Hebei Deko Commercial Co., Ltd. (hereinafter referred to as the “DEKO”), the company is located in China’s “Land of Casting” Hebei province, DEKO mainly supplies products involved in municipal engineering and road construction and related products, such as Ductile iron Pipe, Pipe Fitting, Valve, Manhole covers, Gratings, Public Illumination, Urban Furnishing, Flange and Pipe Repair Clamp etc…. we can also produce according to the drawings and samples provided by customers, our products have been exported to Europe, Africa, Asia, Middle East and Southeast Asia etc… providing import and export business for domestic and foreign customers.

DEKO has its own fully automatic vertical production line and now we have reached a strategic cooperation with several manufacturers and become the only designated agent service by manufacturers and can be better provide customers with the best prices, excellent product quality, DEKO’s aim is: to supply the required products and high quality service for every customers and maintain long-term and stable cooperation.

南钢制造有限公司是一家专业生产

碳钢管、不锈钢管、结构型材和管件的公司。

其产品广泛应用于核电站、火力发电厂、

原子能发电厂、石油天然气、石油化工、化肥、化工、

医药等领域。南钢拥有丰富的生产经验,

优质的产品和完善的售后服务赢得了广大

客户的信赖。

Our factory is an enterprise manufacturing pipe fittings for more than 30 years. It is supplying Malleable iron fittings, Ductile iron fittings , Gray iron fittings and other steel products, with long history and unchanging faith of producing high quality products.

Main products:Malleable iron pipe fittings, Tube clamps, Air hose couplings, Camlock couplings, Carbon steel pipe nipples, Electric power fittings, Steam couplings, Gas meter connectors etc.

- Founded in 1986, Covering 12,000 square meters, having more than 200 workers. We have a registered capital of 8.88 million, and the annual export volume of 10 million USD.

- As a high-tech enterprise, we have our own R&D team, which can open molds through samples or drawings provided by customers, and even assist customers in developing new products through functional descriptions.

- From purchasing material, casting, annealing, trimming, galvanizing, machining, packing, to exporting, have formed stop production system.

- Various casting techniques: Currently 90% of the products have been changed to coated sand production. And equipped with coated sand production line, which can control the quality requirements of coated sand, and coated sand buried box casting line, further improve the quality of products. Most suitable casting way can be defined according to any products.

- casting surface: our own researched prescription of sand and mold design is used, there’s no joint line, no shift, no sand inclusion, no crack on products, we will satisfy every client.

- Material assurance: on –the –spot sample analysis+ chemical composition analysis after casting, double tests to guarantee stability of material. Electric heating automatic temperature control equipment can precisely control the furnace heats uniformly to ensure product are with the same tenacity.

- Surface treatment: self-color + rust preventing oil, electroplating, hot dip galvanizing, first electroplating and then hot dip galvanizing, first electroplating and then backed galvanizing, first electroplating and then plastic spraying. Different products need different surface treatment, best surface treatment can be defined according to different products.

- Machining technique: we have professional threading machines and CNC lathes to make threads, threads are 100% within specified scope of gauge and plug gauge, included angle of threads is within 90°+-0.5°. High efficiency and high quality producing way make our products have more market value.

- Our certificates: Our factory passed TSE for Turkey, INMETRO for Brazil, and CE, ISO9001:2008, IQNET etc.

- Our clients: Our factory is cooperating with many well-known enterprises, main market for malleable iron pipe fittings is Europe, main market for pipe clamp fittings is U.K., and main market for air hose couplings is USA. There’re also many different kinds of products for specialized application, and are very advantageous in their fields.

Our website:http://www.donghuancast.com

湖南格瑞特钢管有限公司,拥有24年的钢管制造经验,是盛世达集团第一家子公司,是世界一流的埋弧直缝焊管生产和服务商。

Eastern Steel Manufacturing Co.,Ltd is a leading manufacturer and distributor of seamless steel pipe, welded steel pipe, OCTG products and fittings. We supply first-step processing, semi-finished parts and finished parts to help our clients meet fabrication requirements beyond their capacity or to improve operations by moving forward the pre-production processing.

LANDYOUNG GRP pipe is manufactured in accordance with international standard using Helical FILAMENT winding process and Continuous FILAMENT winding process on computer controlled machines.

DESCRIPTIONS

LANDYOUNG GRP pipe is manufactured in accordance with international standard using Helical FILAMENT winding process and Continuous FILAMENT winding process on computer controlled machines.

Helical FILAMENT winding process(Bell and spiogot joints)

GRP Pipe is manufactured using the helical (reciprocal) filament winding process by which impregnated glass fiber reinforcement with resin are applied onto a precision steel mandrel in a prescribed pattern. Repeated application of wetted fibers results in a multi-layered structural wall construction of the required thickness.

Continuous FILAMENT winding process(Coupling joints)

GRP Pipe is manufactured on a continuous filament winding machine. This machine consists of a mandrel composed of a helical wound continuous steel band, supported by beams forming a cylindrical shape. As the formed mandrel turns creating a multi-layered structural wall of the required thickness.

Applications

- Infrastructure &Municipal

- Industrial

- Water Diversion

- Desalination

- PowerPlant

- Petrochemicals

- Oil & Gas and Marine

- Agriculture Irrigation

- Storm Water

- Cooling Water

- Hydropower penstock

Advantages

Minimum 50 years service life

LANDYOUNG GRP pıpes are manufactured with corrosion resistant non-metallic raw materials. Since corrosion is not a problem, cathodic protection and extra insulation against corrosion are not needed; thus operational expenses and difficulties do not exist.

Light weight

Weight of GRP pipe:1/4 of steel pipes; 1/10 of concrete pipes

Can be transported as nested, providing great savings

Quick and easy installation, no need for heavy and expensive equipment

Excellent hydraulic properties

Hazen Williams flow coefficient is 150(c=150). Due to the low friction losses, less pumping energy is required.compared to steel and concrete pipes, same flow rates can be ensured using smaller diameters.

No lime or deposit formation inside

Unlimited service area-application in every environment

Can be installed underground, aboveground, and also underwater.

Bell and spigot joints and coupling joints ensure total leak-tightness.

Flexible:successful experience in earthquake regions

Can be installed inside old lines for relining.

LANDYOUNG GRP pipes are environmentally friend

If you are interested in our products, please visit our website

Product Range and properties

| LANDYOUNG offers a wide product range of GRP pipes and fittings to meet Specific requirements of any project. | ||||||||||

|

||||||||||

I

Jade Special Metals is India’s 10th largest supplier, trader & Exporter of Stainless Steel, Carbon steel pipes and round bar. We are specialised in Stocking & Distributing various Stainless Steel, carbon steel pipes, round bar & sheet plates to worldwide for specific & urgent requirements.

As a well-known local seamless steel pipe Exporter and supplier, we produce a wide range of products mainly in materials, types and sizes. Tycoon piping contain stock and supply seamless pipes for boiler in every standard and commercially available lengths according to your requirements.

As the most valuable subsidiary under SHINESTAR STEEL GROUP, PRIME STEEL PIPE is the solution provider for steel pipes and fittings. We are dedicated in providing high performance-price ratio steel pipes and fittings for the oil, gas, construction, energy and petrochemical industries. In prime steel pipe, we believe honest communication, expertise in steel industry, and prompt execution lead to strong long term relationships. Our professional team provides “one-stop procurement” service to coordinate with clients projects regulation, site and terrain. We ensure the best quality of products by assigning skillful experts at every stage of activities. To keep the honesty in mind, to win reputation by trust is our principle.

Copper Mould Tube & Plate

We specially in supplying Copper Mould Tube, Crystallizing equipment of continuous casters, Mould cooling jacket, Repair of Metallurgical Copper Mould Tube, etc.

Equipments & Spare parts for Continuous Casting Machine.

- Copper mould tube( square, rectangle and round )

- Crystallizing equipment of continuous casters

- Mould cooling jacket.

- repair of copper tube moulds

The copper alloys chosen for the moulds must maintain their physical properties at the operating temperatures of the continuous casting process.

The temperature gradation from the inner wall of the mould to the outside face of the mould can cause serious distortion problems, and Metallurgical Copper Mould Tube is imperative that the correct alloy is chosen for the various operating conditions.

Square Copper mould tube STANDARD MATERIALS

Phosphorus de-oxidised copper

This alloy has been proven to be excellent for the manufacture of moulds in the continuous casting of billets. The main composition of this alloy are Cu +Ag 99.90min, P0.0015 / 0.040.

Copper -Silver alloy

The addition of a small amount of silver, whilst not increasing the melting point of copper, does increase the recrystallisation temperature by almost 100℃, and also helps to give better thermal conductivity at the operating temperatures.

This alloy is normally used in moulds for the continuous casting of blooms and slabs .In this case, the moulds are much thicker than in the billet moulds, and the moulds temperature can be higher. The main composition of this alloy are Cu+Ag99.90 min. Ag 0.08 / 0.12 O 0.004 / 0.012.

The continuous casting of molten steel into billets, blooms and slab products, has been highly refined over the years into an extremely sophisticated system. The continuous casting process is expected to produce metallurgically sound products at the lower possible cost, and this is being achieved in many steelworks throughout the world.

Copper moulds have played an important role in the development of the continuous casting process. Their funcition is to receive the molten steel and to allow rapid heat transfer from the steel to the cooling water to enable quick solidification.

The mould must exhibit excellent thermal conductivity, be resistant for thermal erosion ,and be resistant to distortion from thermal stress. So far only copper and a few copper alloys meet the above conditions, both economically and technically.

Mould cooling jacket supplier SOLIDIFICATION

The rate of solidification in the continuous casting process dictates the speed of production. The molten steel, which is in contact with the inner faces of the copper mould, starts to sllidify as rapidly as the heat is extracted, forming a shell. The shell increases in thickness as more heat is extracted, and eventually total solidfication is achieved. the process is similar to the solidification of ingots in ingot moulds. In continuous casting, the whole process is speeded up, with the aim to produce and homogeneous shell growth. Consequently, the mould is an important part of the continuous casting process, and the manufactured quality of the mould plays and important role in their length of life.

INNER SURFACE COATINGS

Over the years, Metallurgists and Engineers have been working together to develop better continuous casting moulds. The steel companies require a more economical mould which will give a longer service life. Surface coating of the inner walls of the mould has given the best results to date. Coatings available are Chromium and Nickel plating. Also, a combination of the two give good results on slab casting.

SPECIFICATIONS OF COPPER MOULD

Square 60 x 60 – 350 x 350 (mm)

Rectangle 120 x 160 – 180 x 300 (mm)

Diameter 100-400 (mm)

Size(mm): 90×90, 100×100, 110×110, 115×115, 120×120

130×130, 135×135, 140×140, 143×143, 150×150

155×155, 160×160, 165×165, 175×175, 180×180

200×200, 220×220, 100×170, 100×173, 130×240

150×200, 150×210, 150×220, 160×200, 160×220

150×225, 160×235, 165×225, 175×225, 180×220

200×240, 240×240, 235×235

Radius(mm): 4000, 5000, 5250, 6000, 7000, 7500, 8000, 9000, 10250, 10300, 11000, 12000

Length(mm): 700, 750, 780, 790, 800, 810, 812, 850, 900, 1000

We are one of the leading Suppliers and Exporters of Tube Fittings, Pipe Fittings Threaded, and Ferrule Fittings, Needle Valves, Ball valves, Manifold Valves, hex nipple in Mumbai India.

Ceramic lined pipe is made through the self-propagating high-temperature synthesis (SHS) technique.

Self-propagating High-temperature Synthetic process

Self-propagating high-temperature synthesis (SHS) is used to describe a process in which the initial reagents (usual powders), when ignited, spontaneously transforms into products due to the exothermic heat of reaction.

The combination of high rigidity of ceramic and high elasticity of steel gives the pipe unmatchable features like abrasion resistant, heat resistant, and corrosion-resistant material for use in the fields of power generation, metallurgy, mining, and chemical industry, etc. It has many advantages over steel pipes, cast stone pipes, and steel-plastic compound pipes.

Usage of Ceramic Lined pipe

The ceramic-lined pipe transportation has been widely used in the industries of electric power, metallurgy, coal, petroleum, chemical engineering, building materials, mechanism, and so on.

The ceramic lined elbow throughout the power, metallurgy, coal, petroleum, chemical, building materials, machinery, and other industries, and high-speed development. When lining the wear-resistant ceramic elbow to deliver high grinding material (such as ash, coal, ore powder, etc.), there is a lining of wear-resistant ceramic elbow wear fast, especially the elbow Wear faster. When lining a ceramic-lined elbow to deliver a highly corrosive gas, liquid or solid, there is a problem that the lined wear-resistant ceramic elbow is corroded and is quickly damaged.

There is a problem that it is expensive to use a heat-resistant steel pipe when the material having a higher temperature is conveyed in the lining of the wear-resistant ceramic elbow. After lining the wear-resistant ceramic elbow, these problems are solved.

The ceramic lined elbow is widely used in wear and tear of mine filling material, ore powder and tailings transportation, coal-fired power plant powder, smelting, ash and other things lined with wear-resistant ceramic elbow are also very appropriate.

The ceramic lined pipe, Elbows, Reducer, Tees, and others manufactured in our factory have been used in over 200 thermal power plants, more than 50 mines, and the industries of coal, building materials, mechanism, petroleum, and so on.

Abrasion

Ceramic layer Ceramic Lined Reducer Pipe with flange reducer Al2O3 content greater than 89%, micro-hardness HV1000-1500, which has high abrasion resistance, wear resistance more than ten times higher than carbon steel after quenching, superior tungsten carbide drill.

Application range

- coal pulverizing system of power plant pipeline, including, powder transmission pipeline, thick powder separator pipeline, coal drop pipe, combustion system of a windpipe, a secondary air pipe, three pipeline and burner pipelines, in addition to ash slagging system the discharge pipe, powder pipe, dry ash conveying pipe;

- Iron and steel plant raw material conveying pipeline, collecting pipe, dust pipe, ash pipe, ash pipe, mixing pipe, grinding export pipeline, coal pipeline, coal pipeline, separator pipe, burner radius pipe, etc.;

- Cement plant selection machine outlet pipe, choose machine inlet pipe, pipe dust pipe, vertical mill outlet pipe, circulating air duct, high-temperature air blower, lower material pipe, etc.;

- Petroleum, chemical, mining, coal, coal washing plant, smelting, paper, aluminum, building materials, powder engineering, food machinery, and other processing and conveying material pipes.

Corrosion

Ceramic materials are neutral, chemically stable, have excellent corrosion resistance and acid resistance, resistant to various inorganic acids, organic acids, organic solvents, and their degree of corrosion of stainless steel is more than ten times.

Temperature

Temperature above 2000celsius degree, long-term work in the range of -50 -900 celsius degree.

Easy welding.

The ceramic adjustable tube can be welded, flanged, flexible connectors, and other fast way links, very easy to install.

Clean and easy maintenance

Smooth walls, can prevent scaling, fouling, and self-cleaning functions. Tightness.

Remarks:

- Under the direction of the arrow diagram for the export direction.

- Bend radius is usually 1.5-5 times the diameter of steel pipe (1.5-5D).

- Othe specifications of the composite pipe can be manufactured according to the user requirements.

- The weight is calculated by theoretics, maybe have some tolerance, and real weight will be weigh-in after they finish.

Hoop strength is the resistance against radial pressure. The strength of the ceramic-lined steel composite pipe is 300 to 500MPa.

Features and Advantages of ceramic lined pipe

Ceramic Liner pipe is a high technology production technology-self-fuel high-temperature clutch synthesis method.

1). High Abrasion Resistant:

Vickers hardness of the corundum lining is HV1100 to1500, as high as that of tungsten-cobalt hard alloys, and the abrasion resistance is 20 times as carbon steel pipes. The composite ceramic-lined steel elbow was used in a mining plant for about fifty thousand hours. The general service life of a common steel elbow is about 700 hours.

2). Corrosion Resistant:

Corundum is a neutral material and is acid-proof and fouling-free.

3). Heat Resistant:

Ceramic lined composite steel pipes can work under circumstances of -50 to 800 Celsius degree.

4). Lower Weight and Convenient Installation:

The ceramic-lined steel pipes are lighter than alloy pipes, cast iron pipes, and cast stone pipes and can be welded or connected through flanges, which reduces the expense of transportation and makes the pipes easier to install.

For the pipes with the same sizes, types, and lengths, the weight of the ceramic pipe is about 1/2 of the wearable cast alloy steel pipe’s, while the cost has reduced 10%~20% per meter.

The weight of ceramic-lined steel pipe is about 1/3 of the cast stone bent pipes, 1/2 of the cast stone straight pipes.

Ceramic (Corundum: a-Al2O3) lined abrasion resistant straight pipe and fittings are lined with highly abrasion-resistant ceramic by SHS ——-Self-propagating High-temperature Synthetic process.

- The ceramic-lined steel composite pipe can be joined by welding the steel pipe layer.

- Ceramic-lined pipes can take place of expensive stainless steel, titanium, nickel, cast stone, or alloy pipes.

- Extended service life can also reduce maintenance costs.

Self-Propagating Ceramic Pipe

Self-propagating ceramic steel pipes create a new generation of abrasion and corrosion-resistant engineering pipelines.

The self-propagating ceramic steel pipe has very good wear resistance, Excellent corrosion resistance, and Excellent thermal resistance performance.

SHS-self-propagating ceramic steel pipe and elbow create a new generation of abrasion and corrosion-resistant engineering pipeline. The composite pipe is composed of three layers: ceramic, intermediate, and steel layers.

The ceramic layer is formed by molten alumina at a temperature above 2500 degrees. The molten alumina produced from the reaction Fe2O3+2Al=2Fe+Al2O3 spreads on the inside wall of the steel pipe under the influence of a centrifugal force, then solidifies, so the ceramic layer has high density and smooth surface and bonds to the steel pipe.

Applicable Industries:

- The pipe needs excellent wear resistance property: Power plant, Mining, Sea Port, Coal Plant, And pipe for transporting the powder, slurry, sand, etc.

- Coal washing plant, pipe for transporting coal and other material.

- Pipe for transporting the melted aluminum.

- Any pipe which needs to wear protection, corrosion protection, etc.

Benefits:

- Excellent wear resistance, Alumina content of the ceramic liner is higher than 95%, Hardness HV1000-1500. The wear protection performance is more than 10 times better than carbon steel after quenching,

- Excellent corrosion resistance, stable chemical properties.

- Excellent thermal resistance performance up to 2000℃ Can be used in the area from-50℃ to 900℃ for a long time.

- Can be connected with another pipe by welding, flange and soft fast connecting, and easy installation.

BESTAR is a China-leading product service provider and exporter of steel pipe, also the most valuable subsidiary of Shinestar Holdings Group. BESTAR passed the SGS Certification of China Supplier System, ISO9001 Quality Management System Certification, ISO 14001 Environment Management System Certification, ISO45001 Occupational Health & Safety Management System Certification and CE certification, got comprehensively high score in the HuaXia D&B assessment and has been rated AAAAA credit enterprise by China Credit Evaluation Association. BESTAR, committed to provide professional service to global clients including the lowest price support, professional technical support, flexible payment methods, strong financial support, the integrated procurement program as well as comprehensive bidding program to help customers create value, has become the most reliable partner in the steel pipe industry.

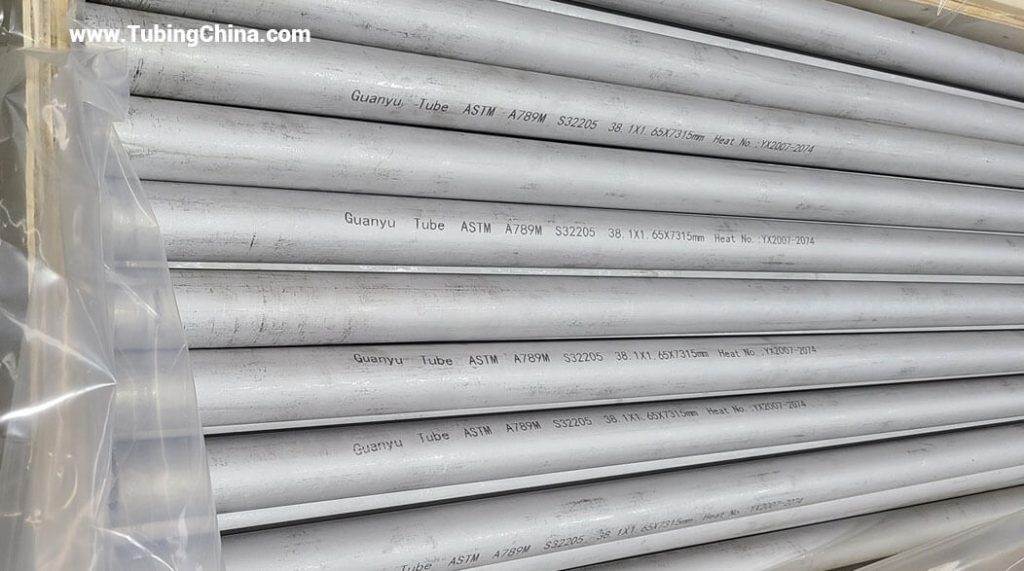

ISO9001:2015, PED 2014/68/EU certified. Zhejiang Guanyu Steel Tube Co., Ltd is specialized manufacturer of High Quality Stainless Steel Tubes & Pipe, Nickel Alloy Tubing & Pipe in China. Production area covers an area of 35,000 square meters. Annual output capcity more than 10,000 metric tons.

We have built a complete quality management system and organization according to ISO 9001:2015 and PED 2014/68/EU. Quality control begin with an audit trail and continues from the point of steel melting. for the raw materials, we select the best quality raw material for our customers. right through to the finished product. This level of attention to detail extends throughout the design and manufacturing chain, all kinds inspection will be all though the producing process ensure the Stainless Steel Tubes/Tubing/Pipe and Nickel Alloy Tubes/Tubing/Pipe finished in qualified. With destructive and non-destructive tests according to standard specification and customer’s special requirement, and including verification of performance by independent third-party test houses.

Steel tubes India is manufacturer and exporter of cold drawn seamless, welded and ERW steel tubes and pipes.Steel Tubes India is industrial steel pipes suppliers to Oil & Gas piping, petrochemical refineries & Chemical processing industry.We are Stockist & Supplier of Stainless Steel, Alloy Steel, Carbon Steel, Mild Steel, Nickel Alloys in form of Seamless Tubes, Welded & ERW Pipes & Tubes.

Changzhou Tengyue Special Material Technology Co., Ltd ( called in short of Tengyue SMT )

Tengyue SMT is one of leading manufacture and supplier of seamless stainless steel tubes and pipes, duplex steel tubes and pipes and nickel-based alloy steel tubes and pipes for 30+ years. With the trust and support of 500+ partners, our products are applied in more than 50 global markets.

Striving for the high-quality products and constant technological innovation, Tengyue SMT established long-term industry-university-research relations with Changzhou University and Metal Institute, Meanwhile, we actively participate in national science and technology projects and acquired the key technologies of heat transfer tube manufacturing. By carrying out continuous systematic research, the company obtained 25 national authorized patents, including the authorized invention patent closely related to the production technology of the project product “Manufacturing Process of Special Stainless Steel Tubes for Double Tube Sheet Heat-exchangers “.

Certification & Credit Obtained: ISO, Special Equipment (pressure piping components) Manufacturing Licenses and Pressure Vessel PED, etc; in 2019, it obtained E-Park legal person credit certification level A and product quality rating level B.

Manufacturing Annual Capacity: 10000tons

Dimension: OD.6.0 ~ 219.0mm, W.T. 1.0 ~ 22.0mm, Length up to 25 meters.

Materials: 304 & 316 series, duplex steel, and nickel Base alloy 6 and 8 series

Standards: GB, ASTM / ASME, JIS, EN and DIN

Products Applied in key field of petroleum, petrochemical, chemical machinery, nuclear power, boilers, heat exchangers, ships, papermaking, textiles, chemical fiber machinery, medical equipment, environmental protection and other industries.

By constantly updating the production line, improving the production process and the management system and perfecting the detection system, Tengyue Special Material wholeheartedly provides customers with high-quality and highly reliable stainless steel products.

Nansteel Manufacturing Co.,Ltd manufacture and supply differenet steel products, like

seamless steel pipe, carbon steel pipe, stainless steel pipe, casing etc.For

more,visit:https://www.nan-steel.com/

Rafit Metal & Alloys produces and Exports impeccable and super compound darting which incorporates: Hex screw, Hex Nuts, Stud fasteners, Threaded Bars, Washers, Hex attachments and so forth according to guidelines ASTM, ASME, DIN and UNI. The application enterprises are oil and Gas, Chemical, Petrochemical, Power and Energy and Marine industries(On Shore/Offshore).

Unifit Metalloys is one of the leading Pipes Manufacturer, Dealer, Supplier and Exporter of Buttwelded Pipe Fittings, Socket Weld Fittings, Threaded Fittings, Forged Fittings, In India. Quality Forge and Fittings is the name of a brand trusted worldwide and used in all leading industries. Trust is the synonym for Quality Forge and Fittings.

We, R-PIPE OVERSEAS Are BIGGEST STOCKHOLDER & EXPORTER of Pipeline Products and Exporting to More Than 40 Countries Including U.S.A, Europe,

Gulf & Asian Countries And Regions In The World. Our High – Quality Products And Strong International Reputation In The Industries Related To The

Chemicals, Engineering, Pharmaceuticals, Fats & Fertilizers, Sugar Mills & Distilleries, Cement Industries, Ship Builders, Paper Industries, Pumps & Petrochemicals,

Textile, Dairy, Oil & Natural Gas, Allied Industries Organization In Term Of The Specific Materials, Technology Are Highly Valued By Indian & Foreign Customers.

Materials:

PIPES | TUBES | PLATES | SHEETS | FLANGES | FASTENERS | FORGED FITTINGS | BW FITTINGS | ROUNDBARS. IN HIGH NICKEL ALLOYS | DUPLEX STEEL | STAINLESS STEEL | ALLOY STEEL | CARBON STEEL ETC.

REGARDS

ARVIND JAIN – SALES HEAD

R-PIPE OVERSEAS

T: +91 22 6659 5201

M: +91 9930551137

Whatsapp: +91 9082065807

Skype: asj.rpipe

E: info@rpipeoverseas.com & rpipeoverseas@gmail.com

W: http://www.rpipeoverseas.com

A: Shop No. 28, Gr. Flr, 153/154, Shree Ishwaleshwar Siddhesh Deep CHS,

PB Marg, Mumbai – 400008. (INDIA)

GST TIN NO.: 27ALTPJ6984G1ZB