- Angles (Aluminium) (3)

- Bars (Aluminium) (7)

- Channels (Aluminium) (3)

- Pipes (Aluminium) (10)

- Plates (Aluminium) (6)

- Sheets (Aluminium) (11)

- Wire (Aluminium) (13)

Aluminum sheet supplier RAYIWELL MFG can supply 1050 1060 1070 2024 3003 4017 5052 aluminum plate, anodized aluminum sheet, Brushed aluminum sheet, Mirror finished aluminum sheet, diamond aluminum plate, aluminum tread plate, 5 bars aluminum plate, 3 bars aluminum plate coil at very competitive price

Aluminium Coil or Aluminum Plate Sheet Supplier RAYIWELL MFG can supply Aluminum plate refering to the aluminum material with a thickness of more than 0.2mm to less than 500mm, a width of more than 200mm, and a length of less than 16m. With the progress of large equipment, there are more aluminum plates that can be as wide as 600mm).

Aluminum plate refers to a rectangular plate processed by rolling aluminum ingots, which is divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, medium-thick aluminum plate, and patterned aluminum plate.

Aluminium Coil Aluminum Plate Sheet Supplier RAYIWELL MFG / RUIYI can offer aluminum sheet grade below

1000 series:1050,1060,1070,1080,1100,1145,1200,1235, etc.

2000 series:2014,2017,2018,2024,2025,2219, 2219,2618a etc.

3000 series:3003,3004,3102,3104,3105,3005, etc.

4000 series:4032,4043, 4017, etc

5000 series: 5005,5052,5454,5754,5083,5086,5182,5082, etc.

6000 series:6061,6063,6262,6101, etc

7000 series:7072,7075,7003 etc

8000 series: 8011, etc.

Temper of aluminum sheet: O, H, W, F, T

H:H12, H14, H16, H18, H19, H22, H24, H26, H32, H34, H111, H112, H114, H116

T: T0-T651

Size of aluminum sheet

Thickness:0.2-6.0mm

Width:100-2400mm

Length:200-11000mm

Mother coil: CC or DC

Weight: About 2mt per pallet for general size

MOQ: 5ton per size

Protection: paper inter layer, white film, blue film, black-white film, micro bound film, according to your requirement.

Surface: clean and smooth, no bright speck, corrosion, oil, slotted, etc.

Standard product: GBT3880, JIS4000, EN485, ASTM-B209

Delivery time: about 30days after receiving the deposit

Payment: T/T, L/C at sight

Trading terms: FOB, CIF, CFR

Aluminum sheet coils have many applications as below

1. Lighting decorations 2. Solar reflectors 3. Building appearance 4. Interior decoration: ceilings, walls, etc. 5. Furniture, cabinets 6. Elevators 7. Signs, nameplates, bags 8. Car interior and exterior decoration 9. Interior decorations: such as Photo frame 10. Household appliances: refrigerators, microwave ovens, audio equipment, etc. 11. Aerospace and military aspects, such as China’s large aircraft manufacturing, Shenzhou spacecraft series, satellites, etc. 12. Mechanical parts processing 13. Mold manufacturing 14. Chemical or insulation pipe coating. 15. High-quality ship board

Due to many grades, please feel free to contact us if you want to know the detailed specification.

Item: aluminum alloy ingot

Weight: 6KG

Grade: LYD112, ZLD101, ZLD101A, ZLD102, ZLD106, ZLD107, ADC10, ADC12, AC4B, A3870, 51K, A365 etc.

We are Aluminum alloy ingot supplier and Aluminum alloy ingot factory

Technical specification:

Due to many grades, please feel free to contact us if you want to know the detailed specification.

Packing: Approx 500~900kg each bundle strapped by steel bands without any wooden pallets, total 13 layers including foot ingots, no double stacked bundles.

We also provide scrap copper wire, 6063 Aluminum bar, Zinc alloy ingot, cobalt sheet and soon

| Number | Chemical composition % | ||||||||

| impurities ≤ | |||||||||

| Cu | Si | Mg | Fe | Zn | Mn | Ni | Sn | Al | |

| ADC12 | 1.5-3.5 | 9.6-12 | 0.3 | 0.9 | 1.0 | 0.5 | 0.5 | 0.3 | >86 |

Company’s main business scope is aluminum and the aluminum sheet, aluminum cathode copper production and sales of ingot magnesium , lead ingot, zinc ingot, tin ingot, aluminium ingot, ADC12, as well as a variety of scrap metal, because of high quality products and reasonable export prices, which is to cultivate the foundation of our strong technical capabilities and market mainly in continental Europe, the americas, Africa and the Middle East.

Aluminum bar can be used in aviation, aircraft construction, rivet, trailer wheel, the propeller components, metallic building material, forging material, welding material, etc.

Aluminium Rod Alloy 6063 Round Bar For Moulding

- Tempers: T6,

- Available shapes: Flats, squares and rounds

- Standard: ISQ SGS ASTM ENAW

6063 is an aerospace aluminum bar with cold finished or extruded aluminum wrought alloy with high strength, adequate machinability and improved stress corrosion control. Fine grain control results in good tool wear.7075 Aluminum bar , aluminum bar for aircraft construction

6063 Aluminum bar is one of the highest strength aluminum alloys. It has good fatigue strength and average machinability. Often used where parts are highly stressed. It is not weld able and has less corrosion resistance than other aluminum alloys. The mechanical properties depend on the temper of the material. Commonly used in the bicycle industry, aircraft structures, and in rifles for the American military.

2024 Aluminum bar Application:

Aluminum bar can be used in aviation, aircraft construction, rivet, trailer wheel, the propeller components, metallic building material, forging material, welding material, etc.

We also provide scrap copper wire, 6063 Aluminum bar, Zinc alloy ingot, cobalt sheet and soon

| Grade | 6063, 6061, 2024, 7075 etc |

| Round Bar Extruded | φ10mm – φ410mm |

| Round Bar Drawn | φ1.0mm – φ10.0mm |

| Square & Flat Bar | 8mm x 8mm – 570mm x 10mm |

| Angle Bar | 8mm x 8mm x 1mm – 280mm x 40mmx4mm |

| U Bar | 10mm x 10mm x 1mm – 110mm x 260mm x 16mm |

[Aluminum Casting for sale]Complex aluminum casting process

Complex aluminum casting such as Aluminum Casting Gate, it is a new technology, which is based on electromagnetic pump low-pressure casting technology, aluminum smelting and forming compound purification technology and manufacturing core, to produce high-quality aluminum casting modern technology. Electromagnetic pump low-pressure casting metal liquid transfer system has a stable flow, flow control is convenient, ease the process of molten alumina suction and easy to achieve the advantages of using the process automation, which not only improves the casting quality of aluminum casting, but also can improve the working environment. Reduce labor intensity, achieve automation and modern casting production.

Purification of molten enamel alloy castings is an important part of the aluminum smelting and composite purification facilities in addition to aeration and spin foam ceramic filters with high degassing performance, except for metal inclusions. In addition, it USES a new long-life lining material, with an independent insulation/heating system that can be used for mass continuous production, but also for batch production. This technology has high efficiency, long service life, low cost and effective, easy to install, use and flexibility. There are three main aspects to be considered in solving complex problems of quality aluminum casting:

(1) melting and melting of liquid aluminum;

(2) smooth transition aluminum metal halide lamp,

(3) size and stability of the mold and sand core process.

That’s all for the sharing, thanks for your reading, and we also supply Aluminum Patio Furniture for sale, if you have any demand for our products, just feel free to contact us.

Located in Liaoning province in northeastern China, LianJiang Metals Company have specialized in aluminum and iron casting production since 1997. We are an OEM partnership that manufactures Cast Aluminum and iron parts for clients all over the world and in different industries such as Street Lighting Base, patio furniture & Garden Decoration company.

With over 20 years of casting work experience and expertise, we offer a full range of casting processes including:sand casting,gravity casting,die-casting,vacuum casting

If you want to know more about the product, please click here.

Aluminum ingot with high purity quality and low price

Aluminium Ingot

-Introduce: high purity aluminium ingot

Advantages

-Primary advantages

-Why should I buy?

China factory price aluminium ingot 99.7%

Hot sale Aluminum ingots purity 99.7% 99.85% 99.9% with good quality

-What makes this product different to ?

high purity

factory price

Hot sale

purity 99.7% 99.85% 99.9%

high purity aluminium ingot Main functions

-Key Features

Silver white light metal. It’s malleable. Products are often made into rod, sheet, foil, powder, ribbon and silk. A layer of oxide film can be formed to prevent metal corrosion in humid air. When heated in the air, aluminum powder can burn violently and emit dazzling white flame. It is easy to dissolve in dilute sulfuric acid, nitric acid, hydrochloric acid, sodium hydroxide and potassium hydroxide solution, but difficult to dissolve in water. The relative density is 2.70. Melting point 660 ℃. Boiling point 2327 ℃. Aluminum is the third most abundant metal element in the earth’s crust after oxygen and silicon. With the development of aviation, construction and automobile industries, the unique properties of aluminum and its alloys are required, which is greatly conducive to the production and application of this new metal aluminum. It is widely used.

https://www.co-nikel.com/product-aluminium-ingot.html

Used for industry such as automobile,pinning and weaving,electron broadly and so on

The use of a substance depends to a great extent on its nature. Aluminum has a wide range of applications because of its many excellent properties.

Aluminum and its alloy are one of the most economical and applicable materials which are widely used at present. Since 1956, aluminum production in the world has exceeded copper production, ranking first in non-ferrous metals. We are aluminium ingot supplier

Aluminum ingot China Specifications

2, high standard.

3, High quality.

4, Competitive price

Chemical composition: Al

Weight: 20 / 25kg

Al (Min): 99.9%, 99.85, 99.7%, 99.5%….

Place of Origin: China (Mainland)

Appearance: Silvery white

Bundling, 805mm * 180mm * 100mm / block 810mm * 810mm * 1020mm / bundle

Bundling, 810mm * 180mm * 100mm / block 810mm * 810mm * 1020mm / bundle

Composition and materials

| Grade | Chemical Composition % | |||||||||

| AL>= | Impurities<= | |||||||||

| Si | Fe | Cu | Ga | Mg | Zn | Mn | Others | Sum | ||

| Al99.9 | 99.90 | 0.50 | 0.07 | 0.005 | 0.02 | 0.01 | 0.025 | – | 0.010 | 0.10 |

| Al99.85 | 99.85 | 0.80 | 0.12 | 0.005 | 0.03 | 0.02 | 0.030 | – | 0.015 | 0.15 |

| Al99.7 | 99.70 | 0.10 | 0.20 | 0.010 | 0.03 | 0.02 | 0.030 | – | 0.030 | 0.30 |

| Al99.6 | 99.60 | 0.16 | 0.25 | 0.010 | 0.03 | 0.03 | 0.030 | – | 0.030 | 0.40 |

| Al99.5 | 99.50 | 0.22 | 0.30 | 0.020 | 0.03 | 0.05 | 0.050 | – | 0.030 | 0.50 |

| Al99.00 | 99.00 | 0.42 | 0.50 | 0.020 | 0.03 | 0.05 | 0.050 | – | 0.050 | 1.00 |

Company’s main business scope is aluminum and the aluminum sheet, aluminum cathode copper production and sales of ingot magnesium , lead ingot, zinc ingot, tin ingot, aluminium ingot, ADC12, as well as a variety of scrap metal, because of high quality products and reasonable export prices, which is to cultivate the foundation of our strong technical capabilities and market mainly in continental Europe, the americas, Africa and the Middle East.

Introduction

pre disposal waste aluminum is a common name for recycled aluminum.

After pretreatment, part of the recovered aluminum will be cold-processed to turn it into powder aluminum, while the other part will be recycled by means of heavy medium dressing and parabolic dressing.

recycled aluminum Processing method

The purpose of the pre-disposal of waste aluminum is to get rid of other metals and impurities mixed in the waste aluminum; to classify the waste aluminum according to its composition, so that the alloy components in the waste aluminum can be used to the maximum extent; and to dispose of the oil, oxide and paint on the surface of the waste aluminum.At the end of the pre-treatment, the waste aluminum is disposed into the burden suitable for the furnace conditions, and the fourth is to make the aluminum (including alumina) that is guessed correctly by the waste aluminum get the most economical and reasonable use.

The pre-disposal skills of ALUMINUM SCRAP supplier are very brief and backward. Even in large recycled aluminum plants, the pre-disposal skills of waste aluminum are not relatively advanced.In terms of the disposal method for recovery and recycling of waste aluminum of a single type, waste aluminum of a single type or no other impurities is usually not pre-disposed in a disorderly manner, but only classified according to the type and composition of the waste and accumulated independently.A single type of aluminium scrap when use only check assay gives a composition, can know the composition of batch, is high-quality recycled aluminium material, usually need not to make any advance disposal charging melting, in a certain aluminum alloy melting, can choose the corresponding components and types of aluminium scrap directly participate in reverberatory furnace smelting, and can be easily melting into the corresponding trademark of aluminum alloy.Some waste aluminum containing high copper and zinc can also be used as the central alloy for adjusting the composition of aluminum alloy in the smelting process.In the enterprise that chooses small reverberatory furnace or crucible furnace, want to want according to need to break large volume waste aluminium (shear or other method) the material that accords with furnace standard is quick.It is worth mentioning that a small number of non-aluminum metals will be mechanically contained in some single type of China scrap aluminum, such as scrap steel parts such as screws on the Windows and doors of scrap aluminum, although the content is very small, but will seriously affect the quality of the alloy, so it must be separated before smelting.

Heavy medium dressing

That is, the method of heavy media heavy selection is used to separate the heavy non-ferrous metals, such as copper, whose density is higher than that of aluminum, which USES the principle that the density of aluminum is smaller than that of other heavy non-ferrous metals, so that the waste aluminum floats on the medium, while the heavy non-ferrous metal sinks on the bottom, achieving the purpose of separation.But the key is to screen a medium that is denser than aluminum and less than copper, and that medium is not water or any other liquid, definitely a fluid.When the fluid is doing reciprocating motion, the waste aluminum is floating on the top of the medium is separated.

metallurgical accessories Parabolic dressing

By using the principle that objects of basically the same volume fall at different points when they are thrown out by the same force, various waste non-ferrous metals with different densities in the scrap aluminum can be separated.When the same force is used to shoot an object with different density but basically the same volume along a straight line, various objects move along the direction of the parabola and have different landing points.The simplest experiment can be carried out on a horizontal conveyor belt. When the mixed wastes run at high speed along the conveyor belt, the waste aluminum is thrown out along a straight line at the end of the operation. Due to the different gravity of various wastes, the waste aluminum falls to the ground at different points, so as to achieve the purpose of waste aluminum separation.In this way, recycled aluminum, copper, lead and other wastes can be separated evenly.The equipment manufactured according to this principle has been adopted in foreign countries and is in the research stage at home.

Aluminum Window Manufacturers Thermal Break Aluminium Casement Window with Tempered Glass

https://www.gangyagroup.com/product-living-room-ideas.html

Quick Details

Model NO.135 series

Warranty: 3 years

After-sale Service: Online technical support, On site Installation, On site Training, On site Inspection, Free spare parts, Return and Replacement Project Solution Capability:

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

Application: Apartment, House,hotel, office, building

Design Style: Modern

Place of Origin: Guangdong, China

Brand Name: HK GANGYA

Model Number: 135

Frame Material: Aluminium

Open Style: Swing

Opening Pattern: Horizontal

Function: Soundproof

Material: Aluminum Alloy

Name: Aluminum casement Window

Profile: Aluminum

Certificates: ROHS; SEC

Open type: casement

Hardware: Hopo top brand, or international brand,such as roto

Frame Color: Customize Color

Keyword: Commercial Aluminum Windows

OEM: Acceptable

Screen netting material: fiberglass; stainless steel; retractable

Anping County Anlida Metal Wire Mesh Co., Ltd. was founded in 2001 in July and was formally established company in 2006. Which is located in Anping County, Hengshui City, Hebei Province, next to the da guang express way. It is “the quality standard of qualified enterprises” Hebei ProvinceChina construction metal doors and Windows, curtain wall industry “innovative enterprise”, the national federation of industry and commerce hardware mechanical and electronic chamber of commerce building metal doors and Windows, curtain wall) committee “vice President of units, commodity wholesale market in the development of China market society committee” merchants nationwide credit management model “, “member of” China hardware products association.

Our products:Expanded Metal Mesh,Aluminum Metal Mesh,Perforated Metal Sheet,Grating,Wire Mesh, etc.

The development direction of the company has a perfect IS09001 international quality management system, and has a group of senior team full of enthusiasm, including experienced, technical comprehensive, excellently engineer, technician team. They constitute the company’s a strong backing.

The company has also quality control in production process and a full range of testing test equipment, which makes that the quality of products can be guaranteed for a long time .We sincerely thank the customers who have given us support and love over the years. We hope to get your continued support, as always, we will provide you with the best quality products and services.

Anping TianHui Wire Mesh Products Co., Ltd. is located in anping county, Hebei province, which also be called “Hometown of wire mesh”in china. Started the factory from the year 1986, We are one of the top manufacturers and exporters of Woven wire Mesh, Screens and welded Wire Mesh in China.

We has over 160 sets of wire mesh machines, have around 20000 rolls in stock for stainless steel wire mesh & welded mesh. We have gained a global sales network reaching to the Local market, USA, Middle-East, Europe and Africa etc.

Our company has been based on “good quality, timely delivery, reasonable price, considerate service” the purpose to serve the masses of customers; And is in line with “quality seek survival, prestige seek development” production principles, in our emphasis on product quality at the same time, also actively communicate with the customer, understand customer needs, to realize our shortcomings, and for clients to provide professional and timely after-sales service, won the praise of the vast old and new customers. Our products are widely used in petroleum, textile, metallurgy, construction, farming, machinery, landscape protection, production and manufacturing, and other fields.

Our Main Products: Stainless Steel Wire Mesh, Shale Shaker Screen, Crimped Wire Mesh, Dutch Wire Mesh, Copper Wire Mesh, Brass Wire Mesh, Stainless Steel Welded Wire Mesh, Galvanized Welded Wire Mesh, Filter Discs And Wire Mesh Processed Products.

TIANHUI Sincerely hope to establish long term business relationship with worldwide customers on the basis of sincerity and mutual benefits.

304 is a chromium-nickel austenitic stainless steel with incredible quality and astonishing utilization assurance as furnished in the reinforced condition with a normal brinell hardness of 175.Characterised by high disintegration insurance all around air damaging circumstances it indicates sublime security from most oxidizing pros, general foodstuffs, purifying courses of action, dyestuffs, most common chemicals, notwithstanding a wide collection of inorganic chemicals furthermore hot oil gases, steam start gases, nitric destructive and to a lesser degree sulphuric destructive.

Overseas Aluminium is a dynamic group, which was established over a decade ago to cater to growing demands of Aluminium Products. We have a team of young visionaries who end eavour for excellence in every aspect related to our products. As importers, exporter, dealers & stockists with huge stocks Overseas Aluminium become within one of the most reliable source for quality within a short span. Our aim is to provide our buyers with everything in aluminium under one roof viz.

What is special about the degreasing process of aluminum alloy castings

Die-Casting Tooling Design is also a processing method, so many parts are obtained by die casting, the performance of the die casting is based on the material composition. Take the aluminum alloy casting with zinc as the main component for example, the parts can only be applied after special treatment.

As the surface of the aluminum alloy casting is a very dense surface layer, inside is the evacuation of porous structure, so in its degreasing is special, can only use alkaline degreasing agent for degreasing. In addition, we have high requirements on the decoration of products, so mechanical polishing is required before degreasing, followed by chemical degreasing and electrolytic degreasing.

Because the polishing paste that aluminium alloy die casting USES contains paraffin in polishing, for emulsive paraffin, the temperature that removes wax water wants to exceed 70 degrees to just have the effect. Generally, wax removal water can only remove wax without degreasing, and chemical degreasing should be carried out again. The chemical activity of zinc alloy is very strong, so the alkalinity of chemical degreasing liquid should not be too strong, or it will corrode the surface of casting. If in this process can be used with ultrasound, the effect will be more ideal. The degreasing process of aluminum alloy castings is very important. The above mentioned operations should be in accordance with the requirements to ensure the quality of the die casting products.

Located in Liaoning province in northeastern China, LianJiang Metals Company have specialized in aluminum and iron casting production since 1997. We are an OEM partnership that manufactures Cast Aluminum and iron parts for clients all over the world and in different industries such as Street Lighting Base, patio furniture & Garden Decoration company.

With over 20 years of casting work experience and expertise, we offer a full range of casting processes including:sand casting,gravity casting,die-casting,vacuum casting

If you want to know more about the product, please click here.

HuaYi Casting Foundry and LianJiang Metals Company are two collaborative enterprises owned and operated by same management team.

-LianJiang Metals Company designs and markets products.

-HuaYi Casting Foundry focuses on manufacturing the products.

Located in Liaoning province in northeastern China, HuaYi Casting Foundry and LianJiang Metals Company have specialized in aluminum and iron casting production since 1997. We are an OEM partnership that manufactures cast aluminum and iron parts for clients all over the world and in different industries such as street lighting, patio furniture & garden decoration company.

With over 20 years of casting work experience and expertise, we offer a full range of casting processes including:

-sand casting

-gravity casting

-die-casting

-vacuum casting

1>The payment term is flexible according to the order quantity, price, and other factors.

2>We have no Minimum Order Quantity (MOQ) limitation on orders. Therefore, you can place your order at whatever size quantity fits your specific needs.

3>Our typical production lead time is about 6 weeks but could be flexible and adjust depending on a customer’s request. Short lead time periods are possible in order to meet a customer’s urgent order delivery need.

4>We will sign a confidential agreement with the customer and will never disclose a customer’s name, designs, or drawings to another other third party.

All related information is protected and secure in our factory.

5>The payment term is flexible according to the order quantity, price, and other factors.

6>We provide customers with prompt after sales services for any quality issue.

7>We have ample capacity to provide the customer with consistent high quality casting work: smooth surfacing, accurate dimensions, and strong mechanical properties.

Our website:http://www.ljmetals.com

Are you looking for scaffolding products or manufacturers?EK scaffolding is the scaffolding manufacturer and supplier in China. We can provide you all types of scaffolding products, such as scaffolding couplers, scaffolding system, cuplock scaffolding, ringlock scaffolding, base jack, etc.

Dhairya Alloys is a Leading Manufacturer, extensive Stockholder of Bars, Plate & piping products for the Oil, Gas, Petrochemical and Nuclear Industries. Dhairya Alloys is the Manufacturer of Butt-weld Fittings, Forged Fittings, Compression Fittings, Outlets, Flanges & Long Radius Bends in Materials like Stainless Steel, Monel, Inconel, Hastelloy, Titanium, Copper, Brass, Aluminium & Nickel Based Alloys. Alloy Steel, Duplex & Super Duplex Steel, Nickel Alloys etc. We also manufacture and supply non-standard items in any material to customer’s specifications

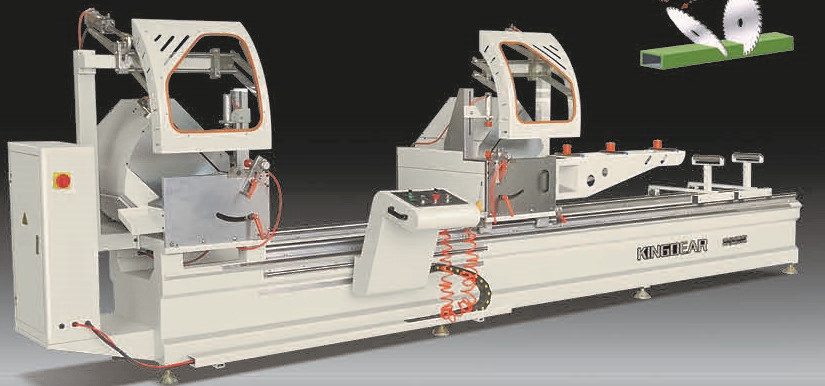

Model No.: LJZ2 -450×3700

PRODUCT DESCRIPTION

Double Head Cutting Saw Equipment Feature

■ Used for aluminum profile cutting.

■ Carbide saw blade give accurate processing and high endurance.

■ The two heads can work independently and simultaneously.

■ Cutting off the required length and two end angles is available by one time processing

Double Head Cutting Saw Technical Parameter

1) Power supply: three phase, four line 380V, 50Hz

2) Saw motor: 1.5Kw x 2, 2,800r/min

3) Pulling motor: 0.55Kw, 1,400r/min

4) Working pressure: 0.4 – 0.6MPa

5) Air consumption: 200L/min

6) Cutting length: max 3,700mm; min. 400mm

7) Cutting width: max 120mm

8) Cutting height: max. 200mm

9) Cutting angle: 0° – 45°

10) Cutter feeding speed: 0 – 3m/min

11) Saw diameter specification: 450mm x 4mm x 30mm-120

12) Overall dimensions: 4,500mm x 1,100mm x 1,400mm

Processing Accuracy

■ Repeat locating length: ≤0.2mm

■ Cutting angle allowance: ±5′

■ Cutting profile surface planeness: ≤0.10mm

■ Cutting profile surface roughness: Ra12.5μm

If you want to know more, you can click here.

Duplex Stainless Steel Plate belongs to a class of steel known as the duplex steel. We are expert in Duplex Steel Coil supplier that are in high demand in many applications ranging from food industry to the chemical industries etc. The additions and quantities of these materials provide the Stainless Steel Duplex Plate an extra ordinary corrosion resistance and tensile strength. Get a wide variety of ASTM A240 Duplex Sheet from our inventory. Best Stockholder of ASTM A240 Duplex Sheet in UAE or China.

Who We Are

Ares Engineering is the expert in the manufacturing metal decorative wire mesh for architectural application. With the most advanced facility, we have the most modern and productive mill in China. Our products―whether they’re expanded metal mesh, laser cut sheet, perforated sheet or stainless steel decorative wire mesh―seamlessly blend form and function, challenging the status-quo. Through consistent growth and innovation we strive for the highest quality products at an unbeatable value.

As a major manufacturer and supplier of metal mesh products, we are committed to quality. Our investment in personnel and equipment provides you–customers with innovative and value-based products that meet or exceed your design expectations. From concept to completion, our team of experts and 35 years of experience in metal products can help you choose the mesh that suits your needs.

Our People

At Ares engineering, we are extremely proud of our employees and our commitment to them. Everyone is full of enthusiasm, diligence, dedication, and always strive to pursue the highest quality craftsmanship. They are the heart of our company and the reason why we are able to provide you with high-quality metal mesh products.

We have professional sales staff, engineers, designer, mesh worker, painting technical worker, quality inspector, customer service representatives, and all of the creative, inventive individuals here at Ares that continue to push the boundaries of what metal mesh can be.

With a professional team of product advisors, we are able to guide you in product selection. If your product requires design and technical support, we can provide suitable suggestions, alternatively we can provide price information, availability and lead times.

Company Profile

Ares engineering has been the leading manufacturer of metal mesh products. We are well respected in the industry for being trustworthy in quality and service.

Ares was built as DBL Expanded Metal Mesh Factory in 1986, which only produce the expanded metal mesh at first. With time goes by, our founder introduced many advanced equipment and enlarge our production range, including not only stretched mesh machines, but also punching machines, laser cutting machines, cutting machines, and decorative wire mesh machines. Then we renamed the company name as Anping County Huijin Wire Mesh Co., Ltd on 2008. Next year, we started the Production of Aluminum Expanded Curtain Wall Panel and Ceiling System and applied for a patented technology.

With the continuous increase of decorative mesh projects, we invested the international-standard PVDF and Powder Coating Painting line, which can control quality well.

On 2019, we set up Branch Company- Hebei Ares Building Decoration Engineering Co., Ltd. The main purpose of the branch establishment is separating projects from traditional businesses, assembling a dedicated project team which can provide solutions and professional service for metal decorative mesh projects.

Now in its 36th year of operation, Ares Engineering looks towards the future. With mechanical and technological advancements, we now offer a wider range of patterns than ever before. New partnerships have allowed us to not only offer new types of products, but to provide technical and design suggestion of projects. Though Ares Engineering continues to build and grow, Quality & To meet and exceed customers\\’ expectations will always remain the fundamental core of our business.

Now in its 36th year of operation, Ares Engineering looks towards the future. With mechanical and technological advancements, we now offer a wider range of patterns than ever before. New partnerships have allowed us to not only offer new types of products, but to provide technical and design suggestion of projects. Though Ares Engineering continues to build and grow, Quality & To meet and exceed customers\\’ expectations will always remain the fundamental core of our business.

History

1986: Built DBL Expanded Metal Mesh Factory

2008: Renamed as Anping County Huijin Wire Mesh Co., Ltd

2009: Started the Production of Aluminum Expanded Curtain Wall Panel and Ceiling System and applied for a patented technology

2012: Invested the international-standard PVDF and Powder Coating Painting line

2019 by now: Set up Branch Company- Hebei Ares Building Decoration Engineering Co., Ltd. Focus on providing solutions and supplying products for metal decorative mesh projects.

Our website:http://www.aresmaterial.com

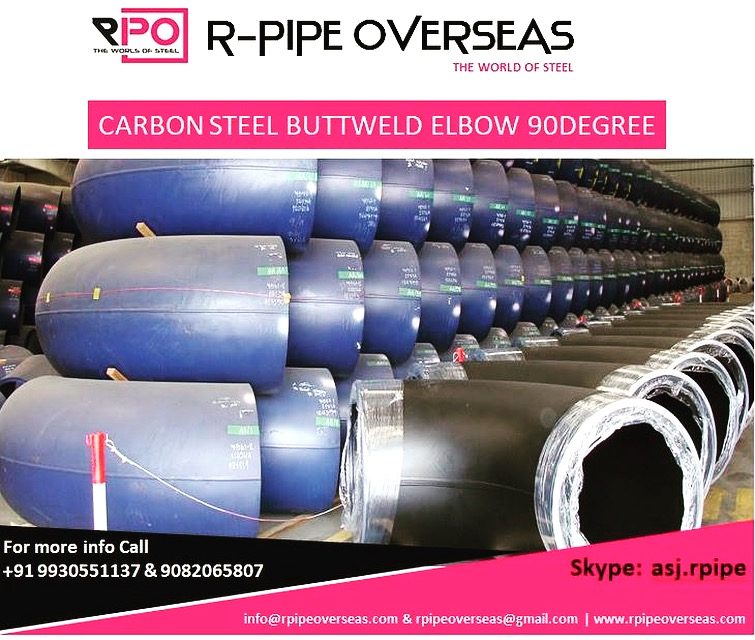

We, R-PIPE OVERSEAS Are BIGGEST STOCKHOLDER & EXPORTER of Pipeline Products and Exporting to More Than 40 Countries Including U.S.A, Europe,

Gulf & Asian Countries And Regions In The World. Our High – Quality Products And Strong International Reputation In The Industries Related To The

Chemicals, Engineering, Pharmaceuticals, Fats & Fertilizers, Sugar Mills & Distilleries, Cement Industries, Ship Builders, Paper Industries, Pumps & Petrochemicals,

Textile, Dairy, Oil & Natural Gas, Allied Industries Organization In Term Of The Specific Materials, Technology Are Highly Valued By Indian & Foreign Customers.

Materials:

PIPES | TUBES | PLATES | SHEETS | FLANGES | FASTENERS | FORGED FITTINGS | BW FITTINGS | ROUNDBARS. IN HIGH NICKEL ALLOYS | DUPLEX STEEL | STAINLESS STEEL | ALLOY STEEL | CARBON STEEL ETC.

REGARDS

ARVIND JAIN – SALES HEAD

R-PIPE OVERSEAS

T: +91 22 6659 5201

M: +91 9930551137

Whatsapp: +91 9082065807

Skype: asj.rpipe

E: info@rpipeoverseas.com & rpipeoverseas@gmail.com

W: http://www.rpipeoverseas.com

A: Shop No. 28, Gr. Flr, 153/154, Shree Ishwaleshwar Siddhesh Deep CHS,

PB Marg, Mumbai – 400008. (INDIA)

GST TIN NO.: 27ALTPJ6984G1ZB

Kingsun New Material Technology Co., Ltd. is located in Lianhua Industrial Park, Pingxiang City, Jiangxi Province, covering a total area of about 200,000 square meters. with a registered capital of 50 million RMB and a designed production capacity of 50,000 tons, the factory was established in 1999. For more than 20 years, it has focused on the research and development, production and sales of non-ferrous metal “casting auxiliary materials“, and is a professional manufacturer of aluminum casting auxiliary materials. Customers for aluminum plate, tape, foil, rod, cable and aluminum ingots, aluminum castings and other aluminum processing enterprises.

At present, we total have 208 workers, four production chain industries, mainly aluminum casting auxiliary materials, specifically divided into: high purity chromium metal series, aluminum flux series, Aluminium alloying tablets series ,aluminum base intermediate alloy series, grain refiner series, foam ceramic filter plate series, total five series and several varieties. All products are dedicated to aluminum processing and casting industry to provide services. The company has sales and service offices in Shanghai, Jiangsu, Zhejiang and Guangdong, and exports to more than 30 countries and regions such as the United States, the United Kingdom, Germany, Italy, Japan, Turkey and Southeast Asia.

More details please contact: http://www.kingsunmaterials.com