Iron Slag Pot for Steel Mill is an essential container for collecting slag generated during steel making. Iron Slag Pot for Steel Mill is made of refractory steel.

Double-twist stranding machines, high-performance twisting machines

Double Twist Stranding Machineare effective, compact production units primarily for use in the manufacture of highly flexible braids, bundled braids, for stranding pairs of wires, triples, quadruple designs …

The machine concept differs from the single-twist system in that one rotor turn generates two cable twists / turn. The braid is given the first twist at the stranding point of the system feed. At this point, the stranding material still has twice the length of lay of the desired final geometry. The final braid length of lay with the second stranding twist is only completed at the second turning point, before being introduced back into the static coil former.

BOW DOUBLE TWIST STRANDING MACHINE

Application for:

Multistrand 7 or 19 copper wire, aluminum wire, tinned copper conduct etc. Also multistrand insulated conduct for power cable, data cable, control cable etc. Laying up of 2/3/4 cores of small size building wires.

Bow Double Twist Stranding Machine Description:

Payoff

Double twist stranding machine

PLC control system with color touch screen

Advanced function (Optional):

1:Motorized payoff or back-twist payoff, tension keep stable from start to end.

2:Bow material : carbon fibre

3:Brake: serve motor

4:Motorized driven capstan. Lay length set on touch screen, no need to change gear mechanically.

5:Auto lubrication system: regularly lubricate important parts to prolong machine service life.

COMPUTER SIMULATION OF AN INDUSTRIAL WIRE DRAWING PROCESS

Wire Stranding Machine is an important industrial process. Wires are reduced in diameter through a series of die/capstan combinations which provide the desired reduction steps. Typical wire drawing machines within BICC Cables Ltd use up to twenty-one dies in one line and it is necessary to optimise the die drafting for each machine and final wire diameter to obtain good machine efficiency and high quality product. An important aspect in the manufacturing process is to avoid wire breakages with the resultant loss of production due to short final lengths and the associated time required to restring the drawing machine. In order to optimise the conditions for each machine and wire size, computer simulations of the process are used to predict performance by estimating factors such as the ratio of drawing stress to ultimate tensile stress, drawing force, back tension and heat generated.

A computer simulation of the multi-line wire drawing process for copper wire has been modelled by the Wrexham Technology Centre of BICC Cables Ltd using a bulk model. The redundant work during the drawing process was included by formulation and equations for the redundant deformation were derived that were in good agreement with published experimental work.

A new computer simulation has been developed to predict the performance of wire drawing process. The model uses a one dimensional explicit finite difference method to determine the plastic deformation in the dies. The redundant work formulation was used as in the previous simulation. This paper describes the numerical methods used and compared the results from the new computer simulation with the previous bulk model. Significant differences are predicted in the stress ratios, drawing force and heat generated for process predictions. The new simulation of the plastic deformation in the dies also indicated optimum semi-die angles away from the traditional eight degrees.

7 Wire Tubular Type Stranding Machine

Owing to the vast industry experience and in depth knowledge of this domain, we are offering a huge collection of high quality 7 Wire Tubular Type Stranding Machine. These products are manufactured using optimum quality raw material. These products are easy to install and requires low maintenance. Customers can avail these products from us at market-leading prices

Basket Type Stranding Machine

Basket Type Stranding Machine is mainly used to strand not only copper/aluminum conductor for the electric wire and cable but also the cable core, steel core, and steel rope. Machine’s make-up: pay-off, driving part, cylindrical part, hydraulic brake device, wire –bobbin frame, die-holder, haul-off device, spindle-type take-up/traversing (Φ50 bar traversing) and an electrical control part, etc.

Rigid Stranding Machine

The Rigid Stranding Machine is used for stranding CU, Al wires, and conductors. Stranding unilay and reverse concentric, round, compressed, compacted or sector-shaped ( straight or spiraled) as per customer requirements.

Main features:

Self-supporting rigid rotor design with 1 6 12 18 24 30 36 Bobbin Cage

High efficiency and speed

Bobbins mounted on pintles

A line drive by A.C. or D.C. motors with electronic or mechanical synchronization between line components.

Different braking device for bobbins

Centralized lubricating system for bearing

Disk type Pneumatic brake for Cage.

Machines with or without back twist

MMI /PLC Equipped, optional

Easy Lay Setting

High Speed Tubular Stranding Machine

High Speed Tubular Stranding Machine with back twist, for 1+6 Bobbin copper / aluminum round & compact conductors and steel wire stranding. This strander is for manufacturing high carbon & low carbon steel wire rope, copper & aluminum conductor

Bow Type Stranding Machine

The Bow Type Stranding Machine is suitable for a wide range of productions, obtained with high speed and productivity; the back twist process gives high quality products. The Bow stranders use components made with most modern materials, like carbon fiber for the bows, tungstene carbide for bushes, hardened steel for rollers.The control of tension of the cores is assured with electro-mechanical or pneumatic self compensated brake, with set up by control panel.The safe use is assured with control of bearing temperatures and supports vibration.The machine is protected with a soundproof cover, with pneumatic open, inside fans and lights.Is possible the bobbins side loading with a motorized trolley, that avoids the use of bridge cranes and reduces dramatically the total loading time of the line.

For Cables Industry:

Stranding of conductors made with copper, aluminium, aluminium alloy, aluminium steel reinforced or supported;

Laying up of 2 – 7 round insulated cores for low and medium voltage;

Laying up of 2 – 7 straight sector shaped insulated cores, with the rotating cradles version;

Possible application of fillers and tapes of every type.

Tubular stranding Machine

The Tubular Stranding machine consists of bearing stands made of welded steel for the tube bearings. Up to reel size of 630mm .The stranding rotor is built up from welded tubes with wire guidings outside the tube. The reels are held in cradles, which are positioned inside the tube. A light beam along the complete length of the machine monitors, if the pneumatically (optional)operated reel-pintles are securely closed and the cradles are in safe condition. The machine is equipped with wire break detectors for each segment, pneumatic disk-breaks and individual drives for the Stranding Rotor, the Capstan and the Take-Up. The operator’s desk gives full control over parameters like Rotor-speed, lay-length and production length.

Main Features:

• Machine placed on a Rigide steel frame with rotor support, fixed on the floor for an easy installation

• Tube rotating on encircling bearings or rollers

• Machine able to work in torsion or total back twist with the possibility of partial back twist

• Wire back tension kept constant from full to empty spool payoff

• Wire/strand break detector for each payoff unit(optional)

• Spool loading/unloading by crane

• Pneumatic pintles equipped with safety locking system

• Independent driving motors for tube, capstans and takeup units

• A.C. motors with flux vector control inverter

HEBEI YOGEM is a supplier of OEM castings.

The materials are mainly involved in grey iron/ductile iron, aluminum alloy, stainless steel, duplex/supper duplex, alloy steel, heat-resistant steel etc. We produce them by lost wax (silica gel; water glass), pre-coated sand and resin sand.

Over 95% of our products are exported to more than 15 countries, such as USA, Canada, European Union countries, Japan, Australia, South Korea and other countries.

Both raw castings and machining components can be done in our work-shop.

Our products are widely used in the filed of pumps, valves, oil & gas, automotive, food machine, agriculture machine, construction and so on. Through many years improvements we have built a complete supply chain including foundries, machining facilities and inspection centre.

Besides technology and innovation, we pay more attention to environmental protection.

More about HEBEI YOGEM Casting Parts, please click:http://www.hebeiyogem.com

Beijing Shenghe Zhongtai Stainless Steel Co.,Ltd was established in 2009 and located in Beijing, China. In the past 9 years, we have focused the Stainless steel material and surface finish. We have passed the ISO9001 test in 2011, and applied the brand of “SUNSONG”in same year. Following the company developed by 2016, we have built our manufacturing base of Hebei Shengnuo Metal Products Co.,Ltd In Hebei province which is the biggest manufacturing base for Stainless steel surface treatment in North of China.

We have imported the advanced cutting equipment to do the coil cutting and flatting. And we have all process machines such as Hairline finish, 8K finish, Bead blasted, Vibration, Anti-finger print, PVD machine and Bending machine, Laser cutting machine.etc. Especially only we could do the surface treatment for the with more than 1500mm.

And our factory covers an area of more than 16000 square meters, introduces advanced equipments such as CNC shearing machine, keyway planer, Bending and laser machine, provides full-service of stainless steel processing. Our annual outputs has exceeded 3000 mts. We are capable to provide one stop services for architecture stainless steel decoration from stainless steel surface treatment, processing, fabrication, assembly and installation.

SUNSONG Decorative Stainless Steel Sheets is neat and beautiful which widely used into kinds of outside decoration of buildings and elevator decoration. We could do many treatment on the Hairline surface such as etching, PVD and so on. The surface would be different and welcomed by customers.

For more, please click here to customize your stainless steel furniture decoration.

HuaYi Casting Foundry and LianJiang Metals Company are two collaborative enterprises owned and operated by same management team.

-LianJiang Metals Company designs and markets products.

-HuaYi Casting Foundry focuses on manufacturing the products.

Located in Liaoning province in northeastern China, HuaYi Casting Foundry and LianJiang Metals Company have specialized in aluminum and iron casting production since 1997. We are an OEM partnership that manufactures cast aluminum and iron parts for clients all over the world and in different industries such as street lighting, patio furniture & garden decoration company.

With over 20 years of casting work experience and expertise, we offer a full range of casting processes including:

-sand casting

-gravity casting

-die-casting

-vacuum casting

1>The payment term is flexible according to the order quantity, price, and other factors.

2>We have no Minimum Order Quantity (MOQ) limitation on orders. Therefore, you can place your order at whatever size quantity fits your specific needs.

3>Our typical production lead time is about 6 weeks but could be flexible and adjust depending on a customer’s request. Short lead time periods are possible in order to meet a customer’s urgent order delivery need.

4>We will sign a confidential agreement with the customer and will never disclose a customer’s name, designs, or drawings to another other third party.

All related information is protected and secure in our factory.

5>The payment term is flexible according to the order quantity, price, and other factors.

6>We provide customers with prompt after sales services for any quality issue.

7>We have ample capacity to provide the customer with consistent high quality casting work: smooth surfacing, accurate dimensions, and strong mechanical properties.

Our website:http://www.ljmetals.com

Stainless Steel Sprocket Product Description

1. Description: This range of sprockets are made from 304 stainless steel material.

2. Standard: British

3. Feauture:

Corrosion resitance

Good quality

Competitive price

Customized possible

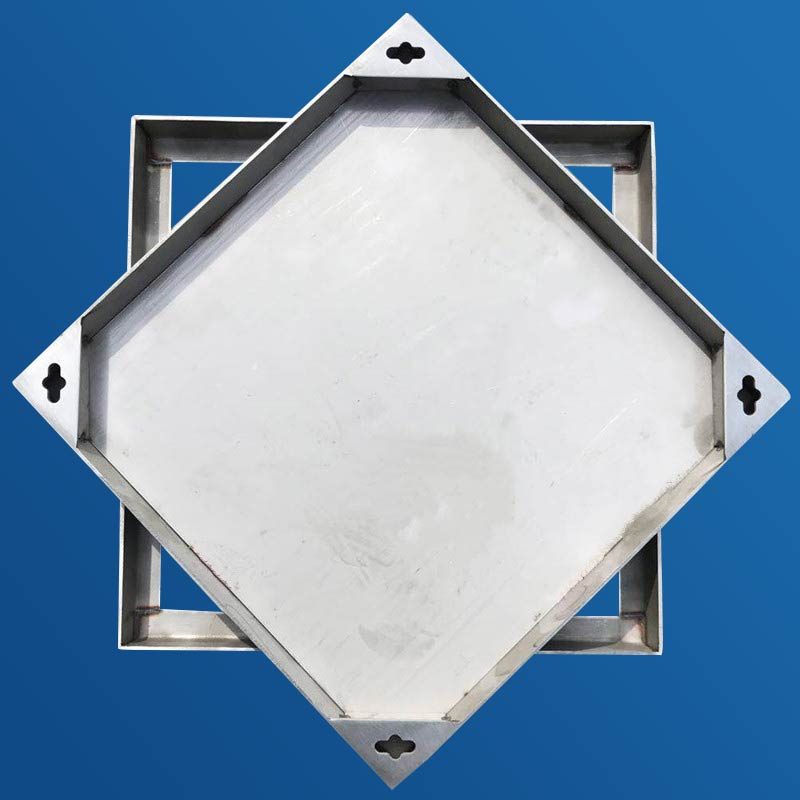

Grass Manhole Cover

Product Information: Manhole Covers,Gratings are manufactured for Construction, Electric, Water, Gas, Sanitary Product specifications: 700mm*650mm*580mm

Grass manhole cover along with elegant look and also extreme sturdiness, grass manhole cover is made from stainless-steel quality 304 in one marking procedure, which are defined by lengthy life span, high compressive strength as well as very easy installment. It is suitable for Local building and also Urban greening.

Unlike regular recessed covers, grass manhole cover include pre-drilled drainage openings which enable rainwater to drain pipes via normally. Incorporated with our copyrighted technology, this water is filtered and lawn will expand inside the tray. Inevitably this leads to a cosmetically pleasing remedy for client and professional. The covers can additionally be loaded with various other materials such as rubber crumb, synthetic grass, decorative crushed rocks or any type of porous surfacing product.

Unique sizes can be manufactured as needed.

Product Properties

- Product Information: Manhole Covers,Gratings are manufactured for Construction, Electric, Water, Gas, Sanitary

Road Facility and Public use.

- Material: Stainless steel, hot dip galvanized

- Designs: EN124 A15, B125, C250, D400, E600 and F900, As per customers’ drawings or samples

- Process: Molding – Casting -Cleaning- Coating- Packing – Shipping

- Coating: Cold applied black bitumen; Without coating; Coating as per customers’ requirement

- Different accessories are available

- Packing: Steel or wood pallet, or as per customers’ requirements

Grass Manhole Cover Features

UV-resistant material makes it possible for application of the covers in areas with higher UV-radiation.

grass manhole cover displays premium Weather condition resistance attributes compared to regular polymer concrete or plastic manhole cover.

Life span: greater than 30 years.

THE BASICS

pre-drilled drain openings

patented innovation

high stamina: constructed from stainless-steel quality 304in one stamping procedure.

severe toughness as well as corrosion resistance.

visual solutions: enables developing visually smooth flooring

Bath Handle Pull YD-BHP12

Item no.: YD-BHP12

Description: Door Handle Pull

Sanitary Hardware Material: Aluminium/zinc alloy

Size: available, customized

Usage: bath hardware, furniture hardware

Process: die casting, machining, surface treatment

Surface: PVD finished, satin nickel, black, mirror finished, bronze, customized

Find here details of GSR selling internal thread cutting. All the thread cutting tools with super quality and competitive price. Our company is a leader in the industry and we will not disappoint you.

We have a whole set of quality management system to guarantee the quality of our products as well as after sale service. GSR tools main products include internal and external threading tool.

Model No.: LJJS-CNC-500×600

PRODUCT DESCRIPTION

CNC Corner Connector Automatic Cutting Saw Equipment Features

■ This machine is mainly for alum windows corner stake cutting, also used for cutting Alum & PVC profiles.

■ PLC auto program controlling, man-machine interface is colored touch screen, input the cutting size and quantity, then it can cut automatically.

■ Automatic feeding system take the linear guiderail and high precision ball screw, driven by stepping motor. High feeding precision and efficiency.

■ Saw blade spindle take special high accuracy spindle, end face and radial runout are less 0.01mm, cutting surface is highly polished.

■ Saw blade feeding system adopts linear guiderail, with high accuracy and high speed (can be stepless speed regulation)

■ Carbide saw blade give accurate processing and high efficiency.

■ Special workpiece clamping system, besides processing common corner stake, it can also process middle frame corner stake.

■ All closed machine body and cover, with good appearance, safe working and low noisy.

CNC Corner Connector Automatic Cutting Saw Technical Parameter

■ Power: 380V 50Hz

■ Motor Rate: 2.2Kw

■ Saw Blade Diameter: Φ500mm

■ R.P.M: 2800r /min

■ Cutting Width: 135mm

■ Automatic Profile Feeding Length: 4-600mm

■ Working air pressure: 0.5-0.8Mpa

■ Weight: 600kg

If you want to know more, you can click here.

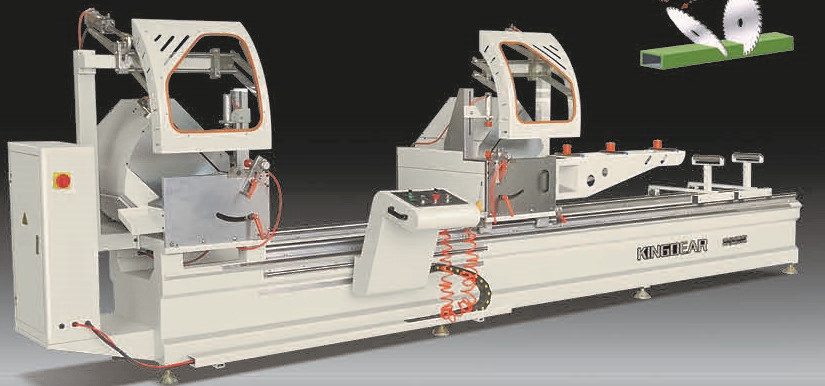

Model No.: LJZ2 -450×3700

PRODUCT DESCRIPTION

Double Head Cutting Saw Equipment Feature

■ Used for aluminum profile cutting.

■ Carbide saw blade give accurate processing and high endurance.

■ The two heads can work independently and simultaneously.

■ Cutting off the required length and two end angles is available by one time processing

Double Head Cutting Saw Technical Parameter

1) Power supply: three phase, four line 380V, 50Hz

2) Saw motor: 1.5Kw x 2, 2,800r/min

3) Pulling motor: 0.55Kw, 1,400r/min

4) Working pressure: 0.4 – 0.6MPa

5) Air consumption: 200L/min

6) Cutting length: max 3,700mm; min. 400mm

7) Cutting width: max 120mm

8) Cutting height: max. 200mm

9) Cutting angle: 0° – 45°

10) Cutter feeding speed: 0 – 3m/min

11) Saw diameter specification: 450mm x 4mm x 30mm-120

12) Overall dimensions: 4,500mm x 1,100mm x 1,400mm

Processing Accuracy

■ Repeat locating length: ≤0.2mm

■ Cutting angle allowance: ±5′

■ Cutting profile surface planeness: ≤0.10mm

■ Cutting profile surface roughness: Ra12.5μm

If you want to know more, you can click here.

Anping TianHui Wire Mesh Products Co., Ltd. is located in anping county, Hebei province, which also be called “Hometown of wire mesh”in china. Started the factory from the year 1986, We are one of the top manufacturers and exporters of Woven wire Mesh, Screens and welded Wire Mesh in China.

We has over 160 sets of wire mesh machines, have around 20000 rolls in stock for stainless steel wire mesh & welded mesh. We have gained a global sales network reaching to the Local market, USA, Middle-East, Europe and Africa etc.

Our company has been based on “good quality, timely delivery, reasonable price, considerate service” the purpose to serve the masses of customers; And is in line with “quality seek survival, prestige seek development” production principles, in our emphasis on product quality at the same time, also actively communicate with the customer, understand customer needs, to realize our shortcomings, and for clients to provide professional and timely after-sales service, won the praise of the vast old and new customers. Our products are widely used in petroleum, textile, metallurgy, construction, farming, machinery, landscape protection, production and manufacturing, and other fields.

Our Main Products: Stainless Steel Wire Mesh, Shale Shaker Screen, Crimped Wire Mesh, Dutch Wire Mesh, Copper Wire Mesh, Brass Wire Mesh, Stainless Steel Welded Wire Mesh, Galvanized Welded Wire Mesh, Filter Discs And Wire Mesh Processed Products.

TIANHUI Sincerely hope to establish long term business relationship with worldwide customers on the basis of sincerity and mutual benefits.

We use a variety of advanced equipment including shears, CNC punching machines, laser cutting machines, composite machines, bending machines, hydraulic presses, and various auxiliary equipment such as uncoilers, leveling machines, deburring machines, spot welding machines, etc., Using cutting, stamping, drawing, bending, welding, riveting and other processes, we can manufacture various Wonderful custom sheet metal products of different shapes for you, and can also do surface treatment for the products, including painting, electroplating, wire drawing, etc.

If you need sheet metal fabrication service we are one of the most capable and affordable sources and we can get the job done right.

At Wonderful, we use advanced equipment to provide you with various exactness cnc machining service, including milling, turning, EDM, wire cutting, EDM and so on. Using our 3-axis, 4-axis and 5-axis CNC machining centers, our skilled machinists can use a variety of plastic and metal materials to manufacture turning and milling parts. Our CNC machining center can not only produce perfect samples for you, but also customize more small batch products for you, making us a one-stop service provider for your advanced design and small batch product needs.https://www.wdfprecision.com/