou Industrial Zone,Cangzhou City Hebei Province China.Our workshop occupying 150000 square meters, our manufacturing process include machining, shot blasting ,epoxy powder coating,assembling, testing, packing, which is the whole process of valve production from foundry to finished Products. Welcome old and new customers visit our factory and develop business with us.

HENAN FORWARD STEEL EXPORT CO.,LTD

Tel: +86-371-61310228 You also can visit us by sa514steel.com througth google

Address: Tower-A Room 3106 Kai xuan Plaza zhengzhou city of henan province China

http://sa514steel.com

Email: admin@qfsteels.com

SA240 TP310S Stainless, SA240 309S stainless, SA240 316TI stainless, SA240 304H stainless

1. What we do?

HENAN FORWARD STEEL EXPORT CO.,LTD Stainless warehouse provide ASME SA240 Stainless steel plate Bevel,Groove and cutting disc stainless steel machined parts .we have 1000tons tp316L,tp310s,tp304l,tp321, tp304h, tp316h,tp310h, tp321h,2205, S31803, 410, 430, 409, 443, 439, 310SI2, 316TI Stainless steel plate stock.

Besides that, our factory also provide the CNC Cutting platform and water cutting platform. Disc cutting, special parts cutting, stainless steel bevel and stainless steel groove service. Our machined precision to min 0.2 for the surface of machined.

Our cutting service had approved by Mexico and USA, and Canada Project.

2. Our mainly stainless steel grade for ASME SA240

SA240 TP202,SA240 TP201,

SA240 TP304,SA240 TP304L,SA240 TP304H, SA240 TP304N, SA240 TP304LN

SA240 TP316L,SA240 TP316, SA240 TP316H,SA240 TP316N, SA240 TP316LN,SA240 TP316TI

SA240 TP309S, SA240 TP309H,SA240 TP309,SA240 TP309Cb

SA240 TP310S, SA240 TP310, SA240 TP310H

SA240 TP347,SA240 TP347H,

SA240 TP348,SA240 TP348H,

SA240 TP321, SA240 TP321H

SA240 TP317L,SA240 TP317

SA240 TP444,SA240 TP410, SA240 TP430,SA240 TP443, SA240 TP439

3. Products Service of our unitedsteel warehouse.

Stainless steel plate

Stainless disc steel plate.

Stainless steel cutting

Stainless seamless pipe

Stainless seamless Tube

Stainless welded steel pipe

Stainless machined bevel

Stainless machined groove

4. Our Stainless steel thickness

Stainless plates

0.25mm-150mm thickness

Width: 20mm to 2500mm

Length 20mm to 10000mm

Max weight of each plate 6 tons.

Stainless seamless pipe

outer diameter 3.2-200mm,

Wall thickness 0.5-12.7mm

5. Stainless Production time:

5-8days in usual size.

If you need the bevel and groove stainless parts, we need min extra 7days.

6. Stainless Payment Item for HENAN FORWARD STEEL EXPORT CO.,LTD

TT payment Or 30% TT advance and balance should be paid after BL documents.

7. Why you choose us?

a. The faster production time, and most of production, we can control them in one week if the total weight are not large.

b. Better service, we promise that your inquiry will be sent official quotation in 24hours.

c. Faster delivery, we had owned transport truck department and transport stainless to our port in 24hours.

d. Quality promise processing: PMI Test at each stainless steel plates before delivery. We accept the third party inspection, GL. SGS.BV, DNV, LR,ABS and others.

8. Trade Item:

FOB, EXW, CFR AND CIF

Packages by wooden pallet, delivery by containers.

9. How to contact HENAN FORWARD STEEL EXPORT CO.,LTD?

Your can searh our company name from google or visit sa514steel and qfsteels through searching them at google.

Mr David

0086-371-61310228

admin@qfsteels.com

http://sa514steel.com

C-shaped hooks for hanging posters and signs, store decoration and display items, and for hanging and connecting various items. These CNC Wire hooks wholesale are made of durable 2mm thick metal wire.

Other sizes can be provided on request.

A pack of 100

More information please click here.

3 Type 2 Wall Tie(CE marked)

Product Name: Type 2 Wall Tie(CE Marked)

Item Code: Smart Craftsmen-WTT2

Surface Treatment: Shiny.

Raw Material: Stainless Steel 304( Grade1 4301) or Up on your request.

Package: 250 pieces / Inner Box, 2 or 4 Inner boxes / Master Carton.

Place of Origin: Hebei, China.

Standards: PD 6697 and EN 845-1:2013+A1:2016.

The type 2 wall ties for sale are suitable for general-purpose neckties with a space between 50mm and 150mm, which can be used in European domestic residential and small commercial buildings up to 15 meters high. Smart Craftsmen Type 2 wall ties are CE marked, and the measured dynamic stiffness <113MN/m3 meets the requirements for external masonry walls

Approve the performance requirements of Document E. The test result meets the PD 6697 standard and confirms BS EN 845-1: 2013 + A1: 2016.

benefit

Answer: The specially designed safety end provides an excellent mortar key, which reduces the risk of on-site injury and prevents entanglement.

B: Clear and easy to distinguish packaging, which can be conveniently used on site when different types of wall ties are needed.

C: It is made of corrosion-resistant stainless steel, and high-strength steel wire is cold bridged to minimize heat loss.

D: Multiple drops can prevent water from flowing in any direction where the cable tie is installed.

note

Other special length and wire thickness can be provided according to customer requirements.

An ISO 9001:2008 Certified Company, The Metal Factory is India’s most trusted manufacturer, exporter and supplier of stainless steel tubes (ASTM A 312 304/304L, 316/316L), carbon steel pipes (ASTM A A106, A53, API 5L), alloy steel seamless pipes (ASTM A335 P11, P22), mild steel pipes, industrial steel tubes, galvanized steel pipes and black steel pipes.

We can manufacture and supply steel pipes which can be fabricated to customers design and specification in a variety of length and thickness requirements. We can also offer cold drawn seamless steel tubes to meet the custom design and specifications of our customers. We specialise in the manufacture and supply of cold drawn seamless steel tubes, and large diameter stainless steel welded pipes (100% X-Ray Tested). ISO 9001:2008 Certification ensures consistency in our operations and testing procedures.

Steel Pipes and Steel Tubes supplied by The Metal Factory are used across wide range of industries including food processing, power generation, oil and gas, petrochemicals, petroleum pipelines, medical equipment, biopharma, pharmaceuticals, electrical engineering, fertilizer industry, dairy processing, boiler manufacturing and nuclear energy among others.

METLINE has been proudly servicing the steel pipe industry for over 40 years, as a major supplier and manufacturer of custom size steel pipes and steel tubes. We are the exclusive suppliers of stainless steel welded pipes, stainless steel seamless tubes, stainless steel tubing, alloy steel seamless pipes, boiler steel tubes, heat exchanger tubes, capillary tubes, coiled tubing, and galvanized steel pipes. We are serving all major cities and countries in their needs for steel pipes and steel tubes.

Our products are supplied to all major Industrial areas and cities in India such as Mumbai, Delhi, Bangalore, Hyderabad, Ahmedabad, Chennai, Kolkata, Surat, Pune, Nagpur, Indore, Thane, Bhopal, Visakhapatnam, Vadodra, Nashik, Faridabad, Rajkot, Aurangabad, Ranchi, Coimbatore, Raipur, Mysore, Bhubaneswar, Salem, Bhilai, Bhiwandi, Bikaner, Mangalore, Kochi (Cochin), Bhavnagar, Tirupur, Ankleshwar, Assam, Siliguri, Jamshedpur, Warangal, Nellore, Agartala and Thoothukudi.

Our high quality steel pipes, good customer service, and in house pipes and tubes processing capabilities have made us one of the emerging suppliers for steel pipes and tubes in Middle East countries including Bahrain, Cyprus, Egypt, Iran, Iraq, Israel, Jordan, Kuwait, Lebanon, Oman, Palestine, Qatar, Saudi Arabia, Syria, Turkey, United Arab Emirates and Yemen.

India’s #1 Supplier of Stainless Steel Pipes/Tubes, Chrome Moly Pipes, Black Pipes, Galvanised Pipes, Carbon Steel Pipes

Stainless Steel Pipes, Carbon Steel Tubes, Alloy Steel Tubes, MS Pipes Production and Stock Range

Outside Diameter: 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock, OD Size Steel Tubes available Ex-stock

Thickness Range: 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Type: Seamless / ERW / Welded / Fabricated / CDW

Key Steel Pipes & Tubes Products & Grades

1. Stainless Steel Seamless Pipes & Tubes – 304, 304/L, 316/L, 904L, 310S, 321H, 347H, 446

2. Stainless Steel Welded Pipes & Tubes – 304, 304/L, 316/L, 904L, 310S, 321H, 347H, 446

3. Square Stainless Steel Pipes, Round Stainless Steel Tubes, Rectangular Stainless Steel Pipes & Tubes

4. Carbon Steel Seamless Pipes as per ASTM A 106 Grade B/API 5L Grade B/ASTM A 53 Grade B

5. Carbon Steel Seamless Tubes as per BS 3059, ASTM A 179, ASTM A 192, ASTM A 210 GR.A1

6. Alloy Steel Seamless Pipes as per ASTM A335 Grade P1/ P5/ P9 / P11/ P12 / P22 / P91

7. LTCS Pipe – Low Temperature Carbon Steel Pipes as per ASTM A 333 Grade 6

8. Alloy Steel Seamless Tubes as per ASTM A213 Grade T5/T9/T11/T12/T22/T91

9. ERW Black Pipes as per IS:1239/I, IS: 3589 Grade 330 or Grade 410

10. Galvanised Pipes as per IS:1239/I

11. Square and Rectangular Steel Pipes as per IS: 4923

12. ERW Boiler Tubes: BS 3059, ASTM A 214

13. Air Pre Heater Tubes to BS: 6323 PART V

14. Hydraulic Tubes to DIN 2391 ST. 35, ST. 45 & ST. 52

15. Seamless Heat Exchanger Tubes ASTM A 179

16. CDW TUBES IS: 3074 or BS 980

17. CRCA ERW Tubes to IS 3601 OR IS 3074

18. Stainless Steel Electro polished Pipes Manufacturer/Supplier

19. Alloy Steel Fittings Manufacturer – ASTM A234 WP5, P11, P22, P91

Steel grating is generally made of carbon steel, and the surface is hot-dip galvanized, which can prevent oxidation. It can also be made of stainless steel, and the steel grating has the properties of ventilation, lighting, heat dissipation, anti-skid, explosion-proof and so on.

Steel grating is a kind of steel product with square lattice in the middle, which is cross-arranged with flat steel according to a certain spacing and horizontal bars, and welded by pressure welding machine or manually. Steel grating is mainly used as gutter cover. , steel structure platform plate, steel ladder step plate, etc., the cross bar is generally made of twisted square steel.

Advantages of steel grating fence

Material saving: the most material saving method under the same load conditions, correspondingly, the material of the supporting structure can be reduced;

Reduce investment: save material, save labor, save construction period, free of cleaning and maintenance;

Simple construction: on the pre-installed support, it is fixed with bolts or welding, and it can be completed by one person;

Save construction period: the product does not need to be reprocessed on site, and the installation is very fast;

Durable: It has been hot-dip galvanized anti-corrosion treatment before leaving the factory, and has strong impact and heavy pressure resistance;

Modern style: beautiful appearance, standardized design, ventilation and light transmission, giving people an overall smooth modern feeling;

Lightweight structure: less material, light structure, and easy to hoist;

Reduce wind resistance: due to good ventilation, the wind resistance is small in case of strong wind, reducing wind damage;

Anti-contamination: no rain, snow and dust;

Other advantages: ventilation, lighting, heat dissipation, explosion-proof, good anti-skid performance;

Simple design: no need for small support beams, simple structure and simplified design

Acid and alkali corrosion ability: in the range of PH 6 to PH 12.5, a stable protective film is formed on the surface of the zinc layer, and the corrosion resistance is good.

Steel grating use

Steel grating is suitable for alloys, building materials, power stations, boilers, shipbuilding, petrochemical, chemical and general industrial plants, municipal construction and other industries. It has the advantages of ventilation and light transmission, anti-skid, strong bearing capacity, beautiful and durable, easy to clean and easy to install.

Steel grating has been widely used in all walks of life at home and abroad, mainly used as industrial platforms, ladder treads, handrails, passage floors, railway bridge sideways, high-altitude tower platforms, drain covers, well covers, road grilles, three-dimensional It can also be used as a fence for parking lots, institutions, schools, factories, enterprises, sports fields, and garden villas.