Our factory is an enterprise manufacturing pipe fittings for more than 30 years. It is supplying Malleable iron fittings, Ductile iron fittings , Gray iron fittings and other steel products, with long history and unchanging faith of producing high quality products.

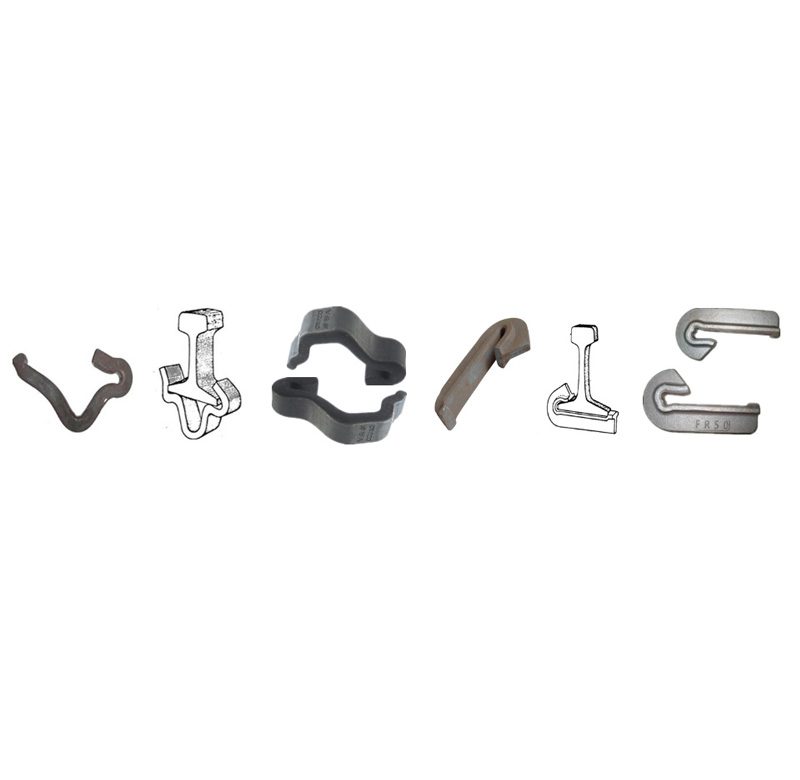

Main products:Malleable iron pipe fittings, Tube clamps, Air hose couplings, Camlock couplings, Carbon steel pipe nipples, Electric power fittings, Steam couplings, Gas meter connectors etc.

- Founded in 1986, Covering 12,000 square meters, having more than 200 workers. We have a registered capital of 8.88 million, and the annual export volume of 10 million USD.

- As a high-tech enterprise, we have our own R&D team, which can open molds through samples or drawings provided by customers, and even assist customers in developing new products through functional descriptions.

- From purchasing material, casting, annealing, trimming, galvanizing, machining, packing, to exporting, have formed stop production system.

- Various casting techniques: Currently 90% of the products have been changed to coated sand production. And equipped with coated sand production line, which can control the quality requirements of coated sand, and coated sand buried box casting line, further improve the quality of products. Most suitable casting way can be defined according to any products.

- casting surface: our own researched prescription of sand and mold design is used, there’s no joint line, no shift, no sand inclusion, no crack on products, we will satisfy every client.

- Material assurance: on –the –spot sample analysis+ chemical composition analysis after casting, double tests to guarantee stability of material. Electric heating automatic temperature control equipment can precisely control the furnace heats uniformly to ensure product are with the same tenacity.

- Surface treatment: self-color + rust preventing oil, electroplating, hot dip galvanizing, first electroplating and then hot dip galvanizing, first electroplating and then backed galvanizing, first electroplating and then plastic spraying. Different products need different surface treatment, best surface treatment can be defined according to different products.

- Machining technique: we have professional threading machines and CNC lathes to make threads, threads are 100% within specified scope of gauge and plug gauge, included angle of threads is within 90°+-0.5°. High efficiency and high quality producing way make our products have more market value.

- Our certificates: Our factory passed TSE for Turkey, INMETRO for Brazil, and CE, ISO9001:2008, IQNET etc.

- Our clients: Our factory is cooperating with many well-known enterprises, main market for malleable iron pipe fittings is Europe, main market for pipe clamp fittings is U.K., and main market for air hose couplings is USA. There’re also many different kinds of products for specialized application, and are very advantageous in their fields.

Our website:http://www.donghuancast.com

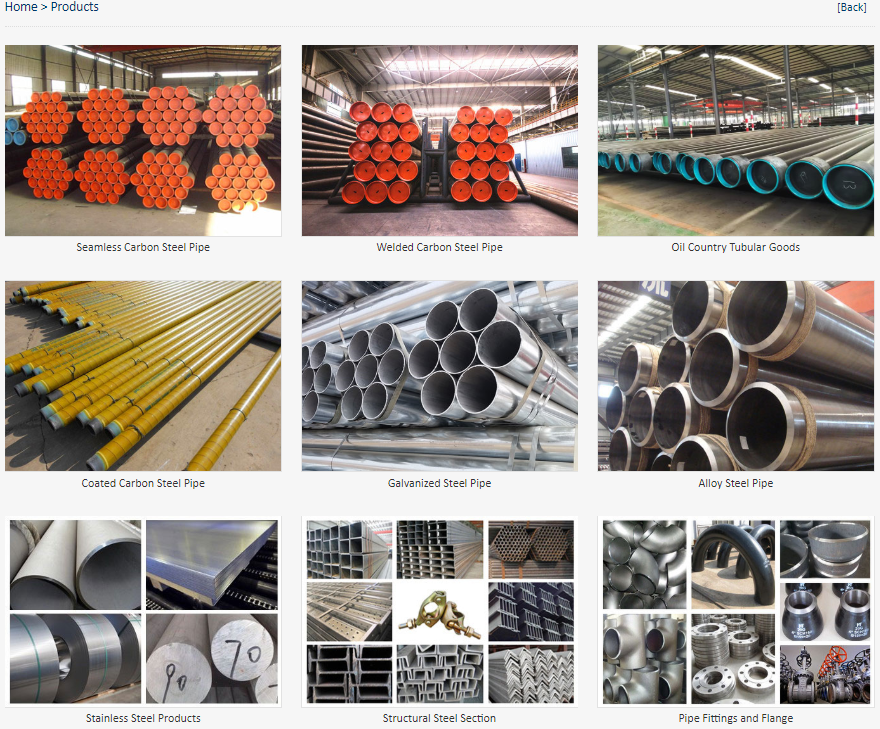

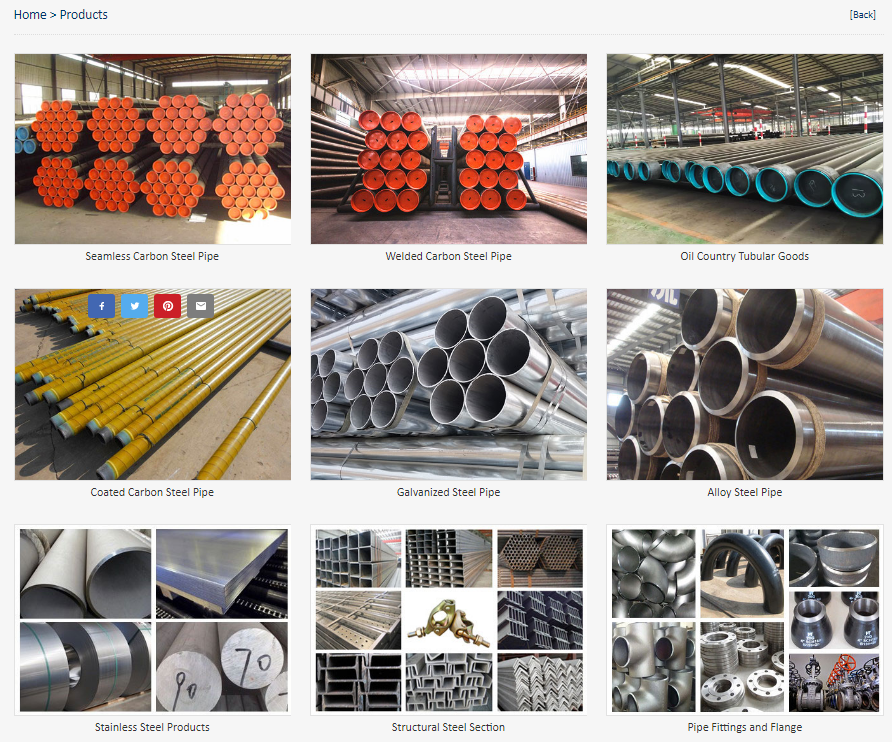

Union Steel Industry Co., Ltd as member of United Steel Industry Group, specialized in steel pipe and pipe fittings designing, manufacturing, stocking and exporting in China.

Our products

- SMLS &ERW Steel Pipe(especially processing galvanized/FPE/3LPE/Grooved/pipe & flange welding …etc with very competitive price)

- Tubing&casing (Professional standard API 5CT PSL1/2 J55 K55 P110 Q125….)

- Structure steel profile(Mainly provide international general standards, advantage prices for some EU standards or other standards)

- steel plate &pipe fittings(flange,elbow,reducer,valve..etc)

We basically have steel in stock and support fast delivery:

- Steel pipe : ASTM A53;ASTM A106;ASTM A333;ASTM A500;ASTM A252 ..etc or Equivalent

- Structural steel hollow section: EN 10025、EN 10219 S235/S275/S355..etc or Equivalent

- Steel plate : ASTM A36, ASTM A283, ASTM A572..etc or Equivalent

- We can also provide various conventional stainless steel products.

You can forward needs on alisa@union-steels.com i will provide you best price .

Application:

Hot Rolled Stainless Steel Clad Plate is extensively used in Oil, chemistry, electricity, paper making, alkali production, watering works, vehicles, salt, medicine, food and also public facilities.

Advantage for KLS Stainless Steel Clad Plate:

Stainless steel dressed plate makes the combination far more stronger than that of the surge bonding, more eco-friendly than the explosion bonding, and also the turn-around time is quicker. The toughness of the bonding interface is uniform that makes the anti-corrosion layer totally used, and also hot-rolled cladding modern technology can generate a clad plate with extremely with and also ultra length.

Machining Methods for Stainless Steel Clad Plate China :

Eruptive Clad: Overlap stainless plate on carbon steel plate with a cushion in middle to leave particular space.Explosive material will be paved externally of stainless plate and when eruptive product exploding, high energy can make stainless plate effect carbon steel plate with high speed to joint.In optimal condition, the strength for square mm could get to 400 Mpa.

Thickness Scope:10 mm-300mm.

Warm Rolled Clad: Hot rolled stainless steel dressed plate is rolled of stainless and also carbon steel plates in vacuum condition.In such process, the attired plate and base plate must be in pure clean condition.Besides, for improving the stamina of conbining, there are also a collection of technological approaches with physics and chemical therapies.

Density Scope:0.6 mm-50mm.

Cold Rolled Clad: Cold rolled Stainless dressed plate is made after annealing-pickling-cold rold-mid annealing-pickling manufacturing process to stainless-steel clad plates.This material is with far better yield stamina than exact same grade stainless plate.Min density would get to 0.6 mm.

About AH Magnet

AH Magnet is an ISO9001 accredited Chinese manufacturer/Chinese supplier of all kinds of high performance permanent magnets products with over 30 years of experience in the field. Our headquarter is located in Anhui Province and we have two active sintered neodymium iron boron magnets factories in Anhui and Zhejiang China covering a combined area of 80,000 square meters.

We offer a wide variety of neodymium magnets to choose from such as N, M, H, SH, UH, AH and EH grades, and have a wide variety of applications, from servo motors, stepper motors, brushless motors to permanent magnet synchronous motors. We also customized magnets assemblies according to the customers’ design requirements, such as magnetic coupling, laminated magnet, Halbach array, magnetic motor parts and so on. Our rich cooperative experience and professional R&D ensures that we always keep the same pace with customers and industrial innovation.

As an experienced NdFeB magnets manufacturer, we are committed to serving our customers in the following ways:

Ensuring high performance products

Ensuring timely product delivery

Ensuring flexibility by tailoring products according to our customers’ needs

Ensuring that our prices are competitive

Our Company is committed in our duty to the environment and in our social responsibilities. In the past decade, we have offered environmentally friendly permanent magnets and assemblies to our customers. We also recycle all our inhouse wastes. We are also committed to providing a better environment to our factory workers and making substantial donations regularly to impoverished mountainous area.

It is the vision of our all staves that our Company will stand strong for many more decades to come.

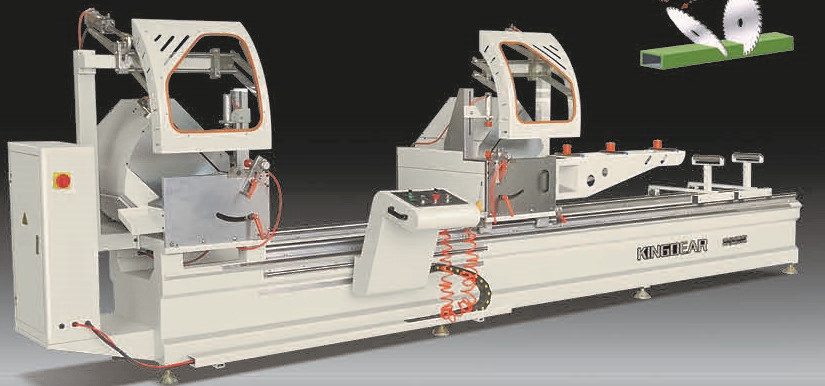

Double-twist stranding machines, high-performance twisting machines

Double Twist Stranding Machineare effective, compact production units primarily for use in the manufacture of highly flexible braids, bundled braids, for stranding pairs of wires, triples, quadruple designs …

The machine concept differs from the single-twist system in that one rotor turn generates two cable twists / turn. The braid is given the first twist at the stranding point of the system feed. At this point, the stranding material still has twice the length of lay of the desired final geometry. The final braid length of lay with the second stranding twist is only completed at the second turning point, before being introduced back into the static coil former.

BOW DOUBLE TWIST STRANDING MACHINE

Application for:

Multistrand 7 or 19 copper wire, aluminum wire, tinned copper conduct etc. Also multistrand insulated conduct for power cable, data cable, control cable etc. Laying up of 2/3/4 cores of small size building wires.

Bow Double Twist Stranding Machine Description:

Payoff

Double twist stranding machine

PLC control system with color touch screen

Advanced function (Optional):

1:Motorized payoff or back-twist payoff, tension keep stable from start to end.

2:Bow material : carbon fibre

3:Brake: serve motor

4:Motorized driven capstan. Lay length set on touch screen, no need to change gear mechanically.

5:Auto lubrication system: regularly lubricate important parts to prolong machine service life.

COMPUTER SIMULATION OF AN INDUSTRIAL WIRE DRAWING PROCESS

Wire Stranding Machine is an important industrial process. Wires are reduced in diameter through a series of die/capstan combinations which provide the desired reduction steps. Typical wire drawing machines within BICC Cables Ltd use up to twenty-one dies in one line and it is necessary to optimise the die drafting for each machine and final wire diameter to obtain good machine efficiency and high quality product. An important aspect in the manufacturing process is to avoid wire breakages with the resultant loss of production due to short final lengths and the associated time required to restring the drawing machine. In order to optimise the conditions for each machine and wire size, computer simulations of the process are used to predict performance by estimating factors such as the ratio of drawing stress to ultimate tensile stress, drawing force, back tension and heat generated.

A computer simulation of the multi-line wire drawing process for copper wire has been modelled by the Wrexham Technology Centre of BICC Cables Ltd using a bulk model. The redundant work during the drawing process was included by formulation and equations for the redundant deformation were derived that were in good agreement with published experimental work.

A new computer simulation has been developed to predict the performance of wire drawing process. The model uses a one dimensional explicit finite difference method to determine the plastic deformation in the dies. The redundant work formulation was used as in the previous simulation. This paper describes the numerical methods used and compared the results from the new computer simulation with the previous bulk model. Significant differences are predicted in the stress ratios, drawing force and heat generated for process predictions. The new simulation of the plastic deformation in the dies also indicated optimum semi-die angles away from the traditional eight degrees.

7 Wire Tubular Type Stranding Machine

Owing to the vast industry experience and in depth knowledge of this domain, we are offering a huge collection of high quality 7 Wire Tubular Type Stranding Machine. These products are manufactured using optimum quality raw material. These products are easy to install and requires low maintenance. Customers can avail these products from us at market-leading prices

Basket Type Stranding Machine

Basket Type Stranding Machine is mainly used to strand not only copper/aluminum conductor for the electric wire and cable but also the cable core, steel core, and steel rope. Machine’s make-up: pay-off, driving part, cylindrical part, hydraulic brake device, wire –bobbin frame, die-holder, haul-off device, spindle-type take-up/traversing (Φ50 bar traversing) and an electrical control part, etc.

Rigid Stranding Machine

The Rigid Stranding Machine is used for stranding CU, Al wires, and conductors. Stranding unilay and reverse concentric, round, compressed, compacted or sector-shaped ( straight or spiraled) as per customer requirements.

Main features:

Self-supporting rigid rotor design with 1 6 12 18 24 30 36 Bobbin Cage

High efficiency and speed

Bobbins mounted on pintles

A line drive by A.C. or D.C. motors with electronic or mechanical synchronization between line components.

Different braking device for bobbins

Centralized lubricating system for bearing

Disk type Pneumatic brake for Cage.

Machines with or without back twist

MMI /PLC Equipped, optional

Easy Lay Setting

High Speed Tubular Stranding Machine

High Speed Tubular Stranding Machine with back twist, for 1+6 Bobbin copper / aluminum round & compact conductors and steel wire stranding. This strander is for manufacturing high carbon & low carbon steel wire rope, copper & aluminum conductor

Bow Type Stranding Machine

The Bow Type Stranding Machine is suitable for a wide range of productions, obtained with high speed and productivity; the back twist process gives high quality products. The Bow stranders use components made with most modern materials, like carbon fiber for the bows, tungstene carbide for bushes, hardened steel for rollers.The control of tension of the cores is assured with electro-mechanical or pneumatic self compensated brake, with set up by control panel.The safe use is assured with control of bearing temperatures and supports vibration.The machine is protected with a soundproof cover, with pneumatic open, inside fans and lights.Is possible the bobbins side loading with a motorized trolley, that avoids the use of bridge cranes and reduces dramatically the total loading time of the line.

For Cables Industry:

Stranding of conductors made with copper, aluminium, aluminium alloy, aluminium steel reinforced or supported;

Laying up of 2 – 7 round insulated cores for low and medium voltage;

Laying up of 2 – 7 straight sector shaped insulated cores, with the rotating cradles version;

Possible application of fillers and tapes of every type.

Tubular stranding Machine

The Tubular Stranding machine consists of bearing stands made of welded steel for the tube bearings. Up to reel size of 630mm .The stranding rotor is built up from welded tubes with wire guidings outside the tube. The reels are held in cradles, which are positioned inside the tube. A light beam along the complete length of the machine monitors, if the pneumatically (optional)operated reel-pintles are securely closed and the cradles are in safe condition. The machine is equipped with wire break detectors for each segment, pneumatic disk-breaks and individual drives for the Stranding Rotor, the Capstan and the Take-Up. The operator’s desk gives full control over parameters like Rotor-speed, lay-length and production length.

Main Features:

• Machine placed on a Rigide steel frame with rotor support, fixed on the floor for an easy installation

• Tube rotating on encircling bearings or rollers

• Machine able to work in torsion or total back twist with the possibility of partial back twist

• Wire back tension kept constant from full to empty spool payoff

• Wire/strand break detector for each payoff unit(optional)

• Spool loading/unloading by crane

• Pneumatic pintles equipped with safety locking system

• Independent driving motors for tube, capstans and takeup units

• A.C. motors with flux vector control inverter

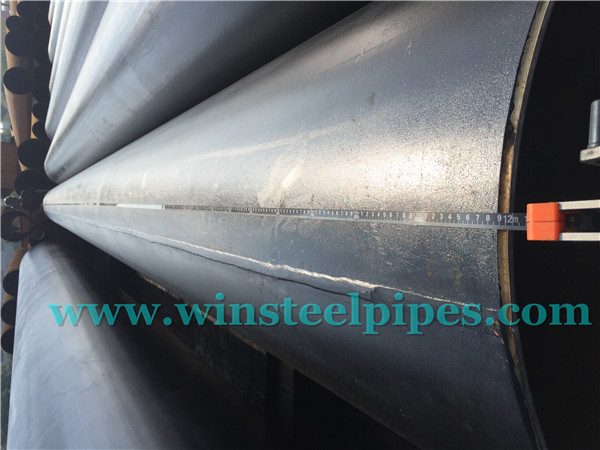

24” steel pipe (609.6 mm steel pipe) is commonly used LSAW pipe in construction usage. Winsteel Group is professional LSAW steel pipe manufacturer. We have got API 5L PSL 1 and PSL 2 certificate, ISO 9001, ISO 14001, OHSAS 18001 certificate, PED and CPR certificate for several years.

Copper pull basin faucet cold and hot mix water bath basin faucet

Jijin Copper hot and cold basin faucet Double Spouts: Pull-out sprayer provides powerful spray or aerated stream. Filtering spout offers purified drinking water. Convenient & Efficient: Swivel design provides water at easy access. Pull-out sprayer can reach every corner for any task. Easy Operation: Double handles ensures separate, precise control over the water flow of the 2 spouts, simple in use and look.

– Please note that this Copper hot and cold basin faucet wholesale does not come with filter system.

– Constructed from solid brass for durability and reliability.

– Finished in a high quality, corrosion resistant polished chrome.

– hot and cold mixed water list kitchen faucet Features a 360-degree swivel pre-rinse spout design.

– Separate water way for filtered water.

– Includes a stainless steel pullout hose that can be extended to 23.6″ (600mm).

– Not suitable for low pressure. Minimum required water pressure is 0.05 MPa (0.5 bar).

– All mounting hardware and hot/cold waterlines are included.

We are a stainless steel suppliers that has proven experience, certified quality and dependable service. We concentrates on Stainless Steel Sheets materials and Coils.

The body and flanges are integral (non-welding). Shot Blasting for every parts of valve. Phosphating to improve corrosion resistance.

rac valves – ball screw gate valves supplier is a type of large bore gate high pressure valve which were improved from Cameron FLS-R gate valve, its the main component of frac tree, the frac valve is often used on the top of the wellhead on high pressure oil well, can do the frac job for Isolating the fluid from the well. The body and flanges are integral (non-welding). Shot Blasting for every parts of valve. Phosphating to improve corrosion resistance.

Features:

Valve with Ball Screw

Ball screw structure lowers operating time

Stem structure is pressure balanced with switch indicator

wellhead equipment manufacturers Specifications:

Applies to big bore high pressure system

Working pressure:2000 PSI-20000 PSI

Connection: Flange* Thread、Union、BW

Size: 1 13/16″-7 1/16′

Working temperature:K. L .P. R .S. T. U. V

Material Class :AA.BB.CC ,DD .EE.FF.HH

Specification level: PSL1-PSL4

Performance Requirement: PR1. PR2

AQE wellhead valves Application: Oil, Chemical industry, etc.

Medium: Oil、Gas、Water.etc

Learn more information about wellhead equipment,you can visit our website.

Changzhou Tengyue Special Material Technology Co., Ltd ( called in short of Tengyue SMT )

Tengyue SMT is one of leading manufacture and supplier of seamless stainless steel tubes and pipes, duplex steel tubes and pipes and nickel-based alloy steel tubes and pipes for 30+ years. With the trust and support of 500+ partners, our products are applied in more than 50 global markets.

Striving for the high-quality products and constant technological innovation, Tengyue SMT established long-term industry-university-research relations with Changzhou University and Metal Institute, Meanwhile, we actively participate in national science and technology projects and acquired the key technologies of heat transfer tube manufacturing. By carrying out continuous systematic research, the company obtained 25 national authorized patents, including the authorized invention patent closely related to the production technology of the project product “Manufacturing Process of Special Stainless Steel Tubes for Double Tube Sheet Heat-exchangers “.

Certification & Credit Obtained: ISO, Special Equipment (pressure piping components) Manufacturing Licenses and Pressure Vessel PED, etc; in 2019, it obtained E-Park legal person credit certification level A and product quality rating level B.

Manufacturing Annual Capacity: 10000tons

Dimension: OD.6.0 ~ 219.0mm, W.T. 1.0 ~ 22.0mm, Length up to 25 meters.

Materials: 304 & 316 series, duplex steel, and nickel Base alloy 6 and 8 series

Standards: GB, ASTM / ASME, JIS, EN and DIN

Products Applied in key field of petroleum, petrochemical, chemical machinery, nuclear power, boilers, heat exchangers, ships, papermaking, textiles, chemical fiber machinery, medical equipment, environmental protection and other industries.

By constantly updating the production line, improving the production process and the management system and perfecting the detection system, Tengyue Special Material wholeheartedly provides customers with high-quality and highly reliable stainless steel products.

Expanding gate valve consists of one gate body and related gate segment. The contact surface between are designed to milled V structure. AQE Expanding gate valves are available in sizes 2-1/16 “through 4-1/16”. working pressure of 2000 psi through 5000 psi.

wellhead design Features

The upper/lower roller thrust bearing minimizes operation torque;

Seats can be lubricated from grease injection fitting to reduce abrasion and promote long life;

Non-rising stem design minimize operation space

Click here for more information.

Shijiazhuang Jintai Purification Equipment Co., Ltd was founded in 1994 (reformed from a state-owned enterprise to a private limited liability company in 2004), located at No.69, Tiangui Street, High-Tech Zone, Shijiazhuang , Hebei Province.

The company has been committed to the development of metal porous materials and related technologies and applications. As early as more than 20 years ago, Jintai began to focus on the development and production of metal porous powder sintered filter elements. It has 15 invention patents and utility model patents. It has been a high-tech enterprise and has passed ISO9001 quality management system certification. After more than 20 years of technical accumulation, Jintai can now provide customers with a variety of product materials and specifications to meet customer needs.

The company’s business covers all provinces in China, and some products are exported to Germany, Italy, Spain, India, Taiwan and other places. Some large domestic companies have designated the company’s products. The company’s products mainly include titanium filter, stainless steel filter, sparger, filter, filter device and system, sheet and disc, saucer-shaped filter disc, aeration ring and so on. Products are widely used in medicine, metallurgy, petroleum and petrochemical, fine chemicals, food and beverage, air purification, electronics industry, textile industry, water treatment and other fields.

Elbow- Banded Hot-dipped Galvanized Malleable Iron Pipe Fittings with BS Thread

| Product Item | Wholesale malleable iron pipe fitting: elbows, tees, sockets, bends, nipples, unions, crosses, flanges, plugs, backnuts, crosses over, round caps, etc. |

| Material | Malleable cast iron |

| Technics | Casting |

| Size | 1/8″-6″ |

| Edges | Banded, beaded or plain; with or without Ribs. |

| Malleable cast iron elbow Thread Standard | BS ANSI & DIN |

| Finish | Black, Eclectic Galvanized, Hot Dipped Galvanized, all be antirust treatment |

| Shape | Equal, Reducing |

| Grades | Heavy series, Standard series, Medium series, Light series |

| Packaging | Cartons, woven bags, wooden boxes |

| Quality Control | Excellent material, precise angles, good antirust property |

| malleable iron pipe fittings manufacturer Usage | Suitable for joining pipe lines of team, gas, oil, air |

| Certificate | ISO9001:2000; SGS Certificate |

| Others | 1.Special design available according to requirement. |

| 2.MOQ: 1000pcs. Negotialble as per type. | |

| 3.Packaging:In cartons or bags with/without pallet |

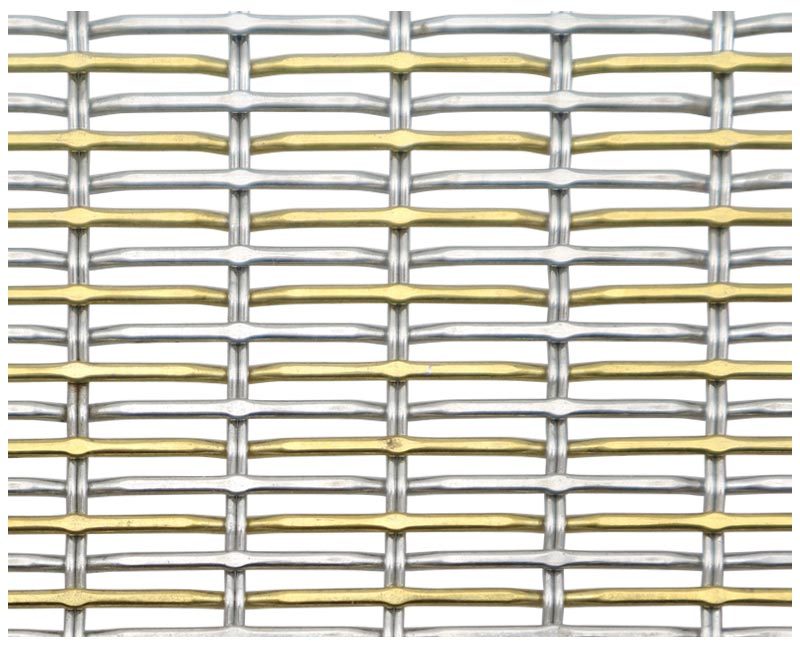

Flexible stainless steel cable mesh

Flexible stainless steel cable mesh, also called stainless steel cable mesh or stainless steel rope mesh, it is made of high quality stainless steel wire cable. According to the production process can be divided into ring type and interweave type. It is mainly used in the construction of wildlife parks, large animal pens or birdhouses, garden greening walls and handrail fillers or safety nets.

The Bzwiremesh plant has been producing this product since 1990. The independently developed equipment and skilled technology of the plant ensure the delivery of high quality products and perfect service on a global scale.

Flexible stainless steel rope net by S.S. SUS304, SUS316, SUS316L and other various material types of wire rope, two main strand structure: 7 * 7 and 7 * 19. Our mesh products are divided into two main lines according to the type of weave: interweave and ferring. Ring type series according to the ring material is divided into aluminum alloy mesh and stainless steel mesh.

Advantages of BZ stainless steel rope mesh:

High tensile strength, light weight;

Good weather resistance and corrosion resistance;

With good transparency, you can watch the animals and appreciate;

Large mesh span allows for large surface mounting.

Steel Dealers in Chennai is one of the top leading companies. They are best in supplying all types of steel for building construction. They also make avail of products like TMT bars, M.S angles, M.S channels, R.S joist, M.S rounds, M.S wire rods, rails, HR sheets, HR coils, HR plate, CR sheets and GP/GC sheets.

Changsong industrial equipment (Shandong) Co., Ltd. is an innovative and technological & international industrial solution company, established by the management team of Shandong University MBA graduates. Based on experience and international cooperation with SIEMENS-VAI (Primetals), Xstrata, Glencore, SMS, DME, Koniambo, Metso, Vale, SDEPCI, SDM, WESCO, Hiab and other world-renowned companies, through integration of well-known industrial products and spare parts supply channels of headquarters, our business ranges from supplying Complete sets of metallurgical equipment and spare parts,Bisalloy Shangang, fireproofing of shangang, transportation equipment and facilities. Include steel, casting, forging and other metal materials to supplying high-end mechanical and electrical equipment, and instruments.

We have thousands of sub-vendors for the business of joint manufacturing, we also work as agent of many world-renowned brands, we have broad overseas channels accumulated over the years, working together with our strategic partners to provide lean supply chain services, focusing on high-quality customers, to solve the customer’s urgent, special, small orders. JGPI also help all types of enterprises to develop overseas markets, provide commercial and technological consulting services for domestic and foreign enterprises supporting by various industry associations, research institutions, and teams of expert.

Serving your needs of industry

Meeting your demands of advanced instruments

Providing quality and economic hydraulic parts

Service

- Project routine procurement

- Project supplementary procurement

- Production material procurement

- Spare parts procurement

- Collected manufacturing of equipment

- Repair of equipment

- International marketing

- International consultancy of technology and commerce

- Integrated cooperation of project

We focus on the introduction of advanced products and technology to China, the introduction of creative products and enterprises to overseas markets. We integrate industry and expert resources to provide services in fields of energy, environmental protection, metallurgy, chemical, medical, research and other industries. Our corporate culture:

Customer Value Oriented

Customer Trust as the Goal

Quality and Safety as the Gene

We insist on continuous improvement, prevention, access to the trust of suppliers and customers to jointly ensure the smooth progress of the project, to make the world better through our joint efforts.

Seamless Cold-Drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes – ASTM A179/A179M grade pipe temperature withstanding capabilities, it is applied to steel pipe of tubular heat exchanger, condensers and similar heat transfer equipment. ASTM A179 seamless tubes are used in For tubular heat exchangers,condensers,and similar heat transfer apparatuses. , cement and construction industries,water pump,oil pump,mud pump,petrochemicals and steel plants.

- Application:

- apply to the heat exchangers, condensers and heat transfer equipment and similar pipe.

- Production Standard, Grade, Steel No:

- ASTM A179/ASME SA179

- GB6479 10, 20, 16Mn, 15MnV, 12CrMo, 15 CrMo, 12Cr2Mo, 12SiMoVNb

- Delivery conditions:

- Annealed, Normalized, Normalized and Tempered

- Mill test certificates will be issued according to EN10204 3

- Packing: packed in wooden crates, wrapped in plastic, and suitably protected for sea-worthly delivery or as requested.

- Size (mm):

- Outer Dimensions.: 6.0mm – 114.0mm

- Wall Thickness:1mm – 15 mm

- Length: max 12000mm

- Inspection and Test:

- Chemical Composition Inspection, Mechanical Properties Test(Tensile Strength,Yield Strength, Elongation, Flaring, Flattening, Bending, Hardness, Impact Test), Surface and Dimension Test,No-destructive Test, Hydrostatic Test.

- Surface treatment:

- Oil-dip, Varnish, Passivation, Phosphating, Shot Blasting.

- Both ends of each crate will indicate the order no., heat no., dimensions, weight and bundles.

美国联合钢铁工业有限公司(USI Group)是中国最大的钢管集团之一,成立于1989年,海外总部位于新加坡,国内总部位于中国江苏省苏州市苏州工业园区。

USI集团拥有20个分支公司,总资产:10亿美元,员工10000多人,以及6个工厂(分别位于天津,苏州和沧州市),用于生产电焊管(ERW,SSAW和LSAW),无缝碳钢管,镀锌焊接管,方形/矩形钢管,不锈钢管/盘管/板/片,管件,法兰等。

我们先进的设施以及在生产的各个阶段均具有出色的质量控制,可确保产品质量,因为由于我们优质的产品和出色的客户服务,我们赢得了客户的满意并在油气管道行业中享有良好的声誉,我们的客户包括PDVSA,NIOC,中石化,中石油等。

Beijing Shenghe Zhongtai Stainless Steel Co.,Ltd was established in 2009 and located in Beijing, China. In the past 9 years, we have focused the Stainless steel material and surface finish. We have passed the ISO9001 test in 2011, and applied the brand of “SUNSONG”in same year. Following the company developed by 2016, we have built our manufacturing base of Hebei Shengnuo Metal Products Co.,Ltd In Hebei province which is the biggest manufacturing base for Stainless steel surface treatment in North of China.

We have imported the advanced cutting equipment to do the coil cutting and flatting. And we have all process machines such as Hairline finish, 8K finish, Bead blasted, Vibration, Anti-finger print, PVD machine and Bending machine, Laser cutting machine.etc. Especially only we could do the surface treatment for the with more than 1500mm.

And our factory covers an area of more than 16000 square meters, introduces advanced equipments such as CNC shearing machine, keyway planer, Bending and laser machine, provides full-service of stainless steel processing. Our annual outputs has exceeded 3000 mts. We are capable to provide one stop services for architecture stainless steel decoration from stainless steel surface treatment, processing, fabrication, assembly and installation.

SUNSONG Decorative Stainless Steel Sheets is neat and beautiful which widely used into kinds of outside decoration of buildings and elevator decoration. We could do many treatment on the Hairline surface such as etching, PVD and so on. The surface would be different and welcomed by customers.

For more, please click here to customize your stainless steel furniture decoration.

Ductile iron feed pipe is simple to joint, can be laid in all weather conditions and often without the need for selected backfill. Its high safety factor and ability to accommodate ground movement make it the ideal pipeline material for a wide range of applications.

Ductile iron feed pipe supplier is available in a range of diameters from 80mm to 1600mm and are suitable for both potable water transmission and distribution (in accordance with BS EN 545) and sewerage (in accordance with BS EN 598).

ductile pipe manufacturer is simple to joint, can be laid in all weather conditions and often without the need for selected backfill. Its high safety factor and ability to accommodate ground movement make it the ideal pipeline material for a wide range of applications.

Tongmao Ductile iron feed pipe have a number of advantages over other pipe materials:

Easy to install

Full range of accessories are widely available

Suited to a host of applications both above and below ground

Strength of the material allows it to withstand significant internal pressure and also makes it less susceptible to impact damage

It has the nature of iron, the performance of steel, excellent corrosion resistance, good ductility and easy installation.

The main components are carbon, silicon, manganese, sulfur, phosphorus and magnesium.

The ductile iron pipe lengths is generally six meters, which can also be customized.

If you want to know the ductile iron pipe sizes and dimensions, please contact us